Caterpillar® 236, 246 and 248 Skid Steer Loaders - Finning (UK)

Caterpillar® 236, 246 and 248 Skid Steer Loaders - Finning (UK)

Caterpillar® 236, 246 and 248 Skid Steer Loaders - Finning (UK)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

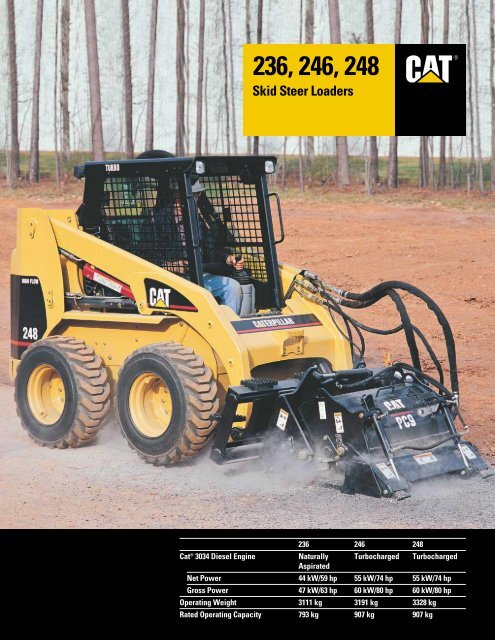

<strong>236</strong>, <strong>246</strong>, <strong>248</strong><br />

<strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong><br />

®<br />

<strong>236</strong> <strong>246</strong> <strong>248</strong><br />

Cat ® 3034 Diesel Engine Naturally Turbocharged Turbocharged<br />

Aspirated<br />

Net Power 44 kW/59 hp 55 kW/74 hp 55 kW/74 hp<br />

Gross Power 47 kW/63 hp 60 kW/80 hp 60 kW/80 hp<br />

Operating Weight 3111 kg 3191 kg 3328 kg<br />

Rated Operating Capacity 793 kg 907 kg 907 kg

Caterpillar ® <strong>236</strong>, <strong>246</strong> <strong>and</strong> <strong>248</strong> <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong><br />

Designed, built <strong>and</strong> backed by Caterpillar to deliver exceptional performance <strong>and</strong><br />

versatility, ease of operation, serviceability <strong>and</strong> customer support.<br />

Performance <strong>and</strong> Versatility<br />

Cat 3034 <strong>and</strong> 3034T engines provide<br />

high engine horsepower <strong>and</strong> torque<br />

allowing part-throttle operation for<br />

lower sound <strong>and</strong> fuel consumption.<br />

An exclusive anti-stall feature<br />

incorporated into the hydrostatic<br />

drivetrain delivers maximum power<br />

to the wheels <strong>and</strong> work tools without<br />

stalling the engine. A mechanical quick<br />

coupler makes work tool changing<br />

quick <strong>and</strong> easy <strong>and</strong> interfaces with<br />

a wide selection of Caterpillar Work<br />

Tools. pg. 4-7<br />

Ease of Operation<br />

Operator comfort <strong>and</strong> ease of operation<br />

are designed into the operator’s station<br />

from every aspect. Ergonomic features<br />

such as low-effort joystick controls,<br />

a comfortable padded armrest <strong>and</strong><br />

adjustable, contoured seat reduce<br />

operator fatigue. The loader arms,<br />

quick coupler <strong>and</strong> cab are all designed<br />

to provide excellent visibility to the<br />

work tool. Even more cab options are<br />

available to further enhance operator<br />

comfort. pg. 4<br />

Serviceability<br />

The <strong>236</strong>, <strong>246</strong> <strong>and</strong> <strong>248</strong> are designed for<br />

quick <strong>and</strong> easy routine maintenance <strong>and</strong><br />

service. The rear door opens 90 degrees<br />

<strong>and</strong> the cooling package tilts up out of<br />

the way for unparalleled access to the<br />

engine compartment. Maintenance<br />

points are grouped in easy-to-reach<br />

locations <strong>and</strong> all filters are vertically<br />

mounted to reduce fluid spills. The cab<br />

tilts to the rear, exposing hydraulic<br />

pumps, motors, valves <strong>and</strong> lines.<br />

Both the hydraulic tank <strong>and</strong> the radiator<br />

have a sight glass for fast daily fluid<br />

level checks. pg. 6<br />

Built for tough work<br />

The <strong>236</strong>, <strong>246</strong> <strong>and</strong> <strong>248</strong> <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong>,<br />

