GRABENER Coin and Medal Embossing Press ... - Retecon.co.za

GRABENER Coin and Medal Embossing Press ... - Retecon.co.za

GRABENER Coin and Medal Embossing Press ... - Retecon.co.za

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

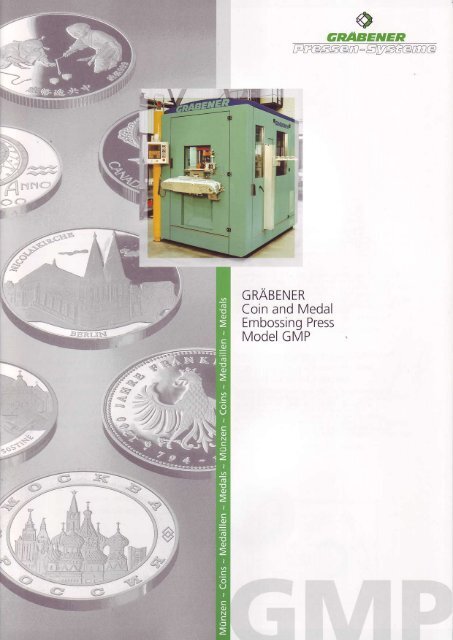

<strong>GRABENER</strong><br />

<strong>Coin</strong> <strong>and</strong> <strong>Medal</strong><br />

<strong>Embossing</strong> <strong>Press</strong><br />

Model GMP<br />

A<br />

v

Cost-eff icient embossing<br />

oT supenor qua ry <strong>co</strong>rns<br />

ano meoats<br />

f/lod fication of the <strong>GRABENER</strong> <strong>Coin</strong> <strong>and</strong> <strong>Medal</strong><br />

<strong>Embossing</strong> <strong>Press</strong>, GMP model series, has created<br />

an outst<strong>and</strong> ng mach ne that measures up lke no<br />

other to meeting the exacting requ rements ot<br />

minting valuab e <strong>co</strong>l ector\ <strong>co</strong>lns <strong>and</strong> meda s.<br />

The <strong>GRABENER</strong> range en<strong>co</strong>mpasses <strong>co</strong>!n <strong>and</strong> rneda<br />

emboss ng presses wth nom nai ratings of<br />

3,600 kN, 6,300 kN <strong>and</strong> 10,000 kN.<br />

A o_gs oe the 'ra- uäl / op6'dled a N/D \4 ' odo<br />

<strong>GRABENER</strong> offers the Gl/lP-TK mode, with<br />

automatic transfer feed <strong>and</strong> cassette <strong>co</strong>nvey ng<br />

system for high y e<strong>co</strong>nomical product on of arge<br />

bar.he.<br />

Based on the proven design prinr p e of<br />

<strong>GRABENER</strong> knuckle-joint presses, we have<br />

imp emented a nurrber of requirements <strong>and</strong><br />

rdaa,r' (lo proope thou'c-(ron"'<br />

"tion!^<br />

The enhanced performance of the press, <strong>and</strong> the<br />

top qua ity <strong>co</strong> ns <strong>and</strong> meda s it produces are<br />

delight ng mints <strong>and</strong> the r customers al ke.<br />

'41

Advantages of the<br />

<strong>GRABENER</strong> knuckle-joint system<br />

Typical of <strong>GRABENER</strong> knuckle-joint presses is the<br />

extremely rig d press <strong>co</strong>nstruction <strong>and</strong> favourable<br />

time-path sequence n the embossing area.<br />

The principle:<br />

The press frame fLrnctions as a ram wh ch is moved<br />

downwards by tfle knuck e-loint. The bo ster plate<br />

<strong>and</strong> press housing are rigidly <strong>co</strong>nnected<br />

to each other<br />

The advantages:<br />

The softer mpact ofthe die on the <strong>co</strong>in, <strong>co</strong>mpared<br />

with other drive types, <strong>and</strong> the length er <strong>co</strong>ntact<br />

liTe p.olong<br />

roolIfe <strong>and</strong><br />

rmorove<br />

rre en bossrng<br />

oJ diffic!lt re iefs-<br />

o<br />

<strong>GRABENER</strong><br />

Even parts of intricate des gn can be produced wth a<br />

single stroke. For top-qualty m rror f nish. <strong>GRABENER</strong><br />

<strong>co</strong>in <strong>and</strong> meda embossing presses can additona ly be<br />

