P R E S S I N F O R M A T I O N Schoeller Textiles ... - GoExpo

P R E S S I N F O R M A T I O N Schoeller Textiles ... - GoExpo

P R E S S I N F O R M A T I O N Schoeller Textiles ... - GoExpo

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

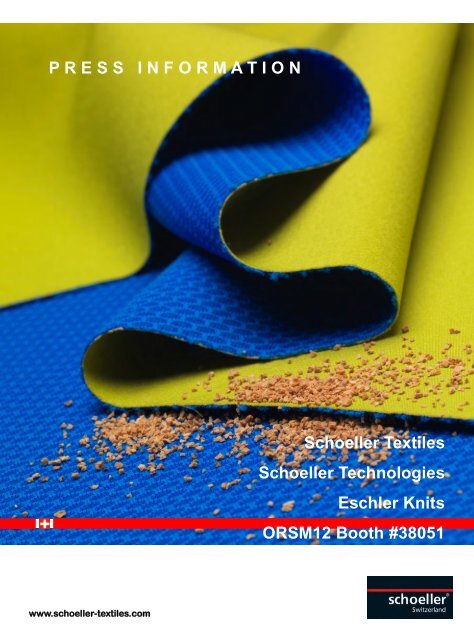

P R E S S I N F O R M A T I O N<br />

www.schoeller-textiles.com<br />

<strong>Schoeller</strong> <strong>Textiles</strong><br />

<strong>Schoeller</strong> Technologies<br />

Eschler Knits<br />

ORSM12 Booth #38051

27.07.2012 Trademarks<br />

<strong>Schoeller</strong> Textil AG: keprotec ® schoeller®-PCM schoeller ®<br />

<strong>Schoeller</strong> Technologies AG: 3XDRY ® NanoSphere ® c_change<br />

bluesign technologies ag: bluesign ®<br />

DuPont: Kevlar ®<br />

Invista: Cordura ® Lycra ®<br />

PRESS INFORMATION<br />

Contact: Shannon Walton<br />

Phone: 970.260.9282<br />

shannon@schoellerusa.com<br />

www.schoeller-textiles.com<br />

Corks are popping for the naturally warmest soft-shell from <strong>Schoeller</strong>:<br />

corkshell TM wins OutDoor INDUSTRY AWARD 2012<br />

Sevelen, July 2012: The new corkshell TM technology from the Swiss fabric and<br />

technology specialists <strong>Schoeller</strong> Textil AG convinces the jury of international experts<br />

and wins one of the coveted OutDoor INDUSTRY AWARDS 2012 in the Material<br />

Innovation category at the OutDoor Fair Friedrichshafen. The technology, which makes it possible to create<br />

<strong>Schoeller</strong>’s warmest ever soft-shell, receives the award for particularly outstanding products.<br />

In the competition organised for the 7 th time by iF International Forum Design, 48 entrants out of a total of<br />

322 from 25 countries were distinguished with an OutDoor INDUSTRY AWARD 2012: Ten of them with a<br />

Gold Award. The award is a seal of quality and offers an added value to both the trade and consumers in<br />

terms of the function, innovation, durability and sustainability of products.<br />

50% higher thermal insulation<br />

With the award winning corkshell TM technology, the soft-shell<br />

pioneer <strong>Schoeller</strong> has, for the first time, succeeded in combining<br />

the outstanding natural features of cork with those of highperformance<br />

fabrics. corkshell TM displays significantly higher<br />

thermal insulation than comparable conventional soft-shell<br />

products and depending on the fabric structure, can be up to<br />

50%. corkshell TM thus offers a level of thermal insulation never seen before while also providing a high level<br />

of breathability. It incorporates the positive properties of natural cork without negatively affecting other<br />

functional features. In addition, corkshell TM is bluesign ® approved and therefore complies with the world’s<br />

strictest standard for textiles.<br />

The jury of international experts is made up as follows: Boris Gnielka (Outdoor Magazin, Stuttgart / Germany),<br />

Mark Held (European Outdoor Group, Zug / Switzerland), Monica Viganò (Outdoor Magazine, Meda / Italy), Nora<br />

Kühner (fashion design consulting, Munich / Germany and IDEAS Active Sports Design Network, Rorschach /<br />

Switzerland) as well as Alessandra Soresina (wildlife biologist, writer and photographer, Milan / Italy).

