newsletter - director-e

newsletter - director-e

newsletter - director-e

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

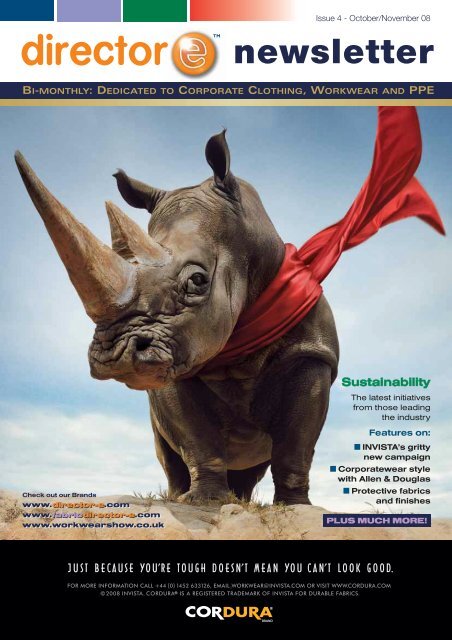

<strong>newsletter</strong><br />

JUST BECAUSE YOU’RE TOUGH DOESN’T MEAN YOU CAN’T LOOK GOOD.<br />

FOR MORE INFORMATION CALL +44 (0) 1452 633126, EMAIL.WORKWEAR@INVISTA.COM OR VISIT WWW.CORDURA.COM<br />

JUST BECAUSE YOU’RE TOUGH DOESN’T MEAN YOU CAN’T LOOK GOOD.<br />

.© 2008 INVISTA. CORDURA ® IS A REGISTERED TRADEMARK OF INVISTA FOR DURABLE FABRICS.<br />

FOR MORE INFORMATION CALL +44 (0) 1452 633126, EMAIL.WORKWEAR@INVISTA.COM OR VISIT WWW.CORDURA.COM<br />

.© 2008 INVISTA. CORDURA ® ®<br />

IS A REGISTERED TRADEMARK OF INVISTA FOR DURABLE FABRICS.<br />

®<br />

Issue 4 - October/November 08<br />

BI-MONTHLY: DEDICATED TO CORPORATE CLOTHING, WORKWEAR AND PPE<br />

Check out our Brands<br />

www.<strong>director</strong>-e.com<br />

www.fabric<strong>director</strong>-e.com<br />

www.workwearshow.co.uk<br />

Sustainability<br />

The latest initiatives<br />

from those leading<br />

the industry<br />

Features on:<br />

■ INVISTA’s gritty<br />

new campaign<br />

■ Corporatewear style<br />

with Allen & Douglas<br />

■ Protective fabrics<br />

and finishes<br />

PLUS MUCH MORE!

Welcome<br />

Dear Reader,<br />

This year, <strong>director</strong>-e is proud<br />

to sponsor one of the<br />

biggest events on the<br />

calendar: Expoprotection -<br />

the exhibition for risk<br />

management. At the<br />

show INVISTA and<br />

Klopman International<br />

will jointly launch, what<br />

they believe to be, the<br />

‘next generation’ in<br />

workwear fabric:<br />

Klopman Vantage fabric<br />

featuring CORDURA ®<br />

brand technology.<br />

To find out more about<br />

this exciting innovation<br />

and what else is being showcased in the workwear<br />

sector check out our exhibition preview on page 12.<br />

The launch of this fabric is one of the latest chapters in<br />

INVISTA’s CORDURA ® Editor: Catherine Christie<br />

brand campaign but it’s by no<br />

means the full story - this can be read on page three.<br />

In our other features: India may be some way behind<br />

countries such as China when it comes to off-shore<br />

manufacturing but it’s hotly tipped to grow over the<br />

next few years. In the light of this, Reena Mital reports<br />

on the new finishes that are being developed there on<br />

page six.<br />

Sustainable practices could be within reach of corporate<br />

clothing and workwear companies, no matter what their<br />

size, as we find out on page eight. One way of achieving<br />

this is by increasing the efficiency of your company<br />

through supply chain management. We spotlight software<br />

system ApparelGMS on page seven.<br />

British corporate clothing is continuing to close in on the<br />

high street when it comes to current trends. Corporatewear<br />

supplier Allen & Douglas demonstrates this with aplomb on<br />

page five, as it reinvents the uniforms of prestigious hotel<br />

group Thistle. Meanwhile, on page 11 UK building society<br />

Nationwide gives <strong>director</strong>-e a preview of the special<br />

collection that its staff will soon be sashaying to work in like<br />

true fashionistas.<br />

If you would like to present a new product or innovation to<br />

the industry you can email me at Catherine@<strong>director</strong>-e.com<br />

I hope that you enjoy the issue!<br />

Catherine<br />

2<br />

www.workwearshow.co.uk<br />

Contents<br />

Visit <strong>director</strong>-e at Expoprotection: Hall 5 stand A81<br />

5<br />

8<br />

2 Welcome<br />

Comment<br />

6<br />

13<br />

3 Workwear<br />

INVISTA reaches out to some of its<br />

toughest customers<br />

4 <strong>director</strong>-e<br />

There’s more to the industry’s media<br />

service than what meets the eye<br />

5 Corporate Clothing<br />

Allen & Douglas revamps the uniform<br />

of a major hotel<br />

6 Finishes<br />

Reena Mital finds out what finishes<br />

are emerging in the Indian market<br />

7 Supply Chain Management<br />

Software<br />

Look no further than ApparelGMS<br />

8 Eco Action<br />

Sustainable practices don’t need to<br />

be costly or time consuming for<br />

workwear, corporate clothing and<br />

PPE companies.<br />

10 Fabrics<br />

Janet Prescott gets a feel for the<br />

latest protective fabrics<br />

11 Nationwide<br />

Buyer Shelley Dodd discusses the<br />

building society’s new special<br />

collection<br />

12 Exhibition<br />

Our sneak preview of Expoprotection<br />

will help you plan your visit<br />

14 Uniform Solutions<br />

The former procurement manager of<br />

British Airways is on-hand to help<br />

15 Information<br />

Diary dates and news in brief<br />

Editor:<br />

Catherine Christie<br />

BA (Hons) PG Dip<br />

Catherine@<strong>director</strong>-e.com<br />

Fabric, Fashion &<br />

Trend Editor:<br />

Janet Prescott<br />

Janet@<strong>director</strong>-e.com<br />

International Editor:<br />

Reena Mital<br />

Reena@<strong>director</strong>-e.com<br />

Circulation/Subscription:<br />

Hannah Johnson<br />

Hannah@<strong>director</strong>-e.com<br />

Managing Director:<br />

Yvette Ashby<br />

Yvette@<strong>director</strong>-e.com<br />

Published bi-monthly by:<br />

Marston Consulting<br />

Limited/TA<br />

<strong>director</strong>-e.com<br />

South House 3A<br />

Suite 4<br />

Bond Estate<br />

Bond Avenue<br />

Bletchley, Milton Keynes<br />

MK1 1SW<br />

Tel: + 44 (0) 870 870 4578<br />

Fax: +44 (0) 870 870 4679<br />

Email: info@<strong>director</strong>-e.com<br />

www.<strong>director</strong>-e.com<br />

www.fabric<strong>director</strong>-e.com<br />

The opinions expressed in<br />

this publication are not<br />

necessarily those shared by<br />

the editor or<br />

publishers. Although the<br />

highest level of care has<br />

been taken to ensure<br />

accuracy the publishers do<br />

not accept any liability for<br />

omissions or errors or claims<br />

made by contributors or<br />

advertisers, neither do we<br />

accept liability for damage or<br />

loss of unsolicited<br />

contributions.<br />

The publishers exercise the<br />

right to alter and edit any<br />

material supplied. This<br />

publication is protected by<br />

copyright and may not be<br />

reproduced in part or in full<br />

without specific written<br />

permission of the publishers.

