Beamlock System Catalogue - Barbour Product Search

Beamlock System Catalogue - Barbour Product Search

Beamlock System Catalogue - Barbour Product Search

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

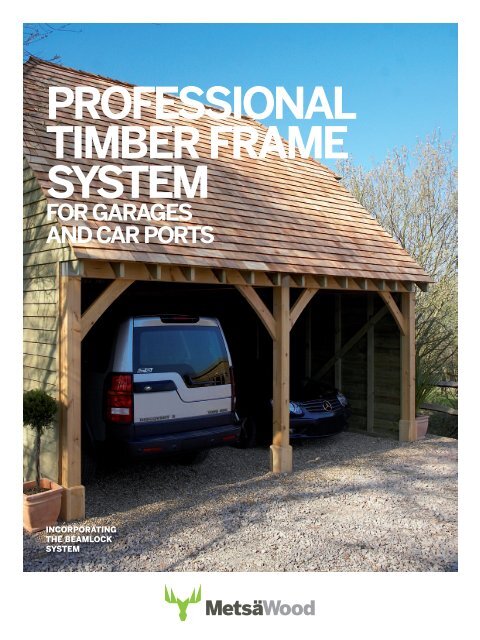

PROFESSIONAL<br />

TIMBER FRAME<br />

SYSTEM<br />

FOR GARAGES<br />

AND CAR PORTS<br />

INCORPORATING<br />

THE BEAMLOCK<br />

SYSTEM

CONTENTS<br />

BUILDING WITH BEAMLOCK 03<br />

QUALITY CONSTRUCTION 04 - 05<br />

TWO BAY GARAGES OVERVIEW 06 - 07<br />

TWO BAY CAR PORTS OVERVIEW 08 - 09<br />

GARAGES<br />

HIPPED ROOF GARAGE<br />

TWO BAY WITH 40º ROOF PITCH 10<br />

BARN-END GARAGE<br />

TWO BAY WITH 45º ROOF PITCH 11<br />

GABLE-END GARAGE<br />

TWO BAY WITH 45º ROOF PITCH 12<br />

GABLE-END GARAGE<br />

TWO BAY WITH 28º ROOF PITCH 13<br />

CAR PORTS<br />

HIPPED ROOF CAR PORT<br />

TWO BAY WITH 40º ROOF PITCH 14<br />

BARN-END CAR PORT<br />

TWO BAY WITH 45º ROOF PITCH 15<br />

GABLE-END CAR PORT<br />

TWO BAY WITH 45º ROOF PITCH 16<br />

GABLE-END CAR PORT<br />

TWO BAY WITH 28º ROOF PITCH 17<br />

EXTENSION KIT<br />

FOR GARAGES AND CAR PORTS 18 - 19<br />

THE BENEFITS OF USING BEAMLOCK 20<br />

COMPONENTS,<br />

CARE AND MAINTENANCE 21<br />

POST SUPPORT<br />

AND FOUNDATION REQUIREMENTS 22<br />

GENERAL INFORMATION<br />

AND INSTALLATION 23<br />

02 PROFESSIONAL TIMBER FRAME SYSTEM – FOR GARAGES AND CAR PORTS

BUILDING WITH BEAMLOCK<br />

COULD NOT BE EASIER<br />

A high quality engineered system based upon the<br />

traditional oak bay framed method of construction,<br />

<strong>Beamlock</strong> achieves a traditional look with the reduced<br />

cost that only modern technology production methods<br />

can bring, and is quick and easy to build.<br />

<strong>Beamlock</strong> gives you a new trade: the look of traditional carpentry built with<br />

the reliability and precision of factory-cut components.<br />

<strong>Beamlock</strong> is a time-saver that’s delivered direct from factory to site<br />

and cuts construction times to the minimum. The results are stunning<br />

and long-lasting, yet the components are predictable, lightweight and easy<br />

to handle. There’s also the option of having a team of specialist engineers<br />

install it for you*.<br />

Although major components are pre-treated we would recommend an<br />

additional timber treatment to prolong the life of the structure.<br />

Your merchant knows how easily <strong>Beamlock</strong> goes together and what<br />

additional materials you'll need to further enhance the building.<br />

SO WHY CHOOSE BEAMLOCK<br />

STRONGER<br />

THAN OAK<br />

SAFE<br />

SITE<br />

TIME SAVING<br />

DESIGN<br />

Stronger than an oak<br />

mortise and tenon system.<br />

<strong>Beamlock</strong> is a ‘safe site’ product providing<br />

high-strength beams at easily managed lengths.<br />

Unique time-saving design, all key components<br />

are pre-cut and ready to fit.<br />

To specify <strong>Beamlock</strong> just follow our simple<br />

step-by-step guide...<br />

1 Select a garage or car port from the 16 featured in this brochure<br />

( for the complete range see pages 6-9)<br />

2 Specify whether you want your chosen structure to be supplied<br />

with or without cedar roof tiles<br />

3 Select the optional extension kit to increase the number of bays if<br />

required<br />

4 Specify whether you want our optional installation service*<br />

5 Discuss with your merchant any additional materials that you<br />

may require (roof felt, battens, tiles etc.)<br />

6 The garage or car port kit will be delivered direct to site within<br />

28 days of order confirmation<br />

* All structures must be erected on a suitably prepared foundation, which is not included in<br />

