KEEPING THE MIDDLE EAST MOvING - TRENCHLESS MIDDLE ...

KEEPING THE MIDDLE EAST MOvING - TRENCHLESS MIDDLE ...

KEEPING THE MIDDLE EAST MOvING - TRENCHLESS MIDDLE ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CONFERENCE PROGRAMME<br />

REGISTRATION DETAILS<br />

EXHIBITOR INFORMATION<br />

Bringing you the latest in trenchless technology<br />

& land–based utility pipeline engineering<br />

Trenchless Middle East Edition. October 2011<br />

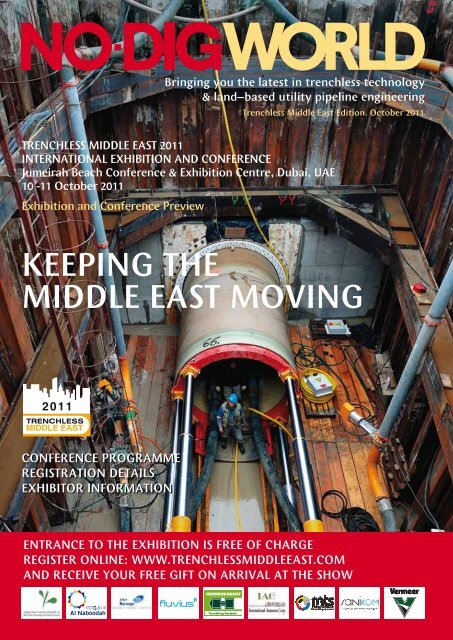

<strong>TRENCHLESS</strong> <strong>MIDDLE</strong> <strong>EAST</strong> 2011<br />

INTERNATIONAL EXHIBITION AND CONFERENCE<br />

Jumeirah Beach Conference & Exhibition Centre, Dubai, UAE<br />

10 -11 October 2011<br />

Exhibition and Conference Preview<br />

<strong>KEEPING</strong> <strong>THE</strong><br />

<strong>MIDDLE</strong> <strong>EAST</strong> <strong>MOvING</strong><br />

2011<br />

ENTRANCE TO <strong>THE</strong> EXHIBITION IS FREE OF CHARGE<br />

REGISTER ONLINE: WWW.<strong>TRENCHLESS</strong><strong>MIDDLE</strong><strong>EAST</strong>.COM<br />

AND RECEIvE YOUR FREE GIFT ON ARRIvAL AT <strong>THE</strong> SHOW

organised by<br />

Publisher<br />

Paul Harwood<br />

T + 44 (0) 845 094 8066<br />

E pharwood@westrade.co.uk<br />

Advertising<br />

Stuart Hillyard<br />

Gary King<br />

T + 44 (0) 845 094 8066<br />

E shillyard@westrade.co.uk<br />

design & Production<br />

Trevor Dorrell<br />

T + 44 (0) 845 094 8066<br />

E trevor@frontpagepublishing.co.uk<br />

The publishers accept no responsibility in respect of<br />

advertisements appearing in the magazine and the<br />

opinions expressed in editorial material or otherwise do<br />

not necessarily represent the views of the publishers.<br />

The publishers accept no responsibility for actions<br />

taken on the basis of any information contained<br />

within this magazine. The publishers cannot accept<br />

liability for any loss arising from the late appearance<br />

or non-publication of any advertisement for any reason<br />

whatsoever.<br />

ISSN 1479-0815<br />

2011<br />

International Society<br />

For Trenchless Technology<br />

trenchless middle eAst is<br />

organised by<br />

WESTRADE GROUP LTD<br />

Westrade group ltd,<br />

112-114 high street,<br />

rickmansworth, herts,<br />

Wd3 1AQ uK<br />

tel: +44 (0) 845 094 8066<br />

fax: +44 (0) 870 429 9275<br />

Web: www.westrade.co.uk<br />

sponsors<br />

Welcome.....<br />

I am very pleased to welcome you to the fourth issue of NO-DIG WORLD, a<br />

publication that doubles as the Show Guide to the upcoming <strong>TRENCHLESS</strong><br />

<strong>MIDDLE</strong> <strong>EAST</strong> 2011 event being held at the Jumeirah Beach Conference &<br />

Exhibition Centre, Dubai, UAE on 10 - 11 October 2011, supported by The<br />

International Society for Trenchless Technology (ISTT) and the Institution of<br />

Civil Engineers (ICE).<br />

Known also as No-Dig technology and as NDRC (Non Disruptive Road<br />

Crossing) in the Gulf region, Trenchless Technology embraces techniques<br />

from micro tunnelling and directional drilling to pipe bursting, lining and inspection systems,<br />

aimed at minimising or eliminating the need for disruptive excavations whilst providing a quick,<br />

efficient and economical solution to the construction and renovation of sewers, water mains,<br />

electricity cables and telecommunications networks.<br />

This is a developing global Industry. Products and techniques are reviewed and improved<br />

on a regular basis. New innovations are proven to enhance performance. Major projects are<br />

completed every day somewhere around the world, proving that trenchless techniques provide<br />

economic solutions and reduced environmental impact. The social costs are reduced, benefiting<br />

communities, as well as the travelling public.<br />

The two day exhibition will be complemented by a conference programme, assembled in<br />

collaboration with the International Society for Trenchless Technology (ISTT). The conference will<br />

include presentations by local and international speakers, thus providing an exciting platform for<br />

delegates to learn, debate, share knowledge, benchmark, and network with like minded industry<br />

colleagues.<br />

We, here at Westrade, are specialist organisers of shows focused on promoting the latest<br />

equipment and techniques used in Trenchless Technology which is now becoming the preferred<br />

option for utility installation and repair, designed to keep traffic on the move.<br />

If you haven’t yet planned your visit to Trenchless Middle East, don’t miss this opportunity to<br />

come and see this unique line-up of products on display from exhibitors worldwide, and talk to the<br />

experts who can provide solutions to the challenges ahead.<br />

For all information on how to get here and where to stay, visit our website<br />

www.trenchlessmiddleeast.com I am sure you will find time invested here will be both profitable<br />

and enjoyable.<br />

The success of Trenchless Middle East is of course dependant on the support of the industry.<br />

We offer our thanks to all exhibitors for their participation and professional displays and of course<br />

to our sponsors. Their commitment and support to the event is greatly appreciated.<br />

Paul Harwood<br />

Sales and Marketing Director<br />

Westrade Group Ltd.<br />

contents<br />

conference ProgrAmme And timetAble PAge 24 - 25<br />

eXhibition floor PlAn PAge 26<br />

eXhibitor Profiles PAge 27<br />

Product guide PAge 32

full house At<br />

trenchless middle eAst 2011, dubAi<br />

I am very pleased to welcome you to<br />

the fourth issue of NO-DIG WORLD, a<br />

publication that doubles as the Show<br />

Guide to the upcoming <strong>TRENCHLESS</strong><br />

<strong>MIDDLE</strong> <strong>EAST</strong> 2011 Exhibition and<br />

Conference being held at the Jumeirah<br />

Beach Conference & Exhibition Centre in<br />

Dubai, UAE, on 10 -11 October 2011.<br />

Known also as No-Dig and also as<br />

NDRC (Non Disruptive Road Crossing) in<br />

the Gulf region, Trenchless Technology<br />

embraces techniques from micro<br />

tunnelling and directional drilling, to pipe<br />

bursting, lining and inspection systems,<br />

aimed at minimising or eliminating<br />

the need for disruptive excavations<br />

whilst providing a quick, efficient and<br />

economical solution to the construction<br />

and renovation of sewers, water mains,<br />

electricity cables and telecommunications<br />

networks.<br />

This is a developing global Industry.<br />

Products and techniques are reviewed<br />

and improved on a regular basis. New<br />

innovations are proven to enhance<br />

performance. Major projects are completed<br />

every day somewhere around the world,<br />

proving that trenchless techniques<br />

provide economic solutions and reduced<br />

environmental impact. The social costs are<br />

minimised, benefitting communities, as<br />

well as the travelling public.<br />

The two day exhibition will be<br />

complemented by a top quality<br />

conference programme, assembled in<br />

collaboration with the International Society<br />

for Trenchless Technology (ISTT). The<br />

conference will include presentations by<br />

local and international speakers, thus<br />

providing an exciting platform for delegates<br />

to learn, debate, share knowledge,<br />

benchmark, and network with like minded<br />

industry colleagues.<br />

We, here at Westrade, are specialist<br />

organisers of shows focused on promoting<br />

the latest equipment and techniques used<br />

in Trenchless Technology which is rapidly<br />

becoming the preferred option for utility<br />

installation and repair around the world.<br />

If you haven’t yet planned your visit to<br />

<strong>TRENCHLESS</strong> <strong>MIDDLE</strong> <strong>EAST</strong> 2011, don’t<br />