PROFILE<br />

Brave New World<br />

A global campaign unveiled by INVISTA’s CORDURA ® brand<br />

celebrates the blood, sweat and determination of life’s adventurers<br />

A new episode has opened in the history of INVISTA’S CORDURA ® brand: the global<br />

integrated fibres and polymers business is honouring the achievements of CORDURA ®<br />

fabric users through a gritty and emotional advertising campaign to be launched in early<br />

2009. INVISTA says that the powerful new campaign solidifies its commitment to the<br />

passion of its consumers by reflecting the mindsets and challenging situations of those<br />

who use CORDURA ® fabric around the world.<br />

Honouring everyday heroes<br />

Known for more than 30<br />

years for its resistance to<br />

abrasions, tears and<br />

scuffs, CORDURA ® fabric<br />

- the registered trademark<br />

of INVISTA for durable fabric - is<br />

designed to work in a multitude of<br />

tough environments for a wide range<br />

of products, including luggage,<br />

backpacks, boots, military garments,<br />

workwear and performance apparel.<br />

Now, INVISTA believes it’s time to<br />

celebrate its users - those who,<br />

because of their lifestyles, jobs or<br />

hobbies, can benefit from a fabric that<br />

is just as durable as they are.<br />

Cindy McNaull, global brand manager<br />

for the CORDURA ® brand, says:<br />

“We’ve made a considerable effort to<br />

better understand the emotional<br />

connection that exists between the<br />

CORDURA ® brand and its loyal<br />

users. The new campaign really<br />

aims to celebrate those consumers<br />

by highlighting some of their<br />

greatest feats.”<br />

Hanging tough<br />

So how has INVISTA managed it?<br />

The company has used campaign<br />

advertisements that showcase<br />

unsentimental portraits of limitpushing<br />

situations to reflect the<br />

individual durability of adventurers and<br />

the essence of the CORDURA ®<br />

brand. The images burst with<br />

ruggedness, sweat, muscle and<br />

determination - revolving around the<br />

headline: As long as the world is full of<br />

durable people, we’ll keep making<br />

durable fabrics.<br />

Billy Barnes, creative <strong>director</strong> at<br />

Howard, Merrell & Partners, the<br />

strategic branding and advertising firm<br />

that developed the launch, says:<br />

“There are people out there who do<br />

extremely brave or challenging things<br />

either for their jobs or just for fun.<br />

Who better to honour these<br />

individuals and the adventures they<br />

face than the fabric brand that is right<br />

there with them?”<br />

The new campaign made its official<br />

debut at the Outdoor Retailer<br />

Summer Market in August 2008 in<br />

Salt Lake City, where a series of<br />

concept adverts were displayed as<br />

well as a “How Durable Are You?”<br />

story contest. The fully developed<br />

campaign will launch, however, during<br />

the first quarter of 2009, and<br />

integrated global communications will<br />

be targeted toward the workwear,<br />

outdoor, luggage and military<br />

segments through print, interactive<br />

and various other forms of media.<br />

A strong presence<br />

In line with the focus of the new brand<br />

campaign, the CORDURA ® brand will<br />

also be making its presence felt at<br />

major events within the workwear,<br />

corporate clothing and PPE industry.<br />

To support and recognise the<br />

individuals who drive the European<br />

workwear business, INVISTA’s<br />

CORDURA ® brand has signed up to<br />

become the overall sponsor of the<br />

first Business Manager’s Awards at<br />

the Workwear and Corporate Clothing<br />

Show in April 2009. Susannah<br />

Rayfield, European brand manager for<br />

the CORDURA ® brand, says: “We’re<br />

honoured to be associated with such<br />

an event and, as we continue to<br />

develop more innovative offerings as<br />

part of the CORDURA ® brand<br />

portfolio, we’ll be able to satisfy more<br />

of the needs of this global market.”<br />

INVISTA’s CORDURA ® brand team<br />

will also be exhibiting at the up -<br />

coming Expoprotection show in Paris<br />

from 4th-7th November. They will<br />

present a range of new fabric<br />

offerings from stand C77 in Hall 5,<br />

and will also showcase the new<br />

CORDURA ® brand hangtags and<br />

sew-in labels, which will come into<br />

use towards the end of 2008.<br />

The new hangtags will feature the<br />

slogan ‘Durable. Versatile. Reliable’.<br />

This is an apt summary not only of<br />

CORDURA ® brand fabrics and what<br />

we can continue to expect from them,<br />

but also of the adventuring men and<br />

women who use them.<br />

CORDURA ® Brand Inquiries:<br />

Susannah Rayfield<br />

INVISTA Textiles (UK)<br />

Tel: +44 (0)1452 633126<br />

Email: workwear@INVISTA.com<br />

www.CORDURA.com<br />

Who better to honour these individuals than<br />

the fabric brand that is right there with them?<br />

Susannah Rayfield,<br />

European brand manager<br />

for the CORDURA ® brand<br />

JUST BECAUSE YOU’RE TOUGH DOESN’T MEAN YOU CAN’T LOOK GOOD.<br />

FOR MORE INFORMATION CALL +44 (0) 1452 633126, EMAIL.WORKWEAR@INVISTA.COM OR VISIT WWW.CORDURA.COM<br />

.© 2008 INVISTA. CORDURA ® IS A REGISTERED TRADEMARK OF INVISTA FOR DURABLE FABRICS.<br />

www.<strong>director</strong>-e.com 3<br />

Visit <strong>director</strong>-e at Expoprotection: Hall 5 stand A81<br />

®

Directing the Industry<br />

If you work in the working<br />

garment industry, you will no<br />

doubt have come across<br />

<strong>director</strong>-e in some shape or<br />

form. Apart from the <strong>newsletter</strong><br />

that you are reading now, the global<br />

media service’s websites and<br />

conferences may also be familiar to<br />

you. These facets of the company<br />

work together to inform and<br />

educate the industry on the latest<br />

news, trends, innovations and<br />

events - making <strong>director</strong>-e a<br />

suitable media partner for exhibition<br />

Expoprotection, which takes place<br />

in Paris in November. This year,<br />

<strong>director</strong>-e’s wish to bring<br />

manufacturers, suppliers,<br />

4<br />

www.workwearshow.co.uk<br />

distributors and buyers<br />

together under one roof<br />

also came to fruition. It<br />

partnered up with<br />

Ocean Events to launch<br />

the Workwear and<br />

Corporate Clothing<br />

Show at the<br />

Birmingham NEC in<br />

April and has plans to<br />

make next year’s even<br />

bigger and better.<br />

Web Service<br />

Whether you like your<br />

daily dose of industry<br />

news or prefer to get<br />

your teeth into an<br />

analytical feature,<br />

www.<strong>director</strong>-e.com<br />

provides plenty of<br />

information on<br />

workwear, corporate<br />

clothing and PPE, while<br />

www.fabric<strong>director</strong>-e.com brings<br />

you the latest developments in the<br />

world of fabric. Members can read<br />

up to 100 news stories on the sites<br />

each week, with sourcing hotspots,<br />

sustainability and nanotechnology<br />

representing just a fraction of the<br />

topics that are investigated,<br />

alongside exhibition previews and<br />

conference reviews.<br />

A comprehensive, easy-to-search<br />

sourcing <strong>director</strong>y featuring<br />

thousands of contact details is also<br />

available, helping members to<br />

source fabrics, garments and<br />

equipment. And if you have difficulty<br />

choosing, simply click on the<br />

Visit <strong>director</strong>-e at Expoprotection: Hall 5 stand A81<br />

<strong>director</strong>-e has a number of tools at its disposal to keep you ahead of the<br />

