WHEEL LOADER - CablePrice

WHEEL LOADER - CablePrice

WHEEL LOADER - CablePrice

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

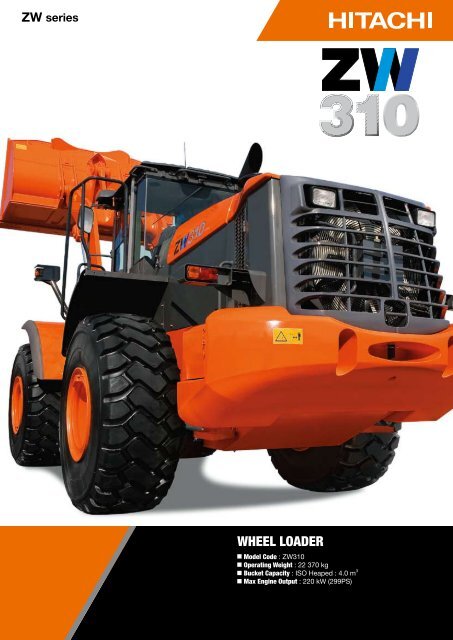

ZW series<strong>WHEEL</strong> <strong>LOADER</strong>Model Code : ZW310Operating Weight : 22 370 kgBucket Capacity : ISO Heaped : 4.0 m 3Max Engine Output : 220 kW (299PS)

Introducing the New-GenerationWheel Loaders:SeriesTop-Class Production with Amazing MobilityThe new ZW Series wheel loaders are packed with numerous innovative technologiesand mechanisms. Total control of engine and pump torque is an industry's first.Three work modes and three driving modes help enhance operating ease and yieldhigh production. What's more, lots of advanced designs give power and speed forloading and travel.The ZW Series will set a new standard of productive, easy-to-operate wheel loaders.ProductivityThree work modes to increaseproduction and decrease fuelconsumptionThree driving modes for optimum speedshiftAutomatic transmission with loadsensingsystemHigh-torque engine and capacioustorque converterTorque proportioning differentialLimited slip differential (Optional)Smoother simultaneous operations withadvanced hydraulic circuitSelectable clutch cutoff TimingLift arm auto leveler (Optional)Ride control system (Optional)Page 4-7Panoramic comfortable cabBi-level auto air conditioner andpressurized cabFront & rear defrostersLow noise designPanoramic cabEnhanced upward visibilityGood rear visibilityErgonomically positioned switches andcontrolsDown-Shift Switch (DSS) andUp-Shift Switch (USS)Multi-functional joystick lever (Optional)Air suspension seat (Optional)Page 8-9Enhanced DurabilityRobust differential gearsDurable axlesVariable displacement pumpsRobust frameHydraulically operated cooling fan withheat-sensing systemCapacious hydraulic oil coolerProtected fuel tankAluminum radiator and oil coolerLED indicators and instrumentsO-Ring Seal (ORS) joints and waterresistantelectric connectorsPage 10-11Easy MaintenanceExtended hydraulic oil replacementintervalsEasy drainingConveniently located filtersEasy-to-replace air conditioning filtersHN bushingsStrategically located Fuel supply portLarge tool boxEasy-to-read monitorFlat cab floorHinged radiator coverDirt-Less (DL) front framePage 12-13SafetyFull fan guardEmergency steering system (Optional)Mis-operation protectionROPS / FOPS cabHighly reliable dual-line brake systemOther safety featuresPage 14EnvironmentHigh-pressure fuel injection systemHitachi Silent (HS) fanLow noise engineMarking of recyclable partsPage 15SpecificationsPage 16-19The new engine complieswith the Emission RegulationsU.S EPA Tier 3 and EU Stage III AThe advanced low noisedesign complies withthe coming EU noiseregulation 2000 / 14 / EC,STAGE IINote : Pictures may or may not includestandard and optional equipment thatare specified individually by countries.

Packed with Numerous Technological Advances forAmazing Mobility and Big ProductionThe new ZW Series is packed with lots of technological advances: theTT* system, newly developed hydraulic system and transmission, wellmatching of operations, impressive mobility and big production with lessfuel consumption, and much more.*Total Torque-controlThree Work Modes to Increase Production and Decrease Fuel ConsumptionmodeSystemP modeFrontspeedLift armdigging forceTraction forceSlowMediumLargemodeEngineOutputP mode(Power mode)N mode(Normal mode)L mode(Light mode)EngineSpeedN mode L modeFrontspeedLift armdigging forceTraction forcemodeFrontspeedLift armdigging forceTractionforceMediumMediumMediumMediumSmallFastThree work modes are selectableaccording to job needs and operator'spreference. In each work mode, TT*system controls the total torque of theengine and pump for well matchedpenetration force and implement speedaccording to job needs. The three workmodes can be optimally selected tosuit materials to be handled for higherproduction.Three Driving Modes for OptimumSpeed ShiftDriving modeswitchThe three driving modes can be selectedaccording to job needs and operator'spreference.L mode :Starts with the second gear, and makesgear shift at fast timing. Suitable forlong-distance travel on level ground.Work modeselect switchP mode: Heavy-duty excavationN mode: LoadingL mode: Light-duty operationN mode :Starts with the second gear and makesgear shift at slow timing. Suitable forordinary digging and loading operationsuch as V-shaped load and carrymethod.H mode :Makes gear shift at timing similar to theN mode, and automatically shifts downto the first gear according to loadingconditions without need for shift downby DSS* or manual shifting.*Down-Shift SwitchAutomatic Transmission with Load-Sensing SystemLoad increaseAuto shiftdown whenload increasesSpeed increaseShiftup when speedincreasesOptimal speed shift timing isautomatically selected in response toboth travel speed and load.Smooth Speed Shift by ElectronicControlQuick, smooth speed shift canautomatically be done with less shocksby electronic control through helicalgears. This allows speedy job-to-jobtravel with less soil spills in load-andcarryoperation.High-Torque Engine and CapaciousTorque ConverterMax. output : 220 kW (299 PS)Rated output : 216 kW (294 PS)Max. torque : 1 400 N•m (143 kgf•m)The new engine yields big torque ata low speed in direct response toacceleration without need for full throttle.The capacious torque converter enablespowerful travel under heavy load, suchas climbing steep or long hills withoutlosing speed.Torque Proportional Differential(Standard)The torque proportional differentialadjusts driving forces to both wheels.When road resistances under bothwheels are different, this feature preventsslippage of a wheel on softer ground,unlike conventional differentials. Thisfeature enables the ZW series to get outof swamps or rough terrain easily.Limited Slip Differential (Optional)On snowy roads and rough terrain, thelimited slip differential can work insteadof the torque proportional differential.This delivers effective driving force toboth wheels for enhanced grip and lessslippage during travel.

