CANS OF THE YEAR AWARDS - SPG Events

CANS OF THE YEAR AWARDS - SPG Events

CANS OF THE YEAR AWARDS - SPG Events

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

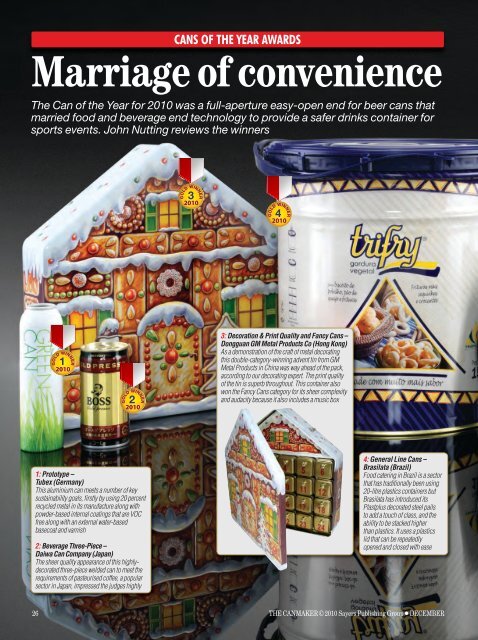

<strong>CANS</strong> <strong>OF</strong> <strong>THE</strong> <strong>YEAR</strong> <strong>AWARDS</strong>Marriage of convenienceThe Can of the Year for 2010 was a full-aperture easy-open end for beer cans thatmarried food and beverage end technology to provide a safer drinks container forsports events. John Nutting reviews the winners34123: Decoration & Print Quality and Fancy Cans –Dongguan GM Metal Products Co (Hong Kong)As a demonstration of the craft of metal decoratingthis double-category-winning advent tin from GMMetal Products in China was way ahead of the pack,according to our decorating expert. The print qualityof the tin is superb throughout. This container alsowon the Fancy Cans category for its sheer complexityand audacity because it also includes a music box1: Prototype –Tubex (Germany)This aluminium can meets a number of keysustainability goals, firstly by using 20 percentrecycled metal in its manufacture along withpowder-based internal coatings that are VOCfree along with an external water-basedbasecoat and varnish2: Beverage Three-Piece –Daiwa Can Company (Japan)The sheer quality appearance of this highlydecoratedthree-piece welded can to meet therequirements of pasteurised coffee, a popularsector in Japan, impressed the judges highly4: General Line Cans –Brasilata (Brazil)Food catering in Brazil is a sectorthat has traditionally been using20-litre plastics containers butBrasilata has introduced itsPlastplus decorated steel pailsto add a touch of class, and theability to be stacked higherthan plastics. It uses a plasticslid that can be repeatedlyopened and closed with ease26 <strong>THE</strong> CANMAKER © 2010 Sayers Publishing Group ● DECEMBER

