Professional kitchens ? la Metos Professional kitchens ? la Metos

Professional kitchens ? la Metos Professional kitchens ? la Metos

Professional kitchens ? la Metos Professional kitchens ? la Metos

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Professional</strong> <strong>kitchens</strong><br />

à <strong>la</strong> <strong>Metos</strong><br />

Catalogue 2003-2004

2 |<br />

Improved values for<br />

Index:<br />

A complete solution pp. 4<br />

<strong>Metos</strong> Food Production<br />

Process pp. 6-9<br />

During decades, <strong>Metos</strong> has been an essential part of the<br />

professional kitchen. Our more than 80 years’ experience<br />

also from the end-user business has given us a compre-<br />

hensive overall view of different kinds of requirements and<br />

solutions for professional <strong>kitchens</strong>. Our mission is to take advantage of this vital<br />

experience when developing new products and services for increased profitability and<br />

satisfaction for our customers.<br />

Our innovative solutions within the cooking range consists of ergonomically designed<br />

mixing kettles, combi steamers and b<strong>la</strong>st chillers, and through our innovative<br />

dishwashing concept the end customer can achieve significant savings on both energy<br />

costs and environmental impact.<br />

Our own sales companies cover the main countries in the northern part of Europe,<br />

<strong>Metos</strong> Dishwashing Concept pp. 10<br />

<strong>Metos</strong> Concepts pp. 12-13<br />

Technical Support Center pp. 14<br />

Kitchen IT pp. 16-17<br />

<strong>Metos</strong> Center pp. 18-19<br />

<strong>Metos</strong> and the Environment pp. 20<br />

Products pp. 26-314<br />

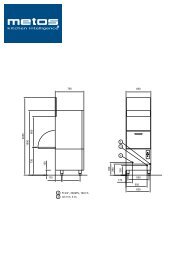

Instal<strong>la</strong>tion Drawings pp. 270-314<br />

Table of Contents pp. 25<br />

Alphabetical Index pp. 339

<strong>Professional</strong> Kitchens<br />

Benelux, the UK and France, with focus on innovative kitchen<br />

solutions as well as on after sales services. We are also one of the<br />

leading suppliers of ‘marine galleys’. In other areas we operate<br />

through our business partners.<br />

This wide geographical spread makes us a serious alternative for<br />

multinational agreements and solutions.<br />

Our faith in the future is strong. We continue our developments<br />

on innovative products and services as well as on improving our<br />

distribution, enabling food service professionals to focus on their<br />

most essential task – the profitable preparation of superb meals.<br />

<strong>Metos</strong> wants to be your preferred long-term business partner.<br />

We look forward to cooperating with you!<br />

With best regards,<br />

Michael Ramm-Schmidt<br />

CEO, <strong>Metos</strong> Group<br />

| 3

4 |<br />

A complete solution<br />

A well-functioning professional kitchen starts from a thorough p<strong>la</strong>nning. In most of<br />

<strong>Metos</strong>’ own sales units we can provide a “full service” solution. It is a complete product<br />

range supported by several service functions such as CAD kitchen p<strong>la</strong>nning, concept<br />

development, instal<strong>la</strong>tion, spare parts and service, individual product training and users<br />

manuals, and, of course, skilled people.<br />

Instal<strong>la</strong>tion Drawings<br />

Kitchen design<br />

On the basis of features determined by the specific<br />

needs of the customer, we select the equipment<br />

for the different processes of the kitchen.<br />

We design systems where the level of automation<br />

corresponds to the customer’s requirements<br />

(e.g. dishwashing, self-monitoring).<br />

The correct dimensioning of the space and the<br />

appropriate p<strong>la</strong>cement of the equipment reduce<br />

unnecessary investments and make the day-today<br />

operation more efficient.<br />

A symbol library for CAD-users consisting of most<br />

of the equipment in the catalogue is avai<strong>la</strong>ble on<br />

the web, www.metos.com.<br />

Our Kitchen “designers” can assist in kitchen floor p<strong>la</strong>ns<br />

and instal<strong>la</strong>tion drawings, calcu<strong>la</strong>te budgets and prepare<br />

equipment lists and visualizations. Our partners / customers<br />

include architects, end-users, contracting p<strong>la</strong>nners,<br />

builders, shipyards and shipping companies. Design<br />

activities include p<strong>la</strong>nning of new <strong>kitchens</strong> and renovations<br />

of existing ones, p<strong>la</strong>nning the operation and<br />

overall management of production <strong>kitchens</strong>. The business<br />

idea of the kitchen is always the starting point for<br />

the design in a new kitchen project or a major renovation.<br />

We always p<strong>la</strong>n the production methods in cooperation<br />

with the client and on the basis of his specific<br />

targets.<br />

Customer feedback and Concept Development<br />

The <strong>Metos</strong> Group consists of several sales and production units in several European countries.<br />

We manage the whole value chain from research and development to production, sales<br />

and instal<strong>la</strong>tion. This, combined with the wide feedback from direct customers, enables us<br />

to develop customer-driven concepts both cost-effectively and quickly.

Individual Product Training<br />

Once a product or a total kitchen project is installed<br />

and ready for commissioning, our chef can be present<br />

to give individual product training to the enduser.<br />

Only correct and optimized use of the equipment<br />

will assure the highest productivity and flexibility<br />

of the kitchen.<br />

Education<br />

Instal<strong>la</strong>tions<br />

As an option, our deliveries can<br />

include instal<strong>la</strong>tion. We install total<br />

<strong>kitchens</strong> as well as single units.<br />

Our installers are specialized in<br />

installing <strong>Metos</strong> products in a reliable<br />

way, where safety and technical<br />

functionality aspects are<br />

checked.<br />

We have the possibility to organize separate theme<br />

and training days, either open to everyone or<br />

tailored specifically for specific customer groups,<br />

in our new <strong>Metos</strong> Center in Fin<strong>la</strong>nd or in our other<br />

<strong>Metos</strong> Centers in Europe.<br />

| 5

6 |<br />

Three main production lines produce the food<br />

that is based on the menu. The supplementary<br />

production line fulfils the special needs for frying<br />

and shares the load of cooked products together<br />

with combi kettle and combi steamer line in the<br />

<strong>la</strong>rge scale production.<br />

Raw material<br />

storage<br />

Logistics<br />

<strong>Metos</strong> Food Produ<br />

Preparation<br />

Diets<br />

Diet Line<br />

Food Production<br />

Central production unit<br />

Liquid and mixed<br />

food, masses<br />

Combi Kettle Line<br />

Solid items<br />

Combi Steamer Line<br />

Support production<br />

Frying<br />

Cooking<br />

PROVENO<br />

CLIMAPLUS COMBI ®<br />

ARDOX<br />

FUTURA<br />

FUTURA MARVEL<br />

Chilling<br />

PROVENO<br />

FLO-ICE ®<br />

Chilling<br />

– B<strong>la</strong>st Chiller<br />

– contact chilling

ction Process<br />

In the cook & chill operation the food<br />

is produced to a food bank or a food<br />

library. Regenerating may occur in the<br />

same type of units that are used in the<br />

main production. This increases the<br />

simplicity and process control.<br />

Cold storage<br />

Food Bank<br />

Warm<br />

transport<br />

Food Production<br />

Satellite kitchen<br />

(Regenerating, same units)<br />

The green areas describe<br />

kitchen logistics. Every<br />

time the food moves in<br />

the kitchen, it also refines.<br />

Logistics Logistics<br />

Cold<br />

transport<br />

CLIMAPLUS COMBI ®<br />

FUTURA MARVEL<br />

Front Cooking<br />

Serving<br />

| 7

8 |<br />

<strong>Metos</strong> Innovative<br />

Cooking

<strong>Metos</strong> Ardox range<br />

<strong>Metos</strong> Proveno combi-kettle<br />

The unique TempGuard temperature control technology<br />

saves working time spent on supervision and<br />

cleaning. It also ensures the food quality and even<br />

cooking by controlling the heating effect and the<br />

temperature of the food fully automatically.<br />

Unaccepted cooking result because of fluctuating<br />

temperature and food burning is the thing of the<br />

past. Cooking, mixing and chilling in one unit decreases<br />

food transfers, eases work load, saves time<br />

and improves hygiene. For the first time also chilling<br />

of liquid or semi-liquid food is extremely fast and<br />

easy.<br />

<strong>Metos</strong> CPCM combi-steamer<br />

Thanks to the unique patented ClimaPlus<br />

Control® technology the humidity in the<br />

cooking cabinet can be controlled and regu<strong>la</strong>ted<br />

continuously and fully automatically and<br />

therefore the optimal cooking climate can be<br />

achieved every time no matter what the food<br />

or the load is. Anyone can easily achieve excellent<br />

and even cooking result every day.<br />

<strong>Metos</strong> Futura Marvel pressure cooker<br />

In steam, under +100 °C, +100 °C or pressurized<br />

steam up to +120 °C is the right way to cook various<br />

number of food items faster than with any other unit.<br />

There is a lot to cook in the professional kitchen:<br />

pasta, rice, vegetables, potatoes etc. Release the combi<br />

steamers for combi cooking and save time and effort<br />

by cooking in <strong>Metos</strong> Futuramarvel cooking cabinet.<br />

The f<strong>la</strong>t-top Ardox range offers all needed temperatures for<br />

cooking of sensitive and highly controlled diets. Separate<br />

heating zones and horizontally even f<strong>la</strong>t top and edges, height<br />

adjustment and special surface of the f<strong>la</strong>t top that radiates<br />

only minimal heat makes working easy and comfortable.<br />

| 9

10 |<br />

Storing<br />

Transporting<br />

Sorting<br />

clean dishes<br />

Drying<br />

Setting the tables<br />

Serving<br />

The <strong>Metos</strong><br />

dishwashing<br />

circle<br />

Washing<br />

Clearing<br />

the tables<br />

Delivery of<br />

dirty dishes<br />

Sorting<br />

Accumu<strong>la</strong>tion<br />

Pre-rinsing<br />

Soaking

<strong>Metos</strong><br />

Dishwashing<br />

Concept<br />

The dishwashing material flow is an endless circle and the process contains the<br />

same stages, irrespective of whether small or <strong>la</strong>rge capacities are concerned.<br />