with many work tool options, are highly<br />

versatile, compact construction machines.<br />

They are designed to deliver traditional<br />

Cat reliability, durability <strong>and</strong> productivity<br />

in the toughest working conditions.<br />

2

Customer Support<br />

Caterpillar dealers offer unmatched<br />

customer support, with excellent<br />

warranty programs <strong>and</strong> fast parts<br />

availability. This results in maximum<br />

uptime <strong>and</strong> minimum repair costs.<br />

Equipment maintenance services<br />

help optimise machine performance<br />

<strong>and</strong> reliability.<br />

They include:<br />

■ Customer Support Agreements<br />

■ S•O•S<br />

sm<br />

oil analysis<br />

■ Maintenance contracts<br />

■ Scheduled technical inspections.<br />

Equipment management services help<br />

optimise profits.<br />

They include assistance with:<br />

■ Machine <strong>and</strong> work tool selection<br />

■ Rental <strong>and</strong> leasing<br />

■ Purchasing <strong>and</strong> financing<br />

■ Owning <strong>and</strong> operating cost<br />

management<br />

Work Tools<br />

Cat <strong>Skid</strong> <strong>Steer</strong> Loader Work Tools<br />

extend the versatility of the machine.<br />

Built for performance <strong>and</strong> durability<br />

these tools deliver high productivity,<br />

long service life <strong>and</strong> excellent value.<br />

pg. 7<br />

Mechanical Quick Coupler<br />

Cat <strong>Skid</strong> <strong>Steer</strong> Loader Work Tools can<br />

be changed quickly <strong>and</strong> easily with the<br />

machine’s integral mechanical quick<br />

coupler system. pg. 7<br />

High Flow Hydraulics (for the <strong>248</strong> only)<br />

Caterpillar’s high flow system utilizes<br />

a load sensing variable displacement<br />

pump which will provide maximum<br />

pressure to the work tool at any engine<br />

speed. The system is capable of sending<br />

100% of engine power to the work tool;<br />

maximising productivity. With high<br />

hydraulic horsepower, the Cat <strong>248</strong><br />

allows optimal operation of complex<br />

hydromechanical work tools such as<br />

cold planers <strong>and</strong> stump grinders.<br />

3

Operator Station<br />

Operator fatigue is reduced <strong>and</strong> production is increased as a result of pilot operated<br />

joystick controls.<br />

Left Control Panel. The upper left<br />

control panel contains st<strong>and</strong>ard<br />

equipment including indicator lights<br />

(LED’s), key start switch, hour meter,<br />

parking brake switch, glow plug<br />

switch, auxiliary override switch<br />

<strong>and</strong> continuous flow.<br />

Optional equipment includes an<br />

automatic self-leveling switch <strong>and</strong><br />

auxiliary electrical control switch.<br />

Right Control Panel. The upper right<br />

control panel contains a fuel level<br />

gauge <strong>and</strong> an interior lamp, as well as<br />

provisions for an optional rotating<br />

beacon, front <strong>and</strong> rear-working lights.<br />

Cab. The ergonomic cab is designed to<br />

provide the operator with easy to use, pilot<br />

operated controls in a comfortable working<br />

environment. Twin tilt cylinders, coupled<br />

with a wide cab opening, three-point grab<br />

h<strong>and</strong>les <strong>and</strong> deep, skid resistant steps make<br />

it easy for an operator to get in <strong>and</strong> out of<br />

the cab. The entire cab also tilts rearward to<br />

provide excellent service accessibility.<br />

St<strong>and</strong>ard Equipment. The st<strong>and</strong>ard offerings<br />

for the Cat <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong> operator<br />

station are a ROPS/FOPS cab, an adjustable<br />

fore/aft static seat with a retractable seat belt,<br />

armrests, h<strong>and</strong> <strong>and</strong> foot throttles, a rear wall<br />

liner, instrumental panel, floormat <strong>and</strong> pilot<br />

hydraulic control system.<br />

Cab Options. The deluxe cab includes a<br />

suspension seat, headliner, horn <strong>and</strong><br />

additional working lights. A cold weather<br />

package is also available that includes<br />

sliding side windows <strong>and</strong> cab heater.<br />

A cab door is also available.<br />

Instrument Panels. Two instrument panels are<br />

located in the upper right <strong>and</strong> upper left h<strong>and</strong><br />

corners of the cab to maximise the viewing<br />

area to the loader when in the raised position.<br />

Hydraulic Joystick Controls. The <strong>Skid</strong> <strong>Steer</strong><br />