the optional installation service. See Foundation Requirements on page 22.<br />

DELIVERED<br />

DIRECT<br />

AVAILABLE<br />

NATIONWIDE<br />

INSTALLATION<br />

SERVICE *<br />

Delivery direct to site.<br />

Available nationwide through selected timber and<br />

builders’ merchants (for Northern Ireland and<br />

non-UK mainland areas please call for details).<br />

*Optional installation service available .<br />

Call 0845 601 7886 for details.<br />

FOR GARAGES AND CAR PORTS – PROFESSIONAL TIMBER FRAME SYSTEM 03

QUALITY CONSTRUCTION<br />

OPTIONAL CEDAR SHINGLES<br />

FEATHER-EDGE PROTECTIVE CLADDING<br />

VERTICAL SUB-FRAME UPRIGHTS<br />

<strong>Beamlock</strong> complies with BS EN 594 (interpreted to BS5268-6.1) for racking, BS6399 PT2 1997<br />

for wind loading and BS476-21 fire resistance and is preservative treated for Use Class 3.1.*<br />

*A SECONDARY PROTECTIVE COAT NEEDS TO BE APPLIED AND MAINTAINED TO ACHIEVE “USE CLASS 3.”<br />

TIMBER SHROUD POST-SUPPORT COVER<br />

If you have any queries please contact<br />

our helpline on 0845 601 7886<br />

04 PROFESSIONAL TIMBER FRAME SYSTEM – FOR GARAGES AND CAR PORTS

PRE-CUT AND<br />

PRE-TREATED RAFTERS<br />

HIGH-STRENGTH BEAMS<br />

138mm X 165mm<br />

PRE-CUT SUPPORTING BRACES<br />

SUBSTANTIAL SUPPORT POSTS<br />

138mm X 138mm<br />

Garage and car port models with a 28° pitch (see pages 13 and 17), fitted with cedar<br />

shingles, will achieve a maximum height of 3997mm (adjustable feet at maximum<br />

height) provided that they are erected on level foundations at ground level.<br />

Garage and car port models (28° pitch) supplied without the cedar shingle roof tiles achieve a<br />

maximum height of 3932mm to the top of the ridge board, provided that they are erected on<br />

level foundations at ground level. When selecting roofing materials careful consideration should<br />

be given to the manufacturer’s recommended installation as well as the overall height of the<br />

structure at the ridge, as this may affect planning requirements and therefore choice of material.<br />