latest news and developments in workwear, corporate clothing and PPE<br />

company profile section for more<br />

information on what each business<br />

can offer. Our websites currently<br />

have around 92,000 members<br />

worldwide - to join them log onto<br />

www.<strong>director</strong>-e.com now.<br />

Newsletter<br />

Register as a member on the<br />

website and you can subscribe to<br />

receive <strong>director</strong>-e’s bi-monthly<br />

<strong>newsletter</strong> for free! Delivered<br />

straight to your door, the <strong>newsletter</strong><br />

is an extension of the website,<br />

containing even more features and<br />

company profiles to allow you to<br />

read the latest on workwear,<br />

corporate clothing, technical textiles<br />

and PPE wherever you are.<br />

Conferences<br />

<strong>director</strong>-e organises some of the<br />

most talked about conferences in<br />

the industry, having earned a<br />

reputation for presenting the topics<br />

that matter most. Visitors come<br />

from all over the world to hear<br />

<strong>director</strong>-e’s experienced speakers<br />

present on crucial issues such as<br />

controversial EU legislation, trading<br />

with China and the latest market<br />

trends. The next conference will<br />

take place at the Workwear and<br />

Corporate Clothing Show on 2nd<br />

April 2009. Find out more about<br />

this exciting event on page nine.<br />

Workwear and Corporate<br />

Clothing Show<br />

In 2006, <strong>director</strong>-e joined forces<br />

with Ocean Events to form<br />

Corporate Clothes Show LLP, and<br />

went on to become joint owners of<br />

the Workwear and Corporate<br />

Clothing Show.<br />

The inaugural show took place<br />

this April at the Birmingham<br />

NEC, and was voted an<br />

overwhelming success.<br />

“The Workwear & Corporate<br />

Clothing<br />

Show is the<br />

UK’s only<br />

exhibition<br />

specifically<br />

dedicated to<br />

this multimillion<br />

pound<br />

industry,”<br />

says joint managing <strong>director</strong><br />

Lorne Cheetham. “It is an essential<br />

event for the entire buyer/seller<br />

spectrum from textile manufacturers<br />

to end-users, embracing all workrelated<br />

garments.<br />

“If you’re in the business of buying<br />

workwear, corporate clothing or<br />

PPE, this is your only chance to see<br />

so many suppliers, feel the quality<br />

of materials, network with all the<br />

professionals, discuss your<br />

requirements, negotiate the best<br />

deals and keep one step ahead of<br />

your competitors.”<br />

Next year’s show will return to the<br />

NEC on 1st and 2nd April, and will<br />

include an exhibition with over 100<br />

stands as well as the popular<br />

catwalk fashion show. The much<br />

anticipated Business Manager<br />

Awards, which recognise the<br />

buyers who play such a vital role<br />

in the industry, will also make<br />

its debut. Hosted by designer Jeff<br />

Banks and sponsored by<br />

CORDURA ® Fabric, the awards will<br />

take place at the prestigious Hilton<br />

Birmingham Metropole Hotel as<br />

part of a glitzy gala dinner.<br />

During the awards ceremony, 20<br />

specially handcrafted awards<br />

will be presented to the<br />

winners and runners-up of the<br />

workwear, corporate clothing and<br />

PPE categories.<br />

To find out more about the<br />

Workwear and Corporate<br />

Clothing Show or to book<br />

your stand, contact show<br />

manager Emma Barrett<br />

by telephone on<br />

+44 (0)1425 470666<br />

or by email on<br />

emma@workwearshow.co.uk<br />

Check out our Brands<br />

www.<strong>director</strong>-e.com<br />

www.fabric<strong>director</strong>-e.com<br />

www.workwearshow.co.uk

PROFILE<br />

Staying in Style<br />

As Allen & Douglas’s latest collection is rolled out, Catherine Christie tries it<br />