miss this opportunity to come and see<br />

this unique line-up of products on display<br />

from exhibitors worldwide, and talk to the<br />

experts who can provide solutions to the<br />

challenges ahead.<br />

For all information on how to get here<br />

and where to stay, visit our website<br />

www.trenchlessmiddleeast.com I am sure<br />

you will find time invested here will be<br />

both profitable and enjoyable.<br />

The success of Trenchless Middle East<br />

is of course dependant on the support of<br />

the industry.<br />

We offer our thanks to The International<br />

Society (ISTT) for their support, as well as<br />

their advice and assistance in compiling<br />

our Conference programme. We also<br />

welcome the support of The Institution<br />

of Civil Engineers (ICE) and we welcome<br />

their members to the event. Last but by<br />

no means least, we acknowledge the huge<br />

support from our sponsors and exhibitors.<br />

See you at the show in Dubai, 10-11<br />

October!<br />

2011<br />

4 No-Dig World 2011 www.trenchlessmiddleeast.com<br />

rehAbilitAtion ProJect<br />

in Kingdom of sAudi ArAbiA<br />

International Aramoon Corp (IAC), is the first Trenchless<br />

Technology specialized local contractor in Saudi Arabia.<br />

The CEO & President of IAC, Faiz Al-Elweet reports that<br />

IAC has recently completed a rehabilitation project in<br />

KSA for The Water Authority of Eastern Province. The<br />

client was facing severe problems in their gravity sewers<br />

(600mm and 700mm pipelines).<br />

CCTV inspection work in progress<br />

IAC were called upon to discuss the project and<br />

perform inspection & condition assessment for the<br />

gravity sewers, including providing services for pipeline<br />

rehabilitation works. The pipeline material was ductile<br />

iron with a total length of 2300m. The pipes were<br />

located at an average depth of 4m below the ground<br />

surface in Dammam City - KSA.<br />

CCTV inspection during cleaning process<br />

Extensive cleaning was made to facilitate the CCTV<br />

robotic inspection and as a result, several problems<br />

were identified in the pipelines, such as infiltration, wall<br />

incrustations, partial blockages, severe corrosion.<br />

IAC combined Jet-Vacuum Truck ready for<br />

cleaning works<br />

After evaluation and condition assessment, IAC<br />

recommended No-Dig pipe rehabilitation using CIPP-UV<br />

system for the gravity sewer pipelines in order to restore<br />

the 100% hydraulic efficiency and structural strength of<br />

the pipelines.<br />

IAC employee prepares for working in confined<br />

space (Manhole)<br />

BKP Berolina-Liner System, the CIPP-UV system<br />

supplier of equipment, liners and training, had made<br />

the structural calculation and liner design based on the<br />

information provided by IAC.<br />

eXhibitor neWs<br />

During the preparation and installation of CIPP-UV<br />

system IAC had given very careful attention for safety<br />

precautions especially when rehabilitating sewer<br />

infrastructure in heavy traffic areas.<br />

Liner material installation<br />

The CIPP-UV system is designed for fast and efficient<br />

onsite installation that minimizes the economic, social<br />

and environmental impacts. IAC is well prepared to meet<br />

the demand in the Region and has the full capability to<br />

undertake such No-Dig repair & rehabilitation works of<br />

wastewater network for the clients. n<br />

Site engineer operates & controls the UV<br />

curing system<br />

www.aramoon.com<br />

general@aramoon.com<br />

www.trenchlessmiddleeast.com No-Dig World 2011 5

eXhibitor neWs eXhibitor neWs<br />

vermeer neW technology<br />

A new technology is entering the guided<br />

boring industry, primarily focused on gravity<br />

sewer installations. The AXIS Guided<br />

Boring System is capable of achieving<br />

pinpoint line and grade accuracy in a variety<br />

of ground conditions, and for many different<br />

pipe sizes and materials.<br />

A recent project was the successful<br />

installation of a 153m section of 450mm<br />

HDPE pipe. The goal was to eliminate a<br />

pump station and convert the existing sewer<br />

from a forced main to gravity flow. The<br />

topography in the area, which included<br />

very hilly terrain, a stream, and existing<br />

wet well elevations raised many concerns.<br />

The greatest challenge, however, wasn’t<br />

the topography. The line would be bored<br />

through layered shale and limestone rock.<br />

A 343mm cutter was used for the pilot<br />

bore, and the AXIS system achieved an average<br />

production rate of 4.3m per hour. Though<br />

the pilot alone could have been considered<br />

a challenge, the real test was yet to come.<br />

Rock bores had been completed for smaller<br />

pipe installations, but prior to this project, the<br />

system had not been used to upsize in rock.<br />

In order to install the HDPE with an OD of<br />

470mm, a larger hole would need to be cut,<br />

while still maintaining the perfect line and<br />

grade achieved on the pilot shot.<br />

Requiring a minimum over-cut due to<br />

bursting With roPe<br />

ABS Trenchless has introduced<br />

the rope bursting system – the<br />

world’s first large pipe bursting<br />

system with a rope as the pulling<br />

mechanism and a pulling force of<br />

more than 1,000 kN.<br />

The rope bursting system (RBS),<br />

from the ABS Trenchless GmbH company<br />

in Germany, uses an innovative clamping<br />

technology in order to complete relining<br />

jobs with long pulling distances exceeding<br />

1,000 m. This is done in one run, using<br />

only one machine pit in certain soil<br />

conditions. The RBS-Burster line is available<br />

with pulling capacities between 40 and<br />

190 tonnes.<br />

With the use of return pulleys, this<br />

technology also makes it possible to<br />

overdrive larger doglegs and bent old<br />

pipes. The single operator is able to control<br />

everything from a safe distance above the<br />

pulling unit, as the Burster is operated by<br />

radio remote control – an important safety<br />

feature to the machine.<br />

In addition to the safe handling, the new<br />

rope pull technology makes the work much<br />

easier for the operator as there is no need<br />

for rods to be removed.<br />

Along with pipe bursting, the pulling<br />

system can also be adapted for slip lining,<br />

relining and swagelining jobs, making the<br />

machine very versatile.<br />

Roping in France<br />

ABS Trenchless, with Entreprise de Travaux<br />

Publics GIROUD GARANPON, Isére, France,<br />

recently completed a project in Vorion, near<br />

Grenoble, France with the RBS helping to<br />

supply cleaner drinking water to the town.<br />

For this project the team used a RBS<br />

1,200 machine to burst through two<br />

sections of water pipelines. The old pipes,<br />

which had an OD 250 mm for a 420 m<br />

section and an OD 200 mm for a 210 m<br />

section were replaced with new HDPE OD<br />

250 mm pipes. With a pulling force of 40<br />

the gun barrel straight hole, a 490mm hole<br />

opener was selected, which allowed for a<br />

20mm annulus. The cutter was built with<br />

standard roller cone cutters, and the pipe<br />

was installed successfully, averaging around<br />

3m per hour.<br />

As the hole opener approached the softer<br />

rock, production increased and the last 85m<br />

section was completed in under 8 hours.<br />

tonnes, the 420 m section was reached in<br />

only one drill string. Project Manager Marco<br />

Wulff said “This is the first time that a 420<br />

m section was burst in only one string.”<br />

Trenchless techniques were chosen for<br />

this job as the site was close to a nature<br />

reserve and for the preservation of trees.<br />

In addition to this, due to the amount of<br />

water that was involved, it would have been<br />

impossible to do use the traditional open-cut<br />

method. Special tools were needed as the<br />

concrete pipes had curves and bends that<br />

are quite difficult to crack.<br />

The advantage to using a rope is that<br />

it can be redirected with a pulley and can<br />

burst more of the diameter. Only taking<br />

two days to complete the bursting, the full<br />

project was done in just one week.<br />

6 No-Dig World 2011 www.trenchlessmiddleeast.com<br />

iAc sPeciAlized<br />

locAl<br />

contrActor At<br />

International Aramoon Corp. (IAC) is the<br />

pioneer and the first specialized local contractor<br />

in the Kingdom of Saudi Arabia with core<br />

specialty in the field of No-Dig Pipe Inspection,<br />

Condition Assessment and Rehabilitation.<br />

The CEO & President of IAC, Eng. Faiz<br />

Al-Elweet says (IAC) is an engineering contractor<br />

which has been founded in Riyadh since 1990.<br />

IAC is specialized in Water Leak Detection,<br />

Test and Repair for Water and Sewer Networks<br />

without Excavation, by using Trenchless<br />

Technology.<br />

Head Office of IAC is in Riyadh and it has<br />

branch offices in Dammam/ Al-Khobar, Ahsa,<br />

Tabuk, Madinah and Abha in KSA.<br />

We have undertaken projects throughout<br />

Saudi Arabia and since last five years we have<br />

executed (& progressing) projects for Water<br />

Leak Detection and Repair for about 15,000Km<br />

of pipelines for various diameters and 550,000<br />

House Connections in the various cities in<br />

Saudi Arabia.<br />

IAC had developed locally “WATCH LEAK”<br />

software, which is a Water Management<br />

System to monitor and quantify leaks in Water<br />

Supply Networks.<br />

The traditional water audit collects the<br />

data manually during a single historic time,<br />

but “WATCHLEAK” collect real-time network<br />

information. This software is a GIS based web<br />

interface tool in order to help the Water Network<br />

Operation & Maintenance staff to identify<br />

District Meter Area (DMA) with higher water<br />

usage and to react before developing a visible<br />

and costly failure.<br />

During the last five years, IAC has<br />