Handling dishes before and after the diswasher causes the main use of <strong>la</strong>bour costs<br />

in the process, whereas the dishwasher itself causes the main part of water, energy<br />

and chemical costs and lifetime environmental impact.<br />

The <strong>Metos</strong> Dishwashing Concept is a model providing customers with dish-<br />

washing solutions that produce the hygiene level specified by the customer at the<br />

lowest possible total costs during the life cycle (<strong>la</strong>bour, investment, chemical,<br />

energy, water costs and cost for broken dishes and utensils).<br />

Key factors for success are:<br />

• profound understanding of customers’ dishwashing process<br />

• complete and coherent product assortment<br />

• unique products to provide hygiene and process economy<br />

• specialised and competent distribution channels, both own and partners<br />

| 11

12 |<br />

Home Meal Rep<strong>la</strong>cement<br />

Most of today’s hectic consumers put much focus on high<br />

quality meals. Thus the importance of both convenience stores<br />

and in-house <strong>kitchens</strong> in supermarkets has grown significantly.<br />

A carefully p<strong>la</strong>nned and properly equipped kitchen<br />

enables profitable food production and serving, and is highly<br />

responsive to changing future requirements. <strong>Metos</strong> applies<br />

the same solid know-how it has developed as a market-leading<br />

supplier of professional <strong>kitchens</strong> to the supermarket kitchen<br />

as well. We put the most comprehensive product range and<br />

the best service package on the market at your disposal, handling<br />

the entire value chain, from design to operator training.<br />

Bake Off solution<br />

Banquet Concept for 20-1000 guests<br />

The smell of freshly baked bread and a f<strong>la</strong>shy disp<strong>la</strong>y is<br />

an alluring way to attract customers. Quality baking<br />

result doesn’t happen by chance, the right tools are<br />

required. <strong>Metos</strong> has a deep tradition in the production<br />

of bakery ovens. Our product range and accessories,<br />

developed in cooperation with our customers, completely<br />

cover all the needs of in-store baking. High quality,<br />

proven solutions that enable efficient operation and<br />

<strong>la</strong>st for years are our hallmark.<br />

The superior quality of the meals served using the <strong>Metos</strong> System Rational Banquet concept<br />

is based on a physiological fact: a meal heated quickly just before serving is of far better<br />

quality than meals kept for a long time in warm storage.<br />

The <strong>Metos</strong> banquet concept makes it possible to<br />

shift the food preparation to a quiet moment. This<br />

improves the final result and reduces costs. By the<br />

time the serving starts the beautifully arranged, carefully<br />

baked and heated portions are ready for the entire<br />

clientele at the same time. During baking and<br />

heating optimal humidity management (ClimaPlus<br />

Control) protects the food quality. The seamlessly integrated<br />

parts of the finished concept, such as p<strong>la</strong>te<br />

trolleys and heat-retaining hoods, ensure that everything<br />

works just as it should. The system is adaptable<br />

to any set of conditions.

Automatic dishwashing<br />

To us, the need for a first c<strong>la</strong>ss washing result is selfevident.<br />

We have also carefully considered the environmental<br />

impact and running costs of the equipment<br />

throughout its life cycle. These things go hand in hand:<br />

the dishwasher consumes water, heating electricity and<br />

electricity production consumes non-renewable natural<br />

resources. Electricity consumption is also always<br />

the heaviest running cost. Our long-term focus on these<br />

issues has produced the new methods of improving<br />

the operation of dishwashers reducing costs and conserving<br />

the environment (ICS+).<br />

The Chicken Concept<br />

<strong>Metos</strong> ClimaPlus Combi-steamer ovens have become<br />

a household word at store grills. The patented humidity<br />

control system guarantees that the products are<br />

consistently and uniformly delicious. You will notice<br />

uncompromising <strong>Metos</strong> quality in the running costs<br />

of the oven as well. The minimal baking loss, the<br />

record-fast baking process and fully automatic cleaning<br />

guarantee an excellent return on your investment.<br />

Coffee Shop solutions<br />

The world of coffee beverages is a multifaceted one,<br />

both for our clients and their customers. The <strong>Metos</strong><br />

Coffee Shop is a total concept for efficient and profitable<br />

sales of coffee beverages and re<strong>la</strong>ted products.<br />

The starting point is always the customer needs and<br />

the respective space solution. Optimal general p<strong>la</strong>nning<br />

and the right space solution <strong>la</strong>y the foundation<br />

for a successful <strong>Metos</strong> Coffee Shop concept that always<br />

meets the precise needs of the customer.<br />

| 13

14 |<br />

International<br />

Technical<br />

Support Center

International<br />

Technical Support Center<br />

The central Technical Support Center (TSC), located<br />

at our head office just outside Helsinki, guarantees<br />

the high level of After Sales services to you<br />

and to your <strong>Metos</strong> products. For our international<br />

business partners and subsidiaries we have <strong>la</strong>nguage-skilled,<br />

dedicated personnel to provide technical<br />

training, support and spare parts services. They<br />

are also securing the high quality of the technical<br />

documents for <strong>Metos</strong> products.<br />

Technical Training and Support<br />

Long-term commitments on<br />

Spare Parts Services<br />

Our centralized handling of both products and spares enables<br />

us to provide high avai<strong>la</strong>bility and cost efficiency for thousands<br />

of different spare parts. Weekly we have hundreds of<br />

shipments of spares all around the world. Even for products<br />

which no longer are produced, we guarantee spare parts avai<strong>la</strong>bility<br />

for 10 years.<br />

In order to make sure that our customers receive accurate and up-to-date technical support<br />

and service, we provide continuous technical training for our own and our partners After<br />

Sales personnel. The high level of After Sales services is guaranteed by ‘hands on’ service<br />

training in the new Technical Training Center in Fin<strong>la</strong>nd. Individual trouble shooting assistance<br />

is also given when needed. In order to continuously<br />

improve our product development processes,<br />

feedback from After Sales operations all over<br />

the world is gathered by TSC to be forwarded to<br />

our product development and external suppliers.<br />

| 15

16 |<br />

Kitchen IT

Technical Documentation<br />

Our technical documentation group is responsible for the high standard of technical documentation.<br />

All information is processed and distributed with modern IT-technology. In the<br />

near future, our high quality technical documents will be avai<strong>la</strong>ble for our customers over<br />

the Internet.<br />

<strong>Metos</strong> HACCP<br />

The primary goal of the information systems of kitchen equipment is to collect and store<br />

information about a food production process. This goal is based on HACCP (Hazard Analysis<br />

Critical Control Point), which is a set of guidelines prescribed by <strong>la</strong>w, covering the production<br />

chain of foodstuffs. The principle of HACCP is to switch in foodservice safety from<br />

traditional monitoring to prevention. In practice this means collecting and storing information<br />

re<strong>la</strong>ted to a process as well as a<strong>la</strong>rming about abnormal situations. Systems to support<br />

this are often called On-line kitchen or kitchen IT.<br />

At <strong>Metos</strong>, kitchen IT is regarded as a strategically significant issue. <strong>Metos</strong> has from the very<br />

beginning adopted the policy of developing systems and equipment as open as possible. The<br />

customer may already have equipment and systems to<br />

which new equipment should be connected. This does<br />

not succeed if the equipment/systems do not support<br />

open communication.<br />

<strong>Metos</strong> has several very advanced products which support<br />

HACCP. These include for example kettles, dishwashing<br />

machines and cold storing products. <strong>Metos</strong> can<br />

provide an all-inclusive solution to customer.<br />

| 17

18 |<br />

<strong>Metos</strong> Center

<strong>Metos</strong> Center<br />

The new <strong>Metos</strong> Center in Helsinki is one the <strong>la</strong>rgest<br />

exhibition and training centers in northern Europe, where<br />

you can see the <strong>la</strong>test professional kitchen solutions,<br />

<strong>Metos</strong> concepts and the most recent selection of equipment.<br />

