Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

6<br />

<strong>Oerlikon</strong> <strong>Schlafhorst</strong> <strong>Express</strong> Innovations<br />

The Autoconer 5 product family<br />

for rewinding packages<br />

Attractive, made-to-measure models for optimum package quality<br />

Individual requirements for rewinding – our offer in detail<br />

An attractive, interesting segment in the field of package winding is<br />

the rewinding of packages. The broad spectrum of textile process<br />

sequences gives rise to different basic conditions and demands on<br />

the rewinding process. Looking at the different package forms and<br />

the various end applications, it soon becomes clear that one rewinding<br />

machine alone cannot provide the solution for optimum quality<br />

and flexibility.<br />

The logical consequence of this is that <strong>Oerlikon</strong> <strong>Schlafhorst</strong> offers<br />

various models and concepts in the Autoconer 5 product family that<br />

meet the different requirements of the rewinding process. The decision<br />

as to which machine type and configuration is right can be carefully<br />

considered and made with reference to the individual customer<br />

requirements.<br />

You can take both textile requirements and process-related conditions<br />

into account in the selection.<br />

The textile criteria include:<br />

• Format and presentation of the feed package<br />

• Level of clearing of the yarns to be processed<br />

• Requirements of downstream processing stages<br />

• And a new feature: choice of traversing technology<br />

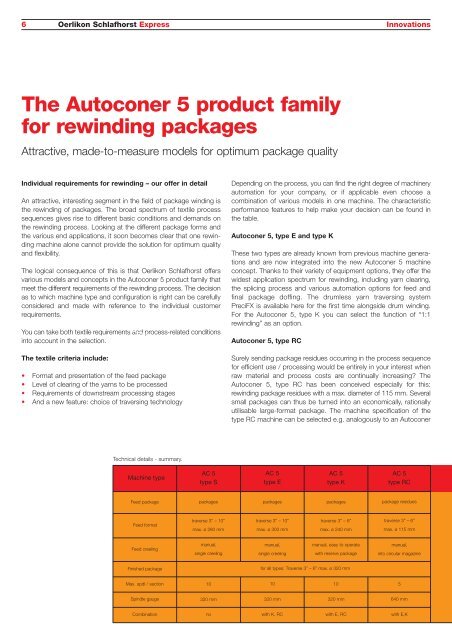

Technical details - summary.<br />

Machine type<br />

AC 5<br />

type S<br />

Feed package packages<br />

Feed format<br />

Feed creeling<br />

Finished package<br />

Max. spdl / section<br />

Spindle gauge<br />

Combination<br />

traverse 3” – 10”<br />

max. ø 280 mm<br />

manual,<br />

single creeling<br />

10<br />

320 mm<br />

Depending on the process, you can find the right degree of machinery<br />

automation for your company, or if applicable even choose a<br />

combination of various models in one machine. The characteristic<br />

performance features to help make your decision can be found in<br />

the table.<br />

Autoconer 5, type E and type K<br />

These two types are already known from previous machine generations<br />

and are now integrated into the new Autoconer 5 machine<br />

concept. Thanks to their variety of equipment options, they offer the<br />

widest application spectrum for rewinding, including yarn clearing,<br />

the splicing process and various automation options for feed and<br />

final package doffing. The drumless yarn traversing system<br />

PreciFX is available here for the first time alongside drum winding.<br />

For the Autoconer 5, type K you can select the function of “1:1<br />

rewinding” as an option.<br />

Autoconer 5, type RC<br />

Surely sending package residues occurring in the process sequence<br />

for efficient use / processing would be entirely in your interest when<br />

raw material and process costs are continually increasing? The<br />

Autoconer 5, type RC has been conceived especially for this:<br />

rewinding package residues with a max. diameter of 115 mm. Several<br />

small packages can thus be turned into an economically, rationally<br />

utilisable large-format package. The machine specification of the<br />

type RC machine can be selected e.g. analogously to an Autoconer<br />

AC 5<br />

type E<br />

AC 5<br />

type K<br />

AC 5<br />

type RC<br />

packages packages package residues<br />

traverse 3” – 10”<br />

max. ø 300 mm<br />

manual,<br />

single creeling<br />

traverse 3” – 6”<br />

max. ø 240 mm<br />

manual, easy to operate<br />

with reserve package<br />

for all types: Traverse 3” – 6” max. ø 320 mm<br />

traverse 3” – 6”<br />

max. ø 115 mm<br />

manual,<br />

into circular magazine<br />

10 10 5<br />

320 mm 320 mm 640 mm<br />

no with K, RC with E, RC with E,K