successfully executed and ongoing projects<br />

for Sewer Networks are about (40,000m)<br />

including flow control & diversion (i.e. By-Pass,<br />

dewatering…etc), Hydro-Jet Cleaning, CCTV<br />

Robotic Inspection, Pipelines Condition<br />

Assessment, Pipelines Rehabilitation (MH-MH<br />

Internal Lining).<br />

IAC introduces several Trenchless<br />

Techniques and cost effective solutions for No-<br />

Dig Pipes Rehabilitation such as Cured In Place<br />

Pipe System using Ultra Violet Rays (CIPP-UV)<br />

and Spiral Wounding System as well as Spot<br />

Lining Technique for sectional repair of all types<br />

of host pipes.<br />

stoP<br />

Press<br />

the time of going to press we have<br />

learned that the ISTT (International<br />

Society for Trenchless Technology)<br />

are in the process of finalising the<br />

affiliated agreement for a UAE Society<br />

for Trenchless Technology. An official<br />

signing of the agreement will take place<br />

at Trenchless Middle East 2011. Further<br />

information about the Society will also<br />

be available.<br />

International Society<br />

For Trenchless Technology<br />

www.trenchlessmiddleeast.com No-Dig World 2011 7

eXhibitor neWs eXhibitor neWs<br />

conshield solutions<br />

For thirty years, ConShield has engineered<br />

solutions to reinforce, seal and protect existing<br />

underground structures for both storm water<br />

and sanitary environments; from manholes<br />

to catch basins, wet wells and lift stations as<br />

well as CMP to RCP, because just one product<br />

cannot effectively overcome every problem in<br />

every system.<br />

ConmicShield ® , the liquid additive that<br />

prevents Microbiologically Induced Corrosion<br />

(MIC) in concrete sewer pipe and structures. It<br />

is dosed directly into the concrete mix that can<br />

be used in shotcrete, precast and ready mix,<br />

for both new structures and can be used to<br />

rehab existing structures. ConmicShield ® , has<br />

proven performance since 1996 with several<br />

case studies from all over the country.<br />

ConmicShield ® , has a 100 year design<br />

life and offers full thickness protection for<br />

a fraction of the cost of plastic liners or<br />

polymer coatings. For case studies technical<br />

information and specifications go to<br />

www.conshield.com<br />

PERMACAST ® is our engineered mortar<br />

liner system for manholes. Specially<br />

formulated ultra-high strength mortar is<br />

centrifugally cast from our patented robotic<br />

applicator. It guarantees a consistently dense<br />

and uniform liner at whatever thickness (1/2”<br />

to 2”) is best suited for the condition, depth,<br />

diameter, traffic loading, and ground water<br />

pressure. The highest quality is guaranteed<br />

each and every time since application does<br />

not depend upon a person working inside<br />

cramped and hazardous conditions. Our<br />

formulations are high-strength, quick-setting<br />

and corrosion-resistant. www.permaform.net<br />

CentriPipeTM Centrifugally Cast Concrete<br />

Pipe. is a cost-effective, NO DIG solution for<br />

structural lining of culverts using a spin caster<br />

and our specialty mortar, PL-8000.<br />

The precisely placed and compacted<br />

concrete liner is applied at the best design<br />

thickness for the diameter and conditions.<br />

It contains rust inhibitors to prevent<br />

corrosion of the old metal culvert and it is<br />

highly resistant to abrasion. This process also<br />

provides waterproofing, sealing, structural<br />

reinforcement and corrosion protection, www.<br />

centripipe.com<br />

PERMAFORM ® is the system for complete<br />

replacement of old manholes without digging<br />

or disrupting flows. This process pours a<br />

seamless and structurally independent<br />

“manhole within a manhole” for the best longterm<br />

solution to serious manhole problems.<br />

When biogenic or chemical corrosion is<br />

the problem, a plastic liner is embedded into<br />

the structurally independent concrete wall and<br />

anchored securely with its interlocking tees or<br />

imPreg, cured in PlAce<br />

PiPelining<br />

Over the years ‘cured in place pipelining’<br />

methods for sewer and drainage pipes<br />

becomes more and more a key role in the<br />

no-dig business.<br />

iMPREG is currently manufacturing more<br />

then 150 miles each year and distributing<br />

their products all over the world.<br />

Cured by Steam or latest UV – Technology<br />

the iMPREG Liners are the benchmark for<br />

being the strongest, most cost effective and<br />

most environmentally friendly products in<br />

the market.<br />

Made in Germany, the iMPREG Liner<br />

is manufactured fully quality controlled<br />

according DIN EN ISO 9001. Additionally<br />

the iMPREG Liner is certified by the DIBT<br />

(German Institute for construction techniques)<br />

and meets several industry standards.<br />

Compared to conventional felt liners the<br />

iMPREG GRP Liners show five times more<br />

strength, 100% water tightness and provide<br />

minimum 50 years of Service.<br />

The iMPREG Liners come already pre-<br />

impregnated with special resins and ready<br />

to use on the job side. Shelf lives up to six<br />

months and easy container shipment keeps<br />

your construction flexible abroad.<br />

A pipe section can be rehabilitated in<br />

less then a day. An installation range of DIA<br />

150mm – DIA 1300mm and even more<br />

can be installed in maximum lengths up<br />

to 300 meters each. In middle of 2012<br />

iMPREG is planing to open the new part<br />

of the production plant and is than able to<br />

studs. All inlet and outlet pipe connections are<br />

sealed directly to the inlet/outlet pipes so they<br />

cannot leak.<br />

For severe corrosion, our COR+GARD ®<br />

100% solids epoxy is spun on to form a<br />

protective, composite barrier. In all cases,<br />

each material is applied safely and uniformly<br />

from above without entry into the manhole.<br />

The I&I Barrier ® is the best solution we<br />

have found for sealing the chimney when<br />

resetting frames and covers. COR+FLEX ®<br />

works best when doing an internal chimney<br />

seal without digging.<br />

manufacture liners up to DIA 1600!<br />

Additionally to the liner manufacture<br />

iMPREG provides training on side as well<br />

as on their own training course. With two<br />

own lining equipments and a team of<br />

professionals iMPREG provides a world wide<br />

support.<br />

8 No-Dig World 2011 www.trenchlessmiddleeast.com<br />

lAunch of the goodeng hdd mAchine - gd 8000-ll<br />

China-Burma oil & gas pipeline<br />

Project, contracted by PetroChina<br />

Daqing Oilfield Construction Group.<br />

The launch ceremony of GD8000-LL HDD<br />

Machine for China-Burma oil & gas pipeline<br />

project was held in Goodeng machine’s<br />

production base – Jiangsu Goodeng<br />

Engineering Machinery Assembling Co., Ltd<br />

on Jan. 23rd , 2011. On this day, a colourful<br />

ball swayed to welcome every guest, and<br />

gun salutes declared the beginning of the<br />

ceremony.<br />

Guests included the general manager of<br />

Daqing Oilfield Construction Group Pipeline<br />

Crossing Company, Mr. Guan Lizhi, Dafeng<br />

people’s government mayor, Mr. Wang Hai,<br />

Jiangsu Goodeng Engineering Machinery<br />

Assembling Co., Ltd general manager, Chen<br />

Fenggang, and other management leaders.<br />

GD8000-LL HDD Machine was appointed<br />

by China National Petroleum Corporation<br />

Daqing oilfield Construction Group. After the<br />

successful completion of commissioning,<br />

it was off the assembly line on 22nd<br />

of January and immediately loaded for<br />

shipment to be sent to “China-Burma oil &<br />

gas pipeline project” worksite in Burma on<br />

behalf of China Petroleum.<br />

Except for the structural parts, the power,<br />

hydraulic, electrical, the appliance control<br />

are all imported from abroad. It uses split<br />

and double caterpillar. The maximum pull &<br />

push force is 8100KN, the maximum torque<br />

is 165000N.M, which was independently<br />

researched, developed, and manufactured<br />

by Goodeng machine. With advanced<br />

senses, excellent performance, top quality<br />

service, the large-scale machine produced by<br />

Goodeng machine has become the preferred<br />

product for China National Petroleum<br />

Corporation, China Petroleum & Chemical<br />

Corporation, and many other construction<br />

units.<br />

The strategic meaning of China-Burma<br />

oil & gas pipeline project : with the China-<br />

Burma oil & gas pipeline project started, the<br />

strategic pattern of four oil and gas import<br />

channel has taken shape, which are the<br />

northeast of China (China-Russia crude<br />

oil pipeline), Northwest (Central Asia Gas<br />

Pipeline), Southwest Land (China-Burma oil<br />

and gas pipelines) and marine (sea lanes<br />

through the Malacca Strait). It diversifies<br />

the oil transport channels and protects the<br />

energy supply security in China. It is the<br />

fourth energy import channel after the Sino-<br />

Kazakhstan oil pipeline, the Central Asian<br />

natural gas pipeline, oil pipeline between<br />

China and Russia; it relieves China’s<br />

dependence on the Malacca Strait and<br />

reduces the risk of importing crude oil at sea.<br />

Goodeng Machine Model GD8000-<br />

LL Finishes the following project<br />

successfully: Jiangxi Province Main<br />

project.The first step of Jiangxi<br />

Province gas pipeline—Gan river HDD<br />

Project<br />

On May 13th, 2011, the project in<br />

Fengcheng City Jiangxi province was<br />

finished successfully. It was designed by<br />

Zhongyuan Petroleum Explore Bureau<br />

Projects Construction Main Company and<br />

constructed by Jiangsu Keyi Company using<br />

Goodeng Machine Model GD8000-LL.<br />

The horizontal length of the project is<br />

1887.52 meters and the real working length<br />

is 1890.34 meters (The width of the Gan<br />