Loader is controlled by two hydraulic<br />

joysticks. The right lever controls loader<br />

functions <strong>and</strong> the left lever controls<br />

machine direction.<br />

Operation. The pilot operated joystick<br />

controls <strong>and</strong> the “S” control pattern used<br />

to operate the <strong>Skid</strong> <strong>Steer</strong> Loader reduces<br />

operator fatigue. The accelerator pedal can<br />

be used during load <strong>and</strong> carry, excavating<br />

or backdragging, a h<strong>and</strong> throttle allows you<br />

to run at constant speed. An optional fourth<br />

function control allows the operator to<br />

hydraulically side shift cold planers or<br />

angle brooms.<br />

Auxiliary Hydraulics. On/Off auxiliary<br />

hydraulics are st<strong>and</strong>ard on the <strong>236</strong> <strong>and</strong> <strong>246</strong><br />

allowing for work tool operation. Optional<br />

proportional hydraulics are available to enable<br />

the operator to vary the amount of flow to<br />

the work tool. Proportional hydraulics are<br />

st<strong>and</strong>ard on the <strong>248</strong>.<br />

4

Power Train<br />

Caterpillar Hystat power train delivers aggressive performance <strong>and</strong> easy operation.<br />

Engine. Caterpillar 3034 provides high<br />

engine horsepower <strong>and</strong> high levels of<br />

flywheel torque.<br />

Hydrostatic System. Closed-loop, highoutput<br />

hydrostatic system <strong>and</strong> exclusive<br />

anti-stall system deliver maximum torque<br />

to the wheels. This system allows the<br />

<strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong> to be used at any throttle<br />

setting without the risk of stalling the<br />

engine.<br />

Chains. High-strength, pre-stressed<br />

chains run in an oil bath for continuous<br />

lubrication. Chain wear adjustment is<br />

provided via slots in the axle housings.<br />

Drive Axle. Each drive axle is forged,<br />

induction hardened <strong>and</strong> sealed for long life.<br />

Parking Brake. The parking brake is spring<br />

applied <strong>and</strong> hydraulically released.<br />

The system is inherently safe as it automatically<br />

applies the brakes as soon as<br />

the engine is stopped.<br />

Dealer Support. Unmatched dealer support<br />

<strong>and</strong> factory tested to ensure years of troublefree<br />

operation. The hydraulic system is<br />

cleaned to a level exceeding industry<br />

st<strong>and</strong>ards. The machine is dynamometer<br />

tested on a rolling road to deliver the<br />

performance <strong>and</strong> reliability customers<br />

expect from Caterpillar.<br />

Two Speed Option (<strong>236</strong> <strong>and</strong> <strong>246</strong> only).<br />

The driver can select either a turtle mode,<br />

with up to 10.4 km/h or a rabbit mode with<br />

speeds up to 19.1 km/h.<br />

5

Serviceability<br />

Owning <strong>and</strong> operating costs are reduced through long service intervals <strong>and</strong><br />

convenient maintenance.<br />

Service Access. Service accessibility for<br />

Caterpillar <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong> is a key<br />

