Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Oerlikon Schlafhorst Express - Oerlikon Schlafhorst - Oerlikon Textile

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

8<br />

<strong>Oerlikon</strong> <strong>Schlafhorst</strong> <strong>Express</strong> Innovations<br />

Zinser roving frame<br />

with new features<br />

Fast, economical, gentle on materials<br />

<strong>Oerlikon</strong> <strong>Schlafhorst</strong> now offers you the Zinser 668 and Zinser 670<br />

RoWeMat roving frames with additional features for the efficient<br />

production of fine yarns.<br />

What’s new:<br />

• Creel with optional low installation height<br />

• Additional transport rollers in the intake area safeguard the<br />

sensitive sliver<br />

• The flyer table blowing system with eco-circuit saves energy<br />

The Zinser 668 and Zinser 670 RoWeMat roving frames thus offer<br />

the best and most efficient basis for the production of fine, top-quality<br />

ring yarns.<br />

Quality roving in record time<br />

Steady maximum speeds with low roving breaks are guaranteed by<br />

the unique SynchroDrive drive concept and EasySpin controller.<br />

EasySpin also facilitates fast lot-changing and quality assurance<br />

thanks to simple operation. Using this precise and yet robust<br />

technology and in-depth know-how in package engineering,<br />

productivity and roving quality remain at a sustained high level.<br />

Perfect roving bobbins are the basis for top-class yarns<br />

Only superb roving bobbins produce top-quality ring yarn. The<br />

SynchroDrive and EasySpin controller jointly ensure a precise<br />

bobbin build. Yarn tension remains uniform over the entire bobbin –<br />

this is what we call <strong>Oerlikon</strong> <strong>Schlafhorst</strong> package engineering. The<br />

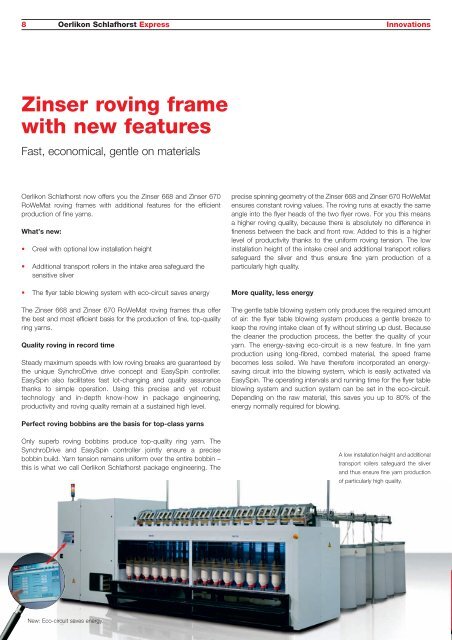

New: Eco-circuit saves energy.<br />

precise spinning geometry of the Zinser 668 and Zinser 670 RoWeMat<br />

ensures constant roving values. The roving runs at exactly the same<br />

angle into the flyer heads of the two flyer rows. For you this means<br />

a higher roving quality, because there is absolutely no difference in<br />

fineness between the back and front row. Added to this is a higher<br />

level of productivity thanks to the uniform roving tension. The low<br />

installation height of the intake creel and additional transport rollers<br />

safeguard the sliver and thus ensure fine yarn production of a<br />

particularly high quality.<br />

More quality, less energy<br />

The gentle table blowing system only produces the required amount<br />

of air: the flyer table blowing system produces a gentle breeze to<br />

keep the roving intake clean of fly without stirring up dust. Because<br />

the cleaner the production process, the better the quality of your<br />

yarn. The energy-saving eco-circuit is a new feature. In fine yarn<br />

production using long-fibred, combed material, the speed frame<br />

becomes less soiled. We have therefore incorporated an energysaving<br />

circuit into the blowing system, which is easily activated via<br />

EasySpin. The operating intervals and running time for the flyer table<br />

blowing system and suction system can be set in the eco-circuit.<br />

Depending on the raw material, this saves you up to 80% of the<br />

energy normally required for blowing.<br />

A low installation height and additional<br />

transport rollers safeguard the sliver<br />

and thus ensure fine yarn production<br />

of particularly high quality.