river is 1363.82 m, the width of sand and<br />

riverbank is 526.52 m). The project pipe is<br />

508×10L415 diameter arc welding steel pipe.<br />

Which adopts strengthen three-coat PE<br />

anti-rotten.<br />

The entry angle is 9°and out is 6°.<br />

The curvature radius is 762m (150 OD).<br />

The project crosses the Jiangxi Gan river.<br />

The geology of the river bed is very<br />

complex because it contains a fault area,<br />

pebble stone area, gravel sand area and<br />

rough soft clay (including many stones). It is<br />

obvious that the project is complicated as it is<br />

also difficult to control the angle and azimuth.<br />

The HDD project is the biggest in scale,<br />

longest in length, most complex.<br />

www.trenchlessmiddleeast.com No-Dig World 2011 9

comPAny neWs<br />

WArsAW: mAJor PiPe JAcKing<br />

Process successfully comPleted<br />

Clean water for the Vistula river<br />

The underground connection to the new “Czajka”<br />

wastewater treatment plant in Warsaw has been<br />

completed successfully and on time. Two Herrenknecht<br />

AVND micromachines handled the difficult drives with<br />

a total of 5,860 meters with bravura. Apart from pipe<br />

jacking with extraordinarily large diameters of 3 meters,<br />

the extreme winter conditions and a high groundwater<br />

level demanded top performance by everyone involved.<br />

With performances of up to 36 meters a day, the<br />

Herrenknecht machines blazed the trail for an efficient<br />

new wastewater system in the Polish capital fast and<br />

efficiently.<br />

Warsaw, Poland / Schwanau, Germany, 6. April<br />

2011. Wastewater systems in many large cities have<br />

already reached their limits requiring modernization<br />

or expansion in order to avoid overflowing into nearby<br />

rivers. For this reason, the city of Warsaw is investing<br />

in the construction of a state-of-the-art wastewater<br />

treatment system. This will treat the wastewater<br />

produced by 80 percent of Warsaw’s inhabitants,<br />

thereby improving the quality of water and life along the<br />

banks of the Vistula over the long term. Hydrobudowa<br />

9 S.A., PRG Metro Sp.z.o.o. and KWG (PBG Group)<br />

have been commissioned to connect the plant with the<br />

underground wastewater network.<br />

The Polish contractors selected the pipe jacking<br />

method for their tunnel project and relied on the<br />

two AVND2000AB (with Extension Kit, Ø 3,025mm)<br />

and AVND2400AB (Ø 3,025mm) hydroshields from<br />

Herrenknecht. This type of machine is worldwide in<br />

use in the construction of supply and disposal tunnels;<br />

they master tunnelling through groundwater and can<br />

penetrate a wide range of heterogeneous soils. In<br />

Warsaw, the machines tunnelled at depths of 10 to 14<br />

meters reaching their final targets after boring through<br />

5,860 meters of soil comprising coarse and fine sand,<br />

clay, loam, gravel and boulders.<br />

Apart from the unusually large diameter of 3 meters<br />

for the pipe jacking method, another challenge was<br />

represented by a high groundwater level which in<br />

some places reached up to 8 meters above the top<br />

of the pipes. The site teams were therefore obliged to<br />

dewater and seal the requisite construction shafts prior<br />

to tunnelling. The Herrenknecht AVND pipe jacking<br />

machines proved its worth during this tunnelling<br />

process. Where required, these machines secure the<br />

tunnel face using a support fluid (bentonite and water<br />

mixture) and an additional compressed air cushion in<br />

the split excavation chamber, allowing safe tunnelling<br />

under water pressure. The separation of solids of the<br />

excavated material from fluids was realized with the<br />

Herrenknecht Separation Plant HSP500, providing a<br />

capacity of 400 to 500 m 3 /h depending on the particle<br />

size distribution.<br />

During the particularly cold winter months of 2010,<br />

the site team continued tunnelling work despite some<br />

extremely low temperatures and a lengthy period of frost.<br />

The Herrenknecht micromachines completed a total<br />

of 16 drives, some with short distances starting at 80<br />

meters, but also including long-distance sections of 800<br />

meters and more. The longest individual drive was 930<br />

meters. The hydroshields safely underpassed a six-lane<br />

highway without having any negative impact on the flow<br />

10 10 No-Dig World 2011 Global www.trenchlessmiddleeast.com<br />

Focus Middle East 2009<br />

of traffic. Hydraulic intermediate jacking stations serve<br />

to reduce the friction forces prevailing in such longdistance<br />

tunnelling projects. Herrenknecht had already<br />

adapted these interjack stations exactly to the thin walls<br />

of the Hobas GRP pipes installed in Warsaw. The longest<br />

section revealed yet another particular feature: two<br />

underground curves with a radius of 450m and 900m<br />

had to be realized. Thanks to the Herrenknecht SLS<br />

RV navigation system the cutterhead is guided exactly<br />

with millimeter precision, the machine operators also<br />

mastered this task in a precise and safe manner.<br />

December 14, 2010 saw completion of the last section<br />

representing a significant milestone for this wastewater<br />

project in Warsaw. During the construction project, the<br />

Herrenknecht equipment achieved impressive advance<br />

rates of up to 36 meters a day (double shift) and an<br />

average of 20 meters per day.<br />

To complete the entire sewer system and connect it<br />

with “Czajka” wastewater treatment plant (WWTP), PRG<br />

Metro Sp.z.o.o. and Hydrobudowa 9 S.A. are additionally<br />

realizing the 1,300m long Vistula River Crossing tunnel with<br />

a Herrenknecht large diameter tunnel boring machine. The<br />

Mixshield S-642 with a diameter of 5.35m was successfully<br />

accepted in February 2011 in the Schwanau/Germany<br />

plant of Herrenknecht. Once this tunnel is completed the<br />

Czajka WWTP could go into operation. n<br />

Project data<br />

Wastewater tunnel in Warsaw, Poland<br />

Geology: 70% coarse and fine sand, 30% clay and loam,<br />

gravel, boulders<br />

Tunnel lengths: total of 5,860 m, 16 drives of 80 to 930<br />

meters<br />

Particular features: high groundwater level, long-distance<br />

driving, curve drives<br />

Machine data<br />

Herrenknecht M-1083M, AVND2000AB with Extension<br />

Kit, excavation diameter 3,025mm Herrenknecht<br />

M-1363M, AVND2400AB, excavation diameter 3,025mm<br />

Cutterhead: mixed-soil cutterheads fitted with disc<br />

cutters and cutting knives<br />

Max. torque: 780kNm, 1,200kNm<br />

Tunnel lining: Pipe Jacking<br />

comPAny neWs

comPAny neWs<br />

beton & rohrbAu<br />

highly customer-orientAted<br />

beton & rohrbau is one of the leading companies in civil<br />

and construction engineering for the public sector.<br />

Throughout Germany and abroad, clients in the public<br />

water and sewage sector provide beton & rohrbau with a<br />

high level of confidence. With nationwide branches beton &<br />

rohrbau is well equipped and highly customer-orientated.<br />

Besides Germany projects are also executed through<br />

subsidiaries and holding companies in Bahrain, Bulgaria,<br />

Georgia, Kazakhstan, Mauritius, Nigeria, Romania, Russian<br />

Federation, Turkey and the United Kingdom. The employees<br />

of beton & rohrbau have many years of experience in<br />

providing water and sewage services for the public sector<br />

and have been recruited from the regions where the<br />

projects take place. With the most up-to-date and innovative<br />

technology, the equipment and machinery of beton &<br />

rohrbau satisfy all current requirements. The technical<br />

and commercial capabilities have made it a consistent<br />

partner for the public water and sewage sector in Germany<br />

and Abroad. The scope of beton & rohrbau encompasses<br />

sewer pipes, portable water, pressurized pipes, sewage<br />

treatment plants and pumping stations, micro-tunnelling<br />

and pipe jacking, the laying and sinking of pipes, caissons<br />

and storm water clarification plants and as well as turnkey<br />

civil engineering projects is one of the main reasons why it<br />

enjoys the confidence of its clients in the public sector.<br />

With a workforce of some 500 members of staff the<br />

beton & rohrbau group meanwhile achieves an annual<br />

turnover of around 100 mi. Euros. At its various regional<br />

locations, beton & rohrbau is one of the most efficient<br />

and productive companies. n<br />

12 No-Dig World 2011 www.trenchlessmiddleeast.com

comPAny neWs<br />

tt-middle eAst/tt-uK, successes<br />

in omAn, sAudi ArAbiA And the uAe<br />

TT-Middle East/TT-UK have been offering their range of<br />

Trenchless Technology (NDRC) products throughout the<br />

Middle East for many years with notable successes in<br />

Oman, Saudi Arabia and the UAE.<br />

A 30” diameter x 110m long steel oil pipeline exchange<br />

project under a major highway between Damman and<br />

Riyadh was completed using a Grundoram Taurus.<br />

Taurus Grundoram installing a 30” steel<br />

pipe under the Damman-Riyadh Highway<br />

Grundomat Soil Displacement Hammers and<br />

Grundodrill HDD rigs are now in daily use throughout<br />

the region laying fibre optic network systems; notable<br />

success has been achieved by Omani companies with<br />

Grundomats and a Grundodrill 15X.<br />

Grundomat road crossing in Oman<br />

Grundodrill HDD working in Oman<br />

HDD drill rod rescue using Grundoram technology saved the company DCL significant financial implications such as<br />

the total cost of a lost drilled bore, contractual penalties, ongoing cost delays in commissioning the final pipelines and<br />

all associated costs involved in planning a new bore and the actual costs of duplicating all the undertakings of a new<br />

bore/installation, etc…<br />

HDD Drill Rod Rescue using Grundoram<br />

Due to the success of the HDD Drill Rod Rescue above, DCL went on to purchase a Prime Drilling PD 250/90 HDD<br />