We organize separate theme and training days, either<br />

open to everyone or tailored specifically for specific<br />

customer groups. If you like, you can also order an equipment<br />

demonstration of the newest combi-steamer, induction<br />

wok or the ICS+ dishwashing operating control<br />

system. Book your time in advance so that we can<br />

arrange the best possible presentation for you and your<br />

group.<br />

<strong>Metos</strong> Marine – Your Partner in<br />

Ship Catering Systems<br />

<strong>Metos</strong> Marine is one of the leading suppliers of galley<br />

equipment to vessels worldwide. Our catering equipment<br />

and furnishings are used in more than 1500 ships<br />

including icebreakers, naval ships, cargo vessels, passenger<br />

ferries and luxury cruise ships. In-house production<br />

of most equipment guarantees consistent quality<br />

control, efficient material handling and short delivery<br />

times. Project management, <strong>la</strong>y-out design and<br />

technical p<strong>la</strong>nning are also part of our engineering services.<br />

The <strong>Metos</strong> Marine agent network covers all important<br />

shipbuilding countries.<br />

International Customers and<br />

Projects<br />

In order to coordinate and maximise the central support<br />

for certain international customers, <strong>Metos</strong> has<br />

created an organisation for handling of these key customers.<br />

Serving these customers is a mix of central<br />

support and coordination combined with local market<br />

and customer know-how from <strong>Metos</strong> national (local)<br />

key account managers.<br />

| 19

20 |<br />

<strong>Metos</strong> and the<br />

Environment

We are committed to environmentally sensi-<br />

tive thinking. In the p<strong>la</strong>nning, production and<br />

delivery of professional <strong>kitchens</strong> we continu-<br />

ously develop new, more environmentally<br />

friendly solutions. In order to achieve improve-<br />

ments we work closely with customers, suppli-<br />

ers and service companies. We have been actively creating an environmental pro-<br />

gram for <strong>Metos</strong> focusing especially on the following points:<br />

* In training, we teach our customers new food preparation methods based on a more efficient<br />

heat transfer technology with current food preparation equipment. The objective is to reduce<br />

the energy and water consumption of professional <strong>kitchens</strong>, in addition to improving the efficiency<br />

of food preparation.<br />

* The consumption figures and their environmental impact can be reduced to less than half of<br />

the previous figures when dishwashers are equipped with the ICS operational control system<br />

we have developed. Even air quality in the kitchen is improved when the excess energy is not<br />

straining the venti<strong>la</strong>tion system.<br />

* The environmental impact of the dishwashers during their entire life cycle is reviewed in our<br />

life cycle analysis. This way the customer can review, at the point of the purchase, the environmental<br />

factors and the real costs of equipment operation.<br />

* We try to minimize the amount of waste produced in the production and delivery of the<br />

products by sorting and recycling. All remaining waste, mostly of stainless steel, is recycled.<br />

* The environmental impact of discarded products is reduced when the right materials are<br />

used in the structures. For instance, our dishwashers are manufactured from 90 % recyc<strong>la</strong>ble<br />

materials.<br />

* <strong>Metos</strong> has created a nationwide reception and recycling system for discarded equipment. The<br />

system ensures that all recyc<strong>la</strong>ble material is put to good use.<br />

| 21

22 |<br />

REYKJAVIK<br />

DUBLIN<br />

Refrigerators<br />

and freezers<br />

<strong>Metos</strong> In Europe<br />

Pot washers<br />

Cold drawer<br />

cupboards<br />

Dishwashers<br />

SALES COMPANY<br />

FACTORY<br />

HEADQUARTERS<br />

METOS BUSINESS PARTNER<br />

LONDON<br />

PARIS<br />

AALST<br />

CASTELFRANCO<br />

Dishwashing<br />

systems<br />

Dishwashers<br />

SOEST<br />

KRUIBEKE<br />

STAVELOT<br />

OSLO<br />

WEIKERSHEIM<br />

Combi ovens<br />

Combi kettles<br />

STOCKHOLM<br />

Cooking<br />

products<br />

BELLUNO<br />

PORDENONE<br />

VÄXJÖ<br />

ÅRHUS<br />

KOPENHAGEN<br />

TALLINN<br />

Grill series<br />

RIGA<br />

VILNIUS<br />

Cold drawer<br />

cupboards<br />

KERAVA<br />

SORSAKOSKI<br />

Bratt pans<br />

Ranges<br />

Serving<br />

counters<br />

Trolleys<br />

Stainless steel<br />

fabrication<br />

MOSCOW<br />

B<strong>la</strong>st chillers and freezers<br />

Serving counters<br />

Bakery ovens

<strong>Metos</strong> In-House manufacturing and sales companies<br />

<strong>Metos</strong> is not only a supplier of equipment and projects, but also one of the <strong>la</strong>rgest equipment<br />

manufacturers in its field. In each sector where we manufacture, we are in the vanguard. We<br />

assume responsibility for the whole delivery chain from the factory to the kitchen floor. This way<br />

we can develop our products jointly to match the needs of our customers. Solid international<br />

expertise enables us to provide better solutions for our local customers<br />

FINLAND<br />

Hackman <strong>Metos</strong> Oy Ab<br />

Sales Office, <strong>Metos</strong> Center and<br />

Training Center, Service,<br />

Administration, Factory<br />

Ahjonkaarre<br />

FI-04220 KERAVA<br />

Tel. +358 204 39 13<br />

In Fin<strong>la</strong>nd 0204 39 13<br />

Fax +358 204 39 4360<br />

In Fin<strong>la</strong>nd 0204 39 4360<br />

<strong>Metos</strong> Marine<br />

Ahjonkaarre<br />

FI-04220 KERAVA<br />

Tel. +358 204 39 13<br />

Fax +358 204 39 4432<br />

Spare parts<br />

Fax +358 204 39 4434<br />

<strong>Metos</strong> Export<br />

Ahjonkaarre<br />

FI-04220 KERAVA<br />

Tel +358 204 39 13<br />

Fax +358 204 39 4433<br />

SWEDEN<br />

Hackman <strong>Metos</strong> AB<br />

Sales Office, <strong>Metos</strong> Center and<br />

Administration<br />

Storsätragränd 26<br />

SE-127 39 SKÄRHOLMEN<br />

Tel. +46 8 775 85 85<br />

Fax +46 8 775 85 22<br />

Nordien-System<br />

Box 42077 (Upp<strong>la</strong>gsvägen 10)<br />

SE-126 13 STOCKHOLM<br />

Tel. +46 8 794 00 00<br />

Fax +46 8 794 01 00<br />

Wexiödisk AB<br />

Mårdvägen 4<br />

SE-352 45 VÄXJÖ<br />

Tel. +46 470 77 12 00<br />

Fax +46 470 237 52<br />

NORWAY<br />

Hackman <strong>Metos</strong> AS<br />

Sales, Administration and Service<br />

Sandstuveien 60 A<br />

NO-1184 OSLO<br />

Tel. +47 23 38 46 00<br />

Fax +47 23 38 46 01<br />

UNITED KINGDOM<br />

<strong>Metos</strong> Ltd<br />

8 Martinfield<br />

Welwyn Garden City<br />

GB-Hertfordshire AL7 1HG<br />

Tel. +44 1707 393 399<br />

Fax + 44 1707 393 311<br />

<strong>Metos</strong> Business Partner<br />

FRANCE<br />

Hackman <strong>Metos</strong> SARL<br />

48, rue Gabriel Lamé<br />

FR-75012 PARIS<br />

Tel. +33 1 56 95 4848<br />

Fax +33 1 56 95 4849<br />

BELGIUM<br />

<strong>Metos</strong> N.V.<br />

Gentsesteenweg 518 A<br />

B-9300 AALST<br />

Tel. +32 53 810 335<br />

Fax: +32 53 810 336<br />

Werkhuizen Rubbens N.V.<br />

Zwaluwbeekstraat 12<br />

B-9150 Kruibeke (Antwerpen)<br />

Tel +32 3 253 01 91<br />

Fax +32 3 253 08 49<br />

ITALY<br />

Dihr S.p.A.<br />

Via del Lavoro, 22/B<br />

I-31033 CASTELFRANCO<br />

VENETO (TV)<br />

Tel. +39 0423 7344<br />

Fax +39 0423 720 442<br />

Olis S.p.A.<br />

I-32030 BRIBANO, BELLUNO<br />

Tel. +39 0437 8558<br />

Fax +39 0437 838 274<br />

Po<strong>la</strong>ris S.p.A.<br />

I-32030 BRIBANO, BELLUNO<br />

Tel. +39 0437 8558<br />

Fax +39 0437 838 509<br />

Baron Cucine <strong>Professional</strong>i S.r.l.<br />

Via Maniago, 39<br />

33080 SAN QUIRINO (PN)<br />

Tel. +39 0434 919451<br />

Fax +39 0434 919318<br />

Friulinox S.r.l.<br />

Via Fiumicino, 15<br />

33170 PORDENONE<br />

Tel. +39 0434 636 611<br />

Fax +39 0434 636 666<br />

GERMANY<br />

<strong>Metos</strong> Großküchensysteme GmbH<br />

Talstraße 27 D<br />

D-97990 WEIKERSHEIM<br />

Tel. +49 79 34 992 920<br />

Fax +49 79 34 992 92 33<br />

ESTONIA<br />

Hackman <strong>Metos</strong> Eesti AS<br />

Sales, Administration, Service,<br />

Stainless Steel Fabrication<br />

Pärnu mnt. 154<br />

EE-11317 TALLINN<br />

Tel. +372 6 500 740<br />

Fax +372 6 500 741<br />

LATVIA<br />

Hackman <strong>Metos</strong> Latvia SIA<br />

Lacplesa Street 87F<br />

LV-1011 RIGA<br />

Tel. +371 7 288 333<br />

Fax +371 7 288 332<br />

LITHUANIA<br />

UAB Hackman <strong>Metos</strong><br />

Lukiskiu gt 3, kab. 209<br />

LT-2600 VILNIUS<br />

Tel. +370 2 224 758 /619 796<br />

Fax +370 2 612 324<br />

RUSSIA<br />

OOO Hackman <strong>Metos</strong><br />

Warshavskoye shosse, 46,<br />

Entrance 3, office 608<br />

RU-115 230 MOSCOW<br />

Tel. +7 095 933 1254/290 8699<br />

Fax +7 095 9379703<br />

NETHERLANDS<br />

<strong>Metos</strong> Business Partner<br />

DENMARK<br />

<strong>Metos</strong> Business Partner<br />

IRELAND<br />

<strong>Metos</strong> Business Partner<br />

ICELAND<br />

<strong>Metos</strong> Business Partner<br />

| 23

24 |<br />

We Have the<br />

Recipe for a Great<br />

Kitchen!