SYKES, DRUMMOND, AND DAVISPHYSICAL REVIEW A 76, 063620 2007Re(k i)Re(k i)Re(k i)Re(k i)1 (a)0−10 |c| 0.51 (c)0.500 |c| 0.51 (e)0.500 |c| 0.51 (g)0.500 |c| 0.5Im(k i)Im(k i)Im(k i)Im(k i)10−10 |c| 0.510−10 |c| 0.510−10 |c| 0.510−10 |c| 0.5Re(k i)Re(k i)Re(k i)Re(k i)1 (b)0.500 |c| 0.51 (d)0−10 |c| 0.51 (f)0−10 |c| 0.51 (h)0Im(k i)Im(k i)Im(k i)Im(k i)10−10 |c| 0.510−10 |c| 0.510−10 |c| 0.510−1−10 |c| 0.5 0 |c| 0.5FIG. 1. Color online Behavior of the quasimomenta for N=6 particles as a function of the interaction strength c0, for eight low-lyingstates, ordered via their energy at c=0. The single-particle momentum states and their energies at c=0 are a 0,0,0,0,0,0 E=0, b1,0,0,0,0,0 E=1, c 1,1,0,0,0,0 E=2, d 1,−1,0,0,0,0E=2, e 1,1,1,0,0,0 E=3, f 1,1,−1,0,0,0E=3, g 1,1,1,1,0,0E=4, and h 1,1,1,−1,0,0E=4. All states shown have a total angular momentum that is either zero a and d or positive b, c,e, f, g, and h—the latter set have a degenerate counterpart with a negative total angular momentum which can be found easily via themapping k i →−k i for all i. The states plotted all have k i 1 for all i—states with quasimomenta such as 2,0,0,0,0,0 at c=0, which aredegenerate with g and h give rise to higher-energy states for c0. On each graph there are six distinct lines for each particle; however,some of these overlap for large regions. To aid visualization the color of the lines indicates how many quasimomenta are overlapping. Blueindicates one root, green two, magenta three, cyan four, and red six.transformation see Eq. 33 in Ref. 25 popularized in theseminal work of Lieb and Liniger 11. The transformationsimplifies the numerics in the repulsive case by spreading thetransformed quasimomenta into numbers which can be easilydistinguished by machine precision. The same is not true inthe case of attractive interactions. As pointed out by Sakmannet al., working with the transformed quasimomenta inthe attractive case requires numerical precision of approximately10 −85 . In this work we solve Eqs. 8 directly. We setthe tolerance of the FSOLVE algorithm to iterate until Eqs. 8are solved such that the left hand side equals the right-handside to an absolute accuracy of 10 −10 . Once the value of chas increased to the point that the quasimomenta are within10 −10 of the string solution, the algorithm terminates.We present the results of these calculations in two differentways. Figures 1–3 show the continuous evolution of thereal and imaginary parts of the quasimomenta for a numberof excited states as c becomes more negative. Figure 1 showseight low-lying excited states for N=6, whereas Figs. 2 and 3show two representative excited states for N=20. Figures 4and 5 show snapshots of the distribution of the quasimomentain the complex plane for N=20. Our calculations elucidatethe deviations from the string solutions at finite density50.We see from Figs. 1b and 1e that as the real parts of k iand k j become equal the imaginary parts bifurcate, and viceversa. These splittings of the quasimomenta provide additionalchallenges for the root-finding algorithm. Because thesplitting often occurs sharply, the initial guess for the quasimomentafound from the previous value of c can be sufficientlyinaccurate that the algorithm does not converge.Thus, if one finds that the root-finding algorithm is not convergingat a particular value of c, then this could be an indicationthat two equal quasimomenta are beginning to split.When this occurs there is always a degeneracy between thequasimomenta as to which one goes up and which one goesdown this degeneracy is of no physical consequence, it ismerely a mathematical hurdle. The numerical fluctuations ofthe values of the quasimomenta are usually somewhere closeto machine precision, 10 −15 , and are difficult to detect. Inorder to observe the splitting we found it was necessary tomanually alter the initial guess for the quasimomenta at thesepoints, forcing one to go up and one to go down again seeFigs. 1b and 1e.There is no fundamental limit to the excited states we canreach with this procedure, and similar graphs can be producedfor up to approximately N=20 particles see Figs. 2and 3 as examples of the N=20-particle gas. In principlethis work could be extended to larger numbers of particles,and in fact we have found the ground state for up to N50. However, the bifurcations in the excited states requiresome time to locate and we have had to deal with them063620-4

Operator-First Designs:Easy-to-Handle Controls forOperator ComfortPanoramic CabAir Suspension Seat (Optional)The panoramic cab gives almost allroundvisibility with the widened frontglass window and pillar less cab rearcorners. Front wheels are always in theoperator's vision, enhancing safety andincreasing loading efficiency.Bi-Level Auto Air Conditioner andPressurized CabFront / Rear DefrostersShock-Dampened CabSilicone (Fluid)Ergonomically Positioned Switchesand ControlsEnhanced Upward VisibilityThe front curved glass window givesgood upward visibility, so the operatorcan directly see the movement of thebucket for safer loading.Good Rear VisibilityThe engine cover is low profile, androunded for better rear visibility, so theoperator can directly see the rear wheelsand counterweight.The air suspension seat can be adjustedin multiple ways: weight-height, foreaftposition, backrest tilt, and armrestangle, seat cushion length and angle,headrest height and angle adjustment,lumber support. Seat heater is equippedas standard.RubberThe bi-level air conditioner allows airconditioning at foot space and overheadsimultaneously. Airflow volume anddirection can automatically be adjustedaccording to the temperature setting.The pressurized cab shuts out dust anddebris even in dusty environment.Hat (Resin Cab Roof)With the front and rear defrosters,airflow comes out from three front airoutlets and two rear outlets to protectrespective windows from fogging,keeping clear vision even in rain andcold weather.The hollow hat is provided atop the cabto form an air space. This greatly helpsreduce the temperature rise in the cab,and increases the cooling efficiency ofthe air conditioner.The cab rests on fluid-filled elasticmounts to absorb shocks and vibration,and reduce resonance.Low Noise DesignThe cab is well sealed, and the new lownoiseengine is utilized to reduce sound,along with the following measures:•Hydraulically operated cooling fan withheat-sensing system•New Hitachi Silent (HS) fan•Sound-absorbing materials insideengine cover and cab•Clever arrangement of hydraulic oiltank and bulkheadSwitches and controls are efficientlylaid out in the right console for ease ofoperation.Down-Shift Switch (DSS) andUp-Shift Switch (USS)DSS and USS are designed for one-geardown-shift and up-shift at the touch of abutton.An Array of Standard AccessoriesMulti-Functional Joystick Lever(Optional)The multi-functional joystick lever isprovided atop of the control lever foroperating ease.Adjustable Steering ColumnThe steering wheel is tiltable, andtelescopic to suit operator of all buildsfor comfortable operation.Hot and cool box Large tray and drink holder Interior light interacting withcab doorSeatback pocket AM / FM stereo radio Sun visor

Enhanced DurabilityAluminum Radiator and Oil CoolerLED Indicators and InstrumentsO-Ring Seal (ORS) Joints andWater-Resistant Electric ConnectorsDurability is enhanced with a number of advanced mechanisms for long,continuous operation.Dependable Drive SystemHydraulically Operated Cooling Fan withHeat- Sensing SystemThe radiator and oil cooler are made ofaluminum instead of conventional steelor copper for corrosion protection.LEDOn the indicators, monitors and alarms,many LEDs are utilized for longer servicelife resulting in less failure, enhancingthe reliability.Numerous elaborate componentsare utilized for higher durability andreliability. The proven ORS joints andhigh-pressure hydraulic lines are utilizedin the hydraulic system, and waterresistantwiring connectors in theelectrical system.Fan speed can be adjusted dependingon fluid temperature to effectively cooldown coolant, hydraulic oil, transmissionoil and torque converter oil. The resultis extended component service life andreduction in fuel consumption. The fanis also separate from the engine for easyservicing.TransmissionThe transmission can effectively reducethe transmitting load. This helps reducesound and extend service life, enhancingreliability.Robust Differential GearsDifferential gears are thickened toincrease rigidity.Durable AxlesFront and rear axles are improved fordurability. The axle housing is thickenedfor tough operation at quarries.Improved Braking AbilityThe brake is a wet-type multi-platebrake, and housed in the axle.Variable Displacement PumpsNew variable displacement pumps areexclusively developed and designedfor Hitachi wheel loaders for toughearthmoving.Capacious Hydraulic Oil CoolerThe ample cooling capacity of thehydraulic oil cooler helps reduce oiltemperature fluctuation, and extendservice life of components.Robust FrameProtected Fuel TankThe box-section frame is thickened and strengthened to resist torsion and increasedurability. Center pins are widely spaced for higher resistance to torsion.The large counterweight is arranged toprotect the fuel tank from collisions withobstacles during operation.10 11