DIAGONAL TIMBER WALL BRACES<br />

FOR GARAGES AND CAR PORTS – PROFESSIONAL TIMBER FRAME SYSTEM 05

TWO BAY GARAGES<br />

OVERVIEW<br />

<strong>Beamlock</strong> two bay garages are available in two options:<br />

1 Complete building with tile battens and cedar shingle tiles supplied.<br />

2 Skeletal framework with roof timbers and cladded walls only<br />

(roof battens and cedar tiles not included).<br />

1 HIPPED ROOF GARAGE WITH CEDAR SHINGLE TILED ROOF<br />

40º roof pitch<br />

2 HIPPED ROOF GARAGE<br />

40º roof pitch (Roof battens and cedar tiles not included)<br />

For full details see page 10<br />

1 BARN-END GARAGE WITH CEDAR SHINGLE TILED ROOF<br />

45º roof pitch<br />

2 BARN-END GARAGE<br />

45º roof pitch (Roof battens and cedar tiles not included)<br />

For full details see page 11<br />

If you have any queries please contact<br />

our helpline on 0845 601 7886<br />

06 PROFESSIONAL TIMBER FRAME SYSTEM – FOR GARAGES AND CAR PORTS

GARAGE FLOOR PLAN (APPLIES TO ALL GARAGES SHOWN)<br />

5.614m<br />

2.6m 2.6m<br />

4.94m<br />

5.216m<br />

ENTRANCE<br />

ENTRANCE<br />

FLOOR PLAN KEY<br />

BEAMS WITH WALLS<br />

BEAMS<br />

POSTS<br />

BRACES<br />

1 GABLE-END GARAGE WITH CEDAR SHINGLE TILED ROOF<br />

45º roof pitch<br />

2 GABLE-END GARAGE<br />

45º roof pitch (Roof battens and cedar tiles not included)<br />

For full details see page 12<br />

1 GABLE-END GARAGE WITH CEDAR SHINGLE TILED ROOF<br />

28º roof pitch<br />

2 GABLE-END GARAGE<br />

28º roof pitch (Roof battens and cedar tiles not included)<br />

For full details see page 13<br />

To add more bays to these garages<br />

see our extension kit on pages 18 & 19<br />

FOR GARAGES AND CAR PORTS – PROFESSIONAL TIMBER FRAME SYSTEM 07

trade professional<br />

TWO BAY CAR PORTS<br />

OVERVIEW<br />

<strong>Beamlock</strong> two bay car ports are available in two options:<br />

1 Complete building with tile battens and cedar shingle tiles supplied.<br />

2 Skeletal framework with roof timbers and cladded walls only<br />

roof battens and cedar tiles not included) .<br />

1 HIPPED ROOF CAR PORT WITH CEDAR SHINGLE TILED ROOF<br />

40º roof pitch<br />

2 HIPPED ROOF CAR PORT<br />

40º roof pitch (Roof battens and cedar tiles not included)<br />

For full details see page 14<br />

1 BARN-END CAR PORT WITH CEDAR SHINGLE TILED ROOF<br />

45º roof pitch<br />

2 BARN-END CAR PORT<br />

45º roof pitch (Roof battens and cedar tiles not included)<br />

For full details see page 15<br />

If you have any queries please contact<br />

our helpline on 0845 601 7886<br />

08 PROFESSIONAL TIMBER FRAME SYSTEM – FOR GARAGES AND CAR PORTS

trade professional<br />

CAR PORT FLOOR PLAN (APPLIES TO ALL CAR PORTS SHOWN)<br />

5.614m<br />

2.6m 2.6m<br />

4.94m<br />

ENTRANCE<br />

ENTRANCE<br />

FLOOR PLAN KEY<br />

BEAMS<br />

POSTS<br />

BRACES<br />

SUPPORT POSTS<br />

5.216m<br />

1 GABLE-END CAR PORT WITH CEDAR SHINGLE TILED ROOF<br />

45º roof pitch<br />

2 GABLE-END CAR PORT<br />

45º roof pitch (Roof battens and cedar tiles not included)<br />

For full details see page 16<br />

1 GABLE-END CAR PORT WITH CEDAR SHINGLE TILED ROOF<br />

28º roof pitch<br />

2 GABLE-END CAR PORT<br />

28º roof pitch (Roof battens and cedar tiles not included)<br />

For full details see page 17<br />

To add more bays to these garages<br />

see our extension kit on pages 18-19<br />

FOR GARAGES AND CAR PORTS – PROFESSIONAL TIMBER FRAME SYSTEM 09

HIPPED ROOF GARAGE<br />

TWO BAY WITH 40º ROOF PITCH<br />

1. Hipped roof garage with battens and<br />

cedar shingle roof tiles supplied.<br />

SIDE ELEVATION<br />

Min. 4.705m<br />

Max. 4.765m<br />

40º Span 4.94m<br />

Min. 2.15m<br />

Max. 2.21m<br />

2. Hipped roof garage supplied without cedar<br />

shingle roof tiles. Requires roofing material,<br />

covering approximately 44.73m 2 .<br />

5.216m<br />

For floor plan please refer to page 7<br />

1. SUPPLIED WITH ROOF BATTENS AND CEDAR TILES CODE<br />

Delivered 125281<br />

Delivered & Erected 125282<br />

NOTE: THIS STRUCTURE MUST BE ERECTED ON A SUITABLY<br />

PREPARED FOUNDATION, NOT INCLUDED IN THE OPTIONAL<br />

INSTALLATION SERVICE. SEE P.22 FOR FOUNDATION<br />

REQUIREMENTS. ALL DIMENSIONS ARE APPROXIMATE.<br />

2. SUPPLIED WITHOUT ROOF BATTENS AND CEDAR TILES CODE<br />

