Rio-Carb-The Product.cdr

Rio-Carb-The Product.cdr

Rio-Carb-The Product.cdr

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

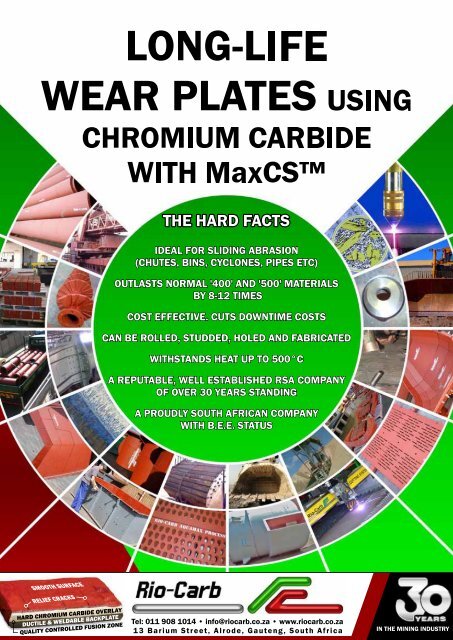

SMOOTH SURFACERELIE FCRACKSHA RD CHROMIU M CARBID EOVERLAYDUCTIL E & WELDA BLE BACKPLATEQUALITY CONTROLLED FUSION ZONETel: 011 908 1014 • info@riocarb.co.za • www.riocarb.co.za13 Barium Street, Alrode, Gauteng, South Africa IN THE MINING INDUSTRY

<strong>Rio</strong>-<strong>Carb</strong> CRC LONG-LIFE WEAR PLATESDescription and SketchEXPLORING THE WONDERS OF CHROMIUM CARBIDE(CrC) LONG-LIFE WEAR PLATESChromium <strong>Carb</strong>ide (CrC) alloys have wonderful properties:•<strong>Rio</strong>-<strong>Carb</strong> exploits this to the full with its MaxCS development•<strong>Rio</strong>-<strong>Carb</strong> liners have a combination of abrasion resistant Chromium <strong>Carb</strong>idealloy, fused onto a ductile and weldable mild steel base plate•<strong>The</strong> CrC alloy consists of CrC particles suspended in a hard and stable matrix•<strong>The</strong> carbide hardness is approx 1800 VPN•<strong>The</strong> matrix is 450 Brinell, giving a macro-hardness of 56-58 Rc•<strong>The</strong> relief checks are desirable and indicate there is no cracking away of thehard layer from the mild steel base<strong>The</strong>re is no commercial steel product available that equals the wear protectionand cost effectiveness of our CrC + MaxCSSMOOTH SURFACERELIEF CRACKSHAR D CHROMIU M CARBID E OVERLAYDUCTILE & WELDABLE BACKPLATEQUALITY CONTROLLED FUSION ZONESMOOTH SURFACERELIE FCRACKSHA RD CHROMIU M CARBID EOVERLAYDUCTIL E & WELDA BLE BACKPLATEQUALITY CONTROLLED FUSION ZONETel: 011 908 1014 • info@riocarb.co.za • www.riocarb.co.za13 Barium Street, Alrode, Gauteng, South Africa IN THE MINING INDUSTRY

<strong>Rio</strong>-<strong>Carb</strong> CRC LONG-LIFE WEAR PLATESTable of PropertiesHardnessCo-efficient of frictionWear RateChemistry (CrC)Backing PlateBending RatioPlate SizesThicknesses AvailableMass: 56 - 58 Rc: μ 0.195 Rc (CrC on polished Mild Steel): 17.3 mm³ (ASTM G-65) ("400" is 162.3mm³): Nominally 24% Chromium : 4% <strong>Carb</strong>on plus Manganese,Silicon and other elements up to 4% - Nickel Free: Typically 300WA Mild Steel: Min. Radius = 40 x thickness overall: 1.5m x 3.0m = 4.5m² usable area: See table below: See table below (same as mass of mild steel @ 7.9 SG)OVERALLPLATETHICKNESSin mmDESCRIPTIONABackingPlatesbeforeWelding inmmBThicknessofHardfaceCladdingin mmCM.S.BackingPlate afterWelding inmmCrCEffectiveHardfaceThicknessin mmMasskg/m²m²/Tonne8 4/4 6 4 4 4 64 15.610 4/6 8 4 6 4 80 12.512 6/6 8 6 6 6 96 10.416 8/8 10 8 8 8 128 7.820 10/10 12 10 10 10 160 6.224 12/12 16 12 12 12 192 5.2SMOOTH SURFACERELIE FCRACKSHA RD CHROMIU M CARBID EOVERLAYDUCTIL E & WELDA BLE BACKPLATEQUALITY CONTROLLED FUSION ZONETel: 011 908 1014 • info@riocarb.co.za • www.riocarb.co.za13 Barium Street, Alrode, Gauteng, South Africa IN THE MINING INDUSTRY