Skincare to wear<br />

27.07.2012 Trademarks<br />

<strong>Schoeller</strong> Textil AG: keprotec ® schoeller®-PCM schoeller ®<br />

<strong>Schoeller</strong> Technologies AG: 3XDRY ® NanoSphere ® c_change<br />

bluesign technologies ag: bluesign ®<br />

DuPont: Kevlar ®<br />

Invista: Cordura ® Lycra ®<br />

PRESS INFORMATION<br />

Contact: Shannon Walton<br />

Phone: 970.260.9282<br />

shannon@schoellerusa.com<br />

www.schoeller-textiles.com<br />

Cosmetotextiles – the really big trend for the future<br />

August 2012: Holistic health is a major trend. It is<br />

estimated that the market for cosmetotextiles – the<br />

integration of cosmetics into textiles, generally on the<br />

basis of microcapsules – will be worth 500 million euro in<br />

2013. Peclers, the Paris trend agency, has already<br />

presented this inspiring new form of “wellbeing”. The<br />

Swiss style expert, Jeroen van Rooijen, is prophesizing<br />

the dawn of a new era, away from tradition and retro and<br />

geared towards individual functionality, practical<br />

wellbeing and passionate authenticity. All these signs<br />

and predictions point towards major change and new<br />

beginnings. New beginnings that <strong>Schoeller</strong> has no<br />

intention of missing.<br />

iLoad ® – the reloadable drug delivery textile<br />

<strong>Textiles</strong> and their functions are constantly evolving. The<br />

integration of cosmetics or medication (under medical<br />

supervision) into textiles offers revolutionary possibilities,<br />

such as skincare via clothing. The increased wellbeing, in<br />

combination with additional functionality, makes<br />

cosmetotextiles “active” promoters of our everyday comfort.<br />

<strong>Schoeller</strong>’s first groundbreaking response to this trend bears<br />

the name iLoad ® and has already been distinguished with the<br />

coveted Swiss Technology Award 2011.

27.07.2012 Trademarks<br />

<strong>Schoeller</strong> Textil AG: keprotec ® schoeller®-PCM schoeller ®<br />

<strong>Schoeller</strong> Technologies AG: 3XDRY ® NanoSphere ® c_change<br />

bluesign technologies ag: bluesign ®<br />

DuPont: Kevlar ®<br />

Invista: Cordura ® Lycra ®<br />

PRESS INFORMATION<br />

Contact: Shannon Walton<br />

Phone: 970.260.9282<br />

shannon@schoellerusa.com<br />

www.schoeller-textiles.com<br />

iLoad ® is a textile carrier material that can be individually loaded<br />

and regenerated with beneficial or therapeutic substances. “The<br />

cornerstone has been laid for this project; now the task is to<br />

examine and further develop possible application technologies,”<br />

explains Hans-Jürgen Hübner, CEO of <strong>Schoeller</strong> Medical AG. To<br />

this end, <strong>Schoeller</strong> is taking a highly scientific approach of a kind<br />

unusual among textile companies and has purchased a<br />

laboratory with high quality research and analysis equipment,<br />

facilities for chemical synthesis and preliminary microbiological<br />

clarification.<br />

As a general practice, <strong>Schoeller</strong> does not just stick to proven<br />

textile structures, but breaks new ground and invests in the future<br />

of medicine, such as with an initial product line for the area of<br />

incontinence. With partnership-based developments, the<br />

company is seeking individual solutions and designs geared<br />

closely to customer requirements. This may take the form of new<br />

distribution channels such as online shops or customer care at<br />

point of sale, where, for example, effective substances for<br />

recharging iLoad ® textiles can be bought. In any event, <strong>Schoeller</strong><br />

firmly intends to be among the frontrunners in the major health<br />

trend and offers interested potential business partners intelligent<br />

possibilities for exciting cooperations.

