Beer Talk - Praj Industries - PRAJ Industries Ltd.

Beer Talk - Praj Industries - PRAJ Industries Ltd.

Beer Talk - Praj Industries - PRAJ Industries Ltd.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Brewery Technology Solutions<br />

FY 2011-12 was a very eventful year for Indian brewing<br />

industry. While the 1st half saw entry of new International<br />

beer brands in India, the 2nd half of the year was sobering of<br />

the Indian beer market due to taxation, policy changes, and<br />

summer cycles. An overall slowdown in the economy also<br />

affected the brewing industry.<br />

And, inspite of this, the Indian brewing industry registered<br />

YOY sales of 240 million cases (FY 2012: 230 million cases).<br />

The first quarter of FY 2012-13 saw a revival in growth,<br />

thereby lifting hopes for a promising year ahead.<br />

<strong>PRAJ</strong> continues to serve the Indian brewing industry by<br />

offering integrated services and solutions for greenfield and<br />

brown field projects on turnkey basis. <strong>Praj</strong> offeres its<br />

customers a host of value added products and services to<br />

ensure higher plant operating efficiencies, optimization in the<br />

OPEX, timely project execution and overall cost<br />

optimization.<br />

With the continued support and trust shown by our<br />

customers, partners and associates, we were successful in<br />

winning and executing challenging greenfield and brownfield<br />

projects for our esteemed clients. Also our association with<br />

some of the leading global beer brands further strengthened<br />

our market position and helped us continue as the most<br />

preferred partner.<br />

With strong global experience in project engineering and<br />

execution of turnkey projects, <strong>Praj</strong> is uniquely placed to serve<br />