differentiator when compared to its<br />

competition. Simplified service is built<br />

into the design of the Cat <strong>Skid</strong> <strong>Steer</strong><br />

Loader <strong>and</strong> maintenance points are<br />

grouped in easily accessible locations.<br />

Engine Access. The rear engine compartment<br />

door opens 90 degrees to expose an<br />

engine that is mounted lengthwise in the<br />

frame. This arrangement gives access to<br />

both the left <strong>and</strong> right side of the engine.<br />

Filters. All filters are easily accessible.<br />

Spin-on filters are vertically mounted for<br />

spill-free changes.<br />

Cooling System. The radiator, hydraulic<br />

oil cooler <strong>and</strong> grill tilt up to give more<br />

access during maintenance or to allow<br />

cleaning between the grill <strong>and</strong> cooling<br />

package.<br />

Tilting Cab. The cab tilts rearward<br />

<strong>and</strong> is held in place by a self-latching<br />

mechanism exposing all pumps,<br />

motors, valves <strong>and</strong> lines to make<br />

repairs easy if necessary.<br />

Ground Level Maintenance. Sight gauges<br />

are conveniently located for daily fluid<br />

level checks. S•O•S sm oil analysis ports<br />

are installed to allow regular monitoring<br />

of the engine <strong>and</strong> hydraulic oil quality<br />

for preventive maintenance. In addition,<br />

ecology drains are fitted to the engine<br />

oil pan <strong>and</strong> hydraulic system, helping<br />

prevent spills. The axles require no<br />

greasing as they are sealed for life.<br />

6

Work Tools<br />

Choose from a wide variety of tools designed specifically for <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong>.<br />

Performance <strong>and</strong> Durability. Cat <strong>Skid</strong> <strong>Steer</strong> Loader<br />

Work Tools extend the versatility of the machine.<br />

Built for performance <strong>and</strong> durability these tools<br />

deliver high productivity, long service life <strong>and</strong><br />

excellent value. Current <strong>and</strong> future offering<br />

includes:<br />

■ general purpose<br />

■ material h<strong>and</strong>ling<br />

buckets<br />

arms<br />

■ augers<br />

■ snowblowers*<br />

■ dirt buckets<br />

■ angle blades<br />

■ grapple forks<br />

■ wheelsaws*<br />

■ utility buckets<br />

■ brooms<br />

■ hammers<br />

■ cold planers<br />

■ light material<br />

■ l<strong>and</strong>scape rakes<br />

buckets<br />

■ grapple buckets<br />

■ trenchers<br />

■ l<strong>and</strong>scape tillers<br />

■ multi-purpose<br />

■ stump grinders<br />

buckets<br />

■ vibratory compactors<br />

■ backhoes<br />

* Available during 2002<br />

■ pallet forks<br />

■ shears<br />

Mechanical Quick Coupler. Cat <strong>Skid</strong> <strong>Steer</strong> Loader<br />

Work Tools can be changed quickly <strong>and</strong> easily<br />

with the machine’s integral mechanical quick<br />

coupler system. The universal skid steer loader<br />

coupler interface has these features:<br />

■ Opposing wedges ensure a tight tool fit,<br />

evenafter years of use.<br />

■ Rugged design with a large contact area absorbs<br />

loads <strong>and</strong> minimises stress.<br />

■ Lubricated vertical pins are chrome-plated<br />

to prevent rust <strong>and</strong> corrosion for smooth<br />

engagement.<br />

Coupler Design. Allows an excellent view of work<br />

tools <strong>and</strong> unobstructed entry <strong>and</strong> exit to the cab.<br />

Integral Quick Coupler. All Cat Work Tools<br />

incorporate an interface that matches the<br />

machine’s integral quick coupler, allowing<br />

the operator to quickly change from one high<br />

performance work tool to another.<br />

Optional Hydraulic Coupler. This provides quick<br />

<strong>and</strong> easy changing of the work tool by replacing<br />

the mechanical locking levers with hydraulic<br />

cylinders. This allows the operator to engage or<br />

disengage the work tool coupler without having<br />

to exit the cab.<br />

7

Engine<br />

<strong>236</strong> <strong>246</strong>/<strong>248</strong><br />

Ratings at 2600 rpm kW/hp kW/hp<br />

Gross power 47/63 60/80<br />

Net power 44/59 55/74<br />

Dimensions<br />

Bore 97 mm 97 mm<br />

Stroke 100 mm 100 mm<br />

Net power rating per ISO 9249 or EEC 80/1269.<br />

The Caterpillar 3034 <strong>and</strong> 3034T engines meet U.S. EPA <strong>and</strong><br />

European Union non-road emission regulations.<br />

Hydraulic System<br />

<strong>236</strong>/<strong>246</strong> <strong>248</strong><br />

Hydraulic Flow St<strong>and</strong>ard HighFlow<br />

Loader<br />

Hydraulic pressure 23 000 kPa 29 000 kPa<br />

Hydraulic Flow 83 l/min 125 l/min<br />

Feature<br />

■ Single, hydraulically-operated joystick controls lift,<br />

lower <strong>and</strong> tilt functions<br />

Operating Specifications<br />

The specification for the <strong>236</strong>, <strong>246</strong> <strong>and</strong> <strong>248</strong> <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong><br />