Delivered 125279<br />

Delivered & Erected 125280<br />

If you have any queries please contact<br />

our helpline on 0845 601 7886<br />

10 PROFESSIONAL TIMBER FRAME SYSTEM – FOR GARAGES AND CAR PORTS

BARN-END GARAGE<br />

TWO BAY WITH 45º ROOF PITCH<br />

1. Barn-end garage with battens and cedar<br />

shingle roof tiles supplied.<br />

SIDE ELEVATION<br />

Min. 5.145m<br />

Max. 5.205m<br />

45º<br />

Span 4.94m<br />

Min. 2.15m<br />

Max. 2.21m<br />

2. Barn-end garage supplied without cedar<br />

shingle roof tiles. Requires roofing material,<br />

covering approximately 47.36m 2 .<br />

5.216m<br />

For floor plan please refer to page 7<br />

1. SUPPLIED WITH ROOF BATTENS AND CEDAR TILES CODE<br />

Delivered 125285<br />

Delivered & Erected 125286<br />

NOTE: THIS STRUCTURE MUST BE ERECTED ON A SUITABLY<br />

PREPARED FOUNDATION, NOT INCLUDED IN THE OPTIONAL<br />

INSTALLATION SERVICE. SEE P.22 FOR FOUNDATION<br />

REQUIREMENTS. ALL DIMENSIONS ARE APPROXIMATE.<br />

2. SUPPLIED WITHOUT ROOF BATTENS AND CEDAR TILES CODE<br />

Delivered 125283<br />

Delivered & Erected 125284<br />

To add more bays to these garages<br />

see our extension kit on pages 18-19<br />

FOR GARAGES AND CAR PORTS – PROFESSIONAL TIMBER FRAME SYSTEM 11

GABLE-END GARAGE<br />

TWO BAY WITH 45º ROOF PITCH<br />

1. Gable-end garage with battens and cedar<br />

shingle roof tiles supplied.<br />

SIDE ELEVATION<br />

Min. 5.145m<br />

Max. 5.205m<br />

45º<br />

Span 4.94m<br />

Min. 2.15m<br />

Max. 2.21m<br />

2. Gable-end garage supplied without cedar<br />

shingle roof tiles. Requires roofing material,<br />

covering approximately 47.36m 2 .<br />

5.216m<br />

For floor plan please refer to page 7<br />

1. SUPPLIED WITH ROOF BATTENS AND CEDAR TILES CODE<br />

Delivered 125289<br />

Delivered & Erected 125290<br />

NOTE: THIS STRUCTURE MUST BE ERECTED ON A SUITABLY<br />

PREPARED FOUNDATION, NOT INCLUDED IN THE OPTIONAL<br />

INSTALLATION SERVICE. SEE P.22 FOR FOUNDATION<br />

REQUIREMENTS. ALL DIMENSIONS ARE APPROXIMATE.<br />

2. SUPPLIED WITHOUT ROOF BATTENS AND CEDAR TILES CODE<br />

Delivered 125287<br />

Delivered & Erected 125288<br />

If you have any queries please contact<br />

our helpline on 0845 601 7886<br />

12 PROFESSIONAL TIMBER FRAME SYSTEM – FOR GARAGES AND CAR PORTS

GABLE-END GARAGE<br />

TWO BAY WITH 28º ROOF PITCH<br />

A ridge height of under 4m is achievable with this<br />

model. The sub-4m ridge is relevant to permissible<br />

development without planning legislation, subject<br />

to other conditions, this may enable structures to<br />

be built without the need for planning permission.<br />

1. Gable-end garage with battens and cedar<br />

shingle roof tiles supplied.<br />

SIDE ELEVATION<br />

Span 4.94m<br />

Min. 2.15m<br />

Max. 2.21m<br />

Min. 3.937m<br />

Max. 3.997m<br />

28º<br />

2. Gable-end garage supplied without cedar<br />

shingle roof tiles. Requires roofing material,<br />

covering approximately 39.53m 2 .<br />

5.216m<br />

For floor plan please refer to page 7<br />

1. SUPPLIED WITH ROOF BATTENS AND CEDAR TILES CODE<br />

Delivered 125277<br />

Delivered & Erected 125278<br />

NOTE: THIS STRUCTURE MUST BE ERECTED ON A SUITABLY<br />

PREPARED FOUNDATION, NOT INCLUDED IN THE OPTIONAL<br />

INSTALLATION SERVICE. SEE P.22 FOR FOUNDATION<br />

REQUIREMENTS. ALL DIMENSIONS ARE APPROXIMATE.<br />

2. SUPPLIED WITHOUT ROOF BATTENS AND CEDAR TILES CODE<br />

Delivered 125275<br />

Delivered & Erected 125276<br />

To add more bays to these garages<br />

see our extension kit on pages 18-19<br />

FOR GARAGES AND CAR PORTS – PROFESSIONAL TIMBER FRAME SYSTEM 13

HIPPED ROOF CAR PORT<br />

TWO BAY WITH 40º ROOF PITCH<br />

1. Hipped roof car port with battens and cedar<br />

shingle roof tiles supplied.<br />

SIDE ELEVATION<br />

Min. 4.705m<br />

Max. 4.765m<br />

40º Span 4.94m<br />

Min. 2.15m<br />

Max. 2.21m<br />

2. Hipped roof car port supplied without cedar<br />

shingle roof tiles. Requires roofing material,<br />

covering approximately 44.73m 2 .<br />

5.216m<br />

For floor plan please refer to page 9<br />

1. SUPPLIED WITH ROOF BATTENS AND CEDAR TILES CODE<br />

Delivered 125263<br />

Delivered & Erected 125264<br />