Safety-First DesignEnvironmentally Friendly DesignAchieving a High-Level of Safety in the Working Environmentwith an Array of Advanced MechanismsROPS / FOPS CabThe ROPS / FOPS cab is provided toprotect the operator from injury in anaccident.ROPS : Roll-Over Protective Structure :ISO3471FOPS : Falling Object Protective Structure :ISO3449Highly Reliable Dual-Line Brake SystemThe dual-line hydraulic brake system isutilized: even if one line fails, the othercan work for braking. The brake is anenclosed wet multi-plate type for reliablebraking.A Cleaner MachineThe ZW Series is equipped with a clean but powerful engine to comply with Tier 3 andStage III A. An engine emission regulations effective in the U.S. EPA and EuropeanUnion from 2006. Exhaust gas is partly re-combusted to reduce particulate matter (PM)output and lower nitrogen oxide (NOx) levels.High-Pressure Fuel InjectionSystemAn injection pump and an injector arepaired at each cylinder to inject fuel intothe cylinder at an ultra-high pressure.By electronic control of the governor,fuel injection timing and amount canprecisely be controlled. This helpsreduce (PM) Particulate Matter, nitrogenoxide (NOx) fuel consumption andvibration.Important: The use of fuels other than light oilis prohibited. Otherwise, the engine may bedamaged.A Recyclable MachineApproximately 95% of the ZW Seriescan be recycled. The resin parts aremarked to facilitate recycling. Themachine is completely lead-free. Theradiator and oil cooler are made fromaluminum and all wires are lead-less. Inaddition, bio-degradable hydraulic oilis available for jobsites where specialenvironmental care is required.Full Fan GuardThe cooling fan is enclosed by a fullguard (metal net) to protect servicetechnicians from injury during servicingand maintenance.Emergency Steering System (Optional)The emergency electric pump deliversthe necessary oil pressure for powersteering even in the case of anemergency. This allows normal steeringat all times even if the engine fails.Mis-Operation Protection:Starting Engine : The engine will startonly when the Forward / Reverse leverin neutral.Starting : The transmission is disabledwhen the parking switch is in the ONposition, even if selecting Forward orReverse.Leaving from Operator Seat : Controllevers and Forward / Reverse lever arelocked to prevent accidental operation.Stopping Engine : The spring-set/hydraulic-released parking brake isautomatically applied even if failing toapply it.Other Safety FeaturesRetractable Seat BeltA Quieter MachineA number of features make this machine quieter. First, isochronous control of the enginespeed means a restriction of engine speed during no-load and light-duty operation tosuppress sound. A fan with curved blades reduces air resistance and airflow noise.Third, a time-tested muffler suppresses engine noise significantly and reducesemissions. This advanced low noise design complies with the 2000 / 14 / EC, Stage II,directive effective in the European Union from 2006.Hitachi Silent (HS) FanThe HS fan is capable of reducing airresistance and air flow sound are utilizedat the radiator and oil cooler for quieteroperation.Low Noise EngineThe cylinder block and ladder frame arestrengthened to reduce engine sound.Inclined Ladder14 15