on for size and finds out how the company is raising the stakes in<br />

corporatewear style<br />

Allen & Douglas’s customers include<br />

celebrity chef Raymond Blanc, the<br />

Holiday Inn and JD Wetherspoon - and<br />

now the corporatewear supplier has<br />

added Thistle Hotels to the list. The<br />

UK-based hotel chain is undergoing a brand<br />

overhaul and chose Allen & Douglas to reinvent its<br />

uniform. On the eve of its roll-out, I went to meet<br />

head designer Claire Conley to find out how the<br />

company manages to strike a balance between<br />

corporate clothing and high street fashion.<br />

The challenge<br />

The brief was simple: UK hotel chain Thistle<br />

challenged Allen & Douglas and a number of other<br />

companies to design a full range of uniforms that<br />

would give a more contemporary and casual feel as<br />

part of a £100m, five-year plan. “They wanted to<br />

make their members of staff more approachable by<br />

lightening up the look and making everyone feel airy,<br />

comfortable and contemporary, rather than have<br />

them standing rigid in top hat and tails,” says Claire.<br />

So how did the company manage to come out<br />

on top?<br />

Doing your homework<br />

Research is a key area for Allen & Douglas and the<br />

company commits countless hours even before any<br />

designs are drawn up. As well as understanding the<br />

hotel’s brand, competition and customers, knowing<br />

about the demands of their wearers is vital - and<br />

can even involve the design team spending a day in<br />

the hotels and carrying out the different job<br />

functions of the wearers. “You may have a<br />

perception of what a housekeeper, receptionist or<br />

even a waiter does, but when you go out and do<br />

the job there will be little things they do that they<br />

shouldn’t really, like housekeepers will stand on the<br />

side of baths and really stretch and reach, which is<br />

important to factor in when designing the garment.<br />

“One of the things people didn’t like about their<br />

uniform when we asked them was that they had to<br />

wear certain items every day - there was no room<br />

for personal expression. So we thought, ‘Why not<br />

give people a couple of different options to start off<br />

with?’ The idea is that, if you wake up one day and<br />

feel quite relaxed, you might decide to wear a piece<br />

of knitwear with a dress, and the next day you<br />

might want to wear a suit. We are finding that more<br />

and more people want this wardrobe look rather<br />

than just a set uniform.”<br />

Allen & Douglas’s consideration of the wearer also<br />

extends to fit and pattern: “Our technical team is<br />

very hot on making sure that patterns look great on<br />

all sizes. As patterns increase with the size, they will<br />

amend their grading rules from size 16 upwards,<br />

which is quite unique to us. And if you are a bit<br />

bigger, generally speaking you normally want your<br />

garments a bit looser.”<br />

Following fashion<br />

Claire always tries to put herself in the position of<br />

those who she is designing for: “I wouldn’t want to<br />

wear something old fashioned and itchy, so why<br />

should they have anything less than what they’d<br />

pay for themselves?” This approach quickly<br />

becomes apparent as I rummage through some of<br />

Allen & Douglas’s latest collections at the company’s<br />

headquarters. Confronted with suave suits, evening<br />

The idea is to give people garments that they<br />

actually want to wear - after all I wouldn’t want<br />

to wear something old fashioned and itchy<br />

dresses, fitted shirt dresses and funky trousers and<br />

tops, you could easily feel like you were perusing the<br />

rails of a high street store.<br />

And that’s just it - Allen & Douglas’s corporatewear<br />

designs are not only wearable but also skilfully<br />

include fashion trends that still look good three years<br />

on, as well as being affordable and functional.<br />

Working with the procurement team to find<br />

designer copycats was one way Claire was able<br />

to bring some of the latest styles to Thistle’s new<br />

uniforms. “I found a Hugo Boss fabric that I<br />

liked and it was a case of getting different<br />

suppliers to find an alternative that kept the look but<br />

made it practical for corporatewear in terms of price<br />

and composition.”<br />

Details are another way in which trends can be<br />

brought to corporatewear and this was paramount<br />

to Thistle’s designs: “If you talk to someone serving<br />

you, you will look at their face and neck area, so we<br />

put some colour on the inside of their collar and<br />

neckband. When they actually give you the food,<br />

you look at the sleeves and the arms, so it’s getting<br />

the details and colour into the correct places and<br />

adding little flashes.”<br />

The result<br />

After all the rummaging, I tried on a sample of a shift<br />

dress designed for a manager. “We’ve adapted a<br />

classic version to suit the curved neckline, which<br />

features throughout the collection and put big bows<br />

around the middle, which is meant to be very soft<br />

and inviting.” It got the thumbs up from me: fitted<br />

but comfortable around the waist and hips, with<br />

Lycra in the fabric to give it some recovery and<br />

vents to make it practical to walk. Next, I tried a top<br />

and trousers uniform for the hotel housekeepers.<br />

The polycotton fabric with elastane made it<br />

breathable and easy to move around in - enhanced<br />

by back action pleats, side vents and wide leg<br />

trousers - but a mandarin collar meant that comfort<br />

didn’t come at the sacrifice of style. And that’s not<br />

all: “Normally we will build the range and have a<br />

couple of classic staple pieces, but we also put in a<br />

few ‘wow’ pieces that are trendier as well - whether<br />

they go through the whole three years or not.”<br />

Allen and Douglas’s design team is certainly in<br />

demand - other companies that they are currently<br />

redesigning uniforms for include Pizza Hut,<br />

Vodaphone and Hilton Garden Inn. That’s three big<br />

endorsements that shouldn’t be taken lightly.<br />

Head Designer:<br />

Claire Conley<br />

Contact: Julie Lindsay<br />

Director of Sales and Marketing<br />

Allen and Douglas Corporate Clothing Ltd<br />

Tel: +44 (0) 1295 272700<br />

Fax: +44 (0) 1295 270486<br />

Email: sales@aandd.co.uk<br />

www.aandd.co.uk<br />

www.<strong>director</strong>-e.com 5<br />

Visit <strong>director</strong>-e at Expoprotection: Hall 5 stand A81

Anti-microbial finishes for hospital uniforms<br />

are not mandatory yet<br />

The Finishing Touch<br />

Continuing our spotlight on India series, Reena Mital reports on India’s<br />

developments in protective finishes for workwear and corporate clothing<br />

The Indian textile industry has only recently<br />

begun using protective finishes such as<br />

anti-microbial, bio-static and fire-retardant<br />

in corporatewear and workwear fabrics.<br />

Almost all leading corporatewear brands<br />

in India - Raymond, Reliance Industries, Reid &<br />

Taylor, Banswara Syntex, Siyaram Silk Mills, Donear<br />

Industries and Sutlej Industries have protective<br />

finishes in a proportion of their fabric. But these<br />

remain a niche product.<br />

“The specialty finished fabrics are an export-driven<br />

business in India,” says Mr KC Agarwal, executive<br />

<strong>director</strong> of Sutlej Industries. “Most manufacturers<br />

offer a limited collection in such finishes to the US<br />

and EU markets but the Indian<br />

market for such products is almost<br />

negligible.” Exports are also of<br />

recent origin. The industry’s efforts<br />

to move into value-added products,<br />

especially after the quota phaseout,<br />

led to the exploration of such<br />

technologies. And the industry has<br />

only, over the last couple of years,<br />

achieved the international quality<br />

standards needed for the export<br />

markets. But the volume of exports<br />

of such fabrics and garments is still<br />

very small. In the case of wool and<br />

polyester viscose blended suiting<br />

fabrics, of the total export of around US$ 300 million,<br />

not more than 2% would account for such finishes.<br />

Ram Bhatnagar, Raymond India Ltd’s vice president<br />

for the international market says: “We will introduce<br />

some anti-microbial, anti-static finished woolen<br />

worsted fabrics at the next Premiere Vision. This will<br />

help us gauge the response of international clients<br />

and give us a fair idea of the business potential of<br />

this new range. International markets will be the<br />

initial focus.”<br />

According to him, while protective finishes in the<br />

suiting fabric segment are still small, the cotton<br />

shirting’s segment is much bigger, but again, with a<br />

focus on the export markets. These finished fabrics<br />

enable exporters to realize premiums in the range of<br />

20%-50% over the commodity fabrics.<br />

6<br />

www.workwearshow.co.uk<br />

The potential of<br />

corporatewear<br />

fabrics treated<br />

with these<br />

chemicals is<br />

huge, but<br />

untapped<br />

Visit <strong>director</strong>-e at Expoprotection: Hall 5 stand A81<br />

Sportswear and gym wear offer huge<br />

potential for anti-microbial finishes<br />

Untapped potential in the domestic market<br />

The potential of corporatewear fabrics treated with<br />

these chemicals is huge, but untapped. A large<br />

proportion of the sales in the domestic market by<br />

most of these players are to the household sector,<br />

with a small portion going into institutional sales,<br />

where to an extent such finishes are used. However,<br />

India remains a price conscious market, and most<br />

consumers are unwilling to pay the high premiums<br />

that such fabrics and garments attract. “Lack of<br />

awareness about the proven benefits of the finishes<br />

is the main reason for poor acceptance of these<br />

finishes in the Indian market,” says Mr Agarwal. For<br />

instance, the traffic police in India could be one of the<br />

most important consumers of anti-<br />

microbial, moisture management<br />

finished fabrics in the country, but<br />

Indian fabric suppliers have been<br />

unable to break into this segment.<br />

According to Ms Mrinal Choudhary<br />

of Rossari Biotech, one of the<br />

leading manufacturers and<br />

suppliers of specialty chemicals in<br />

the country: “The Indian market for<br />

specialty finishes is growing steadily<br />

at a rate of around 8-10% per<br />

annum, but still remains very small.<br />

An obvious consumer would be<br />

hospital staff but a miniscule percentage of hospital<br />

uniforms are treated with anti-bacterial and other<br />

such finishes. School uniforms are another important<br />

segment where such finishes should have been<br />

popular, but penetration again is almost nil.”<br />

According to Ms Choudhary, some international<br />

sportswear brands in India have launched their<br />

collections, which again form a small part of their<br />

total garment collections in the country. Eve Fabrics,<br />

which has recently begun importing school uniform<br />

fabrics treated with anti-microbial, soil resistant,<br />

moisture resistant finishes, is working hard to break<br />

into the Indian market. According to Mr Aditya Modi,<br />

<strong>director</strong> of Eve Fabrics, “We have targeted some of<br />

the high end schools, which have larger budgets for<br />

such spends, but are facing a lot of sales resistance.<br />

There are concerns about costs, and the effects of<br />

such chemicals on the skin. Breaking the traditional<br />

mindsets and practices is not going to be easy.”<br />

Rossari is also planning to create awareness about<br />

the benefits of these finishes on school uniforms.<br />

“We are in the process of charting out a strategy<br />

to target schools, and educate them about these<br />

finishes, which are easy to maintain.<br />

The finishes last up to 40 washes, and can be<br />

reapplied at minimal cost.” The company, through<br />

its tie-up with Aegis, has also launched UV<br />

protective treatments for fabrics. Ms Choudhary<br />

says: “This, along with anti-microbial, soil release,<br />

moisture management finishes is apt for traffic<br />

police uniforms.” The obstacle most companies<br />

face in supplying to government agencies is the<br />

system of tenders with pricing as the deciding<br />

factor. This leaves very little scope to tender for<br />

fabric supplies with added features as this would<br />

invariably increase costs. This has prevented most<br />

fabric manufacturers and suppliers from focusing<br />

on the domestic market, as there are enough<br />

orders from the export markets, and realizations<br />

are good. For Rossari, nonwovens and technical<br />

textiles is an important and growing market for<br />

these finishes, especially in the Meditech segment.<br />

Encouraging industry growth<br />

While government agencies remain unaware of the<br />

latest developments in fabric finishes, textile<br />

organizations are doing their bit to spread<br />

awareness. The textile department of the Indian<br />

Institute of Technology, (IIT) in Delhi, recently made<br />

a presentation to the Board of Police Research &<br />

Development (BPRD) about the need for a more<br />

focused approach to police uniforms. These<br />

included conducting the necessary anthropometric<br />

studies for better fits, using various specialty<br />

finishes that impart the necessary protection and<br />

comfort to the personnel, using the right blends of<br />

fabrics. This is the first such proposal that the<br />

department has ever received.<br />

The Indian textile dyes and chemicals industry has<br />

been dominated by multinationals - Clariant, BASF,<br />

ColorChem, Dystar, to name a few, and has thus<br />

had access to the latest developments in textiles<br />

dyeing and finishing. The situation is no different in<br />

specialty chemicals. Clariant, through its tie-up<br />

with Schoeller Technologies Ag, has recently<br />

introduced the nanotechnology based<br />

NanoSphere textile finish in India. Clariant India has<br />

been the pioneer in bringing to the textile industry<br />

the latest in innovative finishes.<br />

Similarly, Resil Chemicals, in association with<br />

Thomson Research Associates, has introduced<br />

the Ultra-Fresh range of anti-microbials to the<br />

Indian textile industry. Other finishes offered by the<br />

company include water and oil repellent finishes,<br />

and a number of silicone finishes, and sensory<br />

perception technology for textiles. The company<br />

has collaborated with CTF2000 for fire-retardant<br />

finishes. BASF and other multinationals also have<br />

their own range of specialty chemicals for the<br />

Indian textile industry.<br />

The know-how, technologies and raw materials for<br />

protective finished fabrics are available to the<br />

Indian textile and garment industry. The market for<br />

such products will mature as India’s per capita<br />

income grows.