NOTE: THIS STRUCTURE MUST BE ERECTED ON A SUITABLY<br />

PREPARED FOUNDATION, NOT INCLUDED IN THE OPTIONAL<br />

INSTALLATION SERVICE. SEE P.22 FOR FOUNDATION<br />

REQUIREMENTS. ALL DIMENSIONS ARE APPROXIMATE.<br />

2. SUPPLIED WITHOUT ROOF BATTENS AND CEDAR TILES CODE<br />

Delivered 125261<br />

Delivered & Erected 125262<br />

If you have any queries please contact<br />

our helpline on 0845 601 7886<br />

14 PROFESSIONAL TIMBER FRAME SYSTEM – FOR GARAGES AND CAR PORTS

BARN-END CAR PORT<br />

TWO BAY WITH 45º ROOF PITCH<br />

1. Barn-end car port with battens and cedar<br />

shingle roof tiles supplied.<br />

SIDE ELEVATION<br />

Min. 5.145m<br />

Max. 5.205m<br />

45º<br />

Span 4.94m<br />

Min. 2.15m<br />

Max. 2.21m<br />

2. Barn-end car port supplied without cedar<br />

shingle roof tiles. Requires roofing material,<br />

covering approximately 47.36m 2 .<br />

5.216m<br />

For floor plan please refer to page 9<br />

1. SUPPLIED WITH ROOF BATTENS AND CEDAR TILES CODE<br />

Delivered 125268<br />

Delivered & Erected 125269<br />

NOTE: THIS STRUCTURE MUST BE ERECTED ON A SUITABLY<br />

PREPARED FOUNDATION, NOT INCLUDED IN THE OPTIONAL<br />

INSTALLATION SERVICE. SEE P.22 FOR FOUNDATION<br />

REQUIREMENTS. ALL DIMENSIONS ARE APPROXIMATE.<br />

2. SUPPLIED WITHOUT ROOF BATTENS AND CEDAR TILES CODE<br />

Delivered 125265<br />

Delivered & Erected 125267<br />

To add more bays to these garages<br />

see our extension kit on pages 18-19<br />

FOR GARAGES AND CAR PORTS – PROFESSIONAL TIMBER FRAME SYSTEM 15

GABLE-END CAR PORT<br />

TWO BAY WITH 45º ROOF PITCH<br />

1. Gable-end car port with battens and cedar<br />

shingle roof tiles supplied.<br />

SIDE ELEVATION<br />

Min. 5.145m<br />

Max. 5.205m<br />

45º<br />

Span 4.94m<br />

Min. 2.15m<br />

Max. 2.21m<br />

2. Gable-end car port supplied without cedar<br />

shingle roof tiles. Requires roofing material,<br />

covering approximately 47.36m2.<br />

5.216m<br />

For floor plan please refer to page 9<br />

1. SUPPLIED WITH ROOF BATTENS AND CEDAR TILES CODE<br />

Delivered 125272<br />

Delivered & Erected 125274<br />

NOTE: THIS STRUCTURE MUST BE ERECTED ON A SUITABLY<br />

PREPARED FOUNDATION, NOT INCLUDED IN THE OPTIONAL<br />

INSTALLATION SERVICE. SEE P.22 FOR FOUNDATION<br />

REQUIREMENTS. ALL DIMENSIONS ARE APPROXIMATE.<br />

2. SUPPLIED WITHOUT ROOF BATTENS AND CEDAR TILES CODE<br />

Delivered 125270<br />

Delivered & Erected 125271<br />

If you have any queries please contact<br />

our helpline on 0845 601 7886<br />

16 PROFESSIONAL TIMBER FRAME SYSTEM – FOR GARAGES AND CAR PORTS

GABLE-END CAR PORT<br />

TWO BAY WITH 28º ROOF PITCH<br />

A ridge height of under 4m is achievable with this<br />

model. The sub-4m ridge is relevant to permissible<br />

development without planning legislation, subject to<br />

other conditions, this may enable structures to be built<br />

without the need for planning permission<br />

1. Gable-end car port with battens and cedar<br />

shingle roof tiles supplied.<br />

SIDE ELEVATION<br />

Span 4.94m<br />

Min. 2.15m<br />

Max. 2.21m<br />

Min. 3.937m<br />

Max. 3.997m<br />

28º<br />

2. Gable-end car port supplied without cedar<br />

shingle roof tiles. Requires roofing material,<br />

covering approximately 39.53m 2 .<br />

5.216m<br />

For floor plan please refer to page 9<br />

1. SUPPLIED WITH ROOF BATTENS AND CEDAR TILES CODE<br />

Delivered 125259<br />

Delivered & Erected 125260<br />

NOTE: THIS STRUCTURE MUST BE ERECTED ON A SUITABLY<br />

PREPARED FOUNDATION, NOT INCLUDED IN THE OPTIONAL<br />

INSTALLATION SERVICE. SEE P.22 FOR FOUNDATION<br />

REQUIREMENTS. ALL DIMENSIONS ARE APPROXIMATE.<br />

2. SUPPLIED WITHOUT ROOF BATTENS AND CEDAR TILES CODE<br />

Delivered 125256<br />

Delivered & Erected 125258<br />

To add more bays to these garages<br />

see our extension kit on pages 18-19<br />

FOR GARAGES AND CAR PORTS – PROFESSIONAL TIMBER FRAME SYSTEM 17

EXTENSION KIT<br />

FOR GARAGES AND CAR PORTS<br />

AVAILABLE IN 3 ROOF PITCHES: 45º, 40º & 28º<br />

8.352m<br />

2.6m 2.6m<br />

2.6m<br />

4.94m<br />

5.216m<br />

ENTRANCE<br />

ENTRANCE<br />

ENTRANCE<br />

GARAGE EXTENSION<br />

FLOOR PLAN<br />

FLOOR PLAN KEY<br />

EXTENSION BEAM<br />

WITH WALL<br />

EXTENSION BEAMS<br />

EXTENSION POSTS<br />