EQUIPMENTENGINEModel .......................... Dimler Chrysler OM460LAType ............................ 4-cycle water-cooled, direct injectionAspiration .................... Turbocharger and intercooledNo. of cylinders ........... 6Maximum powerDIN 6272, net .......... 220 kW (299 PS) at 1 800 min -1 (rpm)SAE J1349, net ....... 220 kW (295 HP) at 1 800 min -1 (rpm)ISO 9249, net .......... 220 kW (295 HP) at 1 800 min -1 (rpm)EEC 80/1269, net ... 220 kW (295 HP) at 1 800 min -1 (rpm)Bore and stroke........... 128 mm X 166 mmPiston displacement .... 12.816 LBatteries ...................... 2 X 12 V / 754 CCA, 294-min. rated reserveAir cleaner ................... Two element dry type with restriction indicatorPOWER TRAINTransmission................Torque converter,countershaft type powershiftwith computer-controlled automatic shift andmanual shift features included.Torque converter.......... Three element, single stage, single phaseMain clutch.................. Wet hydraulic, multi-disc typeCooling method........... Forced circulation typeTravel speed* (km/h) Forward / Reverse1st............................... 7.0 / 7.02nd.............................. 11.8 / 11.83rd............................... 21.8 / 21.84th............................... 34.5 / 34.5*With 26.5-25-16PR (L3) tiresAXLE AND FINAL DRIVEDrive system................ Four-wheel drive systemFront & rear axle........... Semi-floatingFront............................ Fixed to the front frameRear............................. Trunnion supportReduction anddifferential gear............ Two stage reduction with torque proportionaldifferentialOscillation angle........... Total 26˚ (+13˚,-13˚)Final drives................... Heavy-duty planetary, mounted inboardTIRES (tubeless,nylon body)Drive system................ 26.5-25-16PR (L3)Optional....................... Refer to standard & optional equipment listBREAKSService brakes.............Inboard mounted fully hydraulic 4 wheel wetdisc brake. Front & rear independent brakecircuitSTEERING SYSTEMType............................. Articulated frame steeringSteering mechanism.... Refer to standard & optional equipment listSteering angle.............. Each direction 40˚ ; total 80˚Cylinders...................... Two double-acting piston typeNo. x Bore x Stroke... 2 x 70 mm x 542 mmMinimum turningradius at the centerlineof outside tire............... 5 900 mmHYDRAULIC SYSTEMArm and bucket are controlled by independent control leverArm controls................ Four position valve ; Raise, hold, lower, floatBucket controls with automaticbucket return-to-dig control..... Three position valve ; Roll back, hold, dumpMain pump / Steering pump.... Variable Displacement Axial Plunger PumpCharging pump / Fan pump /Brake and assist pump............ Fixed Displacement Type Gear PumpHydraulic cylindersType.......................... Two arm and one bucket, double acting typeNo. x Bore x Stroke... Arm : 2 x 145 mm x 930 mmBucket : 1 x 185 mm x 510 mmFilters........................... Full-flow 15 micron return filter in reservoirHydraulic cycle timesLift arm raise............. 5.8 sLift arm lower............ 3.0 sBucket dump............ 1.4 sTotal.......................... 10.2 sSERVICE REFILL CAPACITIESlitersFuel tank.................................................................................... 382.0Engine coolant........................................................................... 59.0Engine oil................................................................................... 39.0Torque convertor & transmission................................................ 25.0Front axle differential & wheel hubs............................................ 48.0Rear axle differential & wheel hubs............................................. 48.0Hydraulic oil tank....................................................................... 128.0STANDARD EQUIPMENTENGINE•Coolant recovery tank•Hydraulically Operated Cooling Fan with Heat SensingSystem•Fan guard•Muffler, under hood with large exhaust stack•Environmentally friendly engine oil drain•Engine oil cooler•Quick-release fuel filter and water separator•Glow system (For cold start)•Air filter double element•Fuel double filter•TT (Total Torque-control) systemPOWER TRAIN•Automatic Transmission with Load-SensingSystem•DSS (Down-Shift Switch) and USS (Up-Shift Switch)•Torque proportioning differentials, front and rear•Driving mode selector switch, three modes•Clutch cut-off position switch, three positionHYDRAULIC SYSTEM•TT (Total Torque-control) system•Bucket auto leveler•Lift arm kick-out system•Float system•Reservoir sight gauge•Hydraulic filters, vertical mounting•Two-spool main control valve•O-Ring Seal jointsELECTRICAL•24-volt electrical system•Standard batteries (2), 12-volt with 754 CCA,294-min. rated reserve•Alternator, 50 A and 24-voltsOPTIONAL EQUIPMENTENGINE•Air pre-cleanerPOWER TRAIN•Limited slip differentialHYDRAULIC SYSTEM•Three-spool main control valve•Four-spool main control valve•Third spool piping•Third and fourth spool piping•Multi-function joystick lever•Two-lever and auxiliary lever for third function•Two-lever and auxiliary joystick-lever for third &fourth function•Multi-function joystick lever and auxiliary leverfor third function•Multi-function joystick lever and auxiliary joystickleverfor third & fourth function•Ride control system, automatic type•Lift arm Auto LevelerELECTRICAL•High-capacity batteries (2), 12-volt with 924 COCA,421-min. rated reserve•Alternator, high capacity, 90 A and 24-volts•Front Working Lamps on Cab (2)•Rear Working Lamp on Cab (2)•12-volt outlet•24-volt AM/FM stereo radio with clock•24-volt AM/FM stereo radio with cassetteplayer and clock•LightsDriving with guards / Turn signals withhazard switch / stop, tail and back-up lights•Work lights on cab, front (2)•Work lights, rear (2)•Horn, with push button in center of steering wheeland switch on joystick lever knob or right console•Reverse warning alarm•Monitor and alarm system, multi-function electronicaudible and visual warning include•LCD monitor display: Speedometer / Clock /Hour-meter / Fuel consumption / Odometer /Replacement intervals / Transmission Auto /Clutch cutoff / Ride control / Gear shift•Gauges: Engine coolant temperature /Transmission oil temperature / Fuel level•Warning lights: Engine / Transmission /Discharge warning•Indicator lights: Turn signals / High beam /Working lights / Service / Parking brake /Stop / Brake oil low pressure / Brake oil low level /Seat belt / Glow signal / Maintenance /Forward/Reverse switch / Water separator /Over heat / Engine oil low pressure / Air filterrestriction / Transmission oil filter restriction /Hydraulic oil temperature / Transmission oiltemperature•24-volt AM/FM stereo radio with clockOPERATOR'S STATIONNote : * : ROPES (Roll Over Protective Structure) Conforms to ISO 3471;1994** : FOPS (Falling Objects Protective Structure) Conforms to ISO 3449; 1992 Level allCab•ROPS* / FOPS** / Multi-plane isolation mountedfor noise / Vibration reduction / Front and rearwindshield washers / Safety glass•Adjustable armrest•Bi-Level auto air conditioner and pressurize cab•Front / Rear defroster•Hot and cool box•Sun visor•Seat(Grammer), fabric, high back, mechanicalsuspension, adjustable for weight-height, fore-aft•Installation kit for radio, fused 24-volt radio electricallead, speaker (2), and antenna•Theft deterrent PIN control system•Theft deterrent immobilize key systemOPERATOR'S STATION•Seat(Grammer), fabric, high back, air suspension, seatheating, adjustable for weight-height, fore-aft position,backrest tilt, and armrest angle, seat cushion lengthand angle, headrest height and angle adjustment,lumber support•Seat(Kab), fabric, high back, mechanical suspension,adjustable for weight-height, fore-aftposition, backrest tilt, and armrest angle•Headrest for Grammer seat•Headrest for Kab seat•Retractable seat belt, 76 mm•Lever steering<strong>LOADER</strong> LINKAGE•High-lift armBUCKETS AND ATTACHMENTS•General purpose bucket with bolt on teeth : 3.9 m3,4.1m3 (ISO heaped)•General purpose bucket with bolt on cutting edge :4.2m3 (ISO heaped)•Rock bucket with bolt on teeth : 3.4 m3 (ISO heaped)•Quick coupler and hydraulic control system for quickcoupler locking pins, includes all controls in the cab,lines, and valvesStandard equipment may vary by country, so please consult your Hitachi dealer for details.position, backrest tilt, and armrest angle, seat cushionlength and angle, lumber support•Seatback pocket•Retractable seat belt, 50 mm•Large tray and drink holder•Rubber floor mat•Adjustable steering column•Steering wheel, textured with spinner knob•Rear view mirrors, outside (2) and inside (2)•Handrails and steps, ergonomically located and slipresistant•Coat hook<strong>LOADER</strong> LINKAGE•Z-bar loader linkage provides (High bucket breakout)BUCKETS AND ATTACHMENTSFull line of Hitachi pin on buckets with selection of boltoncutting edges, and teeth-segmented bolt on edges•General purpose bucket with bolt-on cutting edges :4.0 m3 (ISO heaped)TIRES•Bias ply :26.5-25-16 PR (L3)•Multi-piece rimsOTHERS•Fenders, front and rear•Articulation locking bar•Anti-vandal protection, includes lockable engineenclosure, and fuel fill•Counterweight, built-in•Drawbar, with rocking pin•Lift and tie-down hooks•Open type rear grillOptional equipment may vary by country, so please consult your Hitachi dealer for details.•Full line of Hitachi buckets for quick coupler withselection of bolt-on cutting edges, and bolt-on teeth•Full line of construction utility forks, and attachments•Fork : Max. load 9 100 kg (Pin on type)•Log grapple : Max. load 9 100 kg (Pin on type)•Fork grapple : Max. load 9 100 kg (Pin on type)TIRES•Bias ply :26.5-25-20PR (L3)•Radial ply :26.5R25 (L3)26.5R25 (L4)26.5R25 (L5)OTHERS•Bucket cylinder rod guard•Auto lubrication system•Heavy counterweight•Additional counterweight (rear mount type)•Bottom guards, front frame and transmission•Full rear fender and mud guard•Rear license plate bracket•Biodegradable hydraulic oil•Fire extinguisher (Dealer installed)•Emergency steering system16 17

<strong>WHEEL</strong> <strong>LOADER</strong>These specifications are subject to change without notice.Illustrations and photos show the standard models, and may or may not include optional equipment,accessories, and all standard equipment with some differences in color and features.Before use, read and understand the Operator’s Manual for proper operation.Hitachi Construction Machinerywww.hitachi-c-m.comKL-EN00306.02 (XD/SO GT3)Printed in Japan