Preparation Equipment<br />

Vegetable slicers ......... 26-35<br />

Cutters .............................36<br />

Washing and peeling<br />

machines ......................... 38<br />

Meat blocks ......................38<br />

Cutting boards .................. 38<br />

Cooking Equipment<br />

Kettles ........................ 48-59<br />

Ovens<br />

Combi-steamers ......... 62-72<br />

Convection ovens ....... 73-75<br />

Roasting-baking ovens 74-75<br />

Bakery ovens ............... 76-77<br />

Ranges and Bratt pans<br />

Induction ranges ... 84-85, 93<br />

Electric ranges ............ 86-88<br />

Ranges, grill series ....... 94-99<br />

Vapo grill ..........................92<br />

Cooking suites .................. 93<br />

Grill series .................. 94-95<br />

Restaurant series ......... 96-99<br />

Fryers ...................... 100-101<br />

Heating <strong>la</strong>mps ................101<br />

Bar systems ............. 104-107<br />

Cabinets for wines ..........144<br />

Shakers, blenders ............108<br />

Lemons juicers ...............108<br />

Fully automatic<br />

coffee machines ..............112<br />

Espresso machines ..........117<br />

Urn models ............. 118-119<br />

Thermometers ..................40<br />

Can opener .......................40<br />

Scales ................................40<br />

Slicing machines ...............41<br />

Vacuum packing ...............42<br />

Varimixers .................. 43-47<br />

Hand mixers .....................43<br />

Holding cabinets ......... 78-79<br />

Conveyor ovens .......... 80-81<br />

Microwave ovens..............82<br />

Pizza ovens .......................83<br />

Pizza counters ................161<br />

Wok..................................84<br />

Bratt pans ................... 89-91<br />

Bratt pans, grill series .... 98-99<br />

Grill and Restaurant Equipment<br />

Bar Equipment<br />

Coffee Brewing Machines<br />

Kettle mixers .............. 44-59<br />

Pressure cookers ......... 60-61<br />

Contents<br />

Index page 339<br />

GN containers ........ 124-125<br />

Transport boxes ...... 126-127<br />

Dinner box .....................128<br />

Heated p<strong>la</strong>tes, cold p<strong>la</strong>tes . 134<br />

Soup warmers, serving<br />

dishes ..............................135<br />

Trays ...............................136<br />

Serving counters ..... 137-143<br />

Cabinets for wines .......... 144<br />

Serving counters ..... 146-149<br />

Cold food systems .......... 156<br />

Refrigerators, freezers ..... 172<br />

Temperature altering<br />

cabinet ............................176<br />

Marine cabinets ..............177<br />

Dishwashers ........... 186-232 Cutlery washers ...... 228-231<br />

Pot washers ............. 197-199 Trolley washer ................232<br />

Contact grills ..................102<br />

Prewash and unloading Dishwashing baskets 234-239<br />

Hot dog steamer ............. 102 tables ..............................200 Sorting units ........... 240-243<br />

Toasters ..........................103 Prewash sprayers .............201 Racks for handling<br />

Sausage steamer ..............103 Granule washers ..... 202-209 dishes ...................... 244-247<br />

Hot dog grill ................... 103 Conveyor mashines 210-225 Dishwashing trolleys 248-253<br />

Sa<strong>la</strong>manders ................... 103<br />

Holding appliances .... 78, 133<br />

Flight-type washers .........226<br />

Ice f<strong>la</strong>ker ......................... 109<br />

Juice dispenser ................109<br />

Ice cube and crush<br />

makers .................... 110-111<br />

Bar counters ................... 158<br />

G<strong>la</strong>ss jug models ..... 120-121<br />

Water boilers .................. 123<br />

Accessories ............. 122-123<br />

GN containers, food transport<br />

Food serving<br />

Cold cabinets and rooms<br />

Dishwashing<br />

Trolleys, Tables, Shelves<br />

Trolleys ................... 248-260<br />

Waste trolleys ......... 254-255<br />

Wall and floor shelves 261-263<br />

Instal<strong>la</strong>tion Drawings<br />

Instal<strong>la</strong>tion drawings 270-314<br />

Tray transport trolleys ..... 129<br />

Food transport and serving<br />

trolleys .................... 129-132<br />

Banquet trolleys ..............133<br />

Cold drawer cupboards .... 156<br />

Cold basins ............. 157, 161<br />

Cold counters ......... 157-158<br />

Heated cupboards and<br />

counters ..........................159<br />

P<strong>la</strong>te and water dispensers 160<br />

Stand for g<strong>la</strong>sses and cups 135<br />

Tray track ......... 146-149,163<br />

G<strong>la</strong>ss disp<strong>la</strong>ys ......... 162-171<br />

Cold and freezer rooms178-179<br />

B<strong>la</strong>st chillers and<br />

freezers ........... 176, 180-185<br />

Racks for handling<br />

dishes ...................... 244-247<br />

Tables ..................... 264-269<br />

| 25

26 |<br />

METOS CC-34 COMBI CUTTER<br />

The <strong>Metos</strong> CC-34 combi cutter - a vegetable slicer and a<br />

cutter with a common body<br />

Standard<br />

slicers<br />

10 mm<br />

For slicing<br />

solid products.<br />

Fine cut<br />

slicers<br />

1 mm, 2 mm<br />

4 mm, 6 mm<br />

For slicing solid, soft<br />

or juicy products,<br />

cabbage grating.<br />

Crimping<br />

slicers<br />

4,5 mm<br />

For slicing<br />

decorative<br />

slices<br />

Dicing grid<br />

10x10 mm<br />

15x15 mm<br />

Used with<br />

slicer head.<br />

<strong>Metos</strong> CC-34 is a combi cutter avai<strong>la</strong>ble in different<br />

combinations to satisfy all needs of a small operation<br />

preparing 10-80 portions per day. The vegetable slicer<br />

attachment can process appr. 2 kg vegetables per minute depending<br />

on the slicer disc used. The cutter attachment has a 3 litre stainless<br />

steel bowl with a processing capacity of appr. 1,2 litre liquid products,<br />

such as soups, sauces, desserts etc. Meat, fish and other solid product<br />

can be minced in amount of appr. 1 kg. When processing solid<br />

products best result is obtained if the products are cut to 3x3 cm<br />

pieces before processing.<br />

Changing the vegetable slicer and the cutter bowl to the CC-34 motor body<br />

is quick and easy. The vegetable slicer component, the slicer heads with<br />

p<strong>la</strong>stic bodies (see pictures above), the cutter cover, the scraper and the<br />

b<strong>la</strong>de can be cleaned in a dishwasher. The CC-34 takes very little space and<br />

is easily lifted aside when not needed. A GN1/2-150 container fits in front<br />

of the slicer on the desk.<br />

The CC-34 combi cutter has 4 speeds and a pulse function. The automatic<br />

speed setting senses whether the vegetable attachment or the cutter<br />

attachment is used. The body of the slicer is of aluminium, the slicer of<br />

polycarbonate, the cutter bowl of stainless steel and the cover and the cutter<br />

scraper of polycarbonate. The slicer speeds are 500 and 800 rpm, those of<br />

the cutter 1450 and 2650 rpm. The pulsating speed is 800 rpm for the slicer<br />

and 2650 rpm for the cutter. The motor has an overheat protector with<br />

automatic recovery. The slicer body weight 8,6 kg, vegetable cutter 1,0 kg,<br />

discs abt. 0,4 kg. Cutter bowl with knives 1,4 kg.<br />

<strong>Metos</strong> CC-34 combi cutter is avai<strong>la</strong>ble in following combinations:<br />

■ Vegetable slicer CC-34, including motor base and vegetable attachment.<br />

■ Cutter CC-34, including motor base and complete cutter attachment<br />

■ Combi cutter CC-34, including both cutter and vegetable attachments and<br />

4 slicer discs for the vegetable attachment.<br />

■ Cutter bowl, which can be purchased separately to complete the vegetable<br />

slicer CC-34.<br />

Graters/<br />

shredders<br />

2, 4.5, 6 and 8 mm.<br />

For stripping<br />

potatoes, carrots,<br />

cheese and<br />

cabbage.<br />

Fine grater<br />

For grating<br />

nuts and<br />

biscuits.<br />

Julienne<br />

cutters<br />

2x2, 4.5x4.5 mm<br />

For stripping<br />

roots, cucumber<br />

etc.<br />

<strong>Metos</strong> Code Dimensions mm Delivery<br />

Vegetable slicer CC-34 4221025 285x350x465 vegetable slicer CC-34 without slicer discs<br />