Overview <strong>Schoeller</strong> Fabric Collection Summer 2014 – Focus on Outdoors<br />

Nature meets engineering to define the new standard for wellbeing<br />

27.07.2012 Trademarks<br />

<strong>Schoeller</strong> Textil AG: keprotec ® schoeller®-PCM schoeller ®<br />

<strong>Schoeller</strong> Technologies AG: 3XDRY ® NanoSphere ® c_change<br />

bluesign technologies ag: bluesign ®<br />

DuPont: Kevlar ®<br />

Invista: Cordura ® Lycra ®<br />

PRESS INFORMATION<br />

Contact: Shannon Walton<br />

Phone: 970.260.9282<br />

shannon@schoellerusa.com<br />

www.schoeller-textiles.com<br />

June 2012: Nature-inspired <strong>Schoeller</strong> technologies such as energear TM , corkshell TM or ecorepel ®<br />

define a new type of “wellbeing“: Individual functionality, practical health and passionate<br />

authenticity. Featured in ocean shades or as vibrant points of color, new textiles set the tone in<br />

summer 2014.<br />

PURE ENERGY<br />

3XDRY ® feelgood technology.<br />

In summer 2014, that extra portion of energy is supplied by energear TM<br />

technology with a specially tailored mineral-matrix, now also available in light<br />

colored fabrics. Based on the long-aknowledged capacity of certain minerals<br />

to reflect long-wave rays, energear TM ensures that the energy (Far Infrared<br />

Rays) radiated by the body is reflected back to it. This additional energy has a<br />

positive effect on performance capacity and wellbeing. Among other options,<br />

energear TM is available on fine, smooth schoeller ® -dynamic fabrics in<br />

delicate mint green with additional coldblack ® heat and UV protection and<br />

CORK SHELL<br />

With the new corkshell TM technology from<br />

<strong>Schoeller</strong>, it is now possible to combine the<br />

outstanding properties of natural cork with<br />

those of high quality functional textiles. In the<br />

thin schoeller ® -WB-400 fabrics in lime green<br />

with a vibrant blue back, for example, or the<br />

reversible double-face in the exciting color<br />

combination slate/chili, corkshell TM offers<br />

significantly higher heat insulation than comparable conventional soft-shells while also providing high<br />

breathability and outstanding clothing comfort.

27.07.2012 Trademarks<br />

<strong>Schoeller</strong> Textil AG: keprotec ® schoeller®-PCM schoeller ®<br />

<strong>Schoeller</strong> Technologies AG: 3XDRY ® NanoSphere ® c_change<br />

bluesign technologies ag: bluesign ®<br />

DuPont: Kevlar ®<br />

Invista: Cordura ® Lycra ®<br />

PRESS INFORMATION<br />

Contact: Shannon Walton<br />

Phone: 970.260.9282<br />

shannon@schoellerusa.com<br />

www.schoeller-textiles.com<br />

ECO REPEL<br />

A further ecological innovation from <strong>Schoeller</strong><br />

is ecorepel ® , the fluorocarbon-free finishing<br />

technology for natural water repellence.<br />

<strong>Schoeller</strong> presents this impregnation on a<br />

schoeller ® -WB-400 in full-bodied meadow<br />

green with white fleece backing and a sturdy,<br />

abrasion resistant schoeller ® -dynamic in<br />

golden brown or sky blue. The new USP<br />

(“Ultralight Soft Protection”) technology similarly reflects the zeitgeist in modern fabrics. They are ultra-light<br />

compared to materials with similar functions. The vibrant green, silver-grey or petrol crosswise-elastic<br />

schoeller ® -styltec with a smooth, technical look provides protection from the rain as a light spring/autumn<br />

jacket and is windproof and, by nature, breathable.<br />

ONE OF A KIND<br />

Color is still a top story for summer 2014 and has never been more individual<br />

than with the fascinating One of a kind dyeing process, with which <strong>Schoeller</strong><br />

has succeeded in capturing the fascination of uniqueness in fabric. With this<br />

ecological dyeing process, random chance results in fabric designs that make<br />

every garment an unmistakably unique item. In a very fine, smooth<br />

implementation, the schoeller ® -dynamic fabric glows in shades of yellow,<br />

red and green and is reminiscent of the patina on copper.

SMART PROTECTION<br />

27.07.2012 Trademarks<br />

<strong>Schoeller</strong> Textil AG: keprotec ® schoeller®-PCM schoeller ®<br />

<strong>Schoeller</strong> Technologies AG: 3XDRY ® NanoSphere ® c_change<br />

bluesign technologies ag: bluesign ®<br />

DuPont: Kevlar ®<br />

Invista: Cordura ® Lycra ®<br />

PRESS INFORMATION<br />

Contact: Shannon Walton<br />

Phone: 970.260.9282<br />

shannon@schoellerusa.com<br />

www.schoeller-textiles.com<br />

The ceraspace TM technology from <strong>Schoeller</strong><br />

opens a completely new dimension in terms of<br />

both abrasion and heat proofing. The fall-proof<br />

yet pleasantly soft elastic schoeller ® -WB- 400<br />

fabric in olive green or black with the 3D<br />

ceraspace TM coating looks super as a trim or<br />

even full garment as a scooter jacket. Very light<br />

and comfortable protection from wind and rain<br />

is provided by the new, bi-elastic 2 ½-layer membrane fabric in grass green, red or black. Thanks to a fine<br />

coating on the reverse of the schoeller ® -WB-formula fabric with c_change TM climate membrane, the inside<br />

of the functional lightweights no longer needs to be lined.