EXTENSION<br />

BRACES<br />

CAN BE<br />

USED ON ALL<br />

MODELS<br />

Extension kit shown<br />

for Barn-end garage.<br />

GARAGE EXTENSION KITS<br />

GARAGE TYPE DELIVERED DELIVERED AND ERECTED<br />

CODE<br />

CODE<br />

40° Hipped roof with roof battens and cedar tiles 125298 125300<br />

40° Hipped roof without roof battens and cedar tiles 125296 125297<br />

45° Gable/Barn-end with roof battens and cedar tiles 125303 125304<br />

45° Gable/Barn-end without roof battens and cedar tiles 125301 125302<br />

28° Gable-end with roof battens and cedar tiles 125294 125295<br />

28° Gable-end without roof battens and cedar tiles 125292 125293<br />

18 PROFESSIONAL TIMBER FRAME SYSTEM – FOR GARAGES AND CAR PORTS

8.352m<br />

2.6m 2.6m<br />

2.6m<br />

4.94m<br />

ENTRANCE<br />

ENTRANCE<br />

ENTRANCE<br />

CAR PORT EXTENSION<br />

FLOOR PLAN<br />

FLOOR PLAN KEY<br />

EXTENSION BEAMS<br />

EXTENSION POSTS<br />

EXTENSION<br />

BRACES<br />

Roofing material required to cover garage<br />

and car port single bay extensions:<br />

40º Hipped Roof<br />

Approximate coverage 20.88m 2<br />

45º Barn-end<br />

Approximate coverage 22.69m 2<br />

45º Gable-end<br />

Approximate coverage 22.69m 2<br />

5.216m<br />

28º Gable-end<br />

Approximate coverage 18.39m 2<br />

CAN BE<br />

USED ON ALL<br />

MODELS<br />

Extension kit shown<br />

for Barn-end car port.<br />

CAR PORT EXTENSION KITS<br />

CAR PORT TYPE DELIVERED DELIVERED AND ERECTED<br />

CODE<br />

CODE<br />

40° Hipped roof with roof battens & cedar tiles 125316 125318<br />

NOTE: EXTENSION KITS ARE SUITABLE TO EXTEND<br />

A GARAGE OR CAR PORT BY ONE ADDITIONAL BAY -<br />

IF MORE THAN ONE EXTENSION KIT IS REQUIRED<br />

FOR MULTIPLE APPLICATIONS PLEASE CONTACT<br />

OUR HELPLINE FOR ADVICE.<br />

40° Hipped roof without roof battens & cedar tiles 125314 125315<br />

45° Gable/Barn-end with roof battens & cedar tiles 125321 125322<br />

45° Gable/Barn-end without roof battens & cedar tiles 125319 125320<br />

28° Gable-end with roof battens & cedar tiles 125312 125313<br />

28° Gable-end without roof battens & cedar tiles 125310 125311<br />

If you have any queries please contact<br />

our helpline on 0845 601 7886<br />

FOR GARAGES AND CAR PORTS – PROFESSIONAL TIMBER FRAME SYSTEM 19

THE BENEFITS<br />

THE BENEFITS OF USING BEAMLOCK<br />

<strong>Beamlock</strong> Connection<br />

This timber connection is designed not only for high strength but also for use in our variable climate. Due to the fundamental<br />

connection relying on the steel plates and tubes matching up, the moisture changes in the wood do not cause any concern or<br />

inhibit the connection system from working efficiently and easily. The <strong>Beamlock</strong> connection system is made with a combination<br />

of high tensile stainless steel (grade 304L) and aluminium components. The <strong>Beamlock</strong> design is durable and can achieve a<br />

service life of up to 30 years for external exposure.<br />

Installation Advantages<br />

Choose either to self build or opt for the <strong>Beamlock</strong> installation service. Two people can easily build a <strong>Beamlock</strong> structure with<br />

minimal tools and skills. Simple assembly means that you will benefit from the unique time-saving design, reducing build times<br />

and labour costs. The modular concept also guarantees compact storage and transport solutions.<br />

1/2 Hour Fire Approval<br />

<strong>Beamlock</strong> <strong>System</strong> complies to BS 476-21 half hour fire exposure, which is considered suitable for the support of upper floor<br />

loading. This may negate the requirement for fire calculations if half hour fire determination is required.<br />

True 90˚ degree Angles<br />

The <strong>Beamlock</strong> <strong>System</strong> automatically creates appropriate angles and upright. Due to the simplicity of the connection system, you<br />

cannot get the angles wrong!<br />

Weight and Construction Advantages<br />

<strong>Beamlock</strong> is a safe site product providing strength at easily managed weights. Posts and beams are supplied in easily transportable<br />

modular lengths to a maximum of 4.968m. There is no need for a crane or multi-lift as two people can handle all components.<br />