Vegetable slicer CC-34 4221057 285x350x465 vegetable slicer CC-34 + 4 discs:<br />

+ 4 package 4,5x4,5 mm julienne cutter, 2 mm grater,<br />

2 and 4 mm fine cut slicers, wall rack<br />

Cutter CC-34 4221032 285x350x465 motor base, cutter attachment, 3 l s/s bowl<br />

Combi cutter CC-34 4192744 285x350x465 vegetable slicer, cutter CC-34 + 4 discs:<br />

+ 4 package 4,5x4,5 mm julienne cutter, 2 mm grater,<br />

2 and 4 mm fine cut slicers, wall rack<br />

Cutter bowl CC-34 4221064 ø 220 x 205 cutter complete, 3 l s/s bowl, b<strong>la</strong>de and cover with scraper<br />

Wall rack 4087517 Wall rack for 3 slicer discs<br />

El. connection 230V 1~ 50Hz 1,0 kW 10A slow<br />

Stock product

METOS RG-100 VEGETABLE SLICER<br />

The <strong>Metos</strong> RG-100 slices, cubes, strips and grates. It handles fruit,<br />

vegetables, roots, mushrooms, cheese, bread and nuts. The 17 rapidly<br />

interchangeable slicer heads ensure the right dimensions, a perfect<br />

cut and optimal texture. The razor-sharp slicer heads made of tempered<br />

stainless steel make for fine, equal tomato slices.<br />

The RG-100 takes up little space. A GN1/1-100 bowl fits in front, under<br />

the slicer on the desk. Long produce items, such as cucumbers, can be sliced<br />

continuously through the wide feeder tube (57 mm of diameter). An optional<br />

angle tube feeder is avai<strong>la</strong>ble. The angle tube feeder is suitable e.g. for cutting<br />

of wok vegetables or for decorative cutting of vegetable for sa<strong>la</strong>ds and<br />

sandwiches. The feeder is aluminium and a p<strong>la</strong>stic pusher is included. The<br />

feed tube diameter is 50 mm. The <strong>Metos</strong> RG-100 cuts up to 5 kg/min.<br />

Suitable for <strong>kitchens</strong> making up to 400 portions/day.<br />

Standard<br />

slicers<br />

10 mm<br />

For slicing solid<br />

products.<br />

Julienne<br />

cutters<br />

2.5x2.5,<br />

4.5x4.5, 6x6<br />

and 8x8 mm.<br />

For stripping<br />

roots and cucumber<br />

etc. 8x8<br />

mm head for<br />

French fries.<br />

Dicing grid<br />

7.5x7.5 mm<br />

10x10 mm<br />

15x15 mm<br />

20x20 mm L 2)<br />

Used with standard<br />

slicers or fine<br />

cut slicer slicers.<br />

Stand<br />

Fine cut<br />

slicers<br />

1.5 ja 2 mm<br />

(2 knives), 4 mm,<br />

6 mm, 10 mm, 14<br />

mm 1)<br />

For slicing solid, soft<br />

and juicy produce,<br />

stripping of cabbage.<br />

Can be used also<br />

with a dicing grid for<br />

cubing.<br />

The <strong>Metos</strong> RG-100 can be installed on a height<br />

adjustable counter, lowered appliance stand or trolley<br />

(optional). The stand includes three removable<br />

p<strong>la</strong>stic GN-containers. The stand is suited for RG-<br />

100, RG-200 and RG-250 models. Stainless steel<br />

trolley on page 30.<br />

Crimping slicer<br />

4.5 mm<br />

For slicing decorative<br />

slices<br />

Graters/<br />

shredders<br />

1.5, 2, 3, 4.5, 6<br />

and 8 mm.<br />

For grating carrots, potatoes,<br />

cheese, bread,<br />

nuts etc, stripping cabbage.<br />

■ Hinged detachable feeding cylinder<br />

■ Ergonomic press with a 57 mm dia. tubu<strong>la</strong>r feeder<br />

■ Efficient ejector<br />

■ Hygienic, easy-to-clean construction<br />

■ Machine won’t start with cover or feeder open<br />

■ Large outlet for quick operation<br />

■ Ergonomic design: dish compartment in front, tilted<br />

towards the operator, dirt-repellent surface, feeder<br />

with a <strong>la</strong>rge handle<br />

■ Sturdy<br />

■ Motor with overheat protector<br />

■ 5 kg/min < 400 portions/day<br />

<strong>Metos</strong> RG-100 for small and medium-size <strong>kitchens</strong><br />

Fine graters<br />

For grating raw potatoes,<br />

hard dry<br />

cheese, such as Parmesan<br />

cheese and<br />

dry bread.<br />

Technical specifications<br />

Machine: Housing in elox-treated polished aluminium alloy<br />

Motor: equipped with an overheat protector<br />

Power transmission: p<strong>la</strong>netary gear. Safety equipment: two<br />

mechanical safety switches and a brake. The tool bodies are of<br />

aluminium or asetal p<strong>la</strong>stic, 185 mm dia. knives in stainless steel.<br />

Speed: 350 rpm. Net weights: Machine 16 kg, cutting tools average 0.5 kg.<br />

In order to keep the tools sharp and their use<br />

safe and efficient, a practical wall-mounted<br />

rack is avai<strong>la</strong>ble. The rack is designed for three<br />

heads.<br />

<strong>Metos</strong> Code Dimensions mm El. connection Delivery<br />

RG-100 4127343 245x425x495 230V 1~ 50Hz 0,25 kW 10A Machine body<br />

RG-100, 4-pack. 4144211 245x425x495 230V 1~ 50Hz 0,25 kW 10A Machine, fine cut slicer 1.5 and 4 mm<br />

grater dics 2 and 8 mm, wall rack for discs<br />

RG-100, 7-pack. 4129012 245x425x495 230V 1~ 50Hz 0,25 kW 10A Machine, fine cut slicer 1.5 and 4 mm standard slicer<br />

10 mm, dicing grid 10x10 mm, grater discs 2 and 8<br />

mm, julienne cutter 4,5x4,5 mm,<br />

2 pcs wall racks<br />

Stand 4220198 575x625x655 1 pc GN1/1-200 p<strong>la</strong>stic container<br />

Wall rack 4087517 for 3 discs<br />

Angle tube feeder 4220141<br />

| 27

28 |<br />

METOS RG-200 VEGETABLE SLICER<br />

Slicer discs<br />

6, 8, 10 mm<br />

For slicing solid<br />

products. For dicing<br />

with a dicing grid.<br />

Slicer disc<br />

12,5 mm 3)<br />

For dicing with<br />

12.5x12.5 mm and<br />

bigger dicing grids.<br />

E.g. for roots and<br />

fried potatoes, dicing<br />

cabbage for casseroles<br />

and soups or<br />

for dicing boiled potatoes<br />

for sa<strong>la</strong>ds.<br />

<strong>Metos</strong> RG-200 for medium size <strong>kitchens</strong><br />

Crimping slicer<br />

4.5 mm<br />

E.g. for preparing<br />

grooved beetroot<br />

slices.<br />

Dicing grids<br />

6.25x6.25, 7.5x7.5,<br />

l0xl0, 12.5x12.5,<br />

15x15, 20x20 5)<br />

mm.<br />

For dicing with a<br />

slicing disc.<br />

Technical specifications:<br />

Machine: Casing of anodized polished aluminium alloy<br />

Motor: Motor with overheat protector<br />

Transmission: p<strong>la</strong>netary gear. Safety equipment: mechanical<br />

safety clutch and brake. Disc bodies of aluminium with 185 mm<br />

dia., knives of stainless steel.<br />

Rotating speed: 350 rpm.<br />

Net weights: machine 18.3 kg, cutting discs 0.5 kg in average.<br />

Fine cut slicer,<br />

2 knives<br />

1.5, 2 mm<br />

For slicing solid<br />

and soft products,<br />

such as roots, onions<br />

and cucumbers,<br />

shredding<br />

cabbage.<br />

The <strong>Metos</strong> RG-200 slices, cubes, strips and grates. It handles<br />

fruit, vegetables, roots, mushrooms, cheese, bread and nuts.<br />

The 23 rapidly interchangeable slicer heads ensure the right<br />

dimensions, a perfect cut and optimal texture. The razor-sharp slicer<br />

heads made of tempered stainless steel make for fine, uniform tomato slices.<br />

Despite its small size the RG-200 is very efficient. Peak efficiency has been achieved<br />

with many practical and technical solutions, such as an oversized feed hopper. The<br />

spacious feed opening reduces the preparatory work, since most products can be fed<br />

without cutting. Lengthy products such as cucumbers can be sliced continuously<br />

through the <strong>la</strong>rge 57 mm dia. feed hopper. An optional angle tube feeder is avai<strong>la</strong>ble.<br />