<strong>Rio</strong>-<strong>Carb</strong> CrC LONG-LIFE WEAR PLATESTMMaxCSA unique aspect, <strong>Rio</strong>-<strong>Carb</strong>'s winning formulaChromium <strong>Carb</strong>ide alloys have wonderful properties. <strong>The</strong>y arecost-effective, extremely hard (1800 V.P.N.), heat resistant(up to 500°C), and when deposited by weld cladding have ahardness of 56-58 Rc.But this is not the final story. Controlling the cooling rateafter weld cladding, results in the CrC Crystals growing intovertical dendrites (or columns of crystals, all facing upwards).When attacked by wear, these CrC Crystals perform like thebristles on a brush. Long-lasting. <strong>The</strong> close packaging ofthese dendrites is also promoted during cooling.Couple these properties to the sub-arc depositing systemduring the plate manufacture with the flat-bed welding basewith water cooling and we have MaxCS (Maximum <strong>Carb</strong>ideSaturation).Our CrC liners contain 24-25% Chromium. This is 12 to 15times the amount of Chromium in "400" & "500" Q+Tmartensitic steels!Hence the price increase for CrC, but consider the extendedwear-life of 8-10 times against martensitic plates.Same dendrites viewed from the top.Imagine the "toothbrush" effectVertical dendrites (columns of CrC Crystals)viewed from the side.HARDNESS IS NOT EVERYTHING!Two samples from the Sand-Rubber WheelAbrasion test clearly shows the extra wear onsample (A) at 58 - 62 Rc Hardness.<strong>The</strong> sample (B) at 50-54 Rc shows less wearand abrasion, despite being softer.<strong>The</strong> answer: Sample (B) is <strong>Rio</strong>-<strong>Carb</strong> CrC platewith MaxCS.<strong>The</strong> higher carbide saturation of MaxCSextends the wear life.MaxCS is a Registered TrademarkSMOOTH SURFACERELIE FCRACKSHA RD CHROMIU M CARBID EOVERLAYDUCTIL E & WELDA BLE BACKPLATEQUALITY CONTROLLED FUSION ZONETel: 011 908 1014 • info@riocarb.co.za • www.riocarb.co.za13 Barium Street, Alrode, Gauteng, South Africa IN THE MINING INDUSTRY

Stud Welding30% BETTER THAN COUNTERSUNK HOLESFlash welding at 1200amps for ½ a secondTest demonstrating thestrength of stud (M16)Finished stud witha nut and washerStuds positioned within2mm - for easy installing.Advantages are:1. Excellent strength.2. Smoother surface finish than inserts and Nib-Head Countersunk bolts.3. Easier to install.4. Easier to remove as rusted threads do not have to be flame-cut off.5. Studs can be placed with an accuracy of 2mm.6. Rust protected threads make assembly easy.7. Cheaper than holes, and no need to purchase Nib-Head bolts, washers and nuts.Disadvantages are:Studs can be damaged in transit. However, <strong>Rio</strong>-<strong>Carb</strong> will palletize liner plates such thatthey are not easily damaged during transporting.Stud-Welded Liner Plate GuidelinesFitting: Liners are marked on the Hard-faced Side with the same mark as the drawings.Nuts, and washers are supplied with the liners. Liners can also be permanently plasmaetched on the back, upon request.Tightening: Where it is not practical to "torque" each bolt, a typical 300 - 350mm longring-spanner pulled until "snug" is adequate. (<strong>The</strong>re is a washer to prevent detaching).Protection: <strong>The</strong> threads are protected, which assists de-mounting, even years later,and this can also be done by one person only, on the outside of the chute.Breakages: Should a Stud break-off due to mishandling, or over-tightening, it may bere-welded with a Mild Steel Electrode 2.4mm or 3.2mm dia. (<strong>The</strong> Stud and the backingplate are both weldable mild steel.)SMOOTH SURFACERELIE FCRACKSHA RD CHROMIU M CARBID EOVERLAYDUCTIL E & WELDA BLE BACKPLATEQUALITY CONTROLLED FUSION ZONETel: 011 908 1014 • info@riocarb.co.za • www.riocarb.co.za13 Barium Street, Alrode, Gauteng, South Africa IN THE MINING INDUSTRY