PROFILE<br />

Taking Control<br />

Technopoly’s supply chain management<br />

software is clinching business deals for<br />

corporate clothing and workwear companies<br />

Planning, implementing and controlling<br />

your supply chain are necessary for any<br />

business looking to maximise its<br />

performance and efficiency. Done<br />

manually, it’s time-consuming and<br />

prone to human error, but supply chain<br />

management software - or SCMS - is the antidote<br />

for the corporate clothing and workwear market.<br />

By freeing employees from endless paperwork<br />

through complete stock management and total<br />

control of garment sales and warehousing, it’s little<br />

surprise that more and more businesses are<br />

turning to SCMS manufacturers like Technopoly.<br />

Established in north-west England in 1994,<br />

Technopoly launched its garment sales and stock<br />

control software system - ApparelGMS - four<br />

years later. Since then, <strong>director</strong>s Graham and<br />

Kathleen Helliwell say that interest within the<br />

workwear and corporate clothing industry has<br />

grown and grown as companies realise its<br />

potential. “More demands are being placed on<br />

companies in these sectors for shorter garmentissue<br />

timescales,” says Kathleen. “But they’re now<br />

learning that ApparelGMS can take the strain out<br />

of providing quick and efficient orders. It frees up<br />

companies of all sizes to start chasing and winning<br />

new business rather than being bogged down<br />

with admin.”<br />

A winning combination<br />

Built from the ground up and based on the<br />

Microsoft SQL database engine, ApparelGMS is a<br />

fully-integrated, real-time stock system that gives<br />

the user complete<br />

control of all activities<br />

from initial enquiry<br />

through to garment<br />

dispatch and<br />

invoicing. It also links<br />

directly to Sage<br />

accounts and the<br />

Microsoft Office suite.<br />

Stock can be entered<br />

and searched for in<br />

groups of colours and<br />

sizes among multiple<br />

warehouse sites, while<br />

forecasting screens<br />

predict run-out. Sales<br />

orders can also be entered quickly from either<br />

list or matrix screens, matched to stock and<br />

then tracked - ensuring delivery deadlines are<br />

always met.<br />

Kathleen says: “It’s a bespoke yet simple-to-use<br />

service that’s created to meet customer needs<br />

while having the capability and flexibility to serve<br />

businesses as they expand. Additional modules<br />

like web ordering, finishing, manpack, concessions<br />

and retail POS have all been devised with this<br />

in mind.”<br />

Putting the customer first<br />

It’s not only the product that’s enabled<br />

ApparelGMS to expand businesses - Technopoly<br />

believes that customer service and price are just<br />

as important when it comes to SCMS.<br />

ApparelGMS support staff are on-hand to provide<br />

support or extra training on the phone or online<br />

24 hours a day, while any essential onsite visits<br />

will also be made at no extra cost - keeping<br />

pricing competitive.<br />

This sounds impressive, but Technopoly’s users<br />

are its best advocates. Corporatewear supplier<br />

FCC won a contract to provide a major bus<br />

company with uniforms for their 350 staff after<br />

ApparelGMS gave them online uniform ordering.<br />

You can head to www.apparelgms.com to read<br />

more and, as Kathleen says, find out “straight<br />

from the horse’s mouth’’ how ApparelGMS can<br />

benefit corporate and workwear companies.<br />

Contact:<br />

Technopoly Ltd<br />

Rolands House,<br />

87 Bacup Road<br />

Rawtenstall<br />

Lancashire, United Kingdom<br />

BB4 7NW<br />

Telephone: 01706 830930<br />

Fax: 01706 831090<br />

sales@apparelgms.com<br />

It frees up companies<br />

of all sizes to start<br />

chasing and winning<br />

new business rather<br />

than being bogged<br />

down with admin<br />

www.<strong>director</strong>-e.com<br />

Visit <strong>director</strong>-e at Expoprotection: Hall 5 stand A81<br />

7

A Sustainable Future<br />

In theory, we would all<br />

like to do our bit for the<br />

environment. But the<br />

burning question is what<br />

will sustainability cost<br />

the corporatewear,<br />

workwear and<br />

PPE industry?<br />

When it comes to<br />

sustainability, the<br />

stakes have been<br />

raised. Pressure is<br />

building on<br />

businesses to show their<br />

environmental and ethical credentials.<br />

And the corporatewear, workwear<br />

and PPE industry is no exception, as<br />

the way garments are made and<br />

disposed of is becoming almost as<br />

important to consumers as quality,<br />

cost and service.<br />

Environmental responsibility is at the<br />

very heart of sustainability, but this<br />

can be a problem - particularly when<br />

it comes to corporatewear. In a<br />

sector where uniforms are typically<br />

changed every two to four years,<br />

garments are often sent to landfill<br />

even when their technical<br />

performance and appearance is still<br />

good enough for them to be reused.<br />

But by manufacturing brand new<br />

garments instead of recycling or<br />

reusing discarded ones, more of the<br />

earth’s non-renewable fossil fuels are<br />

used and greenhouse gas emissions<br />

such as carbon dioxide produced.<br />

So what should we do? The Centre<br />

for Remanufacturing and Reuse has<br />

the solution: it’s planning to reduce<br />

the industry’s sustainability impacts<br />

through the launch of a central<br />

resource that will educate businesses<br />

on becoming more sustainable<br />

through environmental and socially<br />

responsible actions - and all while<br />

remaining profitable.<br />

A source of information<br />

The Centre for Remanufacturing and<br />

Reuse (CRR) is a Defra BREWfunded<br />

organisation managed by<br />

consultancy Oakdene Hollins Ltd,<br />

which was set up three years ago to<br />

support and promote product<br />

remanufacturing and reuse in the UK.<br />

Following a Defra project led by<br />

Oakdene Hollins in 2006, which<br />

revealed that 1.2 million tonnes of<br />

general clothing ends up in landfill in<br />

the UK every year, the workwear,<br />

corporatewear and PPE industry<br />

seemed like a good place to<br />

start with increasing recycling and<br />

reuse rates.<br />

CRR is working with a range of<br />

consortium members from across<br />

the corporatewear supply chain and<br />

academia to undertake practical<br />

research into the five areas that can<br />

act as barriers to recycling and reuse:<br />

garment design and construction,<br />

fibre composition, end-of-life<br />

management and taxation. The<br />

information gathered will be made<br />

accessible through an online website<br />

that will launch in April 2009 at the<br />

Workwear and Corporate Clothing<br />

Show at the Birmingham NEC.<br />

“The website will summarise the<br />

findings of the project, feature cases<br />

of best practice, a searchable<br />

database of companies and raise<br />

awareness of the economic, social<br />

and environmental benefits of<br />

corporatewear reuse,” says CRR<br />

consultant Fiona Kelday. “At the end<br />

of the day, it has to make business<br />

sense - that’s a company’s major<br />

bottom line, as much as people say it<br />

It has to make business sense at the end of the day -<br />

that’s the major bottom line, as much as people say<br />

it is all about the environment<br />

8<br />

www.workwearshow.co.uk<br />

Visit <strong>director</strong>-e at Expoprotection: Hall 5 stand A81<br />

is all about the environment.” A guide<br />

will also be produced to inform<br />

buyers of what alternative fibres are<br />

most amenable for use in<br />

corporatewear garments, including<br />

information on their suitability for<br />

recycling and reuse; what to ask for<br />

from suppliers and how to encourage<br />

employees to give their old uniforms<br />

back for reuse. Fiona says: “Although<br />

we are trying to promote reuse and<br />

recycling, we do favour reuse<br />

because the carbon benefits are<br />

greater and you don’t have to put<br />

additional energy into recycling and<br />

shredding things up.”<br />

Industry Leaders<br />

Nationwide is already doing its bit.<br />

While the majority of its obsolete<br />

clothing is sent to developing<br />

countries or recycled for automotive<br />

sound proofing, this year the<br />

company has decided to donate<br />

around 200 garments to Dress for<br />

Success London. The charity helps<br />

disadvantaged women move into<br />

employment by providing an<br />

interview outfit and additional clothing<br />

once they secure a job - a prime<br />

example of the social benefits that<br />

sustainability can bring.<br />

But Fiona believes this form of reuse<br />

could prove an obstacle for some<br />

companies: “A logo is the visual<br />

identity of a company and so<br />

there are security issues surrounding<br />

the reuse of certain uniforms.<br />

Nationwide’s programme works<br />

because their uniform isn’t heavily<br />

logoed and is of a good quality.”<br />

LMB, which has been collecting,<br />

sorting and selling clothes, textiles<br />

and shoes to other countries since<br />

1985, has its own methods for<br />

overcoming such barriers - the LMB<br />

Secure Textile Reuse Service.<br />

Transparency is key and many major<br />

companies use this scheme, with<br />

airlines and banks among their<br />

customer base. To further reduce the<br />

possibility of someone obtaining a full<br />

uniform, LMB splits individual<br />

garments up from the uniform and<br />

mixes them in with different bales of<br />

normal clothing. “It’s not a charity -<br />

they don’t just take any clothing their<br />

customers want a choice,” Fiona<br />

says. “It’s a business - a trade -<br />

encouraging economic growth in<br />

these countries and LMB is a<br />

fantastic example of a family-run<br />

company that cares about<br />

supporting development both in the<br />

UK and overseas.