Introducing the New-GenerationWheel Loaders:SeriesTop-Class Production with Amazing MobilityThe new ZW Series wheel loaders are packed with numerous innovative technologiesand mechanisms. Total control of engine and pump torque is an industry's first.Three work modes and three driving modes help enhance operating ease and yieldhigh production. What's more, lots of advanced designs give power and speed forloading and travel.The ZW Series will set a new standard of productive, easy-to-operate wheel loaders.ProductivityThree work modes to increaseproduction and decrease fuelconsumptionThree driving modes for optimum speedshiftAutomatic transmission with loadsensingsystemHigh-torque engine and capacioustorque converterTorque proportioning differentialLimited slip differential (Optional)Smoother simultaneous operations withadvanced hydraulic circuitSelectable clutch cutoff TimingLift arm auto leveler (Optional)Ride control system (Optional)Page 4-7Panoramic comfortable cabBi-level auto air conditioner andpressurized cabFront & rear defrostersLow noise designPanoramic cabEnhanced upward visibilityGood rear visibilityErgonomically positioned switches andcontrolsDown-Shift Switch (DSS) andUp-Shift Switch (USS)Multi-functional joystick lever (Optional)Air suspension seat (Optional)Page 8-9Enhanced DurabilityRobust differential gearsDurable axlesVariable displacement pumpsRobust frameHydraulically operated cooling fan withheat-sensing systemCapacious hydraulic oil coolerProtected fuel tankAluminum radiator and oil coolerLED indicators and instrumentsO-Ring Seal (ORS) joints and waterresistantelectric connectorsPage 10-11Easy MaintenanceExtended hydraulic oil replacementintervalsEasy drainingConveniently located filtersEasy-to-replace air conditioning filtersHN bushingsStrategically located Fuel supply portLarge tool boxEasy-to-read monitorFlat cab floorHinged radiator coverDirt-Less (DL) front framePage 12-13SafetyFull fan guardEmergency steering system (Optional)Mis-operation protectionROPS / FOPS cabHighly reliable dual-line brake systemOther safety featuresPage 14EnvironmentHigh-pressure fuel injection systemHitachi Silent (HS) fanLow noise engineMarking of recyclable partsPage 15SpecificationsPage 16-19The new engine complieswith the Emission RegulationsU.S EPA Tier 3 and EU Stage III AThe advanced low noisedesign complies withthe coming EU noiseregulation 2000 / 14 / EC,STAGE IINote : Pictures may or may not includestandard and optional equipment thatare specified individually by countries.

Packed with Numerous Technological Advances forAmazing Mobility and Big ProductionThe new ZW Series is packed with lots of technological advances: theTT* system, newly developed hydraulic system and transmission, wellmatching of operations, impressive mobility and big production with lessfuel consumption, and much more.*Total Torque-controlThree Work Modes to Increase Production and Decrease Fuel ConsumptionmodeSystemP modeFrontspeedLift armdigging forceTraction forceSlowMediumLargemodeEngineOutputP mode(Power mode)N mode(Normal mode)L mode(Light mode)EngineSpeedN mode L modeFrontspeedLift armdigging forceTraction forcemodeFrontspeedLift armdigging forceTractionforceMediumMediumMediumMediumSmallFastThree work modes are selectableaccording to job needs and operator'spreference. In each work mode, TT*system controls the total torque of theengine and pump for well matchedpenetration force and implement speedaccording to job needs. The three workmodes can be optimally selected tosuit materials to be handled for higherproduction.Three Driving Modes for OptimumSpeed ShiftDriving modeswitchThe three driving modes can be selectedaccording to job needs and operator'spreference.L mode :Starts with the second gear, and makesgear shift at fast timing. Suitable forlong-distance travel on level ground.Work modeselect switchP mode: Heavy-duty excavationN mode: LoadingL mode: Light-duty operationN mode :Starts with the second gear and makesgear shift at slow timing. Suitable forordinary digging and loading operationsuch as V-shaped load and carrymethod.H mode :Makes gear shift at timing similar to theN mode, and automatically shifts downto the first gear according to loadingconditions without need for shift downby DSS* or manual shifting.*Down-Shift SwitchAutomatic Transmission with Load-Sensing SystemLoad increaseAuto shiftdown whenload increasesSpeed increaseShiftup when speedincreasesOptimal speed shift timing isautomatically selected in response toboth travel speed and load.Smooth Speed Shift by ElectronicControlQuick, smooth speed shift canautomatically be done with less shocksby electronic control through helicalgears. This allows speedy job-to-jobtravel with less soil spills in load-andcarryoperation.High-Torque Engine and CapaciousTorque ConverterMax. output : 220 kW (299 PS)Rated output : 216 kW (294 PS)Max. torque : 1 400 N•m (143 kgf•m)The new engine yields big torque ata low speed in direct response toacceleration without need for full throttle.The capacious torque converter enablespowerful travel under heavy load, suchas climbing steep or long hills withoutlosing speed.Torque Proportional Differential(Standard)The torque proportional differentialadjusts driving forces to both wheels.When road resistances under bothwheels are different, this feature preventsslippage of a wheel on softer ground,unlike conventional differentials. Thisfeature enables the ZW series to get outof swamps or rough terrain easily.Limited Slip Differential (Optional)On snowy roads and rough terrain, thelimited slip differential can work insteadof the torque proportional differential.This delivers effective driving force toboth wheels for enhanced grip and lessslippage during travel.

An Array of Elaborate Mechanisms for ImpressiveMobility and Big ProductionImproved Rise / Run PerformanceSophisticated Mechanisms for Higher Job EfficiencyFloat SystemThe float system lets the lift arm followup road irregularities by using its selfweightonly, without using its hydrauliccircuit. This system is useful in soil-spillcollecting during loading, and snowremoving.Bucket Auto LevelerThe bucket can automatically be leveledparallel to the ground after rollingthe bucket out. This can eliminatecumbersome bucket repositioning forefficient loading.Lift Arm Kick-Out SystemThe lift arm can automatically be raisedup to the preset level. This function isconvenient when loading onto a dumptruck, and when operating at confinedjob sites with restricted working height.Lift Arm Auto Leveler (Optional)The lift arm can automatically be raisedand lowered to the preset level. By usingthe switches in the cab, high and low liftkickouts can be programmed.Arm rising while traveling for improved rise / run performance. On the new ZW Series,10% higher rise/run performance can be expected, boosting loading efficiency andincreasing productivity.Smoother Simultaneous Operations with Advanced Hydraulic CircuitWith the new parallel/tandem circuits,the lift arm and bucket can be operatedat the same time, unlike conventionalmachines. This can remarkably increasedigging and loading efficiency for higherproduction.Operator-Friendly Designs for Higher Job EfficiencyRestriction ValveThe restriction valve can effectivelyreduce shocks when moving the lift armup and down. The bucket does not havea shockless circuit to allow efficient mudremoval.Ride Control System (Optional)Vibration without RideControlVibration by Ride Controlby Using Front WeightThe ride control reduces pitching and bouncing during traveling on rough terrain andsnow road by automatic control of the implement. Shocks and vibration can be wellsuppressed for riding comfort.Selectable Clutch Cutoff TimingS modeN modeD modeClutch cutoffpositionswitchClutch cutoff timing can be selectedfrom three positions to suit various jobconditions, including rapid operation onlevel ground, and surefooted operationon gradient.S mode :The clutch is cutoff at fast timing bydepressing the pedal for speedy loadingon level ground.N mode :The clutch is cutoff by depressing thepedal midway for surefooted loading onslope.D mode :The clutch is cutoff by depressing thepedal fully for dumping into a hopper onslope.OFF :The clutch is disabled.