the beer markets in South East Asia and Africa apart from<br />

India.<br />

In this 10th volume we are proud to share with you our latest<br />

achievements and updates in the field of brewing.<br />

We also look forward to have the pleasure of welcoming you<br />

at our stall in this year's Drink Technology India 2012<br />

exhibition, in Mumbai.<br />

Atul Mulay<br />

Executive Vice President<br />

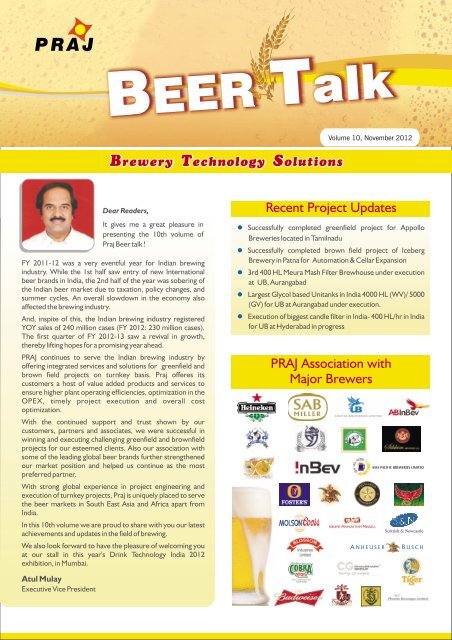

Dear Readers,<br />

It gives me a great pleasure in<br />

presenting the 10th volume of<br />

<strong>Praj</strong> <strong>Beer</strong> talk !<br />

<br />

<br />

<br />

<br />

<br />

Volume 10, November 2012<br />

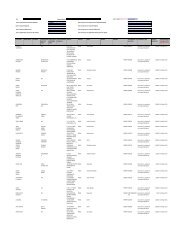

Recent Project Updates<br />

Successfully completed greenfield project for Appollo<br />

Breweries located in Tamilnadu<br />

Successfully completed brown field project of Iceberg<br />

Brewery in Patna for Automation & Cellar Expansion<br />

3rd 400 HL Meura Mash Filter Brewhouse under execution<br />

at UB, Aurangabad<br />

Largest Glycol based Unitanks in India 4000 HL (WV)/ 5000<br />

(GV) for UB at Aurangabad under execution.<br />

Execution of biggest candle filter in India- 400 HL/hr in India<br />

for UB at Hyderabad in progress<br />

<strong>PRAJ</strong> Association with<br />

Major Brewers<br />

ASIA PACIFIC BREWERIES LIMITED<br />

Scottish & Newcastle<br />

A NHEUSER B USCH

Services - Concept to Commissioning<br />

Concept<br />

Development &<br />

Site Selection<br />

Assistance<br />

Assistance in<br />

Statutory<br />

Documentation<br />

After Sales<br />

Support,<br />

Technical<br />

Audits, Spares<br />

Supply<br />

R&D<br />

Back Up,<br />

Sample Analysis<br />

Services<br />

Commissioning<br />

& Supervision,<br />

Training to<br />

Operational<br />

Staff<br />

Feasibility<br />

Viability Study,<br />

Project<br />

Reports<br />

<strong>PRAJ</strong><br />

BREWERY<br />

SOLUTIONS<br />

Equipment<br />

Erection and<br />

Supervision<br />

Services<br />

Manufacturing - Customized Solutions<br />

Civil<br />

Engineering,<br />

Architecture<br />

Services<br />

Project<br />

Management<br />

Services<br />

Process<br />

Engineering<br />

Services<br />

Manufacturing<br />

and Supply of<br />

Equipment<br />

Detailed<br />

Engineering<br />

Services<br />

<strong>PRAJ</strong> has modern manufacturing facilities near ports spread across<br />

about 2.0 lakh sq.ft. covered area and about 350,000 sq. ft. open area.<br />

To meet the aesthetic finish as per customer requirements, we employ<br />

automatic polishing machines in our facilities for polishing of critical<br />

brewery equipments including tanks and vessels.<br />

Highlights of fabrication machinery for high finish brewery equipment:<br />

Pulse TIG and Microprocessor controlled Orbital Welding<br />

Machines<br />

CNC Plasma Cutting Machines Column and<br />

Boom Automatic Plasma Arc Welding Machines<br />

Automatic Polishing Machine (Finish upto 400 grit)<br />

In-house pressing facility for Dish ends<br />

CNC Drilling Machine and VTL<br />

International Standards, Codes and Certifications : Accredited<br />

with ISO 14001 & OHSAS 18001, ASME (U, U2 & H) stamp, CE<br />

marking certifications, ASME Sec. VIII Div. I, ASME BPE, IS 2825, AD<br />

Merkblatter, PD 5500, TEMA, DIN & ASNI (SNT-TC-IA 1984 & 1988).<br />

Stringent testing is carried out at<br />

various stages of procurement and<br />

production, as per international<br />

standards by <strong>PRAJ</strong> QA Team which<br />

follows the QA plan drawn for each<br />

project.

On-Site Manufacturing<br />

<strong>Praj</strong> brewery business group also<br />

provides specialized resources for on-site<br />

field erected tanks and vessels,<br />

equipment installation, vessel retrofit<br />

vessel repair, this allows to go beyond our<br />

capabilities of our manufacturing facilities.<br />

We have extensive experience in<br />

providing on site solutions for <strong>Beer</strong><br />

Industry as per International design<br />

codes. In-house manufacturing of<br />

components in our state of art facility<br />

ensures that all parts such as tank heads,<br />

Brewhouse Heat Recovery Systems<br />

With the increase in oil and utility prices, there is tremendous<br />

pressure on industries to reduce the consumption of utilities. The<br />

discharge steam being vented out of Wort Kettle during boiling<br />

has latent heat which can be utilized by exchanging heat with<br />

other media i.e. water.<br />

In addition to above the ever rising price of fuel has also added<br />

more pressure on the cost of production. Thus by installing <strong>PRAJ</strong>s<br />

Heat Recovery System, we can certainly expect considerable<br />

savings in steam consumption which results into reduction in cost<br />

of Production of <strong>Beer</strong>.<br />

Recent References for Heat Recovery Systems<br />

1) United Breweries <strong>Ltd</strong>., Goa<br />

2) Blossom Breweries <strong>Ltd</strong>., Daman<br />

3) Balaji Distilleries and Breweries <strong>Ltd</strong>., Tamilnadu<br />

4) United Breweries <strong>Ltd</strong>, Andhra Pradesh<br />

5) Wave Distilleries & Breweries <strong>Ltd</strong>, Uttar Pradesh<br />

6) Millennium <strong>Beer</strong> <strong>Industries</strong> <strong>Ltd</strong>., Haryana<br />

7) Millennium <strong>Beer</strong> <strong>Industries</strong> <strong>Ltd</strong>., Maharashtra<br />