equ pped for mult'strike operat on.<br />

Multi-strike for<br />

mirror f inish<br />

Frsessen-<br />

On multFstrike operation, the roli is swLrng away from<br />

the drive cam. The ejector is deactivated<br />

for a programmed number of strokes. With a se<strong>co</strong>nd<br />

pneurnatic cy indet the bottom dle can be moved into<br />

the c ean ng position above the ejector

Convincing design...<br />

. <strong>co</strong>mpact, space-sav ng press drive wth<br />

p anetary gear <strong>and</strong> ntegrated pneumat c<br />

clutch brake unit<br />

precision gu dance of the press frame wth<br />

self-centering ba I bear ngs '<br />

avoidance of air turbulence by<br />

<strong>co</strong>unterbalanc n9 the pressjrarne weght wth<br />

oil springs instead of pneurnatic cylinders<br />

centra o I ubrication with closed o I tank to<br />

eiminate o lm st<br />

cam <strong>co</strong>ntroled elector with clean ng post on<br />

muh -strike operation for h gher-qua ity<br />

ernboss n9 <strong>and</strong> m rror t nish<br />

v bration absorbers forjolt-free <strong>and</strong> low<br />

vibration operatlon

o<br />

GRÄBENER<br />

...<strong>and</strong> simple operation with<br />

<strong>co</strong>mfortable <strong>co</strong>ntrol<br />

. PLC <strong>co</strong>ntrol<strong>and</strong> operator panelwith dispay<br />

. operator guidance to täke the operator<br />

through machine operation <strong>and</strong> help with<br />

data entry<br />

. easy-to-read operating <strong>and</strong> fault repofts on<br />

o spray<br />

. storage of tool data sets<br />

. press force monitoring with programmable<br />

upper <strong>and</strong> lower values<br />

. swivel-type operator panel

GRÄBENEN<br />

nl<br />

Upper <strong>and</strong> lower tool rith<br />

wedge-type adjust m( enr<br />

The errbossing too <strong>co</strong>nsists of an upper <strong>and</strong> ower tool<br />

with wedge-type adlustment. Adjusting the wedge at<br />

the upper tool for applcation of the press force is ear y<br />

done with repettive precis on with the he p ot a<br />

geared motor. The adjustment path <strong>and</strong> press force are<br />

shown on the operator panel disp ay. W th the wedge<br />

adjustment at the lower tool, the embossing die can<br />

be postioned accurately n the embossing <strong>co</strong> lar.<br />

f<br />

Fast tool change with<br />

hydraulic quick-clamping<br />

tool ch uck<br />

To minirnize tool-change time, we have equipped the<br />

presswth a hydraulc quick-camp ng toolchuck. The<br />

embossing die is c amped in the direction of the<br />

embossing force to ensure t remains firrnly clamped<br />

even under load.<br />

Lower-<strong>co</strong>st change parts<br />

Hydraul c tool clarrp ng makes re too ing eas er <strong>and</strong><br />

qu cker t a so alows the use of favourably priced<br />

change parts.

. Upper tool disengagement<br />

eliminates dust nuisance on multistrike<br />

operation<br />

The fourfold <strong>co</strong>lLrmn guided upper tool is disengaged<br />

from the press frame during multi strike operation <strong>and</strong><br />

remains in the embossrng <strong>co</strong> lar in <strong>co</strong>ntact<br />

wiits rhe Lo n.<br />

Dust turbulence on opening the tool s avoided.<br />

Universal ball joint for adaptation<br />

to eccentric relief<br />

Mounting the upper tool in an adjustable un versal bal<br />

joint allows the die to be adapted<br />

for eccentric rel efs<br />

o<br />

GPÄBENER<br />

FFesseA:WsrZAnG<br />

Centering the uppertool<br />

through playfree x-y adjustment<br />

The upper tool s centered to the emboss ng <strong>co</strong>tar<br />

from the front with two adlust ng screws while t<br />

rema ns under hydrauiic pressure from the back.

Fast changeover to<br />

manualfeed<br />

Through preselecton at the operator pane, the<br />

tTansfeT ra ls move automatically aside <strong>and</strong> nto ä<br />

parking positon at the reat ready ng the press<br />

for manua teed.<br />

Cost-eff icient embossing with<br />

automatic transfer feed<br />

d .dssalle onvey ng ,yste1 ens- er d-tordtic<br />

operat on wthout interrupton<br />

. Ie.",.p.re f n"le,loddi-gids "ndedsr<br />

. cassettes are positioned automatica ly<br />

f nished <strong>co</strong>ins are deposited n <strong>co</strong> n trays at the front,<br />