Operator-First Designs:Easy-to-Handle Controls forOperator ComfortPanoramic CabAir Suspension Seat (Optional)The panoramic cab gives almost allroundvisibility with the widened frontglass window and pillar less cab rearcorners. Front wheels are always in theoperator's vision, enhancing safety andincreasing loading efficiency.Bi-Level Auto Air Conditioner andPressurized CabFront / Rear DefrostersShock-Dampened CabSilicone (Fluid)Ergonomically Positioned Switchesand ControlsEnhanced Upward VisibilityThe front curved glass window givesgood upward visibility, so the operatorcan directly see the movement of thebucket for safer loading.Good Rear VisibilityThe engine cover is low profile, androunded for better rear visibility, so theoperator can directly see the rear wheelsand counterweight.The air suspension seat can be adjustedin multiple ways: weight-height, foreaftposition, backrest tilt, and armrestangle, seat cushion length and angle,headrest height and angle adjustment,lumber support. Seat heater is equippedas standard.RubberThe bi-level air conditioner allows airconditioning at foot space and overheadsimultaneously. Airflow volume anddirection can automatically be adjustedaccording to the temperature setting.The pressurized cab shuts out dust anddebris even in dusty environment.Hat (Resin Cab Roof)With the front and rear defrosters,airflow comes out from three front airoutlets and two rear outlets to protectrespective windows from fogging,keeping clear vision even in rain andcold weather.The hollow hat is provided atop the cabto form an air space. This greatly helpsreduce the temperature rise in the cab,and increases the cooling efficiency ofthe air conditioner.The cab rests on fluid-filled elasticmounts to absorb shocks and vibration,and reduce resonance.Low Noise DesignThe cab is well sealed, and the new lownoiseengine is utilized to reduce sound,along with the following measures:•Hydraulically operated cooling fan withheat-sensing system•New Hitachi Silent (HS) fan•Sound-absorbing materials insideengine cover and cab•Clever arrangement of hydraulic oiltank and bulkheadSwitches and controls are efficientlylaid out in the right console for ease ofoperation.Down-Shift Switch (DSS) andUp-Shift Switch (USS)DSS and USS are designed for one-geardown-shift and up-shift at the touch of abutton.An Array of Standard AccessoriesMulti-Functional Joystick Lever(Optional)The multi-functional joystick lever isprovided atop of the control lever foroperating ease.Adjustable Steering ColumnThe steering wheel is tiltable, andtelescopic to suit operator of all buildsfor comfortable operation.Hot and cool box Large tray and drink holder Interior light interacting withcab doorSeatback pocket AM / FM stereo radio Sun visor

Enhanced DurabilityAluminum Radiator and Oil CoolerLED Indicators and InstrumentsO-Ring Seal (ORS) Joints andWater-Resistant Electric ConnectorsDurability is enhanced with a number of advanced mechanisms for long,continuous operation.Dependable Drive SystemHydraulically Operated Cooling Fan withHeat- Sensing SystemThe radiator and oil cooler are made ofaluminum instead of conventional steelor copper for corrosion protection.LEDOn the indicators, monitors and alarms,many LEDs are utilized for longer servicelife resulting in less failure, enhancingthe reliability.Numerous elaborate componentsare utilized for higher durability andreliability. The proven ORS joints andhigh-pressure hydraulic lines are utilizedin the hydraulic system, and waterresistantwiring connectors in theelectrical system.Fan speed can be adjusted dependingon fluid temperature to effectively cooldown coolant, hydraulic oil, transmissionoil and torque converter oil. The resultis extended component service life andreduction in fuel consumption. The fanis also separate from the engine for easyservicing.TransmissionThe transmission can effectively reducethe transmitting load. This helps reducesound and extend service life, enhancingreliability.Robust Differential GearsDifferential gears are thickened toincrease rigidity.Durable AxlesFront and rear axles are improved fordurability. The axle housing is thickenedfor tough operation at quarries.Improved Braking AbilityThe brake is a wet-type multi-platebrake, and housed in the axle.Variable Displacement PumpsNew variable displacement pumps areexclusively developed and designedfor Hitachi wheel loaders for toughearthmoving.Capacious Hydraulic Oil CoolerThe ample cooling capacity of thehydraulic oil cooler helps reduce oiltemperature fluctuation, and extendservice life of components.Robust FrameProtected Fuel TankThe box-section frame is thickened and strengthened to resist torsion and increasedurability. Center pins are widely spaced for higher resistance to torsion.The large counterweight is arranged toprotect the fuel tank from collisions withobstacles during operation.10 11

Reduced Running CostsHN BushingsStrategically Located Fuel Supply PortFlat Cab FloorRunning and maintenance costs are reduced greatly with concentrated inspecting points and durablecomponents.GreaseGrooveThe HN bushing containinghigh-viscosity oil is provided at eachjoint to reduce grease consumption,extend lubrication intervals (100 to 500hours), and increase durability.The fuel supply port is located forconvenient fuel supply from the ground.The cab floor is stepless (flat) for ease ofcleaning.OilLarge Tool BoxReversible Hydraulically OperatedCooling FanNew HN BushingPorePinOil oozed intoclearanceHN BushingThe HN bushing, another exampleof innovative technology developedby Hitachi, features long life and highdurability. High-viscosity oil is vacuumimpregnated in sintered high-hardnessmetal. During operation oil oozesfrom the pores of the bushing into theclearance between pins and bushingproviding lubrication.A large tool box is provided at the topstep of the ladder on the right side of themachine. The tool box can hold a greasegun and tool kit.Easy-to-Read MonitorThe rotation of the hydraulically operatedcooling fan with heat-sensing systemcan be reversed for easy removal ofdirt from the radiator. The fan itself canswing open for easy cleaning.Dirt-Less (DL) Front FrameExtended Hydraulic Oil ReplacementIntervals (Up from 2 000 to 4 000 Hours)Hitachi genuine hydraulic oil canquadruple hydraulic oil replacementintervals. A hydraulic oil drain hose ismounted standard.Conveniently Located FiltersEasy-to-Replace Air Conditioning FiltersExtended Filter Replacement Intervals(250 to 500 Hours)Filter replacement intervals are extendedby increasing engine oil capacity andusing high-performance filters, slashingservicing costs and downtime.Easy DrainingThe engine oil drain port is located forthe convenience of maintenance. Noneed for reaching under the machine.Dual fuel filters with sedimentaryfunction and engine oil filter arestrategically located for the convenientdaily inspection and servicing from theground.The fresh air filter can easily be replacedfrom the cab, and circulation air filteralso replaced by detaching the drinkholder.With the easy-to-read monitor, theoperator can see instructions forscheduled servicing and maintenance.Monitor Indication Items :Clock, fuel consumption, serviceintervals, travel speed, mileage, hourmeterReplacement Alerting : Engine oil /filter, fuel filter, hydraulic oil / filter,transmission oil / filterThe DL front frame is shaped for easyremoval of dirt, stones and snow.12 13