Easy-open ends for drinks cans revolutionisedthe business, helpingexpand worldwide sales to morethan 250 billion a year. The performancerequirements are so high that a significantchange in their design is rarely risked –until this year, when the FIFA World Cupin South Africa provided the opportunityto develop the first full-aperture versionfor a beer can.Such was the impact of the EventCan version of Crown’s SuperEnd<strong>CANS</strong> <strong>OF</strong> <strong>THE</strong> <strong>YEAR</strong> <strong>AWARDS</strong>that the judges for the Can of the Year 2010organised by The Canmaker magazineselected it without question from what wasagreed to be an already high-quality selectionof Gold award winners.The idea behind the end design was tofind a can that could elbow into the marketfor drinks containers at sports eventswhere concerns about safety had enabledplastics bottles and cups to take over.By offering a can with a full aperture(FA) it could be more quickly served openat the bars during the World Cup and atother events.South African Breweries, part of theglobal SABMiller brewing group, firstapproached Paris-based Crown Bevcan in2008, and after discussing various solutionsit was decided to fit full-apertureeasy-open ends onto the cans, so that theycould be used like drinking cups.Objective was to use the ends on a limitededition of SAB’s Castle Lager, distributedthrough bars in the tournament▲7: Beverage Two-Piece –Toyo Seikan Kaisha (Japan)These are the first 50cl aluminium cans to bemade outside of Japan using Toyo Seikan’saTULC process featuring a polyester coating.At Toyo Seikan’s new plant at Guangzhou inChina, the dry-DWI process meets increasinglyimportant sustainability goals of customers bycutting the amount of curing-oven energy andwaste water required in manufacture8: Food Three-Piece –Crown Food Europe (France)Bonduelle, the French-based canned vegetableproducer, has launched its Vapeur range ofhigh-quality products that are heat processedusing less liquid in the can. It is enhanced as acomplete package by the use Crown’s can withan Easylift easy-opening end – a first onvegetable cans – on which the decoration ismatched to the label design9: Bottles –Daiwa Can Company (Japan)This 12cl bottle made by Daiwa forHouse Foods is a new size andmade from polyester-laminatedaluminium coil using D&I techniques56798105: Food Two-Piece –Metalgráfica Renner (Brazil)Brazilian cookie manufacturer Dauperkeeps its products fresh with this cleveruse of a decorated drawn tin using a sliplid made by Renner. The vacuum isreleased to open the can by peeling off aseal in the lid that covers a hole. It’s a twopiece can, but not as we know it6: Aerosol Cans – Boxal (France)This aluminium monobloc can uses aninside curl bead developed by Boxal thatraises tightness performance to meet thehigh-pressure requirements of newcompressed gas applicationsCAN <strong>OF</strong> <strong>THE</strong><strong>YEAR</strong> 201010: CAN <strong>OF</strong> <strong>THE</strong> <strong>YEAR</strong> and Ends, Caps & Closures– Crown Bevcan Europe & Middle East (France)Developed for use during this year’s FIFA World Cup inSouth Africa, this latest full-aperture version of CrownBevcan’s lightweight SuperEnd facilitates serving atbars and easier drinking from the opened beer can,eliminating the need for glass or plastics containersDECEMBER ● <strong>THE</strong> CANMAKER © 2010 Sayers Publishing Group 27