<strong>Rio</strong>-<strong>Carb</strong> CrC Welding ElectrodesChromium <strong>Carb</strong>ide compatibleA heavily coated Chromium <strong>Carb</strong>ide (CrC) electrode for hard-facing ofequipment and machinery components exposed to high abrasion.This electrode has excellent welding properties and with smooth beadsurfaces.High deposition rates and 160% metal recovery for cost effectiveness.Deposit can be machined by grinding only.Also designed for use on <strong>Rio</strong>-<strong>Carb</strong> long-life wear plates.May be deposited directly onto mild steel or over previously hard-facedareas. Not more than 3 runs should be applied, otherwise a “buffer”layer of stainless steel (304 or 312) should be used.Useful for re-enforcing high wear areas.Ideal for bull-nosing / edge welding of <strong>Rio</strong>-<strong>Carb</strong> CrC wear plates.ie: Where edges are exposed to wear such as; vibrating feeders’outflow, and other areas where the mild steel backing may be eroded.Uses:WeldingParameters:Chemistry(after 2 weld runs):Crushers, chutes, fans, cyclones,earth-moving equipment and anywear part subjected to sliding orgouging action. Moderate impact.Amperage 130-160 D.C. +(positive) or A.C. (4mm diameter)Chromium 28%<strong>Carb</strong>on 4.5%Other elements 3%Specifications: AWS E Fe Cr-A1DIN E10-UM-60-RHardness: 58-60 Rc (after 2 weld runs)Storage: Keep dry. Re-bake at 120°C for 2hours if porosity occurs in theweld metal from damp electrodesSMOOTH SURFACERELIE FCRACKSHA RD CHROMIU M CARBID EOVERLAYDUCTIL E & WELDA BLE BACKPLATEQUALITY CONTROLLED FUSION ZONETel: 011 908 1014 • info@riocarb.co.za • www.riocarb.co.za13 Barium Street, Alrode, Gauteng, South Africa IN THE MINING INDUSTRY

Hi-Precision Plasma CuttingOur Hi Precision Plasma Cutter is in full swing.Catering for record order levels (Yes: Good News in Hard Times) thewisdom of purchasing this state-of-the-art equipment is paying off.Fits 100% every time!No fitting problemsCannot come looseNo edge gapsWeld-on studs also availableStuds plasma placed with N.C accuracyEdge at 90°. Minimal gaps.Sized to ½ mm.Holes or studs positioned to 1mm.Repeatable to ½mm.Each liner Plasma Engraved with Part Number.Thickness to ½mm.Flatness to 1mm overall.Ultra smooth countersunk holes with machined insertsSpecifications of CrC LinersAll dimensions within ½mmAll holes within ½mm accuracyFlatness within 2mm over 500mmWith MaxCS and Hi.P.P. (Hi Precision Plasma)<strong>Rio</strong>-<strong>Carb</strong>'s unique deposit process and bead-bonding,eliminates the "direction of flow" problemCan also be cut with AquaJet Water Process for veryaccurate requirements i.e. Fan BladesSMOOTH SURFACERELIE FCRACKSHA RD CHROMIU M CARBID EOVERLAYDUCTIL E & WELDA BLE BACKPLATEQUALITY CONTROLLED FUSION ZONETel: 011 908 1014 • info@riocarb.co.za • www.riocarb.co.za13 Barium Street, Alrode, Gauteng, South Africa IN THE MINING INDUSTRY