System. n<br />

Prime Drilling PD 250/90 System<br />

14 No-Dig World 2011 www.trenchlessmiddleeast.com

comPAny neWs<br />

sAve WAter, sAve money …<br />

Innovative shaft sealing<br />

technologies for tunnelling<br />

pumps – no additional sealing<br />

water required<br />

Though our Earth is made up of 2/3 water, only 1/100<br />

of that water is drinkable. The rest is salt water or<br />

permanently frozen and we can’t drink it, wash with it, or<br />

use it to water plants. Water is a limited resource!<br />

Therefore, it is important that we use our water<br />

wisely and do not waste it. For future generations we<br />

all must do our part to save water, particularly in industrial<br />

application.<br />

Most of these efforts can be reached priceless and as<br />

a benefit you can save money by saving water -<br />

using innovative shaft sealing technologies for your slurry<br />

pumps. As a standard for slurry pumps in tunnelling<br />

packing glands and expeller units combined with packing<br />

rings are installed as state of the art shaft sealing<br />

technologies. Shaft seals of pumps which convey sludges<br />

and slurries containing solid particles require constant<br />

supply of sealing water in order to cool, lubricate and<br />

keep the seal clean. Furthermore a permanent dripping<br />

of sealing water is essential for a trouble free operation<br />

of packing glands. While boring the tunnel a constant<br />

sealing water supply to discharge and feed pumps must<br />

be assured.<br />

After having been charged with particles it has to be<br />

cleaned up before being disposed as waste water.<br />

This means you have to pay for supply, cleaning and<br />

removing the sealing water every day of tunnelling. As<br />

alternative grease lubricated packing glands are used<br />

associated with reduced wear life of the gland and<br />

shaft sleeve.<br />

Nevertheless a permanent greasing of the gland using<br />

a grease pump is necessary as well as periodic on-site<br />

refilling of the storage tank.<br />

Our experienced team of engineers and technicians<br />

designed an innovative shaft sealing solution tailored to<br />

the task. Our experience which we have gained in a large<br />

number of applications is included in the development<br />

and design of our own mechanical seal type HGD which<br />

is available in single- acting and double-acting designs.<br />

In double acting design this seal is supplied with sealing<br />

water from an unpressurized storage tank. Continuous<br />

external sealing water distribution is therefore not<br />

essential. In single acting design no additional sealing<br />

water is required while pump operation.<br />

For rough conditions in tunnelling we use applicationoptimized<br />

materials for the sliding and counter rings.<br />

This ensures reliable operation in a large number of<br />

slurry pump applications in direct pipe, utility- and traffictunnelling<br />

today.<br />

Save Water using innovative shaft sealing technologies<br />

for tunnelling pumps. n<br />

See Arthur Habermann Gmbh & Co. Kg on stand 53.<br />

16 No-Dig World 2011 www.trenchlessmiddleeast.com

comPAny neWs comPAny neWs<br />

Full length lining utilising an inversion drum installation technique<br />

euroPeAn rehAbilitAtion<br />

technology goes globAl<br />

Manhole rehabilitation systems are included in the Fluvius range.<br />

Fluvius GmbH of Germany, in association with its<br />

Eastern European partner Sanikom in Slovenia,<br />

sells products primarily for the trenchless repair<br />

of wastewater pipe systems with the product focus<br />

being mainly on full-length and localised repair up to<br />

a pipe diameter of 800 mm.<br />

The company’s range includes the full spectrum<br />

of consumables, such as resin systems, liners,<br />

fibreglass complexes, renovation packers and<br />

products for flow control and test technology as<br />

well as accessories, that are required for trenchless<br />

installations in wastewater systems, as well as<br />

specialist technical equipment that is designed<br />

either in-house to the highest quality standards<br />

or as products sourced from other renowned<br />

manufacturers. The various renovation methods<br />

offered carry a range of globally recognised industry<br />

approvals and certificates.<br />

Fluvius can provide clients with solution<br />

proposals and entire systems for the renovation and<br />

maintenance of defective wastewater pipes. With<br />

experienced employees that have been active in this<br />

industry sector for many years, the company can<br />

18 No-Dig World 2011 www.trenchlessmiddleeast.com<br />

also offer support as a competent partners in all<br />

technical and commercial issues.<br />

The technologies on offer from Fluvius include<br />

full lining systems for pipelines in diameters from 28<br />

mm up to 800 mm using CIPP technology as well<br />

as lateral lining and lateral sealing systems that can<br />

negotiate bends up to 90 o and diameter transitions<br />

in a single installation. Liners are also offered<br />

for localised repairs (‘patches’) where full length<br />

rehabilitation is not required in diameters from 100<br />

mm up to 900 mm.<br />

In larger man-entry diameters Fluvius also offers a<br />

range of Kevlar/EPDM manually installed pipe joint<br />

seals. For manhole rehabilitation the company has<br />

cementitious grout lining options offering structural<br />

repair and saltwater resistance, as well as localised<br />

manhole leak sealing systems.<br />

Commenting on the event Sebastian Schmitz,<br />

Managing Director of Fluvius said:<br />

“Trenchless Middle East 2011 will give us another<br />

springboard into areas of the world that require the<br />

sort of technology we have on offer. Our technical<br />

team will be at the event offering current and any<br />

potential new clientelle guidance through the Fluvius<br />

range of systems.” n<br />

Fluvius offers ‘patch’ repair localised lining systems<br />

www.trenchlessmiddleeast.com No-Dig World 2011 19

comPAny neWs comPAny neWs<br />

horizontAl directionAl drilling<br />

techniQue for dn 900 PiPes<br />

Horizontal directional drilling technique<br />

used for pipe-by-pipe pulling-in of DN 900<br />

ductile iron pipes in Belgium<br />

Introduction<br />

Constantly spreading built-up areas, wide multi-lane<br />

roads or complicated routes are making it<br />

increasingly difficult and expensive to replace<br />

existing pipeline systems, or lay new ones, by<br />

the open trench technique. This is why trenchless<br />

installation techniques have been under<br />

development and in use for some 30 years now.<br />

The continuing development of the machinery<br />

used is going hand in hand with the modification<br />

of a pipe material with a great tradition,<br />

namely ductile iron, and with changes in the<br />

technology of making restrained joints between<br />

pipes of this material. A successful example of<br />

such new joints is the positive locking BLS ® /<br />

VRS ® -T push-in joint. This joint is flexible and<br />

enables pipes to be laid to tight radiuses by an<br />

angular deflection at the sockets. The welding<br />