8) AM Breweries, Tamilnadu<br />

GLOBAL<br />

ALLIANCES<br />

On-Site Manufacturing of Tanks :<br />

Our capabilities are endless…<br />

shell, man ways, tank top fittings, heat<br />

transfer surfaces are fabricated according<br />

to specifications and coordinated to<br />

support our construction activities on field.<br />

Whenever you need large volume<br />

fermentation vessels or Bright <strong>Beer</strong> tanks,<br />

our team can design, procure materials,<br />

pre-process components, deliver, and<br />

execute the construction on site to<br />

accommodate.<br />

From project start-up to handover, we<br />

instill stringent quality control processes<br />

for the designs, manufactured equipment,<br />

transport, field installation, &<br />

commissioning and final performance<br />

testing to project completion.<br />

Energy Storage<br />

Tank<br />

Vapour<br />

Condensor<br />

Wort Preheater<br />

9) United Breweries <strong>Ltd</strong>., Karnataka<br />

10) United Breweries <strong>Ltd</strong>., Odisha<br />

11) Apollo Distilleries Pvt <strong>Ltd</strong>., Tamilnadu<br />

12) United Breweries <strong>Ltd</strong>., West Bengal<br />

13) United Breweries <strong>Ltd</strong>., West Bengal<br />

14) United Breweries <strong>Ltd</strong>., Maharashtra<br />

15) United Breweries <strong>Ltd</strong>., Punjab<br />

(under execution)<br />

(under execution)<br />

Wort Kettle<br />

Wort<br />

Holding<br />

Tank

Research & Development<br />

<strong>PRAJ</strong> MATRIX –The Innovation Centre<br />

Certified by DSIR, Government of India Built on 5<br />

Acre of land with a built up area of about 85,000 sq<br />

ft <strong>PRAJ</strong> Matrix-The Innovation Center has a Stateof-the-art<br />

<strong>Beer</strong> Analysis Laboratory which follows<br />

EBC, ASBC and MEBAK Standards. This Center<br />

also has modern Pilot and Scale up facilities and<br />

Analysis facility from raw material to final product.<br />

Since its inception in 1998, <strong>Praj</strong> Matrix evolved to become one of<br />

finest R&D centers in India for Research activities in<br />

Fermentation / Heat Transfer, Brewery sciences, and many<br />

more.<br />

<strong>Praj</strong> Matrix undertakes process technology development<br />

programme with global partners / customers and team up with<br />

them for such programme from the various geographies.<br />

<strong>Praj</strong> Matrix provides analytical facilities to customers for raw<br />

material - wort - <strong>Beer</strong> analysis and helps to establish benchmarks<br />

for the customers. With many multinational brands coming into<br />

India, <strong>Praj</strong> Matrix has helped to compare and establish<br />

benchmark quality norms and process parameter development.<br />

Such services help the customers meet uniform requirement of<br />

Compliments from Customers<br />

“On behalf of United Breweries<br />

team, I would like to convey my<br />

sincere appreciation to <strong>PRAJ</strong> and<br />

MEURA for being our valued<br />

technology partner in brewery<br />

business for their invaluable<br />

support & co-operation.<br />

We highly appreciate the<br />

expertise and co-operation<br />

provided by <strong>Praj</strong> Meura alliance in Project Chamundi<br />

and our various Brewery Installations.”<br />

Cedric Vaz,<br />

Executive Vice President, Manufacturing,<br />

United Breweries,<br />

International Brands manufactured in India. <strong>Praj</strong> Matrix has also<br />

undertaken process optimization in our lab scale set up to<br />

establish desired parameters for the various domestic and<br />

International brands.<br />

<strong>Praj</strong>'s commitment to innovation is demonstrated by enabling the<br />

innovative abilities of its scientists and managers at all levels.<br />

Something that all collaborators admire in our partnership<br />

endeavors.<br />

Significant investments in the area of innovation to create new<br />

technologies that will create first in class products and services<br />

across the entire ethanol & brewing industry demonstrates <strong>Praj</strong>'s<br />

emphasis towards innovation.<br />

“<strong>PRAJ</strong> has recently completed a major<br />

expansion in our Bihar Brewery. This is the<br />

first major project of Molson Coors Cobra<br />

India <strong>Ltd</strong>. done with an Indian supplier. We<br />

are glad to say that we were impressed<br />

with their professional approach and<br />

competent resource base with well<br />

equipped modern manufacturing facilities.<br />

<strong>PRAJ</strong>'s experienced project and site<br />

management skills were key to our successful brown field project.<br />

This positive experience has given us confidence to consider <strong>PRAJ</strong><br />

as a partner in our other international projects.”<br />

Matthew Hook,<br />

Director, - Supply Chain Asia<br />

Molson Coors Brewing Company<br />

Brewery<br />

Business<br />

<strong>PRAJ</strong> Industris Limited, <strong>PRAJ</strong> House, Bavdhan, Pune 411021. INDIA. T: +9120 2290 5000 F: +9120 2295 1718 E: info@praj.net W: www.praj.net