Thermanit 625 PW

Thermanit 625 PW

Thermanit 625 PW

Erfolgreiche ePaper selbst erstellen

Machen Sie aus Ihren PDF Publikationen ein blätterbares Flipbook mit unserer einzigartigen Google optimierten e-Paper Software.

<strong>Thermanit</strong> <strong>625</strong> <strong>PW</strong><br />

Flux cored wire<br />

01.2013<br />

Rev.: 1<br />

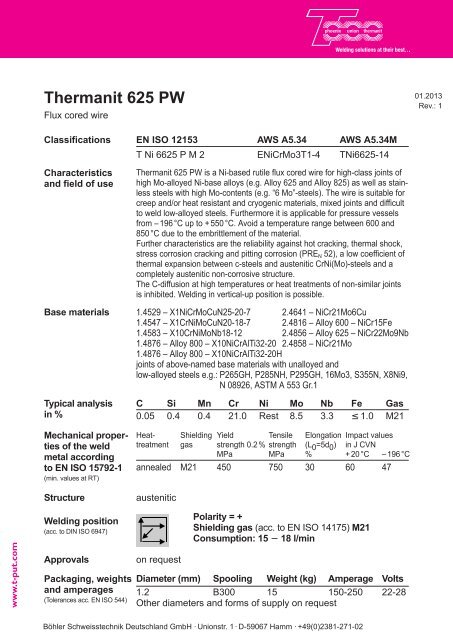

Classifications EN ISO12153 AWS A5.34 AWS A5.34M<br />

T Ni 6<strong>625</strong> P M 2 ENiCrMo3T1-4 TNi6<strong>625</strong>-14<br />

Characteristics<br />

and field of use<br />

Base materials<br />

Typical analysis<br />

in %<br />

Mechanical properties<br />

of the weld<br />

metal according<br />

to EN ISO15792-1<br />

(min. values at RT)<br />

Structure<br />

<strong>Thermanit</strong> <strong>625</strong> <strong>PW</strong> is a Ni-based rutile flux cored wire for high-class joints of<br />

high Mo-alloyed Ni-base alloys (e.g. Alloy <strong>625</strong> and Alloy 825) as well as stainless<br />

steels with high Mo-contents (e.g. “6 Mo „ -steels). The wire is suitable for<br />

creep and/or heat resistant and cryogenic materials, mixed joints and difficult<br />

to weld low-alloyed steels. Furthermore it is applicable for pressure vessels<br />

from – 196 °C up to + 550 °C. Avoid a temperature range between 600 and<br />

850 °C due to the embrittlement of the material.<br />

Further characteristics are the reliability against hot cracking, thermal shock,<br />

stress corrosion cracking and pitting corrosion (PRE N 52), a low coefficient of<br />

thermal expansion between c-steels and austenitic CrNi(Mo)-steels and a<br />

completely austenitic non-corrosive structure.<br />

The C-diffusion at high temperatures or heat treatments of non-similar joints<br />

is inhibited. Welding in vertical-up position is possible.<br />

1.4529 – X1NiCrMoCuN25-20-7 2.4641 – NiCr21Mo6Cu<br />

1.4547 – X1CrNiMoCuN20-18-7 2.4816 – Alloy 600 – NiCr15Fe<br />

1.4583 – X10CrNiMoNb18-12 2.4856 – Alloy <strong>625</strong> – NiCr22Mo9Nb<br />

1.4876 – Alloy 800 – X10NiCrAlTi32-20 2.4858 – NiCr21Mo<br />

1.4876 – Alloy 800 – X10NiCrAlTi32-20H<br />

joints of above-named base materials with unalloyed and<br />

low-alloyed steels e.g.: P265GH, P285NH, P295GH, 16Mo3, S355N, X8Ni9,<br />

N 08926, ASTM A 553 Gr.1<br />

C Si Mn Cr Ni Mo Nb Fe Gas<br />

0.05 0.4 0.4 21.0 Rest 8.5 3.3 ≤ 1.0 M21<br />

Heat- Shielding Yield Tensile Elongation Impact values<br />

treatment gas strength 0.2 % strength (L 0 =5d 0 ) in J CVN<br />

MPa MPa % + 20 °C – 196 °C<br />

annealed M21 450 750 30 60 47<br />

austenitic<br />

www.t-put.com<br />

Welding position<br />

(acc. to DIN ISO 6947)<br />

Approvals<br />

Packaging, weights<br />

and amperages<br />

(Tolerances acc. EN ISO 544)<br />

on request<br />

Polarity = +<br />

Shielding gas (acc. to EN ISO 14175) M21<br />

Consumption: 15 − 18 l/min<br />

Diameter (mm) Spooling Weight (kg) Amperage Volts<br />

1.2 B300 15 150-250 22-28<br />

Other diameters and forms of supply on request<br />

Böhler Schweisstechnik Deutschland GmbH · Unionstr. 1· D-59067 Hamm · +49(0)2381-271-02