The angle tube feeder is suitable e.g. for cutting of wok vegetables or for decorative<br />

cutting of vegetable for sa<strong>la</strong>ds and sandwiches. The feeder is aluminium and a p<strong>la</strong>stic<br />

pusher is included. The feed tube diameter is 50 mm. <strong>Metos</strong> RG-200 slices 6.5 kg<br />

per minute.<br />

Ergonomics and productivity go hand in hand. The cutting disc rack saves space,<br />

makes handling easier and keeps the discs sharp. The RG-200 can be p<strong>la</strong>ced on a<br />

height adjustable counter, equipment stand or trolley. There are two different stands<br />

and a trolley avai<strong>la</strong>ble. See p. 30.<br />

Suitable for <strong>kitchens</strong> preparing max. 600 portions a day.<br />

Fine cut slicer,<br />

1 knife<br />

3, 4, 6, 10, 14 4)<br />

mm<br />

For slicing solid and<br />

soft products, such<br />

as onions, tomatoes,<br />

limes, bananas and<br />

mushrooms, shredding<br />

sa<strong>la</strong>ds.<br />

Graters /<br />

shredders<br />

1.5, 2, 3, 4.5, 6, 8<br />

mm For grating carrots<br />

and cabbages.<br />

Also grates nuts, almonds,<br />

cheese and bread.<br />

■ sturdy<br />

■ efficient ejector<br />

■ motor with overheat protector<br />

■ hinged removable feed hopper<br />

■ ergonomic press with a 57 mm dia. tubu<strong>la</strong>r feeder<br />

■ hygienic, easy-to-clean construction<br />

■ machine won’t start with open cover or press<br />

■ <strong>la</strong>rge, clear switches and a carrying handle at the back<br />

■ ergonomic design: space for dishes in front,<br />

inclined towards operator.<br />

■ dirt-repellent surface, <strong>la</strong>rge handle at the press<br />

■ 6.5 kg/min, < 600 portions /day<br />

Fine graters<br />

For grating raw potatoes,<br />

hard dry<br />

cheese, such as Parmesan<br />

cheese and<br />

dry bread.<br />

Julienne cutters<br />

2.5x2.5, 4.5x4.5,<br />

6x6, 8x8, 10x10 mm<br />

For shredding roots<br />

and potatoes, perfect<br />

for preparing casseroles<br />

and soups. 8x8<br />

and 10x10 mm discs<br />

for curved French<br />

fries.<br />

<strong>Metos</strong> Code Dimensions mm El. connection Delivery<br />

RG-200 4131886 245x475x515/735 230V 1~ 50Hz 0,37 kW 10A Machine body<br />

RG-200, 7-package 4131893 245x475x515/735 230V 1~ 50Hz 0,37 kW 10A Machine, fine cut slicer 1.5 and 4 mm, standard slicer 10<br />

mm, dicing grid 10x10 mm, grater discs 2 and 8 mm,<br />

julienne cutter 4,5x4,5 mm,<br />

2 pcs wall racks<br />

Stock product<br />

Stand 4220198 575x625x655 1 pc GN1/1-200 p<strong>la</strong>stic container<br />

Wall rack 4087517 for 3 discs<br />

Angle tube feeder 4220141

METOS RG-250 VEGETABLE SLICER<br />

<strong>Metos</strong> RG-250 for medium size <strong>kitchens</strong><br />

Slicer discs<br />

6, 8, 10 mm<br />

For slicing solid<br />

products. For<br />

dicing with a<br />

dicing grid.<br />

Slicer disc<br />

12,5 mm 3)<br />

For dicing with<br />

12.5x12.5 mm<br />

and bigger dicing<br />

grids. E.g. for roots<br />

and fried potatoes,<br />

dicing cabbage for<br />

casseroles and<br />

soups or for dicing<br />

boiled potatoes for<br />

sa<strong>la</strong>ds.<br />

Crimping slicer<br />

4.5 mm<br />

E.g. for preparing<br />

grooved beetroot<br />

slices.<br />

Potato chips grid<br />

10 mm 7)<br />

Cuts straight<br />

French fries with<br />

10 mm fine cut<br />

slicer<br />

Dicing grids<br />

6.25x6.25, 7.5x7.5,<br />

l0xl0, 12.5x12.5,<br />

15x15, 20x20 L 5)<br />

mm.<br />

For dicing with a<br />

slicing disc.<br />

Technical specifications<br />

Machine body and feeder: anodized or polished aluminium.<br />

Slicer discs: body of aluminium or acetal, knives of stainless<br />

steel. Disc diameter 185 mm.<br />

Motor: 400V 3/N/PE 50Hz 0,55 kW. Motor has overheat<br />

protection. 10A fuse is required.<br />

Transmission: gear transmission. Safety: Machine has 2 safety<br />

switches. Protection c<strong>la</strong>ss IP 44, for operation switches IP65.<br />

Noise level: 72 dBA (EN31201). Rotationg spedd: 380 rpm.<br />

Net weight: machine 21 kg, discs 0,5 kg average.<br />

<strong>Metos</strong> RG-250 is an efficient and ergonomic vegetable slicer, which can be p<strong>la</strong>ced on<br />

a lowered counter or stand. RG-250 slices, cubes, strips and grates fruit, vegetable,<br />

roots, mushrooms, cheese bread and nuts. The selection of slicer discs comprise 28<br />

different use-alone discs. In addition there are 6 dicing grids of various sizes to be used with<br />

simi<strong>la</strong>r size or smaller slicer disc.<br />

The ergonomics and hygiene of RG-250 have been paid special attention to. The slicer is<br />

p<strong>la</strong>ced on a lowered counter or stand. Right working height is 100-125 cm, at which the user<br />

does not need to bend during the work. The slicer is hygienic and easy to clean: the feed<br />

hopper and presser are detachable and they can be washed with neutral detergent.<br />

The feed hopper volume is 4 litres and it can even <strong>la</strong>rge products, which minimizes preparation.<br />

There is one intermediate wall to support the products, and the products can be p<strong>la</strong>ced<br />

towards it for desired direction of cut. Lengthy products, like cucumbers, leek and celery are<br />

fed thrugh the presser tube.<br />

The slicer discs are simi<strong>la</strong>r to RG-200. In addition there is a potato chip grid to be used with<br />

the 10 mm slicer or fine cut slicer disc.<br />

Vegetable slicer RG-250 is suitable for <strong>kitchens</strong> serving 50-800 portions per day. The capacity<br />

is 8 kg/min.<br />

Fine cut slicer,<br />

2 knives<br />

1.5, 2 mm<br />

For slicing solid<br />

and soft products,<br />

such as roots,<br />

onions and cucumbers,<br />

shredding<br />

cabbage.<br />

Fine cut slicer,<br />

1 knife<br />

3, 4, 6, 10, 14 4)<br />

mm<br />

For slicing solid<br />

and soft products,<br />

such as onions,<br />

tomatoes, limes,<br />

bananas and<br />

mushrooms,<br />

shredding sa<strong>la</strong>ds.<br />

■ sturdy<br />

■ hygienic, easy to clean<br />

■ detachable feed hopper and presser<br />

■ <strong>la</strong>rge ergonomic handle<br />

■ tilted towards the user, easy to use<br />

■ motor with overheat protection<br />

■ spiral draws product to the disc<br />

■ 800 portions/day, 8 kg/min<br />

Graters /<br />

shredders<br />

1.5, 2, 3, 4.5, 6, 8<br />

mm<br />

For grating carrots<br />

and cabbages.<br />

Also grates nuts,<br />

almonds, cheese<br />

and bread.<br />

Fine graters<br />

For grating raw<br />

potatoes, hard dry<br />

cheese, such as<br />

Par-mesan cheese<br />

and dry bread.<br />

Julienne cutters<br />

2.5x2.5, 4.5x4.5,<br />

6x6, 8x8, 10x10<br />

mm<br />

For shredding<br />

roots and potatoes,<br />

perfect for preparing<br />

casseroles<br />

and soups. 8x8<br />

and 10x10 mm<br />

discs for curved<br />

French fries.<br />

<strong>Metos</strong> Code Dimensions mm El. connection Delivery<br />

RG-250 4220166 250x450x586/735 400V3N~ 50Hz 0,55 kW 10A machine body<br />

RG-250, 7-pack. 4220173 250x450x586/735 400V3N~ 50Hz 0,55 kW 10A machine, fine cut slicer 1.5 and 4 mm, standard slicer<br />

10 mm, dicing grid 10x10 mm, grater discs 2 and 8<br />

mm, julienne cutter 4,5x4,5 mm, 2 pcs wall racks<br />

Stand 250 4220198 575x625x655 1 pc GN 1/1-200 p<strong>la</strong>stic container<br />

Stand 4220198 575x625x655 1 pc GN1/1-200 p<strong>la</strong>stic container<br />

Wall rack 4087517 for 3 discs<br />

Stock product<br />

| 29

30 |<br />

METOS STANDS AND TROLLEYS<br />

<strong>Metos</strong> equipment trolley<br />

(equipment stand is without<br />

castors)<br />

<strong>Metos</strong> RN-20 stand with<br />

pull-out shelf and adjustable<br />

feet.<br />

<strong>Metos</strong> RN20 stand is designed for Karhu RN 20 varimixer, it is also suitable for<br />

small vegetable slicers. A pull-out shelf below top. Sturdy construction and adjustable<br />

feet ensure stable work with the mixer. Stainless steel construction throughout.<br />