are with 12 x 16.5 10 PR tyres, 1676 mm dirt bucket, full fuel<br />

65 kg <strong>and</strong> a 75 kg operator.<br />

<strong>236</strong> <strong>246</strong> <strong>248</strong><br />

kg kg kg<br />

Rated operating capacity* 793 907 907<br />

Rated operating capacity<br />

with optional counterweight* 839 952 952<br />

Operating weight 3111 3191 3328<br />

Tipping load 1586 1814 1814<br />

Breakout force<br />

lift cylinder 1970 1968 1954<br />

tilt cylinder 2383 2385 2386<br />

* ISO 5998:1986<br />

Power Train, Axles <strong>and</strong> Brakes<br />

Dual, closed-loop, axial piston hydrostatic pumps driven<br />

directly off engine. Pumps provide pressure <strong>and</strong> flow to two<br />

fixed displacement motors.<br />

Travel speed <strong>236</strong>/<strong>246</strong>/<strong>248</strong><br />

Forward<br />

12.1 km/h<br />

Reverse<br />

12.1 km/h<br />

Features<br />

■ Single hydraulically-operated joystick, controls speed<br />

<strong>and</strong> direction<br />

■ Forged, induction-hardened axles are sealed for life<br />

|<strong>and</strong> maintenance free<br />

■ Direct sprocket to chain drive<br />

■ Multi-disc, spring-applied hydraulically released<br />

parking brake<br />

■ Anti-stall system maximizes torque to the wheels<br />

without stalling engine<br />

ROPS/FOPS<br />

Sound<br />

■ FOPS meets ISO 3449:1992 Level I<br />

■ FOPS Level II meets ISO 3449:1992 Level II<br />

Rollover Protective Structure (ROPS) <strong>and</strong> Falling Objects<br />

Protective Structure (FOPS).<br />

■ ROPS meets ISO 3471:1994<br />

Operator Sound <strong>236</strong> <strong>246</strong> <strong>248</strong><br />

with windows – dB(A) 87 84 89<br />

without windows – dB(A) 89 89 89<br />

Measured according to dynamic test procedures<br />

<strong>and</strong> conditions specified in ISO 6396.<br />

Exterior Sound<br />

As manufactured by Caterpillar, this machine’s exterior<br />

sound power level meets the criteria specified in the European<br />

Directives for Equipment used Outdoors – 2000/14/EC.<br />

8<br />

<strong>236</strong>, <strong>246</strong> <strong>and</strong> <strong>248</strong> <strong>Skid</strong> <strong>Steer</strong> Loader specifications

Dimensions<br />

Dimensions shown are based on st<strong>and</strong>ard machine equipped with optional 12 x 16.5 10 PR tyres <strong>and</strong> 1676 mm dirt bucket.<br />

The specification for the <strong>236</strong>, <strong>246</strong> <strong>and</strong> <strong>248</strong> <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong> are static <strong>and</strong> conform to ISO 5998:1986.<br />

All dimensions are approximate.<br />

19<br />

8<br />

13<br />

6<br />

5<br />

15<br />

17<br />

4<br />

18<br />

9<br />

14<br />

11<br />

10<br />

12<br />

1<br />

7<br />

16<br />

3<br />

2<br />

1 Wheelbase 1134 mm<br />

2 Length with Bucket on ground 3515 mm<br />

3 Length without Bucket 2800 mm<br />

4 Height to top of Cab 2092 mm<br />

5 Max Overall Height 3965 mm<br />

6 Hinge Pin Height at max lift 3099 mm<br />

7 Hinge Pin Height at carry position 257 mm<br />

8 Reach at max lift <strong>and</strong> dump 541 mm<br />

9 Clearance at max lift <strong>and</strong> dump 2398 mm<br />

10 Ground Clearance 235 mm<br />

11 Departure Angle 28˚<br />

12 Bumper Overhang behind rear axle 1038 mm<br />

13 Maximum Dump Angle 40˚<br />

14 Maximum width over tyres 1676 mm<br />

1829 mm<br />

15 Turning Radius from center – left 1623 mm<br />

16 Turning Radius from center – right 1318 mm<br />

17 Turning Radius from center – full 2097 mm<br />

18 New Reach with Level Arms <strong>and</strong> Bucket 1357 mm<br />

19 Rack back Angle at max height 97˚<br />

Service Refill Capacities<br />

Liters<br />

Chain box, each side 7<br />

Cooling system 10<br />

Engine crankcase 7<br />

Fuel tank 90<br />

Hydraulic system 52<br />

Hydraulic tank 35<br />

<strong>236</strong>, <strong>246</strong> <strong>and</strong> <strong>248</strong> <strong>Skid</strong> <strong>Steer</strong> Loader specifications<br />