.r" latt" rpr''r.r _r_g n Ly.le \^i L p e,s oper"lio I<br />

.or'. a'p rdn polöd 'o- '"d' to lronr d low g "e<br />

operator to exercse ongo n9 qua ity <strong>co</strong>ntrol<br />

. the cassette <strong>co</strong>nvey ng system can be moved away<br />

to the rear to allow optimum access for retool ng <strong>and</strong><br />

maintenance<br />

. the press operates <strong>co</strong>nt nLroLJs y, nrin m zing clltch<br />

ano oraKe weaT

I<br />

... how automatic tra nsfer<br />

feed works:<br />

o<br />

GPABEHER<br />

F@d@A:Weeenne<br />

the b anks are separated at the magaz ne,<br />

the stacked b anks are held pneumatically<br />

a ift table loweß blank after b ank from the<br />

mr^r?in6 r^ ih6 rrrn(n^d lovÄ<br />

synchronous y operating grippers <strong>co</strong>nvey the<br />

h:nL < da^,^/

O Perfection to the last detail...<br />

tripartite embossing <strong>co</strong> lar for <strong>co</strong>ins <strong>and</strong> meda s wlth<br />

raised (<strong>co</strong>nvex) edge etter ng<br />

prograffmab e <strong>co</strong>in tLlrnlng station to tlrn <strong>co</strong> ns n<br />

any Sequence for vLsua lnspectlon<br />

lin shed <strong>co</strong>ins are altomatca ly deposted n <strong>co</strong>ln trays<br />

on the front depost table<br />

air let to c ean blanks on manla leed<br />

a r p sto to c ean tools<br />

t

Noise enclosure<br />

withexcess<br />

pressure<br />

inside<br />

to keeP out dust<br />

. modern ndustrial des gn<br />

. optinrized sound <strong>and</strong> dust proofing<br />

. arge doors ior opt mum access<br />

GRÄBENER<br />

P.l--!'.!-trai..,';,'!:-!7i,!!-'1e,rii.E<br />

. arge windows for better v slra <strong>co</strong>ntrol<br />

. inside steps instead of outs de p atforms<br />

. round <strong>co</strong>lumn with swivel-type operator pane<br />

<strong>and</strong> s gnal indication<br />

. opt m zed interor lightng<br />

. rnodu ar <strong>co</strong>nstruction that can, if necessary<br />

be dismantled for inställatlon<br />

'

Good reasons<br />

th at speak volumes<br />

foT <strong>GRABENER</strong>:<br />

Inrproved embor5rn!<br />

mLrit nr ke lor m rro, 1. !h<br />

<strong>co</strong>nrpa.l. 5pä.c 5,rr'rnq prr5s dr !c<br />

sL. l'..ftcr fq ba bcar fg5 lor prc. s of qr d i.!<br />

ol prols frim.<br />

avo daf.e ol a r turb! en.e w th .o srir rig!<br />

to.oLnlerb: af.e the franre vr'e qhL<br />

ceftrd o Lrbr !.1or sy5tem wth,: osed oi tarl<br />

toavodolm!t<br />

.am-.onlro .d ole.tor !r th r:l8in fq po5l on<br />

ope'.tor qr d.i.e lor e.5y m.chine h.nd n!<br />

oper.t n!.nd l.Lr t report nq n teit torn on d sp,ry<br />

pre;s to,,:e mon tollnq $ th proqramm.b e !pper<br />

moLor. uDper too adllnmenL<br />

hvd,au ,c q!.k c.mp nq loo .h!.k<br />

olver <strong>co</strong>n r:hange p.rt5<br />

drrengi!te.br !pper too io avod dLrn i!rbr ef.e<br />

o I m! I sl Ke op-or.i or<br />

lourio d.o !mr oLr d,"d Lrpper .oo<br />

un ver!,r ba lo.i ror.!apt.to. to.F..ent, . e e_!<br />

.cntl]r n!tof !pp.r to., r tl p..r'lr.c r i rdl!sLllir'r:<br />

i!1o r.r. trfllLr i.ril ,r t'<br />

.rr5*fi-; rof!.i, r! !!nefl<br />

tä!;ts.1F lt<br />

tr pa.t,te erbois fll.o . ror.of\'er ed.je ei.er.!<br />

p.ogram r.lr c .o I tr 1r .r! sr;t of<br />

roft depo! t L.ri !<br />

i r let<br />

rliR4EEi.JtETl<br />

Flexible, Precise, E<strong>co</strong>nomical<br />

Good service naturally<br />

G ib-"r-.r PL"$eny(eme GmhH & Co KG<br />

\'.retz irer Str.ße l, 57250 Netphen \'1,r-".t renbJ.h / Gem.ry<br />

Ph..e +19 \21 a7) 9 52 0, FrN +49127l7r9 62 200<br />

elJa iilo@qraebenerm iii{t.onl<br />

!tutuqr,reLrenerm nt n.l .onl<br />

]<br />

:<br />

' r'1:1;,.l;:;''<br />

:.;,<br />

3<br />

a<br />

E<br />

E<br />

ä