Stand and trolley are designed for ergonomic use of small kitchen appliances.<br />

Working on the right level with small vegetable slicers, cutters and varimixers is<br />

very important. Both models have the same construction: f<strong>la</strong>t top facilitates cleaning,<br />

shelf in stand. Construction of stainless steel. Stand with adjustable feet,<br />

trolley with ø 125 mm castors, two of which with brakes.<br />

<strong>Metos</strong> Code Dimensions mm<br />

Stand RN20 4189766 450x640x530<br />

Trolley 4206228 560x640x650<br />

Stand 4189558 560x640x650<br />

The RG-350 stand and trolley are intended for RG-350 vegetable cutter. In the<br />

front, there is a space for a GN1/1 container. Alternatively the <strong>Metos</strong> T-450 multipurpose<br />

trolley can be used to take the cutter output. Stand with adjustable feet,<br />

trolley with rubber castors Ø 125 mm, two of which with brakes. Sturdy<br />

construction stainless steel throughout.<br />

<strong>Metos</strong> Code Dimensions mm<br />

Stand RG-350 4144204 600x450x450<br />

Trolley RG-350 4206235 600x450x450<br />

<strong>Metos</strong> RG-350<br />

stand for vegetable cutters<br />

METOS STANDS FOR SLICER DISCS<br />

The disc stands are suited for all of the slicer discs of the <strong>Metos</strong> RG-200-RG-400 vegetable slicers.<br />

The pegs are fixed at a 5° upward angle ensuring that the discs are kept well in p<strong>la</strong>ce. Each peg can<br />

take two discs. The b<strong>la</strong>de parts don’t touch each other. The discs can be easily and safely be taken<br />

from the stand by lifting them out of the case as the operator can see the whole disc and avoid<br />

touching the sharp b<strong>la</strong>des.<br />

The wall-mounted model is easy to attach to hooks or screws on the wall.<br />

The trolley-mounted model fits <strong>Metos</strong> service trolleys KV-55 - KV-105, GN rail trolley TGN-14<br />

and shelf trolley HV-75. The stand is pressed against the edge of the shelf and it doesn’t have to be<br />

fixed to the trolley. The long supports of the stand lean against the shelves below and stay firmly in<br />

p<strong>la</strong>ce.<br />

The shelf trolley has enough space even for the accessories of the <strong>la</strong>rgest vegetable cutter RG-400.<br />

Stand for slicer discs Code Dimensions mm<br />

Wall mounted 4 pegs, for 8 discs 4189727 430x625x135<br />

Wall mounted6 pegs, for 12 discs 4189734 430x875x135<br />

Trolley-mounted 4 pegs, for 8 discs 4189741 430x633x135<br />

Trolley-mounted 6 pegs, for 12 discs 4189759 430x884x135<br />

Stock product<br />

<strong>Metos</strong> RG-350<br />

trolley for vegetable cutters<br />

Trolley-mounted stand for four vegetable cutter<br />

discs mounted on the <strong>Metos</strong> HV-75 shelf<br />

trolley.

METOS RG-350 VEGETABLE SLICER<br />

The <strong>Metos</strong> RG-350 slices, chips, dices and grates. It handles<br />

fruit, vegetables, roots, mushrooms, cheese, bread and nuts.<br />

The 32 quickly interchangeable cutting discs guarantee exact<br />

measurements, precision slicing and the superior consistency. Thanks<br />

to the extremely sharp cutting discs made of hardened stainless steel<br />

you can also produce fine, uniform tomato slices.<br />

The <strong>Metos</strong> RG-350 is very efficient and perfectly suited for handling <strong>la</strong>rge<br />

volumes. Peak efficiency has been achieved with many practical and technical<br />

solutions, such as the conical feed hopper. The <strong>Metos</strong> RG-350 cuts 12 kg/<br />

min and its capacity is appr. 1200 portions/day. The spacious 195 mm dia.<br />

feed opening reduces the preparatory work, since most products can be fed<br />

without cutting. Lengthy products such as cucumbers can be sliced<br />

continuously through the <strong>la</strong>rge 57 mm dia. feed hopper. Also the spiral lock<br />

screw used to lock the discs pulls the cabbages towards the disc.<br />

Ergonomics and efficiency go hand in hand. Thanks to <strong>la</strong>rge handles, RG-<br />

350 is easy to move. The machine is p<strong>la</strong>ced on a lowered appliance stand or<br />

a trolley. Stainless steel stands for slicer discs are avai<strong>la</strong>ble. The stands can be<br />

attached on the wall or on a shelf trolley. Stands see pg. 30.<br />

Slicer discs<br />

4.5, 6, 10, 15,<br />

20 mm<br />

For slicing solid<br />

products. For<br />

dicing with a<br />

dicing grid.<br />

Slicer disc<br />

12,5 mm 3)<br />

For dicing with<br />

12.5x12.5 mm<br />

and bigger dicing<br />

grids. E.g. for roots<br />

and fried potatoes,<br />

dicing cabbage for<br />

casseroles and<br />

soups.<br />

Crimping slicer<br />

4.5 mm<br />

For preparing<br />

decorative slices of<br />

for instance<br />

beetroots,<br />

cucumbers and<br />

carrots.<br />

Potato chips grid<br />

10 mm 6)<br />

Cuts straight<br />

French fries with<br />

10 mm fine cut<br />

slicer<br />

Dicing grids<br />

6.25x6.25, 7.5x7.5,<br />

l0xl0, 12.5x12.5.<br />

For dicing with a<br />

slicing disc.<br />

Dicing grids L<br />

15x15, 20x20,<br />

25x25 mm.<br />

Dices roots,<br />

potatoes, fruit etc<br />

using 15 and 20<br />

mm slicers or 14<br />

and 20 mm fine<br />

cut slicers<br />

Technical specifications:<br />

Machine: Casing of anodized polished aluminium alloy<br />

Motor: Motor with overheat protector<br />

Transmission: p<strong>la</strong>netary gear.<br />

Safety equipment: 4 safety clutches. Disc bodies of<br />

aluminium with 215 mm dia., knives of stainless steel.<br />

Rotating speed: 360 rpm.<br />

Net weights: machine 32 kg, cutting discs 1 kg in average,<br />

feedhopper 3,7 kg.<br />

Fine cut slicer,<br />

2 knives<br />

1.5, 2, 3 mm<br />

For slicing solid<br />

and soft products,<br />

such as roots,<br />

onions, leeks and<br />

cucumbers,<br />

shredding cabbage.<br />

NB. Dicing grid<br />

must be equal or<br />

bigger than the<br />

fine cut slicer.<br />

The stand has a recess for a<br />

GN pan or a multipurpose<br />

trolley <strong>Metos</strong> T-450, code<br />

2026448, pg. 259.<br />

Fine cut slicer,<br />

1 knife<br />

4, 6, 10, 14,<br />

20 mm<br />

For slicing solid and<br />

soft products, such<br />

as roots, paprika,<br />

leeks, onions, cucumbers,<br />

tomatoes,<br />

citrus fruits, bananas<br />

and mushrooms.<br />

Shreds<br />

cabbage and<br />

sprouts. 4 mm disk<br />

for cutting onions<br />

with a 10x10 mm<br />

or bigger dicing grid.<br />

Graters /<br />

shredders<br />

1.5, 2, 3, 4.5, 6, 8<br />

mm<br />

For grating carrots,<br />

cabbage, dry bread,<br />

almonds and nuts.<br />

8 mm disc ideal for<br />

shredding cabbage<br />

and grating pizza<br />

cheese.<br />

Sturdy<br />

Fast<br />

Motor with overheat protector<br />

Hinged removable feed hopper<br />

Large ergonomic press with a 57 mm dia. tubu<strong>la</strong>r feeder<br />

Hygienic, easy-to-clean construction<br />

Machine won’t start with open cover or press<br />

Large feed cylinder and outlet for quick operation<br />

Large, clear switches and carrying handles<br />

Stand has space for GN container or GN trolley<br />

Inclined towards operator, dirt-repellent surface<br />

Lock nut pulls cabbage towards disc<br />

Conical feed attachment for mass feeding (optional)<br />

12 kg/min, < 1200 portions / day<br />

Feed hopper for<br />

RG-350 slicer<br />

<strong>Metos</strong> Code Dimensions mm El. connection Delivery<br />

RG-350 4143352 325x555x745/895 400V 3N~ 50Hz 0,75 kW 10A Machine body<br />

RG-350, 7-package 4143377 325x555x745/895 400V 3N~ 50Hz 0,75 kW 10A Machine, fine cut slicer 2 and 4 mm<br />

standard slicer 10 mm, dicing grid 10x10<br />

mm grater discs 2 and 8 mm, 3 pcs wall<br />

racks, julienne cutter 4.5x4.5 mm<br />

RG-350 feed hopper 4143401 400x370x580<br />

Stand RG-350 4144204 600x650x450 p<strong>la</strong>ce for GN container or trolley<br />