<strong>CANS</strong> <strong>OF</strong> <strong>THE</strong> <strong>YEAR</strong> <strong>AWARDS</strong>stadia in tinplate 33cl and 44cl cans madeby Nampak in South Africa – with SABtracking the response of consumers.Development of the FA version of theSuperEnd – which itself was launched tenyears ago to provide further lightweightingopportunities – involved 18 months oftrials in which Crown exploited its expertisein food and beverage end manufacturingto meet SAB’s requirements.The 206 end is based on Crown’s existingSuperEnd technology, in which theprofile is reformed during the seamingprocess to enable higher pressure performancewith a lower gauge. Crown alreadysupplies full-aperture easy-open lids forsnack applications, but the demands ofhaving to meet high-pressure performancerequired a number of design modificationsto ensure that the end performed satisfactorilyduring the seaming and pasteurisationprocesses.The opening process was also a majorissue, along with the release of internalpressure as the tab is lifted. When the tabis pulled, a section of the end dips into thecan, enabling leverage to be applied to thescore to complete the opening. Crown’sengineers also ensured that once opened,the exposed edge of the aperture wassmooth for drinking.The end shells for the launch cans weremade by Nampak but converted in the USusing a modified food end press beforeshipping back to South Africa. The shippingproved a problem because the endsnever made it in time for the World Cup,but are almost certainly going to be usedat other competitions in Europe on SAB-Miller’s beers such as Pilsner Urquell.Crown was one of three canmakers towin two Gold awards in Cans of the Year2010, its other award coming from itsinvolvement with a new type of canningprocess for vegetables developed atFrench packer Bonduelle.Crown Food Europe has long suppliedBonduelle with three-piece welded steelcans and its Eole full-aperture ends butthis time the new Vapeur process, aimedat offering the consumer a more fresh-tastingand crisp product such as peas orbeans, presented some new challenges.Vapeur is a steam retort heating processin which less liquid is used in the83x85mm can and is said to improve theflavour of the vegetables while retainingcolour and nutritional value. For thelaunch on the French market Crown FoodEurope is providing its Easylift steel endfeaturing ring pull with better fingeraccess for consumers while being interchangeableon customers’ closingmachines and filling lines.Hong Kong-based GM Metal Productswon two Gold awards with the sameCAN <strong>OF</strong> <strong>THE</strong> <strong>YEAR</strong> 2010Crown Bevcan Europe & Middle East:Full-aperture beverage end on Castle Lager Event can for SABMillerAEROSOL <strong>CANS</strong>GOLD: Boxal (France)Solar Expertise Sun Cream spray aluminium monobloccan for L’OréalSILVER: Sarten (Turkey)Caba deodorant three-piece tinplate can for CabaItaly/Beauty of TodayBRONZE: Exal Corporation (USA)Lemon Dijon Pure Indulgence Topping monoblocaluminium can for Lé Foam LLCBEVERAGE THREE-PIECEGOLD: Daiwa Can Company (Japan)Boss Gold Presso steel three-piece coffee canfor Suntory FoodsNo other awardsBEVERAGE TWO-PIECEGOLD: Toyo Seikan Kaisha (China)Kingway and Pearl River aTULC aluminium beer cansfor Kingway Brewery (Foshan) Co & GuangzhouZhujiang Brewery GroupSILVER: Daiwa Can Company (Japan)Final Fantasy XIII D&I aluminium drinks can for Suntory FoodsBRONZE: SMYPC Metal Container Plant (Philippines)La Natural Coconut Juice D&I aluminium 33cl cans forMabuhay 2000 IMEx CoBOTTLESGOLD: Daiwa Can Company (Japan)Ukon No Chikara Super drink aluminium D&I mini-bottle forHouse FoodsSILVER: Exal Corporation (USA)Blues Golden Ale aluminium monobloc 22oz bottle for16 Mile BreweryBRONZE: Boxal (France)Kidibul sparkling fruit juice aluminium monobloc bottlesfor StassenDECORATION & PRINT QUALITYGOLD: Dongguan GM Metal Products (Hong Kong)Christmas Advent Calendar hinge lid decorated tincontaining internal slip lid tins for GawolSILVER: Meister (Brazil)Slip lid tinplate ‘Butterfly’ tin for Meister promotionBRONZE: Exal Corporation (USA)Team Realtree Outdoor Energy impact-extruded aluminiumbottle for J&M Concepts LLCCommended: CPMC Holdings (China)Commended: Crown Speciality Packaging (France)ENDS, CAPS & CLOSURESGOLD: Crown Bevcan Europe & Middle East (France)Full aperture easy-open beverage end for Castle Lager Eventcan with full-aperture easy-open beverage end for SABMillerSILVER: Impress Group (The Netherlands)Nan Infant Formula three-piece decorated can with Deep-entry: its Christmas Advent themed container.Produced at GM’s Dongguan factoryin China, the tin won in both theFancy Cans and Decoration & Print Qualitycategories. As a fancy can it has almosteverything: the appealing winter-decoratedhouse shape and when you open itthe 24 smaller square tins for the daysleading up to Christmas, topped with amusic box. Its printing quality was alsospectacular, said the lithography expert onthe judging panel.Japan’s Daiwa also won two Goldawards, for Bottles and Beverage Threepiece.Its winning bottle was a new 12clCATEGORY WINNERSDrawn membrane lid and Easy Scoop for Nestlé NutritionBRONZE: Impress Group (The Netherlands)OptiLift steel full-aperture easy-open end for William SaurinCommended: Crown Food Europe (UK)FANCY <strong>CANS</strong>GOLD: Dongguan GM Metal Products Co (Hong Kong)Christmas Advent Calendar hinge lid decorated tin containinginternal slip lid tins for GawolSILVER: Jiabao Packaging Depot (China)Mighty Beanz drawn two-part can with all-over decorationfor MoosetoysBRONZE: Glud & Marstrand (Denmark)Shaped palm-sized snuff can with plastics insert forSwedish MatchFOOD THREE-PIECEGOLD: Crown Food Europe (UK)Three-piece tinplate can with Easylift easy-open end forBonduelle VapeurSILVER: Rimet (Brazil)Three-piece steel can with membrane lid for Nestlé Brasilinfant formulaBRONZE: Metalúrgica Mococa SA (Brazil)Nescafé Cappuccino expanded three-piece tinplate canfor Nestlé Brasil LtdaFOOD TWO-PIECEGOLD: Metalgráfica Renner (Brazil)Cookie container with drawn body and slip lid and vacuumseal for DauperSILVER: Franpac (Massilly Group) (France)Les Dieux drawn tapered aluminium fish can for GendreauBRONZE: Impress Group (Italy)Cirio drawn decorated can with Easy Peel closure forConserve ItaliaGENERAL LINE <strong>CANS</strong>GOLD: Brasilata (Brazil)Trifry food catering Plastplus steel tapered pail for TriânguloAlimentosSILVER: Brasilata (Brazil)Lazzudur paint Top-gun three-piece steel ringless pail forSherwin-WilliamsBRONZE: Companhia Metalúrgica Prada (Brazil)Brasso polish three-piece steel can with plastics closure forReckitt BenckiserCommended: Pirlo - Metal Packaging (Austria)Commended: Industrias Sanz (Spain)PROTOTYPEGOLD: Tubex (Germany)Monobloc aluminium aerosol can with powder coatingSILVER: Companhia Metalúrgica Prada (Brazil)Steel microwaveable can with easy-open end and plastics closureBRONZE: Reichsfeld - Metal Packaging (Austria)Steel welded SI-Can general line can with handlesize made from film-laminated aluminiumcoil for the Ukon No Chikara brand ofnutritional drink from House Foods. InBeverage Three-piece, Daiwa’s winner wasa shaped and embossed can for 185g ofBoss ready-to-drink coffee from Suntory.What many consider as a breakthroughtechnology for canmaking with the highestenvironmental standards was the Goldwinner in the Beverage Two-Piece category.Japan’s Toyo Seikan first developed itsTULC process almost two decades ago touse polyester-laminated canstock thatenabled lubricant washing and much of theink curing and coating process to be elimi-28 <strong>THE</strong> CANMAKER © 2010 Sayers Publishing Group ● DECEMBER