9

St<strong>and</strong>ard Equipment<br />

St<strong>and</strong>ard equipment may vary. Consult your Caterpillar dealer for specifics.<br />

Alarm, Backup<br />

Alternator, 55-amp<br />

Air Cleaner, Dual Element, Radial Seal<br />

Bar, Armrest<br />

Battery, 12-volt, 650 CCA<br />

Brake, Parking (SAHR)<br />

Cab, FOPS Level 1, ROPS, Tilt-up<br />

Cleanout, Belly Pan<br />

Control, Work Tool Electrical (C1/C2 Switch),<br />

<strong>248</strong> only<br />

Controls, Pilot-Operated, H<strong>and</strong><br />

Cooling, Tilt-up, Radiator/Hydraulic<br />

Coupler, Mechanical<br />

Ecology Drain, Engine, Hydraulic<br />

Engine<br />

Cat 3034 (<strong>236</strong>)<br />

Cat 3034 Turbo (<strong>236</strong>/<strong>246</strong>)<br />

Fan, Hydraulic Driven<br />

Filter, Fuel, Bayonet-mount,<br />

Filter, Hydraulic,Spin-on<br />

Floormat, deluxe<br />

Fuel Water Separator, Spin-on<br />

Headliner<br />

Hydraulics, Auxiliary, Front, On/Off,<br />

<strong>236</strong>/<strong>246</strong> only<br />

Hydraulic Circuits, St<strong>and</strong>ard <strong>and</strong> High Flow,<br />

<strong>248</strong> only<br />

Hydraulics, Proportional, Auxiliary<br />

<strong>248</strong> only<br />

Instrumentation (Audible)<br />

Engine Coolant Temperature<br />

Engine Oil Pressure<br />

Hydraulic Oil Temperature<br />

Gauges<br />

Fuel Level<br />

Hour Meter<br />

Indicators<br />

Air Filter Restriction (Engine Compartment)<br />

Alternator Output<br />

Armrest raised/operator out of seat<br />

Engine Coolant Temperature<br />

Engine Oil Pressure<br />

Hydraulic Filter Restriction<br />

Hydraulic Oil Temperature<br />

Park Brake Engaged<br />

Lifting Provision, Four Point<br />

Lights, Red Tail<br />

Muffler Spark Arresting (<strong>236</strong> only)<br />

Pre-filter, Self-evacuating, (Integral part of main filter body)<br />

Pump, Hydraulic Hystat <strong>and</strong> Charge<br />

Pump, Hydraulic Implement<br />

Safety, Control Interlock System<br />

Sampling Port, S•O•S sm Analysis Port, Live Hydraulic<br />

<strong>and</strong> Engine Oil Port<br />

Starting Aid, Glow Plugs<br />

Seat, Static<br />

Seat Belt, 50 mm<br />

Sight Gauge, Coolant <strong>and</strong> Hydraulic<br />

Sound emissions reduction package<br />

Support, Lift Arm<br />

Switch, Three Position Ignition<br />

Tie Downs, Four Point<br />

Tyre<br />

12 x 16.5 10 PR 1829 mm (72 in) Caterpillar Premium Conventional<br />

Throttle, H<strong>and</strong> <strong>and</strong> Foot<br />

10 <strong>236</strong>, <strong>246</strong> <strong>and</strong> <strong>248</strong> <strong>Skid</strong> <strong>Steer</strong> Loader specifications