Typically, on a 4.94m span, the <strong>Beamlock</strong> components weigh just 48kg. The <strong>Beamlock</strong> <strong>System</strong> has been designed to comply<br />

with wind code (BS6399).<br />

Kiln Drying<br />

All timber spends approximately 15 days in individual kilns drying out to 15% (+/- 3%) humidity. The timber contracts by<br />

about 10% and reduces in weight by about 40%.<br />

Treatment<br />

Factory-applied preservative treatment gives compliance for Use Class 3.1* allowing the frame to be exposed to the elements but<br />

requiring further application of protective surface coatings.<br />

Finish<br />

<strong>Beamlock</strong>’s major timber components are pre-treated and are ready to decorate. They are planed to the highest joinery standards<br />

and need no extra preparation before painting or staining.<br />

Quality<br />

<strong>Beamlock</strong>’s major timber components are manufactured to a consistent high quality. We provide joinery grade timber<br />

machined to +/- 1mm.<br />

End Tension Plate<br />

This attractive plate is also an essential technical component of the <strong>Beamlock</strong> <strong>System</strong>. Each unused face is finished off with the<br />

end plate which reduces the longitudinal stresses in the timber.<br />

*A SECONDARY PROTECTIVE COAT NEEDS TO BE APPLIED AND MAINTAINED TO ACHIEVE “USE CLASS 3.”<br />

20 PROFESSIONAL TIMBER FRAME SYSTEM – FOR GARAGES AND CAR PORTS

COMPONENTS,<br />

CARE AND MAINTENANCE<br />

BEAMLOCK COMPONENTS<br />

<strong>Beamlock</strong> uses a modular connection system that enables a quick and easy<br />

build, secure in the knowledge that our engineered components will fit<br />

together perfectly every time.<br />

2<br />

1<br />

2<br />

BEAM FIXING KIT<br />

POST FIXING KIT<br />

3<br />

4<br />

POST<br />

END TENSION PLATE<br />

5<br />

6<br />

BRACE<br />

7<br />

BEAM<br />

BASE PLATE<br />

(TIMBER SHROUD SUPPLIED TO CONCEAL<br />

BASE PLATE FIXING. SEE PAGE 22).<br />

7 1<br />

4<br />

5<br />

3<br />

CARE AND MAINTENANCE<br />

Preservative Treatment of Timber<br />

All <strong>Beamlock</strong> key timber components (frame and posts) have been treated<br />

with Vacsol Aqua double vacuum treatment.<br />

Cutting of the timber on site is unavoidable. This will expose untreated timber<br />

and it is imperative that crosscut, notches and bored holes be liberally swabbed<br />

with Vacsele End Grain Preservative.<br />

6<br />

Vacsol Aqua<br />

Vacsol Aqua is approved to standards and specifications of Building<br />

Regulations of England and Wales and Building Standards Scotland and<br />

the NHBC for many different applications and complies with the<br />

following standards:<br />

C1-10 BWPDA<br />

BS5707 (1997)<br />

BS5589 (1989)<br />

BS5268 Part 5 (1989) BS1186 (1986) BS5502<br />

BS6566 Part 7.<br />

The design life is for 30 years in Use Class 3*.<br />

*A secondary protective coat needs to be applied and maintained to achieve “Use Class 3.”<br />

Colour and Finish<br />

The timber colour is unaffected by the<br />

Vacsol Aqua treatment process, which<br />

leaves complete individual choice as to<br />

how the finished project can be decorated.<br />

If you have any queries please contact<br />

our helpline on 0845 601 7886<br />

FOR GARAGES AND CAR PORTS – PROFESSIONAL TIMBER FRAME SYSTEM 21

POST SUPPORT<br />

AND FOUNDATION REQUIREMENTS<br />

ADJUSTABLE POST SUPPORT<br />

The <strong>Beamlock</strong> <strong>System</strong> includes a comprehensive and unique post-to-ground<br />

fixing solution.<br />

1 2<br />

The specially engineered base plate is designed to maximise full support up to<br />

10 tons (tension pulling strength 1.3 tons) and at the same time positively fix<br />

the post to the ground below.<br />

MAX 60mm<br />

ADJUSTMENT<br />

MAX 60mm<br />

ADJUSTMENT<br />

An additional benefit is the 60mm (maximum) of height adjustment of<br />

the base plate for an over-site that may not be level, an ideal solution in<br />

garages where frequent washing may occur and where a gentle fall is<br />

required for drainage.<br />

TIMBER SHROUD<br />

COVERS FIXING<br />

COMPONENTS.<br />

There are two choices of fixing:<br />

1 New purpose-built ground bearing over-site<br />

(partially covered in concrete).<br />

2 New or existing suitable surface, drill and fix.<br />

300mm<br />

An additional 60mm can be achieved from the same post length giving a<br />

maximum eaves height of 2,210mm.<br />

90mm<br />

300mm<br />

THE POST SUPPORT ENSURES THAT THE TIMBER POST<br />

IS KEPT OUT OF THE GROUND.<br />

FOUNDATION REQUIREMENTS<br />

<strong>Beamlock</strong> garages and car ports are to be erected on suitably prepared and level<br />

foundations, in accordance with the Local Building Regulation requirements.<br />