Meanwhile, corporate clothing<br />

company Dimensions, which clothes<br />

one and a half million wearers every<br />

year, joined up with clothing recyclers<br />

Sisters Textiles in March, to continue<br />

its 100% recycling and reuse policy.<br />

Returns are collected by Dimensions<br />

through the same carrier that delivers<br />

the customer’s garments.<br />

Up to 12 tonnes a month are sent to<br />

Sisters Textiles, which sell them to<br />

countries such as Africa and Poland<br />

for reuse. Garments that are heavily<br />

embroidered or unfit for reuse are<br />

sent to a carpet manufacturer to be<br />

recycled into carpet backing or<br />

underlay. “We have a lot of<br />

customers such as Royal Mail and<br />

the ambulance service who wear<br />

uniforms that are heavily<br />

embroidered,” says quality control<br />

manager Vicki Maxted.<br />

“But we do try and encourage them<br />

through our design department to<br />

reduce the amount of logos that they<br />

have, or to have a secondary pocket<br />

that can be cut away so that the<br />

garment can be reused afterwards.”<br />

Japanese innovation<br />

For other ideas on how the<br />

corporatewear industry can become<br />

more sustainable, it seems that we<br />

only have to look east for inspiration:<br />

for example, leading Japanese<br />

retailer Uniqlo takes back thousands<br />

of its own brand products from<br />

customers every year. The majority is<br />

sorted and sent for reuse in<br />

developing countries and the rest<br />

is either recycled as industrial<br />

rags and insulation or used to fuel<br />

factory furnaces.<br />

In addition, since Japanese<br />

corporate clothing manufacturer<br />

Kurabo started collecting and using<br />

discarded uniforms to generate<br />

Energy from Waste (EfW) for one of<br />

its finishing and dyeing plants in<br />

2002, almost 52 tonnes have been<br />

diverted from landfill. Not only has<br />

this reduced the company’s carbon<br />

footprint, but it has reduced their<br />

energy costs. But sustainable<br />

systems don’t have to be limited to<br />

the final part of the chain, according<br />

to Japanese company Teijin, one of<br />

the world’s largest recycled polyester<br />

producers. Clothing company<br />

Patagonia first pioneered the<br />

recycling of PET bottles to make its<br />

extreme weather fleeces in 1993, but<br />

Teijin believes that its closed-loop<br />

recycling, which it calls ECO<br />

CIRCLE TM , takes the concept to the<br />

next level. Where garments made<br />

from recycled polyester products<br />

often end up in landfill, ECO CIRCLE<br />

TM is an endless recycling cycle that<br />

produces no waste, reduces carbon<br />

dioxide emissions and saves energy.<br />

Clothing companies who sign up to<br />

ECO CIRCLE TM enter into an<br />

agreement to ship their old garments<br />

to Teijin Fiber’s recycling plant in<br />

Matsuyama Japan, where they are<br />

broken down and recycled into<br />

polyester yarn. The companies buy<br />

Teijin’s recycled fabrics to turn back<br />

into garments and these are returned<br />

and recycled back into polyester fibre<br />

at the end of their life cycle.<br />

“People expect a recycled product<br />

to be different in quality to a new<br />

product, but our patented chemical<br />

system breaks the polyester<br />

materials down to their molecular<br />

level to produce recycled polyester<br />

that is the same quality as<br />

polyester manufactured directly<br />

from petroleum,” says business<br />

development manager<br />

Miles Marchant.<br />

“Unlike the material process, which<br />

only involves the melting down of<br />

PET bottles, we can create variations<br />

such as split yarn, hollow yarn and<br />

segmented yarn - these can be used<br />

to make fabrics for use in sportswear,<br />

corporatewear and fashion.”<br />

Most people would probably<br />

question the notion that shipping<br />

discarded garments to Japan from<br />

around the world can actually save<br />

energy and reduce carbon dioxide<br />

emissions. But an independent<br />

We only have to look east for<br />

inspiration: companies there are<br />

leading the way in reuse and<br />

recycling technologies and<br />

initiatives<br />

report from Patagonia’s Common<br />

Threads Recycling Program has<br />

produced figures that state that<br />

shipping garments that have been<br />

collected in the US to Japan for<br />

recycling in the ECO CIRCLE TM<br />

system still results in 76% less<br />

energy usage and 71% less carbon<br />

dioxide emissions than producing<br />

polyester from virgin materials.<br />

This process may be suited to larger<br />

companies that have the resources<br />

to collect their used garments and<br />

ship them to Japan, but Fiona says<br />

smaller companies are often at an<br />

advantage when it comes to making<br />

their business more sustainable.<br />

“I think that sometimes if you are in a<br />

smaller company there aren’t as<br />

many barriers to go through and, if<br />

you have a leader who has a<br />

great vision that can go an awfully<br />

long way.”<br />

ECO CIRCLE TM is a trademark of<br />

TEIJIN FIBERS LIMITED<br />

Time To Change<br />

Fast Facts<br />

■ The UK’s workwear,<br />

corporatewear and PPE<br />

industry was valued at<br />

approximately £446m<br />

in 2007<br />

■ The reuse rate of the<br />

industry currently lies at<br />

less than 5% per year in<br />

the UK<br />

■ If the reuse rate of<br />

corporatewear, workwear<br />

and PPE is increased to<br />

10% by the end of 2009, it<br />

would result in around<br />

22,000 tonnes of CO2<br />

being saved - enough<br />

to fill Wembley Stadium<br />

10 times!<br />

■ Around 24 of the 57<br />

million metric tonnes of<br />

textiles produced around<br />

the world is polyester<br />

Sustainability is at the heart of the 2009 Workwear and<br />

Corporate Clothing Show conference. The event, which will take<br />

place at the Birmingham NEC on 2nd April, will bring together<br />

eight inspiring speakers to present on the three main areas of<br />

sustainability - environment, social and economy - in relation to<br />

the corporate clothing, workwear and PPE industry.<br />

The conference, which is sponsored by Syscom PLC, will give a<br />

general overview of how the industry can become more<br />

sustainable through environmental and socially responsible<br />

actions such as recycling, reuse, ethical sourcing and supply<br />

chain management. These areas will be communicated by<br />

buyers, suppliers and organizations that are making<br />

sustainability work for them while remaining profitable.<br />

Speakers include Campbell Bland, UK market manager at<br />

Lenzing Fibers; Hayley Brooks, sales and marketing <strong>director</strong> at<br />

Dimensions Corporatewear; Fiona Kelday from the Centre for<br />

Remanufacturing and Reuse; Michelle Barry, <strong>director</strong> of<br />

Laurence M. Barry & Co; and Steve Milner, managing <strong>director</strong> of<br />