nated from the canmaking process, reducingplant emissions. Demonstrating that itstechnology is competitive in China, ToyoSeikan’s award-winning 50cl cans are madewith the latest ‘dry-DWI’ technology withaTULC co-extruded aluminium canstock atits latest plant in Guangzhou.Environmental concerns were alsobehind the Gold winner in the Prototypecategory, Tubex, which has developed itsaluminium aerosol cans using powderbasedinternal coatings and water-basedexternals. This enables, along with the useof part-recycled aluminium for the body, astronger sustainability message to be communicatedby customers.The Ends, Caps & Closures categorywas tightly contested. While Crown wonwith its full-aperture beverage end forCastle Lager, it was a close-run race withNestlé’s Nan infant formula can. Thisuses a new Deep-Drawn lid with a membraneend developed by Impress thatenables the usual plastics scoop suppliedto be housed without being placed in theproduct. While that won the Silveraward, Impress also scooped the Bronzewith the latest incarnation of its easyopenfood ends. The Optilift end fromImpress takes the benefits of offeringmore finger access under the tab a stepfurther by exploiting the vacuum createdin the can during processing to draw thepanel away from the tab, creating morespace beneath it on cans supplied forFrench canned food specialist WilliamSaurin.Nestlé was the customer for two othersimilar products that were recognised inthe awards for Food Three-Piece. Brazil’sRimet designed and manufactured a moreconventional but highly-attractive canwith a membrane for Nestlé infant formulawhile Metalúrgica Mococa showedhow expanding the top and bottom of thecan body enhanced the look of cans forNescafé Cappuccino.A Brazilian canmaker also scored in theFood Two-Piece category but not with thesort of can you’d expect. Cookie cans areusually made using three-piece techniqueswith lock seams and slip lids: for cookiemanufacturer Dauper, Metalgráfica Rennerprovided a solution that ensures thecan has a vacuum seal until opened byusing a drawn (and highly decorated) bodyto which the slip lid is a close fit. The centreof the lid has a tiny hole that is sealedby a peel-off label that when removedreleases the vacuum, using a principlesimilar to that developed for wet foods byBrazil’s Rojek.Like the Gold-winning Crown beverageend, Renner showed that crossover technologiesare just one route to new innovationsin metal packaging.DECEMBER ● <strong>THE</strong> CANMAKER © 2010 Sayers Publishing Group 29