Typically a foundation type is decided upon by relevant information such as<br />

soil conditions, frost, heave, proximity to surrounding vegetation, landscape<br />

contour (slope of site), fresh landfill, clay, sandstone, loamy soil, water table and<br />

structural load. These are all relevant issues that may affect the foundation type<br />

(strip, trench, raft or pad foundation). Excavation depth and width, concrete<br />

thickness and proximity of concrete to finished ground level is also very<br />

important in selecting the correct foundation type for your site to save costs.<br />

NOTE: IT IS THE HOMEOWNER OR CONTRACTOR’S<br />

RESPONSIBILITY TO LAY A SUITABLE FOUNDATION AND IS<br />

NOT PART OF METSÄ WOOD’S SERVICE PACKAGE.<br />

22 PROFESSIONAL TIMBER FRAME SYSTEM – FOR GARAGES AND CAR PORTS

GENERAL INFORMATION<br />

AND INSTALLATION<br />

GENERAL INFORMATION<br />

Planning<br />

<strong>Beamlock</strong> garages and car ports are to be erected on suitably prepared and<br />

level foundations, in accordance with the Local Building Regulation<br />

requirements. A full set of elevational plans suitable for planning<br />

submission are available.<br />

Call <strong>Beamlock</strong> Planline 0845 601 7886.<br />

Purchasing and lead times<br />

To order your <strong>Beamlock</strong> structure you will need to contact your local<br />

merchant. After placing your order you will be contacted to confirm your<br />

delivery address and to arrange for a convenient delivery time and date.<br />

Prior to delivery you will receive an order acknowledgement.<br />

Please allow 28 days for delivery.<br />

Delivery<br />

Deliveries are to UK mainland only, with suitable road access. Installation<br />

service only applies where the erection of the structure is within 25m of a<br />

suitable roadway access.<br />

Timber specifications<br />

Full compliance to Use Class 3.1*.<br />

Suitable for external use, not in ground contact.<br />

The <strong>Beamlock</strong> <strong>System</strong> is produced using Pinus Sylvestrus (10,800 - 13,000<br />

bending per N/mm 2 , comparison Oak 10,500 - 14,500 bending N/mm 2 ).<br />

It is made up using lamellas of pine laminated together, providing<br />

incredible strength.<br />

• Timber sections are dried in a climate-controlled kiln.<br />

• The lamellas are then laminated together to form a single solid<br />

beam using a high frequency hot press.<br />

• The beams are planed to section to achieve a tolerance of +/- 1mm.<br />

• The finished components are then treated for Use Class 3.1* using<br />

Vacsol Aqua double vacuum pressure impregnated preservative.<br />

This manufacturing process ensures that all <strong>Beamlock</strong> timber components are<br />

of the highest quality, avoiding all the typical problems such as shrinkage,<br />

splitting and variation in size, normally associated with timber sections of<br />

these dimensions. All external timbers must be coated with a proprietary<br />

brand of wood preserver, stain or paint within 6 months of installation to<br />

avoid UV light degradation of the treatment.<br />

*A SECONDARY PROTECTIVE COAT NEEDS TO BE APPLIED<br />

AND MAINTAINED TO ACHIEVE “USE CLASS 3.”<br />

INSTALLATION<br />

For full instructions on how to erect Metsä Wood Professional Timber Frame<br />

<strong>System</strong> structures please refer to the separate installation manuals.<br />

If you have any queries please contact<br />

our helpline on 0845 601 7886<br />

FOR GARAGES AND CAR PORTS – PROFESSIONAL TIMBER FRAME SYSTEM 23

For more information and a list of stockists in your area visit<br />

www.metsawood.co.uk or call 0800 00 44 44<br />

Metsä Wood is a wood products company delivering<br />

service-oriented solutions developed in collaboration with<br />

its customers. Its premium solutions are based on<br />

ecological, high quality Nordic wood as a raw material.<br />

Wood is the only building material that is truly renewable, if<br />

well managed. Forest certification schemes give assurance<br />

that the timber is legal and from sustainable sources. Metsä<br />

Wood sources certified timber over uncertified and is an<br />

approved Chain of Custody supplier.<br />

MW0072 Oct 12.<br />

The photographs in this brochure are for illustration<br />

purposes only.<br />

Metsä Wood reserves the right to change the range<br />

without notice.<br />

Every effort has been made to ensure that colours are<br />

accurate within the limitations of natural lighting conditions<br />

and the four colour printing process.<br />

METSÄ WOOD<br />

Telephone: 0800 00 44 44<br />

Email: uk@metsagroup.com<br />

www.metsawood.co.uk<br />

MW0072 OCT 12