EU business at Noble Biomaterials.<br />

For more information and to buy your ticket log onto<br />

www.workwearshow.co.uk/conference<br />

www.<strong>director</strong>-e.com<br />

Visit <strong>director</strong>-e at Expoprotection: Hall 5 stand A81<br />

9

Protective Fabrics Gain Ground<br />

3M new reflective flexible tape<br />

Health and safety<br />

New developments in protective fabrics are at the heart of the<br />

latest autumn exhibitions. As a result of increased demands on<br />

employers to ensure the health and safety of their workers,<br />

protective elements are appearing in more areas of workwear, as<br />

well as high tech safety wear. Information is now available to<br />

buyers and employers from suppliers, manufacturers and major<br />

players in the workwear arena. Arco, the UK supplier of safety<br />

equipment and workwear, has developed its biggest ever range<br />

of own-brand and branded products. The company’s new ‘Big<br />

Book’ features 22,000 safety and workwear products, with over<br />

2,000 new products that include safety information important for<br />

small employers.<br />

It’s evident that new products<br />

are constantly being introduced<br />

to this highly regulated area.<br />

Sioen Industries has a wide<br />

range of protective products,<br />

including those that are chemical<br />

and FR resistant, as well as body<br />

armour and flotation systems.<br />

Meanwhile, innovation is particularly<br />

being developed in areas such as<br />

firefighting. An example is Outlast:<br />

“It is our target to be at each corner<br />

of our plant within five minutes”,<br />

says Jürgen Helt Technical Officer of<br />

BASF Fire Department in<br />

Ludwigshafen / Germany, the<br />

largest self-contained chemical<br />

complex and the headquarters of<br />

the BASF group. The right apparel<br />

and equipment is crucial to the<br />

operation, and this includes proper<br />

footwear. To gain time, the BASF<br />

firefighters spend the entire day in<br />

closed firefighter boots. To make<br />

this bearable, they have been<br />

equipped with boots made by<br />

Baltes, containing the temperature<br />

regulating phase change material<br />

(PCM) Outlast ® Adaptive Comfort ® .<br />

The boots are designed to be very<br />

comfortable and light. Mr Helt<br />

added: ‘It’s an essential<br />

10<br />

www.workwearshow.co.uk<br />

improvement due to the<br />

temperature-regulating Outlast ®<br />

lining. We wear the boots all day,<br />

and we no longer feel as if we’re<br />

standing in an oven!”<br />

3M has just introduced a new<br />

Scotchlite Reflective Material<br />

Comfort Trim Series, which can be<br />

used to make conventional clothing<br />

visible without having to add<br />

another reflective layer to an outfit.<br />

The trim is made out of very durable<br />

reflective material, which is flexible<br />

and lightweight. The heat-applied<br />

trim uses the renowned glass bead<br />

technology developed by 3M for<br />

Scotchlite reflective materials but<br />

this time the material is arranged in<br />

diagonally cut segments. This<br />

improves water vapour<br />

transmission, to keep the wearer<br />

drier and cooler. It is also more<br />

flexible, allowing for drape, so that<br />

garments are soft and fluid in<br />

design. Greater wash durability,<br />

meanwhile, ensures that it keeps its<br />

brightness longer.<br />

Enhancing wellbeing<br />

Protective fabrics can also ensure<br />

Visit <strong>director</strong>-e at Expoprotection: Hall 5 stand A81<br />

protection from discomfort such as<br />

cold, sweat or heat, which can affect<br />

the wellbeing of the workforce and<br />

affect productivity and morale.<br />

INVISTA recently launched LYCRA ®<br />

2.0 technology, which increases<br />

comfort through close-to-the-body<br />

stretch and recovery attributes; as<br />

well as the snug fit associated with<br />

minimal stitching. Trends in fashion for<br />

tight fitting, lightweight garments are<br />

paralleled in workwear, and INVISTA<br />

has launched several new branded<br />

textile initiatives: Xtra Life LYCRA ®<br />

fibre for chlorine-resistant and longerlasting<br />

swimwear, LYCRA ® Black<br />

fibre for non-fade dark or black<br />

intimate apparel and LYCRA ® Xtra<br />

Fine fibre collection.<br />

Swiss innovators Eschler have carried<br />

out research on reducing heat on<br />

dark coloured textiles. Deep dyed<br />

textiles treated with Thermoflect by<br />

Eschler prove that UV-rays are largely<br />

reflected to prevent heating up.<br />

DOW XLA fibre directly<br />

addresses problems of UV-light,<br />

chlorine and transpiration-related<br />

limitations of traditional stretch<br />

fibres and is appearing more and<br />

more in workwear to provide a<br />

robust, durable yet comfortable fabric<br />

for uniforms.<br />

As we reported in our last issue, there<br />

is a growing trend of producing<br />

organic or bio fabrics in workwear.<br />

By 2009, 20 percent of all Polartec ®<br />

products will be manufactured from<br />

recycled materials, without sacrificing<br />

fabric quality or performance. For<br />

example, next year, The North Face<br />

Denali, described as ‘the best-selling<br />

fleece jacket of all time’, will switch to<br />

a Polartec ® fabric that contains 87%<br />

recycled content. The new Denali will<br />

save approximately three litres of fuel<br />

and 14 kgs of CO 2 per jacket.<br />

Similarly, Lenzing Fibres introduced<br />

their new botanic principles in Tencel<br />

and Lenzing Modal for activewear<br />

and workwear at the Outdoor Retailer<br />

Show in the US, in August.<br />

Bacteria control is a hot issue.<br />

Klopman’s Sanitized ® antimicrobial<br />

finish is widely used in healthcare<br />

wear in Europe. Manutencoop<br />

management in Italy has chosen<br />

Klopman’s Charlotte quality as a<br />

comfortable lightweight 50%<br />

cotton, 50% polyester<br />

twill that<br />

is suitable for use<br />

where<br />

personnel are in close<br />

contact with the public<br />

White trousers and<br />

coloured tunics made in<br />

Klopman’s ‘Charlotte’ fabric<br />

with the unique antimicrobial<br />

Sanitized finish<br />

and working in warm conditions.<br />

Treated with the Sanitized<br />

antimicrobial finish, it is specifically<br />

designed to actively fight the<br />

proliferation of bacteria and fungi that<br />

are a significant cause of cross<br />

infection and odour.<br />

A large new hospital in Verona uses<br />

colour to distinguish different roles in<br />

the health service, and several<br />

thousand sets of white trousers and<br />

coloured tunics will be made in<br />

Klopman’s Charlotte fabric, which has<br />

been dermatologically tested as safe<br />

for sensitive skin.<br />

Janet Prescott,<br />

Fabric, Fashion and Trend Editor<br />

Baltes firefighter boots

It offers<br />

people a<br />

chance to<br />

stand out<br />

from the<br />

crowd - they<br />

are still<br />

smart and<br />

professional,<br />

but with<br />

more of a<br />

‘high street’<br />

look<br />

A Smart Investment<br />

Special collections can really<br />

give corporatewear uniforms<br />

an edge, says Nationwide<br />

buyer Shelley Dodd<br />

Anticipation “<br />

is rising,”<br />

Shelley Dodd says on the<br />

eve of her special<br />

collection roll-out for<br />

Nationwide building<br />

society - and there’s good reason,<br />

too. Nationwide brings out a special<br />

collection once every two years and,<br />

because it’s limited edition, staff must<br />

get in quick. But what exactly is so<br />

special about a special collection and<br />

what can it add to a corporate<br />

uniform? Shelley sums it up in two<br />

words: current trends. These<br />

garments promise to bring a slice of<br />

catwalk glamour to their local<br />

branches, so it’s not surprising that<br />

staff are already itching to get their<br />

hands on them.<br />

Promoting personality<br />

Nationwide rolls out its main<br />

corporate clothing collection every<br />

two years and there is a special<br />

limited edition collection for each new<br />

range. Their newest main collection<br />

was distributed to over 9,000 wearers<br />

in April and Shelley says it’s been very<br />

well received. “It offers more choice<br />

than ever before and has<br />

incorporated some fabulous new<br />

designs and a print pattern, which<br />

was voted for by the wearers,” she<br />

says. But despite the success of the<br />

main collection, Shelley believes that<br />

it is also worth giving wearers the<br />

option to purchase items from a<br />

special limited collection, which they<br />

can add to their existing wardrobe six<br />

months on.<br />

“In the special collection we try to<br />

offer our female staff a few garments<br />

that are more ‘high fashion’ than our<br />

normal collection and based on<br />

current trends, which we think<br />

they will love. They really offer<br />

people a chance to stand out<br />

from the crowd - they’re still smart<br />

and professional, but with more of a<br />

‘high street’ look.”<br />

Strengthening the brand<br />