Optional Equipment<br />

Optional equipment may vary. Consult your Caterpillar dealer for specifics<br />

Battery, 950 CCA<br />

Belt, Seat, 75 mm (3 in), for Static Seat<br />

Belt, Seat, 75 mm (3 in), for Suspension Seat<br />

Control Group, Two-Speed transmission (19.1 km/h),<br />

<strong>236</strong> <strong>and</strong> <strong>246</strong> only<br />

Control, Work Tool Electrical (C1/C2 Switch)<br />

St<strong>and</strong>ard on the <strong>248</strong><br />

Counterweight, 45 kg increase to ROC<br />

Debris Barrier<br />

Door, Front, Safety Glass with Wiper-Washer<br />

Door, Front, Polycarbonate (for Demolition)<br />

with Wiper-Washer<br />

FOPS, Level II (Attaches to existing FOPS)<br />

Heater, Cab<br />

Horn<br />

Hydraulics<br />

Auxiliary, Proportional<br />

Work Tool joystick <strong>and</strong> lockout (C1/C2)<br />

Self-leveling<br />

Lifting Provision, Single Point (via parts)<br />

Lights<br />

Warning Beacon<br />

Front, Working<br />

Rear Working<br />

Oil, Hydraulic, Cold Climate<br />

Proportional Auxiliary Hydraulics,<br />

St<strong>and</strong>ard on the <strong>248</strong><br />

Seat, Suspension<br />

Tank, Water, for appropriate work tools<br />

Transmission: 2-speed transmission 10 km/19.1 km/h,<br />

<strong>236</strong> <strong>and</strong> <strong>246</strong> only<br />

Tyres:<br />

8.25 x 15 6 PR 1524 mm (60 in) GY LS (<strong>236</strong> only)<br />

8.00 x 16 Solid 1676 mm (66 in) Cat<br />

12.00 x 16.50 1676 mm (66 in) AirBoss<br />

12 x 16.5 10 PR 1676 mm (66 in) GY SGL<br />

12 x 16.5 10 PR 1676 mm (66 in) GY IT323**<br />

12 x 16.5 10 PR 1676 mm (66 in) Galaxy**<br />

12 x 16.5 10 PR 1676 mm (66 in) Caterpillar Premium<br />

Conventional**<br />

12 x 16.5 10 PR 1676 mm (66 in) Caterpillar Premium<br />

Conventional with Poly-Fill*, increases rated operating<br />

capacity to 874 kg on <strong>236</strong> <strong>and</strong> 987 kg on <strong>246</strong>/<strong>248</strong><br />

12 x 16.5 10 PR 1829 mm (72 in) Caterpillar Premium<br />

Conventional**<br />

12 x 16.5 10 PR 1829 mm (72 in) Caterpillar Premium<br />

Conventional with Poly-Fill*, increases rated operating<br />

capacity to 874 kg on <strong>236</strong> <strong>and</strong> 987 kg on <strong>246</strong>/<strong>248</strong><br />

12 x 16.5 10 PR 1829 mm (72 in) GY SGL<br />

12 x 16.5 10 PR 1829 mm (72 in) GY IT323**<br />

12 x 16.5 10 PR 1829 mm (72 in) Galaxy**<br />

33-15.5 X 16.5 12 PR 1829 mm (72 in) Cat**<br />

305-546 10 PR 1676 mm (66 in) Caterpillar Low Side Wall**<br />

305-546 10 PR 1676 mm (66 in) Caterpillar Low Side Wall<br />

with Poly-Fill*, increases rated operating capacity to 854 kg<br />

on <strong>236</strong> <strong>and</strong> 967 kg on <strong>246</strong>/<strong>248</strong><br />

305-546 10 PR 1829 mm (72 in) Caterpillar Low Side Wall**<br />

305-546 10 PR 1829 mm (72 in) Caterpillar Low Side Wall<br />

with Poly-Fill*, increases rated operating capacity to 854 kg<br />

on <strong>236</strong> <strong>and</strong> 967 kg on <strong>246</strong>/<strong>248</strong><br />

Window, Side, Sliding<br />

Windows, top <strong>and</strong> rear<br />

* For best performance, SuperFlex Poly-Fill should only be used on firm<br />

surfaces <strong>and</strong> is not recommended for use with optional counterweight.<br />

**Denotes spare tyre option available with supplement.<br />

<strong>236</strong>, <strong>246</strong> <strong>and</strong> <strong>248</strong> <strong>Skid</strong> <strong>Steer</strong> Loader specifications<br />

11

<strong>236</strong>, <strong>246</strong> <strong>and</strong> <strong>248</strong> <strong>Skid</strong> <strong>Steer</strong> <strong>Loaders</strong><br />

HEHH2552-1 (02/2002) hr<br />

Materials <strong>and</strong> specifications are subject to change without notice.<br />

Featured machines may include additional equipment.<br />

See your Caterpillar dealer for available options.<br />

www.CAT.com<br />

© 2002 Caterpillar<br />

®