Safety-First DesignEnvironmentally Friendly DesignAchieving a High-Level of Safety in the Working Environmentwith an Array of Advanced MechanismsROPS / FOPS CabThe ROPS / FOPS cab is provided toprotect the operator from injury in anaccident.ROPS : Roll-Over Protective Structure :ISO3471FOPS : Falling Object Protective Structure :ISO3449Highly Reliable Dual-Line Brake SystemThe dual-line hydraulic brake system isutilized: even if one line fails, the othercan work for braking. The brake is anenclosed wet multi-plate type for reliablebraking.A Cleaner MachineThe ZW Series is equipped with a clean but powerful engine to comply with Tier 3 andStage III A. An engine emission regulations effective in the U.S. EPA and EuropeanUnion from 2006. Exhaust gas is partly re-combusted to reduce particulate matter (PM)output and lower nitrogen oxide (NOx) levels.High-Pressure Fuel InjectionSystemAn injection pump and an injector arepaired at each cylinder to inject fuel intothe cylinder at an ultra-high pressure.By electronic control of the governor,fuel injection timing and amount canprecisely be controlled. This helpsreduce (PM) Particulate Matter, nitrogenoxide (NOx) fuel consumption andvibration.Important: The use of fuels other than light oilis prohibited. Otherwise, the engine may bedamaged.A Recyclable MachineApproximately 95% of the ZW Seriescan be recycled. The resin parts aremarked to facilitate recycling. Themachine is completely lead-free. Theradiator and oil cooler are made fromaluminum and all wires are lead-less. Inaddition, bio-degradable hydraulic oilis available for jobsites where specialenvironmental care is required.Full Fan GuardThe cooling fan is enclosed by a fullguard (metal net) to protect servicetechnicians from injury during servicingand maintenance.Emergency Steering System (Optional)The emergency electric pump deliversthe necessary oil pressure for powersteering even in the case of anemergency. This allows normal steeringat all times even if the engine fails.Mis-Operation Protection:Starting Engine : The engine will startonly when the Forward / Reverse leverin neutral.Starting : The transmission is disabledwhen the parking switch is in the ONposition, even if selecting Forward orReverse.Leaving from Operator Seat : Controllevers and Forward / Reverse lever arelocked to prevent accidental operation.Stopping Engine : The spring-set/hydraulic-released parking brake isautomatically applied even if failing toapply it.Other Safety FeaturesRetractable Seat BeltA Quieter MachineA number of features make this machine quieter. First, isochronous control of the enginespeed means a restriction of engine speed during no-load and light-duty operation tosuppress sound. A fan with curved blades reduces air resistance and airflow noise.Third, a time-tested muffler suppresses engine noise significantly and reducesemissions. This advanced low noise design complies with the 2000 / 14 / EC, Stage II,directive effective in the European Union from 2006.Hitachi Silent (HS) FanThe HS fan is capable of reducing airresistance and air flow sound are utilizedat the radiator and oil cooler for quieteroperation.Low Noise EngineThe cylinder block and ladder frame arestrengthened to reduce engine sound.Inclined Ladder14 15

EQUIPMENTENGINEModel .......................... Dimler Chrysler OM460LAType ............................ 4-cycle water-cooled, direct injectionAspiration .................... Turbocharger and intercooledNo. of cylinders ........... 6Maximum powerDIN 6272, net .......... 220 kW (299 PS) at 1 800 min -1 (rpm)SAE J1349, net ....... 220 kW (295 HP) at 1 800 min -1 (rpm)ISO 9249, net .......... 220 kW (295 HP) at 1 800 min -1 (rpm)EEC 80/1269, net ... 220 kW (295 HP) at 1 800 min -1 (rpm)Bore and stroke........... 128 mm X 166 mmPiston displacement .... 12.816 LBatteries ...................... 2 X 12 V / 754 CCA, 294-min. rated reserveAir cleaner ................... Two element dry type with restriction indicatorPOWER TRAINTransmission................Torque converter,countershaft type powershiftwith computer-controlled automatic shift andmanual shift features included.Torque converter.......... Three element, single stage, single phaseMain clutch.................. Wet hydraulic, multi-disc typeCooling method........... Forced circulation typeTravel speed* (km/h) Forward / Reverse1st............................... 7.0 / 7.02nd.............................. 11.8 / 11.83rd............................... 21.8 / 21.84th............................... 34.5 / 34.5*With 26.5-25-16PR (L3) tiresAXLE AND FINAL DRIVEDrive system................ Four-wheel drive systemFront & rear axle........... Semi-floatingFront............................ Fixed to the front frameRear............................. Trunnion supportReduction anddifferential gear............ Two stage reduction with torque proportionaldifferentialOscillation angle........... Total 26˚ (+13˚,-13˚)Final drives................... Heavy-duty planetary, mounted inboardTIRES (tubeless,nylon body)Drive system................ 26.5-25-16PR (L3)Optional....................... Refer to standard & optional equipment listBREAKSService brakes.............Inboard mounted fully hydraulic 4 wheel wetdisc brake. Front & rear independent brakecircuitSTEERING SYSTEMType............................. Articulated frame steeringSteering mechanism.... Refer to standard & optional equipment listSteering angle.............. Each direction 40˚ ; total 80˚Cylinders...................... Two double-acting piston typeNo. x Bore x Stroke... 2 x 70 mm x 542 mmMinimum turningradius at the centerlineof outside tire............... 5 900 mmHYDRAULIC SYSTEMArm and bucket are controlled by independent control leverArm controls................ Four position valve ; Raise, hold, lower, floatBucket controls with automaticbucket return-to-dig control..... Three position valve ; Roll back, hold, dumpMain pump / Steering pump.... Variable Displacement Axial Plunger PumpCharging pump / Fan pump /Brake and assist pump............ Fixed Displacement Type Gear PumpHydraulic cylindersType.......................... Two arm and one bucket, double acting typeNo. x Bore x Stroke... Arm : 2 x 145 mm x 930 mmBucket : 1 x 185 mm x 510 mmFilters........................... Full-flow 15 micron return filter in reservoirHydraulic cycle timesLift arm raise............. 5.8 sLift arm lower............ 3.0 sBucket dump............ 1.4 sTotal.......................... 10.2 sSERVICE REFILL CAPACITIESlitersFuel tank.................................................................................... 382.0Engine coolant........................................................................... 59.0Engine oil................................................................................... 39.0Torque convertor & transmission................................................ 25.0Front axle differential & wheel hubs............................................ 48.0Rear axle differential & wheel hubs............................................. 48.0Hydraulic oil tank....................................................................... 128.0STANDARD EQUIPMENTENGINE•Coolant recovery tank•Hydraulically Operated Cooling Fan with Heat SensingSystem•Fan guard•Muffler, under hood with large exhaust stack•Environmentally friendly engine oil drain•Engine oil cooler•Quick-release fuel filter and water separator•Glow system (For cold start)•Air filter double element•Fuel double filter•TT (Total Torque-control) systemPOWER TRAIN•Automatic Transmission with Load-SensingSystem•DSS (Down-Shift Switch) and USS (Up-Shift Switch)•Torque proportioning differentials, front and rear•Driving mode selector switch, three modes•Clutch cut-off position switch, three positionHYDRAULIC SYSTEM•TT (Total Torque-control) system•Bucket auto leveler•Lift arm kick-out system•Float system•Reservoir sight gauge•Hydraulic filters, vertical mounting•Two-spool main control valve•O-Ring Seal jointsELECTRICAL•24-volt electrical system•Standard batteries (2), 12-volt with 754 CCA,294-min. rated reserve•Alternator, 50 A and 24-voltsOPTIONAL EQUIPMENTENGINE•Air pre-cleanerPOWER TRAIN•Limited slip differentialHYDRAULIC SYSTEM•Three-spool main control valve•Four-spool main control valve•Third spool piping•Third and fourth spool piping•Multi-function joystick lever•Two-lever and auxiliary lever for third function•Two-lever and auxiliary joystick-lever for third &fourth function•Multi-function joystick lever and auxiliary leverfor third function•Multi-function joystick lever and auxiliary joystickleverfor third & fourth function•Ride control system, automatic type•Lift arm Auto LevelerELECTRICAL•High-capacity batteries (2), 12-volt with 924 COCA,421-min. rated reserve•Alternator, high capacity, 90 A and 24-volts•Front Working Lamps on Cab (2)•Rear Working Lamp on Cab (2)•12-volt outlet•24-volt AM/FM stereo radio with clock•24-volt AM/FM stereo radio with cassetteplayer and clock•LightsDriving with guards / Turn signals withhazard switch / stop, tail and back-up lights•Work lights on cab, front (2)•Work lights, rear (2)•Horn, with push button in center of steering wheeland switch on joystick lever knob or right console•Reverse warning alarm•Monitor and alarm system, multi-function electronicaudible and visual warning include•LCD monitor display: Speedometer / Clock /Hour-meter / Fuel consumption / Odometer /Replacement intervals / Transmission Auto /Clutch cutoff / Ride control / Gear shift•Gauges: Engine coolant temperature /Transmission oil temperature / Fuel level•Warning lights: Engine / Transmission /Discharge warning•Indicator lights: Turn signals / High beam /Working lights / Service / Parking brake /Stop / Brake oil low pressure / Brake oil low level /Seat belt / Glow signal / Maintenance /Forward/Reverse switch / Water separator /Over heat / Engine oil low pressure / Air filterrestriction / Transmission oil filter restriction /Hydraulic oil temperature / Transmission oiltemperature•24-volt AM/FM stereo radio with clockOPERATOR'S STATIONNote : * : ROPES (Roll Over Protective Structure) Conforms to ISO 3471;1994** : FOPS (Falling Objects Protective Structure) Conforms to ISO 3449; 1992 Level allCab•ROPS* / FOPS** / Multi-plane isolation mountedfor noise / Vibration reduction / Front and rearwindshield washers / Safety glass•Adjustable armrest•Bi-Level auto air conditioner and pressurize cab•Front / Rear defroster•Hot and cool box•Sun visor•Seat(Grammer), fabric, high back, mechanicalsuspension, adjustable for weight-height, fore-aft•Installation kit for radio, fused 24-volt radio electricallead, speaker (2), and antenna•Theft deterrent PIN control system•Theft deterrent immobilize key systemOPERATOR'S STATION•Seat(Grammer), fabric, high back, air suspension, seatheating, adjustable for weight-height, fore-aft position,backrest tilt, and armrest angle, seat cushion lengthand angle, headrest height and angle adjustment,lumber support•Seat(Kab), fabric, high back, mechanical suspension,adjustable for weight-height, fore-aftposition, backrest tilt, and armrest angle•Headrest for Grammer seat•Headrest for Kab seat•Retractable seat belt, 76 mm•Lever steering<strong>LOADER</strong> LINKAGE•High-lift armBUCKETS AND ATTACHMENTS•General purpose bucket with bolt on teeth : 3.9 m3,4.1m3 (ISO heaped)•General purpose bucket with bolt on cutting edge :4.2m3 (ISO heaped)•Rock bucket with bolt on teeth : 3.4 m3 (ISO heaped)•Quick coupler and hydraulic control system for quickcoupler locking pins, includes all controls in the cab,lines, and valvesStandard equipment may vary by country, so please consult your Hitachi dealer for details.position, backrest tilt, and armrest angle, seat cushionlength and angle, lumber support•Seatback pocket•Retractable seat belt, 50 mm•Large tray and drink holder•Rubber floor mat•Adjustable steering column•Steering wheel, textured with spinner knob•Rear view mirrors, outside (2) and inside (2)•Handrails and steps, ergonomically located and slipresistant•Coat hook<strong>LOADER</strong> LINKAGE•Z-bar loader linkage provides (High bucket breakout)BUCKETS AND ATTACHMENTSFull line of Hitachi pin on buckets with selection of boltoncutting edges, and teeth-segmented bolt on edges•General purpose bucket with bolt-on cutting edges :4.0 m3 (ISO heaped)TIRES•Bias ply :26.5-25-16 PR (L3)•Multi-piece rimsOTHERS•Fenders, front and rear•Articulation locking bar•Anti-vandal protection, includes lockable engineenclosure, and fuel fill•Counterweight, built-in•Drawbar, with rocking pin•Lift and tie-down hooks•Open type rear grillOptional equipment may vary by country, so please consult your Hitachi dealer for details.•Full line of Hitachi buckets for quick coupler withselection of bolt-on cutting edges, and bolt-on teeth•Full line of construction utility forks, and attachments•Fork : Max. load 9 100 kg (Pin on type)•Log grapple : Max. load 9 100 kg (Pin on type)•Fork grapple : Max. load 9 100 kg (Pin on type)TIRES•Bias ply :26.5-25-20PR (L3)•Radial ply :26.5R25 (L3)26.5R25 (L4)26.5R25 (L5)OTHERS•Bucket cylinder rod guard•Auto lubrication system•Heavy counterweight•Additional counterweight (rear mount type)•Bottom guards, front frame and transmission•Full rear fender and mud guard•Rear license plate bracket•Biodegradable hydraulic oil•Fire extinguisher (Dealer installed)•Emergency steering system16 17