Members of staff who enjoy wearing<br />

their uniform and feel confident and<br />

comfortable will reflect this in their<br />

work and the way that they deal with<br />

customers. This is why, although the<br />

limited edition collection is available<br />

for any Nationwide employee to<br />

purchase, it’s primarily aimed at those<br />

who work in branches in customerfacing<br />

roles. “Corporate clothing is a<br />

very important tool in reflecting our<br />

brand,” says Shelley. “First<br />

impressions count! We want our<br />

garments to look professional and<br />

modern, and reflect the forwardthinking<br />

Nationwide brand. But<br />

ensuring our employees feel<br />

comfortable in the clothing is<br />

essential and offering more choice<br />

means that we can provide<br />

something for everyone.”<br />

Carrying trends into<br />

corporatewear<br />

But bringing current trends to the<br />

corporate environment is easier said<br />

than done. Firstly, how do you<br />

reconcile the sometimes impractical<br />

styles of high fashion with the daily<br />

demands of a working environment<br />

and, secondly, how do you adapt<br />

those trends to meet your budget?<br />

Designing trend-setting tops to wear<br />

with more classic tailored garments<br />

such as trousers, skirts and jackets is<br />

one way in which Nationwide has<br />

tackled these issues.<br />

The limited edition collection consists<br />

of a three-quarter sleeved jersey tunic<br />

top, a short sleeved knitted top with<br />

belt, a short sleeved polyester blouse<br />

with mock cross over front detail, a<br />

three-quarter sleeved knitted cardigan<br />

with button detail and a short sleeved<br />

polycotton blouse. “The limited<br />

edition tops can be worn with any of<br />

the skirts and trousers available in the<br />

main collection and will give a fresh<br />

and modern look to wearer’s<br />

wardrobe. All the fabrics and<br />

colours we’ve used have been<br />

included in the main collection, so<br />

they will complement the existing<br />

garments perfectly!”<br />

And when it comes to Shelley’s<br />

personal favourites: “I love the tunic<br />

top in this collection. It’s a really<br />

fashionable garment, which will suit all<br />

shapes and sizes and the pleat detail<br />

across the front looks fabulous! The<br />

short sleeved knitted top with a belt is<br />

also a lovely top, which again looks<br />

really modern.”<br />

Making it sustainable<br />

These days, how a garment is made<br />

is becoming just as important in the<br />

fashion and corporate clothing<br />

industries as how it looks and<br />

performs. Shelley has taken important<br />

steps to make this consideration a<br />

priority in both her main and special<br />

collection. “Whenever we produce a<br />

new collection, we ensure that all the<br />

garments are ethically-sourced and,<br />

where possible, we incorporate<br />

sustainable materials.<br />

We have used corozo nut buttons in<br />

our current collection, which are a<br />

100% natural vegetable, and we have<br />

introduced an organic cotton shirt for<br />

the men. Our clothing managing<br />

agent, incorporatewear, also<br />

maintains a close relationship with the<br />

factories to ensure the manufacturing<br />

is completed to a high standard.”<br />

Nationwide employees with corporate<br />

clothing vouchers can order these<br />

limited edition garments from 6th<br />

October - it’s open to everyone else<br />

to purchase from 13th October.<br />

Shelley Dodd, buyer for<br />

Nationwide Building Society<br />

www.<strong>director</strong>-e.com<br />

Visit <strong>director</strong>-e at Expoprotection: Hall 5 stand A81<br />

11

Working Out<br />

Plan your visit to Expoprotection by reading our preview<br />

of some of the workwear companies and products that<br />

you can expect to see this November<br />

Workwear is expected to make a<br />

triumphant return to<br />

Expoprotection, the biennial<br />

exhibition for risk management.<br />

Despite only premiering in 2006,<br />

the Workwear section already looks set to<br />

become as important to the exhibition as the<br />

more traditional sections of Security/Safety, Fire<br />

Fighting, and Health and Safety at Work. At the<br />

last show, over a third of the 24,500 unique<br />

visitors who attended the event declared that they<br />

were mainly interested in the Workwear and<br />

Occupational Risks sections. And this year, the<br />

number of workwear exhibitors has leapt from 95<br />

to 123 companies.<br />

Visitors to the event, which runs from 4th to 7th<br />

November, will witness two new sectors - Natural<br />

Risks and Industrial and Technological Risks - as<br />

well as an Ergonomic Village with products and<br />

services for the workplace. The tradeshow has<br />

also devised a varied program of events, including<br />

a risk management forum and more than 50<br />

conference and workshop sessions led by<br />

experts on comprehensive risk management and<br />

social and economic challenges.<br />

The piece de resistance, however, promises to be<br />

the Innovation Zone, situated at the heart of the<br />

exhibition area, and displaying over a hundred<br />

new products that visitors will be able to test out.<br />

These will include the entries for the Innovation<br />

Awards, which will also be awarded here on the<br />

first day of the show.<br />

To help you plan your visit to the exhibition, here is<br />

Klopman Vantage fabric featuring<br />

CORDURA ® Klopman Vantage fabric featuring<br />

CORDURA brand technology –<br />

combines comfort and durability for<br />

workwear garments<br />

® brand technology –<br />

combines comfort and durability for<br />

workwear garments<br />

12<br />

www.workwearshow.co.uk<br />

Visit <strong>director</strong>-e at Expoprotection: Hall 5 stand A81<br />

a taste of what some of the exhibitors have to<br />

offer in the Workwear section in Hall 5:<br />

Klopman International Stand C76 and<br />

INVISTA’s CORDURA ® brand Stand C77<br />

What better way to celebrate your 40th birthday<br />

and to demonstrate your ongoing commitment to<br />

the European textile sector than with a range of<br />

innovative new fabrics? That’s the thinking behind<br />

Klopman International’s presence at the show.<br />

They’ve teamed up with INVISTA to launch<br />

Klopman Vantage fabric featuring CORDURA ®<br />

brand technology. The fabric exploits the benefits<br />

of CORDURA ® fabric, which is well-known for its<br />

resistance to abrasions, tears and scuffs.<br />

It gives you a 50/50 intimate blend of INVISTA TM<br />

T420 nylon 6.6 and combed cotton in a twill<br />

construction weighing 250g/m2, and Klopman<br />

says: “The new fabric offers the optimum<br />

combination of exceptional abrasion<br />

resistance, comfort and style and is ideal for<br />

use in full garments such as trousers, jackets<br />

and coveralls.”<br />

Meanwhile, new additions to Klopman’s<br />

protectivewear range of fabrics include a<br />

heavyweight 470g/m2 100% cotton flame<br />

retardant fabric accredited to EN ISO 11611,<br />

ISO/DIS 11612 and IEC 61482-2 (Electric Arc)<br />

and an EN 471 accredited 275g/m2 60% cotton<br />

40% polyester high-visibility fabric, with luminosity<br />

characteristics and superior comfort.<br />

Two new fabrics in Klopman’s Bioguard range of<br />

antimicrobial fabrics will also be on display.<br />

Harnessing the antibacterial properties of silver<br />

technology, these fabrics - based on bestselling<br />

styles Bravo and Superbandmaster - offer<br />

antimicrobial protection and are specifically<br />

designed to meet the requirements of critical<br />

hygiene applications, such as in healthcare and<br />

the food industry. Klopman will also be<br />

introducing the first fabric in its range to be made<br />

with Fairtrade Certified Cotton.<br />

Lenzing Fibres Stand G77<br />

One half of Lenzing’s stand will focus on<br />

Lenzing FR ® - a high performance flame resistant<br />

fibre used in fabrics for protection against heat<br />

from liquid molten metal splash, electric arc,<br />

flash fire, flammable liquids, welding sparks and<br />

radiant heat. Protective clothing made of Lenzing<br />

FR ® is inherently flame resistant, and this results<br />

in permanent protection for the lifetime of<br />

the garment.<br />

Lenzing says that the fibre also offers comfort,<br />

flexibility, moisture management properties and<br />

unique body climate control: “The secret is in the<br />

New and improved Microchem ®<br />

4000 coverall from Microgard ®<br />

fibre itself. Lenzing FR ® does not store the heat - it<br />

feels immediately cool, even after severe flame<br />

and heat exposure.” At the exhibition, Lenzing will<br />

demonstrate the fibre’s versatility through a new<br />

clothing concept that combines Lenzing FR ®<br />

fibres with high visibility protection in high visibility<br />

yellow. The fibre can also be blended with other<br />

high performance fibres, such as Aramid fibres for<br />

fire fighting applications or wool for molten<br />

aluminium protection, resulting in a head to toe<br />