bead, which is applied to the spigot end in the<br />

factory, and the metallic locking segments, which<br />

are supported in the locking chamber cast into<br />

the socket, enable very high longitudinal forces<br />

to be transmitted.<br />

Fig 1. The BLS ® /VRS ® -T push-in joint<br />

Fig 2. The cement mortar coating to EN 15542<br />

The horizontal directional drilling technique<br />

using ductile iron pipes<br />

Pipes having the positive locking BLS ® /VRS ® -T<br />

push-in joint (Fig. 1), combined with a cement<br />

mortar coating to EN 15542 [1] as an external<br />

protection able to withstand high mechanical<br />

loads (Fig. 2), are available for the trenchless<br />

installation of ductile iron pipes by the horizontal<br />

directional drilling (HDD) technique.<br />

The BLS ® /VRS ® -T push-in joint is a restrained<br />

socket joint in which a welding bead is applied to<br />

the spigot end in the factory. A locking chamber<br />

cast into the socket receives the locks or locking<br />

segments which, once the spigot end has been<br />

pushed into the socket, are inserted through<br />

openings in the end-face of the socket which<br />

lead into the locking chamber. If axial tractive<br />

forces are exerted on the joint, either by the<br />

internal pressure or by the use of the pipes for<br />

a trenchless pulling-in technique, the welding<br />

bead is supported against these locks or locking<br />

segments and in this way transmits a very high<br />

force (Fig. 3).<br />

Fig 3. Construction of the DN 900 BLS<br />

Ductile iron pipes can be trenchlessly installed<br />

by the HDD technique both as a fully assembled<br />

pipe string and by pipe-by-pipe connection. The<br />

possible length of pipeline which can be pulled in is<br />

determined by the permitted tractive force<br />

on the restrained push-in joint. Details can be<br />

found in DVGW-Arbeitsblatt GW 321 [2] and<br />

in the manual entitled “Trenchless Installation<br />

of Ductile Cast Iron Pipes” [3]. Because of<br />

the results of externally monitored type tests<br />

(internal pressure tests under product standard<br />

EN 545 [4]), the values of permitted tractive<br />

force specified in the latter are in some cases<br />

higher than those specified in DVGW-Arbeitsblatt<br />

GW 321 [2] (Table 1).<br />

® /VRS ® -T<br />

push-in joint with fixing clip for trenchless<br />

pipeline installation<br />

20 No-Dig World 2011 www.trenchlessmiddleeast.com<br />

Fig 4. 1000 kN drilling rig<br />

Installation of a drinking water pipeline<br />

using DN 900 ductile iron pipes<br />

Pidpa is one of the largest Flemish water suppliers and<br />

supplies fresh drinking water to more than a million people.<br />

The company distributes its drinking water by means<br />

of a 12,581 km long pipeline network. The municipality<br />

of Grobbendonk (a small town with just over 10,000<br />

inhabitants), is situated right next to the Albert Canal, an<br />

artificial waterway 129.5 km long which connects the two<br />

Belgian towns of Liège and Antwerp. The existing pipeline<br />

needed to be relaid due to the construction of a new bridge.<br />

In part of the area, the new pipeline runs directly along<br />

the Albert Canal. If open trenches had been used, the water<br />

would have had to be predrained from them, an expensive<br />

undertaking. This was avoided by the trenchless installation<br />

of ductile iron pipes by the horizontal directional drilling<br />

technique with the pipes pulled in pipe-by-pipe.<br />

It was possible to make use in this case of the experience<br />

gained on a project involving DN 600 nominal size pipes<br />

which was completed in 2008 in the town of Ghent [5], also<br />

in Belgium.<br />

A 1000 kN drilling rig (Fig. 4) was used for the drilling<br />

and the subsequent pulling-in of the ductile iron pipes. The<br />

pilot bore having been made, it was widened step by step by<br />

special upsizing heads (Fig. 5). The pipes were connected<br />

on one by one on a special connecting ramp. The first pipe<br />

was connected (Fig. 6) to the traction string and the barrel<br />

reamer by means of a BLS ® /VRS ® -T traction head with<br />

built-in force-measuring equipment.<br />

To make the connection, the segments for locking the<br />

Fig. 5: Upsizing heads<br />

Fig. 6: Pipes being connected on a connecting<br />

ramp<br />

DN 900 BLS ® /VRS ® -T push-in joint are inserted, once the<br />

spigot end of the pipe has been inserted in the next socket,<br />

in the locking chamber (Fig. 8) through the opening leading<br />

into the socket (Fig. 7) and are distributed around the<br />

circumference of the pipe alternately to the left and the right.<br />

In a trenchless installation technique, the segments are<br />

then secured with a steel fixing clip.<br />

This ensures that the locking segments are at all<br />

times firmly in abutment as the pipe is pulled in.<br />

Once the locking segments have been inserted, the<br />

socket joints are protected by a shrink-on sleeve. The sheetmetal<br />

cone (Fig. 9) which is slid on prevents any possible<br />

Fig. 7, left : Opening leading into socket on<br />

DN 600 to DN 1000 size BLS ® /VRS ® -T push-in<br />

joints<br />

Fig. 8, right : Insertion of locking segments<br />

Fig. 9: Pulling-in of the pipes; the push-in joint<br />

is protected by shrink-on material and a sheetmetal<br />

cone slid over the top<br />

damage from being done to the shrink-on sleeve in the bore<br />

as the pipeline is subsequently being pulled in.<br />

To sum up<br />

Ductile iron pipes with restrained BLS ® /VRS ® -T<br />

push-in joints are very well suited to trenchless<br />

installation and have already shown this to be the case on a<br />

large number of completed projects.<br />

The possibility of particularly high forces being<br />

transmitted from pipe to pipe allows economical and costsaving<br />

installation and enables very long runs of pipe to be<br />

pulled in when using trenchless installation techniques. n<br />

Project data<br />

• HDD installation of individually connected<br />

• DN 900 BLS ® pipes<br />

• Pipe external protection: cement mortar<br />

• coating to EN 15542 [1]<br />

• Length of pipeline: 342 m<br />

• Drilling rig: 1,000 kN<br />

• Permitted tractive force for DN 900 BLS ®<br />

• pipes: 1,845 kN<br />

• Max. tractive force which occurred: 500 kN<br />

See Duktus Pipe Systems Fzco on stand 13.<br />

References<br />

[1] EN 15542, Ductile iron pipes, fittings and accessories - External cement mortar coating for pipes – requirements and test methods 2008<br />

[2] DVGW-Arbeitsblatt GW 321, Horizontal directional drilling for gas and water pipelines – requirements, quality assurance and testing 2003-10<br />

[3] Buderus Manual - Trenchless Installation of Ductile Cast Iron Pipes 2009-07<br />

[4] EN 545, Ductile iron pipes, fittings, accessories and<br />

their joints for water pipelines - requirements and test methods 2006<br />

[5] Ertelt, S.: Einzelrohreinzug ductiler Gussrohre<br />

beim HDD-Verfahren – Fortsetzung einer Erfolgsgeschichte [Pipe-by-pipe pulling-in of ductile iron pipes by the HDD technique – a continuing success story] GUSSROHR-TECHNIK 43 (2009), p. 72 ff