Trolley RG-350 4206235 600x650x450 2 castors at rear, 2 swivelling<br />

castors with brakes in front<br />

Wall rack 4087517 for 3 discs<br />

Instal<strong>la</strong>tion drawing on page 271<br />

Fine graters<br />

For grating<br />

potatoes, Parmesan<br />

cheese and ground<br />

toast.<br />

Julienne cutters<br />

2x2, 2.5x6,<br />

4.5x4.5, 6x6,<br />

10x10 mm<br />

For shredding<br />

roots and potatoes<br />

for casseroles and<br />

soups. 2x2 mm for<br />

fine shreds or stick<br />

French fries 2.5x6<br />

mm disk shreds<br />

white cabbage to<br />

short bits. 10x10<br />

mm discs for<br />

curved French<br />

fries.<br />

| 31

32 |<br />

METOS RG-400 VEGETABLE SLICER<br />

Basic delivery of <strong>Metos</strong> RG-400 includes the<br />

body, feed cylinder A and the hopper.<br />

The hopper feeds automatically<br />

without push feed attachment.<br />

The device is suitable for continuous<br />

feeding of round products,<br />

such as potatoes, onions, nuts, almonds<br />

and dry bread pieces - no<br />

manual pushing.<br />

■ <strong>Metos</strong> RG-400 vegetable slicer has been designed for quick handling of <strong>la</strong>rge quantities with<br />

optimal ergonomics<br />

■ <strong>Metos</strong> RG-400 is a durable, versatile and efficient vegetable slicer for the operator demanding<br />

a perfect cutting performance<br />

■ 40 kg / min < 3000 portions / day<br />

■ Ergonomic ■ Large selection of slice dimensions ■ Easy and quick to clean<br />

■ Reliable and low maintenance<br />

■ Versatile applications<br />

■ Special attention paid to safety and reliability<br />

Feed hopper<br />

The manual feed attachment is<br />

easy and light to operate when<br />

for instance cabbage, cheese, carrots<br />

and lettuce are handled.<br />

The feed hopper with its own feed cylinder (model A) for continuous feeding of potatoes, onions, dry<br />

bread pieces, nuts, mushrooms etc. Ailerons direct the products automatically to the disc and no pressing<br />

is necessary. For instance peeled potatoes can be fed into the hopper directly from a bag or a pail. The<br />

feeder is of stainless steel and the feeder cylinder of cast aluminium alloy with a stainless steel lining.<br />

Feed cylinder B<br />

The B model feeder cylinder is used with either a manual push feed attachment, a feeder with 4 openings<br />

or a pneumatic push feed attachment. Model B differs from model A in that it has 3 sharp edges inside.<br />

When either the manual or pneumatic push feed attachment is used, for instance a cabbage can be put<br />

directly into the cylinder, where the discs divide the surface and the spiral-form block screw of the disc<br />

pulls the cabbage onto the disc and makes operation easier. The <strong>la</strong>rge 7 l volume and the 200 mm<br />

opening of the feed cylinder reduce the number of fillings and make feeding of most products possible<br />

without cutting.<br />

Push feed attachment with 4 openings<br />

For continuous operations, such as the preliminary handling of cucumbers, leeks, tomatoes and citric<br />

fruits. Makes slicing easier. Used with feed cylinder B. The 4-opening feed attachment has 2 openings<br />

with 73 mm dia., one with 35 mm dia. 2 different size push rods made of white food industry p<strong>la</strong>stic are<br />

included. The attachment is made of aluminium and it has a separate lock screw for locking the discs.<br />

The 4-opening feed attachment is<br />

designed for continuous feeding<br />

of cucumbers, leeks, Romaine lettuce,<br />

celery and other lengthy<br />

products.<br />

The pneumatic push feed attachment<br />

pushes the product automatically<br />

onto the disc without manual<br />

manipu<strong>la</strong>tion. Makes handling<br />

<strong>la</strong>rge quantities easier.<br />

Manual push feed attachment<br />

For high speed operation, for instance for feeding cabbage,<br />

sprouts, iceberg lettuce, carrots, tomatoes and other<br />

products that have to be supported and pressed. The<br />

design of the attachment makes pushing lighter and no<br />

force is necessary. The running of the machine can also<br />

be controlled, since when the attachment is turned away,<br />

the machine stops and vice versa.<br />

Pneumatic push feed attachment<br />

For automatic handling of products that need to be<br />

pushed, such as cabbage, lettuce, carrots. Processing<br />

cabbage and carrots that used to be the most <strong>la</strong>bour<br />

intensive is now easy and ergonomic thanks to the<br />

pneumatic push feed attachment. The operator fills the<br />

feed cylinder (B) and rotates the attachment onto the<br />

feed cylinder which starts the machine automatically.<br />

Working is safe since the machine stops automatically<br />

when the attachment is rotated away. Choice of three<br />

speeds to match the texture of the handled product.<br />

<strong>Metos</strong> Code El. connection Delivery<br />

RG-400 4132512 400V 3N~ 1,5/0,9 kW 10A Machine body, feed hopper, feed cylinder A<br />

Feed cylinder B 4132537 used with either a manual push feed attachment, a feeder with 4 openings or a pneumatic push feed attachment<br />

4-opening feed att. 4189276 new model from Serial No. 2550<br />

Manual push feed att. 4189269 new model from Serial No. 2550<br />

Pneumatic push feed att. 4189283 Compressed air 35 l/min is required; new model from serial nr. 2550<br />

Compressor 4133146 working pressure 6 bar 1,33 l /s, 230V, 1~0,75 kW, 10 A slow, volume of the tank 19 l<br />

RG 400, 7 package 4132618 Machine body, feed hopper, feed cylinder A, manual push feed attachment,<br />

feed cylinder B, fine cut slicer 2 and 4 mm, standard slicer 10 mm,<br />

dicing grid 10x10, julienne cutter 4.5x4.5, grater/shredder 2 and 8 mm,<br />

3 wall racks<br />

Utensil trolley 4144194 860x535x1060 mm<br />

Wall rack 4087517 for 3 discs<br />

Instal<strong>la</strong>tion drawing on page 271<br />

Stock product

METOS RG-400 VEGETABLE SLICER<br />

Slicer discs<br />

4.5, 6, 10, 15,<br />

20 mm<br />

For slicing solid<br />

products.<br />

For dicing with a<br />

dicing grid.<br />

Slicer disc<br />

12,5 mm<br />

For dicing with<br />

12.5x12.5 mm and<br />

bigger dicing grids.<br />

E.g. for roots and<br />

fried potatoes, dicing<br />

cabbage for casseroles<br />

and soups.<br />

Fine cut slicer,<br />

2 knives<br />

1.5, 2, 3 mm<br />

For slicing solid and<br />

soft products, such as<br />

roots, onions, leeks<br />

and cucumbers,<br />

shredding cabbage.<br />

<strong>Metos</strong> RG-400 technical specification<br />

Capacity: 10-40 kg / min depending on<br />

push feeder, disc and product<br />

Motor: 2 speeds, pinion transmission<br />

Safety: three safety switches<br />

Protection c<strong>la</strong>ss: IP 45<br />

Noise level: LpA (EN 31201): 70 dBA<br />

Pneumatic push feed attachment: three<br />

speeds<br />

Recommended air capacity and<br />

pressure: 35 l / min, 6 bar<br />

Cutting discs: 215 mm dia.,<br />

speed: 400/200 rpm<br />

Materials: Machine body, feed cylinders<br />

and attachments anodized or polished<br />

aluminium alloy or stainless steel<br />

Cutting discs: body of aluminium alloy<br />

and knives of high-grade steel<br />

Weights: Machine body 54 kg<br />

Feed cylinder (B) 6 kg<br />

Feed hopper + cylinder A 12 kg<br />

Pneumatic push feed attachment 11 kg<br />

Manual push feed attachment 5 kg<br />

Discs, average 1 kg<br />

Complies with the following standards:<br />

NFS standard 8, EU machine directive<br />

89/392EEC, EMC directive 89/336/<br />

EEC<br />

Fine cut slicer,<br />

1 knife<br />

4, 6, 10, 14,<br />

20 mm<br />

For slicing solid and<br />

soft products, such as<br />

roots, paprika, leeks,<br />

onions, cucumbers,<br />

tomatoes, citrus<br />

fruits, bananas and<br />

mushrooms. Shreds<br />

cabbage and sprouts.<br />

4 mm disc for cutting<br />

onions with a 10x10<br />

mm or bigger dicing<br />

grid.<br />

Crimping slicer<br />

4.5 mm<br />

For preparing decorative<br />

slices of for<br />

instance beetroots,<br />

cucumbers and carrots.<br />

Dicing grid L<br />

15x15, 20x20,<br />

25x25 mm.<br />

Used in combination<br />

with 15 or 20<br />

mm slicing discs or<br />

14 or 20 mm fine<br />

cut slicer.<br />

A wall rack, made of food industry<br />

quality p<strong>la</strong>stic is also avai<strong>la</strong>ble<br />

for discs, with room for three discs.<br />

Also avai<strong>la</strong>be stainless steel stand<br />

for discs which can be attached to<br />

the wall or to shelf trolley.<br />

.<br />

Dicing grids<br />

6.25x6.25,<br />

7.5x7.5, 10x10,<br />

12.5x12.5.<br />

Dices roots, fruit,<br />

potatoes, cabbage,<br />

carrots, cucumbers,<br />

tomatoes, apples etc.<br />