EQUIPMENTDIMENSIONS & SPECIFICATIONSmemo40°G40°H'HFCIJKNM4°LEDA'A30°BStandard ArmHigh lift Arm*Bucket typeGeneral PurposeRock BucketGeneralPurposeBolt-on TeethBolt-on CuttingedgeBolt-on TeethBolt-on CuttingedgeBolt-on TeethBolt-on CuttingedgeBucket capacityISO heaped m 3 3.9 4.0 4.1 4.2 3.4 3.6ISO struck m 3 3.3 3.4 3.5 3.6 2.9 3.1A Overall length mm 8 945 8 760 8 990 8 805 8 880 9 145A' Overall length (Traveling figure) mm 8 945 8 715 8 865 8 740 8 790 9 090B Overall height mm 8 465C Width over tires mm 3 010D Wheel base mm 3 450E Ground clearance mm 485F Tread mm 2 300G Bucket width mm 3 150 3 150 3 150 3 150 3 150 3 150H Turning radius (Centerline of outside tire) mm 5 900 5 900 5 900 5 900 5 900 5 900H' Loader clearance circle, bucket in carry position mm 7 020 6 970 7 040 6 980 7 010 7 060I Overall operating height mm 5 900 5 900 5 940 5 940 5 890 6 290J Height to bucket hinge pin, fully raised mm 4 395 4 395 4 395 4 395 4 395 4 850K Dumping clearance 45 degree, full height mm 3 000 3 130 2 960 3 100 3 040 3 640L Reach, 45 degree dump, full height mm 1 290 1 180 1 330 1 210 1 250 1 180M Digging depth (Horizontal digging angle) mm 120 110 120 110 120 110N Max. roll back at carry position deg 50StraightkN 173170172170168152(kgf) (17 600) (17 350) (17 550) (17 300) (17 100) (15 550)Static tipping load *Full 40 degree turnkN(kgf)kN(kgf)149(15 200)147(14 950)149(15 150)146(14 900)144(14 700)131(13 400)Breakout force213198193192225181(21 780) (20 200) (19 640) (19 550) (22 960) (18 500)Operating weight * kg 22 280 22 370 22 320 22 410 22 740 23 280Note:1. All dimensions,weight and perfomance data based on ISO 6746-1:1987,ISO 7137:1997 and ISO 7546:19832.Static tipping load and operating weight marked with* include 26.5-25-16PR (L3) tires (No ballast) with lubricants, full fuel tank and operator.Machine stability and operating weight depend on counterweight, tire size and other attachments.High lift Arm specification are included heavy counterweight.BUCKET SELECTION GUIDE18 19

<strong>WHEEL</strong> <strong>LOADER</strong>These specifications are subject to change without notice.Illustrations and photos show the standard models, and may or may not include optional equipment,accessories, and all standard equipment with some differences in color and features.Before use, read and understand the Operator’s Manual for proper operation.Hitachi Construction Machinerywww.hitachi-c-m.comKL-EN00306.02 (XD/SO GT3)Printed in Japan