comPAny neWs<br />

lArge diAmeter tunnelling<br />

in urbAn AreAs<br />

mts Perforator Slurry Systems successfully<br />

at work in Qatar and Australia<br />

Why Large Diameters!<br />

Large diameter pipe jacking has become common feature<br />

in most new urban drainage and sewage schemes. Large<br />

size sewage and storm water drainage collectors are the<br />

sustainable solution to complement modern sewage<br />

strategies, allow long term planning and dealing with high<br />

urban growth rates. Large diameter pipe jacking is also used<br />

for the creation of intake and outlet pipelines into the sea for<br />

desalination plants.<br />

Challenges overcome by German technology.<br />

Large diameter pipelines are commonly designed to be<br />

stretching over long distances. To achieve this safely the<br />

tunneling equipment must fulfill the highest standards for<br />

quality, reliability and flexibility. Mts Perforator machines<br />

Type “mts2000L” have proven to be a most suitable and<br />

also economical choice for meeting such challenges.<br />

In all our projects worldwide mts Perforator After Sales<br />

and Service Staff support the progress locally and from<br />

Germany, so that clients can finish their projects in time. n<br />

Melbourne, Australia: ID2400mm,<br />

OD3040mm, Stormwater pipeline<br />

Three drives ranging from 450m – 650m single drive length,<br />

Clay soil with groundwater, successfully crossing main<br />

highway with less than 2m overburden Adaptation of mts<br />

Mixed Ground Cutting Disc under ground Elaborate set up<br />

for Slurry water recycling, including use of Decanter system<br />

www.melbournewater.com.au<br />

Doha, Qatar, Expressway Qatar, Salwa Road<br />

Project<br />

ID2400mm ID3040mm, Concrete Sewage Collector pipe.<br />

6 drives ranging from 470m-550m single drive length.<br />

Weathered limestone with localized seepage or ground water<br />

Mts Perforator Mixed Ground Cutting Disc<br />

Minimal machine wear and high jacking progress rates<br />

22 No-Dig World 2011 www.trenchlessmiddleeast.com<br />

2011<br />

trenchless middle eAst<br />

dubAi 2011 conference<br />

10 - 11 october 2011<br />

Dr Dec Downey<br />

Dr Sam Ariaratnam<br />

Dear Trenchless Colleagues<br />

I am hoping to see many of you at the Jumeirah<br />

Beach Hotel for this year’s eighth Trenchless Middle<br />

East. Once again we have an excellent technical<br />

programme covering new construction replacement<br />

and rehabilitation of underground utilities with some<br />

outstanding local speakers to bring you specific<br />

experience from the region. This is supported by<br />

an exhibition which grows from strength to strength<br />

featuring the leading system providers from around<br />

the world demonstrating improved equipment and<br />

process options.<br />

Our exhibitors turned out in force in recent months<br />

for International No-Dig Conferences and Exhibitions in<br />

Singapore and Berlin and the Dubai event promises to<br />

bring the best available to the region this year. It is going<br />

to be a show to remember, the challenge for me is to<br />

develop a keynote address to match the rest of the event<br />

highlights. The last year has seen real developments in<br />

construction and renovation, we live in challenging times<br />

and our industry has once again raised the bar – see<br />

you in Dubai.<br />

Best regards<br />

Dec Downey<br />

Conference Programme Director<br />

ISTT immediate past Chairman<br />

conference PrevieW<br />

This Conference is a must for utility engineers and related professionals looking for<br />

detailed information on the latest techniques for the non disruptive installation and<br />

rehabilitation of pipelines and pipe networks.<br />

VIP guests will include ISTT Chairman Professor Sam Ariaratnam, passing through<br />

Dubai en route from No-Dig Down Under. We can be sure that Dr Sam will make a<br />

lively contribution to the conference proceedings.<br />

Conference Registration Fee<br />

US$900/AED 3,300<br />

The delegate registration fee includes:<br />

• Attendance at all conference sessions<br />

• Coffees, refreshments & buffet lunch<br />

10 & 11 October<br />

• Conference papers<br />

• Free entrance to exhibition<br />

• Certificate of attendance<br />

Register online at<br />

www.trenchlessmiddleeast.com<br />

Or simply turn up on the day<br />

www.trenchlessmiddleeast.com No-Dig World 2011 23

trenchless middle eAst<br />

international exhibition and conference<br />

conference ProgrAmme conference ProgrAmme<br />

day 1 - monday 10 october 2011 - new construction<br />

10.30<br />

11.00<br />

12.45<br />

14.15<br />

conference registration and exhibition open<br />

session 1<br />

Welcome – Dr Sam Ariaratnam, chairman International<br />

Society for Trenchless Technology (ISTT), UK<br />

1.1 steP - A sustainable solution for Abu dhabi<br />

A review of the development of the tunnel solution for<br />

delivery of a world class sewerage service for Abu Dhabi.<br />

The presentation will highlight the challenges that have<br />

been faced and how they have been addressed. It will also<br />

update delegates on the current progress of the programme<br />

and how it is impacting on the company and the city.<br />

Alan Thomson, Managing Director, ADSCC, UAE<br />

1.2 new milestone in guided auger boring with front<br />

steer technology<br />

With the development of a novel steering technology,<br />

Bohrtec have for the first time overcome the application<br />

restrictions and enabled applications in very dense<br />

strata. The presentation will demonstrate the<br />

capabilities of this guided auger boring system that<br />

excavates the ground as it advances.<br />

Dr.- Ing. Hans-Peter Uffmann, Bohrtec, GmbH, Germany<br />

1.3 recent innovations in hdPe butt fusion.<br />

This presentation will highlight the recent developments in<br />

the handling and fusion welding process and how these can<br />

help with a variety of trenchless operations.<br />

Keith Mole, International Business Manager, McElroy<br />

Manufacturing Inc, UK<br />

buffet lunch and exhibition viewing<br />

session 2<br />

2.1 horizontal directional drilling (hdd) and<br />

burstlining - exception becomes routine: installation<br />

with ductile iron pipes<br />

This paper will clearly present the possibilities, advantages<br />

and requirements related to the installation of ductile cast<br />

iron pipes on the basis of projects completed in the field<br />

of new pipe installation using the controlled horizontal<br />

directional drilling method (HDD) and pipe replacement<br />

using pipe bursting.<br />

Steffen Ertelt, Duktus Rohrsysteme Wetzlar GmbH,<br />

Germany<br />

15.15<br />

16.00<br />

17.00<br />

18.30<br />

2.2 4.1 m diameter pipe jacking of intake and<br />

outfall tunnels<br />

This case study will feature a project involving the<br />

construction of four 300m intake and outfall tunnels<br />

serving a coal-fired plant under construction at the<br />

shoreline of the North Sea in northern Germany. Due to<br />

time constraints, two slurry pipe jacking machines with<br />

a diameter of 4.1 m are being used simultaneously. The<br />

presenter will share the challenges and experience during<br />

the construction stages.<br />

Dr. Klaus Rieker, Wayss & Freytag, Germany<br />

coffee break and exhibition viewing<br />

session 3<br />

3.1 small diameter on-grade microtunnelling in rock<br />

and highly compacted soils.<br />

One of the newest technologies capable of boring small<br />

diameter on-grade gravity sewer is the recently introduced<br />

AXIST Guided Boring System. The system design was<br />

originally targeted at bores averaging 90m length, with<br />

diameters of 250-350mm and in soft soil conditions. Those<br />

boundaries have been stretched to include longer bores,<br />

larger diameters, and much harder ground conditions. This<br />

paper will present project case studies that have been in<br />

high blow count compacted soils, fractured rock, and solid<br />

rock conditions.<br />

John Milligan, Business Manager, Vermeer USA<br />

3.2 the development of high stress crack resistance<br />

polyethelene for use in trenchless technology<br />

This paper will outline the develoment of polyethylene<br />

materials used in the production of pipes and fittings. It<br />

will also describe how the extensive use of polethylene<br />

in trenchless technology applications has driven the<br />

latest developments in the material, namely pipe grades<br />

that have high stress crack resistance, so allowing the<br />

extension of underground infrastructuer service lifetime<br />

by up to 100 years.<br />

Andrew Wedgner, Kang Peck Tze and David Walton,<br />

Borouge, UAE and Singapore<br />

close of day 1<br />

Cocktail reception in Exhibition<br />

exhibition close<br />

10 - 11 october 2011<br />

day 2 - tuesday 11 october - rehabilitation<br />

The organisers reserve the right to amend the programme or substitute speakers without notice if circumstances should dictate The organisers reserve the right to amend the programme or substitute speakers without notice if circumstances should dictate<br />

10.30<br />

11.00<br />

12.30<br />

14.00<br />

exhibition open<br />

session 4<br />

4.1 Keynote Address – trenchless pipeline<br />

rehabilitation methods<br />

An insight into the methods for rehabilitating water and<br />

wastewater pipelines, diameter and length considerations,<br />

choice of materials and methodologies.<br />

Dr Dec Downey, past chairman International Society for<br />

Trenchless Technology (ISTT), UK<br />

4.2 experiences with uv light-curing ciPP in large pipe<br />

dimensions<br />

This presentation will discuss the development of light<br />

curing CIPP methods which are now successful in dimension<br />

ranges which were in the past dominated by conventional<br />

warm-curing liner technologies. These experiences will<br />

be underlined by case studies of several successful large<br />

dimension rehabilitation projects.<br />

Benedikt Stentrup, Managing director of RELINEEUROPE<br />

Liner GmbH & Co KG, Germany.<br />

4.3 biogenic corrosion – ‘microbiological induced<br />

corrosion’ - in concrete sewerage systems. the impact<br />

and solutions<br />

The industry often incorrectly refers to the deterioration<br />

of concrete sewerage systems as a gas problem. But<br />

the real culprit for concrete is Biogenic corrosion (often<br />

called MIC) a process by which sulfuric acid is produced in<br />

sewer systems when hydrogen sulfide gas and Thiobacillus<br />

bacteria interact. This paper will discuss the process of<br />

concrete MIC, laboratory and field tests and case studies of<br />

the long term effectiveness of the anti-bacterial additive,<br />

ConmicShield ® .<br />

Moosa Damerchie, B.Eng. M.ASCE, International Managing<br />

Director, ConShield Technologies, Inc, USA, William E.<br />

Shook President, AP/M PERMAFORM, USA and Ibrahim<br />

Almajaida, Liwa Contracting, UAE<br />

buffet lunch and exhibition viewing<br />

session 5<br />

5.1 no-dig technologies –innovative solutions for<br />

efficient and fast pipe rehabilitation<br />

The presenter will give an overview on the technologies<br />

for pipe inspection, cleaning and pipe rehabilitation<br />

utilising trenchless technology Various technologies will be<br />

illustrated giving delegates comprehensive overview of the<br />

alternatives available.<br />

Mrs. Ulrike Rabmer-Koller – General Manager of Rabmer<br />

Group, Austria<br />

15.30<br />

16.15<br />

17.30<br />

18.00<br />

2011<br />

5.2 lining of pipes, sewers and tunnels with the spiral<br />

wound sPr renovation technique.<br />

This paper will highlight the rehabilitation of circular and<br />

special profiles of sewer pipes, pipes or tunnels by using<br />

spiral wound technology. The material is a manufactured<br />

endless plastic strip, that is as PVC or HDPE-Liner of high<br />

ring stiffness as static load-bearing system and lightweight<br />

spiral wound directly through the existing shaft structure<br />

into the damaged pipe.<br />

Hans Jürgen König, General Manager KMG Pipe<br />

Rehabilitation Emirates LLC, Abu Dhabi<br />

5.3 techniques to seal infiltration within waste water<br />

networks to meet ini targets<br />

Infiltration into a closed sewer system is one of the<br />

network owners major problems. This paper discusses the<br />

trenchless techniques available to repair and contain the<br />

infiltration, covering traditional and new innovations in<br />

network sealing.<br />

Ian Ramsay, Managing Director Fluvius, UK<br />

coffee break and exhibition viewing<br />

session 6<br />

6.1 Pipe inspection and rehabilitation by ciPP-uv<br />

This presentation will describe various projects focussing<br />

on pipe inspection and the applications and advantages of<br />

using CIPP-UV.<br />

Faiz Al-Elweet, President and CEO, International Aramoon<br />

Corp, Saudi Arabia<br />

conference close<br />

exhibition close

floor PlAn & eXhibitor list<br />

31<br />

30<br />

3 9 11 13 14<br />

1 15<br />

2<br />

4 6 8 10 12<br />

65<br />

ABS <strong>TRENCHLESS</strong> GMBH 21<br />

ABU DHABI SEWARAGE SERVICES COMPANY (ADSSC) 57<br />

AL MAZROUI MEDICAL & CHEMICAL SUPPLIES 56<br />

AL NABOODAH SPECIALIST SERVICES (LLC) 45<br />

AL-WATANI FACTORY FOR FIBERGLASS COMPANY 52<br />

AMERICAN AUGERS 30<br />

ANABEEB PIPE MANUFACTURING FACTORIES 48<br />

APS HOLDINGS 50<br />

ARTHUR HABERMANN GMBH & CO KG 53<br />

BAROID INDUSTRIAL DRILLING PRODUCTS 22<br />

BENTOFRANCE SAS SUD-CHEMIE 47<br />

BETON & ROHRBAU C.-F. THYMIAN GMBH & CO. KG 8<br />

BKP BEROLINA POLYESTER GMBH & CO KG 23<br />

BOROUGE PTE LTD 60<br />

BRAWOLINER KARL OTTO BRAUN GMBH & CO 42<br />

CHANNELINE INTERNATIONAL LTD 50<br />

COLLI DRILL SPA 26<br />

28<br />

33<br />

34<br />

64 60<br />

29<br />

27 25 23 21 19<br />

26 24<br />

37<br />

COLLI EQUIPMENT SRL 26<br />

CONSHIELD TECHNOLOGIES INC 56<br />

DIGITAL CONTROL INCORPORATED 37<br />

DOWN2EARTH BVBA 15<br />

DRILLTO <strong>TRENCHLESS</strong> CO LTD 9<br />

DUKTUS PIPE SYSTEMS FZCO 13<br />

DW/TXS CONSTRUCTION EQUIPMENT (BEIJING) CO.,LTD 55<br />

FLUVIUS GMBH 59<br />

FRISCH & FAUST TIEFBAU GMBH 6<br />

GERMAN SOCIETY FOR <strong>TRENCHLESS</strong> TECHNOLOGY (GSTT) 2<br />

HARD METALS AUSTRALIA PTY LTD 28<br />

HELIMANN GENERAL MAINTENANCE 24<br />

HERRENKNECHT AG 29 & 33<br />

IMPREG GMBH 10<br />

INTERNATIONAL ARAMOON CORPORATION 64<br />

INTERNATIONAL DRILLING SERVICES LTD 43<br />

JACKCONTROL AG 65<br />

22 20 18<br />

43 45 47<br />

40 42 44 46<br />

59 57 55 53<br />

56 54 52<br />

JOSEPH GALLAGHER LTD 16<br />

KAYSON 31<br />

KEM-TRON TECHNOLOGIES INC. 40<br />

KMG PIPE REHABILITATION - EMIRATES LLC 1<br />

KURTEC PIPELINE SERVICES LLC 18<br />

MCALLISTER BROS 16<br />

MTS PERFORATOR GMBH 25<br />

PALMIERI SPA 46<br />

PMPS LINER TECHNOLOGY 20<br />

PRIME DRILLING GMBH 3<br />

PURE TECHNOLOGIES LTD. 64<br />

QATAR GERMAN PIPES COMPANY WLL 54<br />

RABMER ROHRSANIERUNGS GMBH 19<br />

RABMER ROHRTECHNIK GMBH 19<br />

RASA CORPORATION 44<br />

RASA INDUSTRIES CO LTD 44<br />

RELINEEUROPE AG 6<br />

16<br />

48<br />

50<br />

2011<br />

10 -11 October 2011<br />

Jumeirah Beach<br />

Conference & Exhibition<br />

Centre, Dubai, UAE<br />

R.TEC GMBH 19<br />

SANIKOM 59<br />

SCHAUENBURG MAB GMBH 12<br />

SEKISUI NORDITUBE TECHNOLOGIES BELGIUM 1<br />

SEKISUI RIB LOC AUSTRALIA 1<br />

SHANGHAI GOODENG CONSTRUCTION MACHINERY<br />

MANUFACTURING CO LTD 14<br />

SWP SYSTEMS GMBH 4<br />

TARGET UNDERGROUND 16<br />

TRELLEBORG PIPE SEALS 11<br />

TRINITY PUMPS 3<br />

TT GROUP – TT-UK/<strong>MIDDLE</strong> <strong>EAST</strong> & PRIME DRILLING 3<br />

VERMEER <strong>MIDDLE</strong> <strong>EAST</strong> 34<br />

VMT GMBH 65<br />

WIEDEMANN ENVIRONMENT SERVICES 27<br />

WIEDEMANN & REICHARDT MASCHINEN &<br />

FAHRZEUGBAU GMBH 27<br />

WES L.L.C. DUBAI 27<br />

ABS <strong>TRENCHLESS</strong> GMBH Stand No: 21<br />

Wintersohler Straße 5, Drolshagen, 57462, Germany<br />

T +49 2761 50730<br />

F +49 2761 507359<br />

E info@abs-trenchless.com<br />

W www.abs-trenchless.com<br />

ABS Trenchless has been a member of the Bauer group since 2009 and specialises in the<br />

manufacture of equipment and accessories for trenchless installation and replacement of many<br />

types of pipelines. We produce Auger Boring Systens (ABS), Rope Bursting Systems (RBS) and tools<br />

for HDD-Drilling. Our guided Auger Boring System (ABS) is used for the installation of pipes with<br />

dimensions from 150 mm up to 1800 mm and a force of up to 600 tones. If an existing line is to be<br />

renovated or rehabilitated, we can offer you our Rope Bursting System (RBS).<br />

ABU DHABI SEWERAGE SERVICES COMPANY (ADSSC) Stand No: 57<br />

PO Box 108801, Abu Dhabi, United Arab Emirates<br />

T +971 2 694 3333<br />

F +971 2 694 3773<br />

W www.adssc.ae<br />

Abu Dhabi Sewerage Services Company was formed in 2005 and is licensed to operate the collection,<br />

treatment and disposal of waste water for the Emirate of Abu Dhabi. We employ five hundred people<br />

and have a large investment program including four new treatment plants and our landmark Strategic<br />

Tunnel Enhancement Program (STEP).<br />

AL NABOODAH SPECIALIST SERVICES (LLC) Stand No: 45<br />

PO Box 11193, Dubai, United Arab Emirates<br />

T +971 4 3390020<br />

F +971 4 3393573<br />

E specialist.services@alnaboodah.com<br />

W www.alnaboodah.com<br />

Al Naboodah Specialist Services (ANSS) Microtunelling and Directional Division was established in<br />

2001. We have installed over 100km of pipelines with a fleet of 11 microtunnelling machines and 4<br />