27.07.2012 Trademarks<br />

<strong>Schoeller</strong> Textil AG: keprotec ® schoeller®-PCM schoeller ®<br />

<strong>Schoeller</strong> Technologies AG: 3XDRY ® NanoSphere ® c_change<br />

bluesign technologies ag: bluesign ®<br />

DuPont: Kevlar ®<br />

Invista: Cordura ® Lycra ®<br />

PRESS INFORMATION<br />

Contact: Shannon Walton<br />

Phone: 970.260.9282<br />

shannon@schoellerusa.com<br />

www.schoeller-textiles.com<br />

energear TM on schoeller ® -dryskin soft-shell with 3XDRY ® in vibrant<br />

fuchsia<br />

energear TM on schoeller ® -WB-400 with coldblack ® in light pastel<br />

yellow<br />

ecorepel ® on schoeller ® -shape with diagonal structure in coral,<br />

sea-blue or black<br />

One of a kind on thin, slightly-structured schoeller ® -dynamic cloqué<br />

fabric in the colors of the sea

27.07.2012 Trademarks<br />

<strong>Schoeller</strong> Textil AG: keprotec ® schoeller®-PCM schoeller ®<br />

<strong>Schoeller</strong> Technologies AG: 3XDRY ® NanoSphere ® c_change<br />

bluesign technologies ag: bluesign ®<br />

DuPont: Kevlar ®<br />

Invista: Cordura ® Lycra ®<br />

PRESS INFORMATION<br />

Contact: Shannon Walton<br />

Phone: 970.260.9282<br />

shannon@schoellerusa.com<br />

www.schoeller-textiles.com<br />

Light schoeller ® -WB-400 soft-shells in shocking neon pink or classic<br />

navy blue with soft wool-jersey reverse in a mélange look<br />

Bi-elastic three-layer schoeller ® -WB-formula fabric with c_change TM<br />

in full-bodied violet<br />

schoeller ® -dryskin soft-shell in a pastel shade of turquoise<br />

schoeller ® -WB-400 pin-striped soft-shell fabrics in coral, grass green<br />

or black with a light jersey backing

27.07.2012 Trademarks<br />

<strong>Schoeller</strong> Textil AG: keprotec ® schoeller®-PCM schoeller ®<br />

<strong>Schoeller</strong> Technologies AG: 3XDRY ® NanoSphere ® c_change<br />

bluesign technologies ag: bluesign ®<br />

DuPont: Kevlar ®<br />

Invista: Cordura ® Lycra ®<br />

PRESS INFORMATION<br />

Contact: Shannon Walton<br />

Phone: 970.260.9282<br />

shannon@schoellerusa.com<br />

www.schoeller-textiles.com<br />

schoeller ® -sense yoga wear fabric in delicate mint green with stone<br />

grey, leather-like reverse

KJUS<br />

KJUS Ladies & Men Mythos Pants<br />

27.07.2012 Trademarks<br />

<strong>Schoeller</strong> Textil AG: keprotec ® schoeller®-PCM schoeller ® c_change,<br />

<strong>Schoeller</strong> Technologies AG: 3XDRY ® NanoSphere ® coldblack®<br />

bluesign technologies ag: bluesign ®<br />

DuPont: Kevlar ®<br />

Invista: Cordura ® Lycra ®<br />

PRESS INFORMATION<br />

Contact: Shannon Walton<br />

Phone: 970.260.9282<br />

shannon@schoellerusa.com<br />

www.schoeller-textiles.com<br />

Good, better, Mythos: The Mythos Pants are technical, fully-<br />

finished touring pants made of full-stretch schoeller ® -dryskin<br />

double fabric. This dries very quickly, is permanently elastic and<br />

weatherproof. The pants are reinforced for high-altitude use<br />

with a wear-resistant material on the seat, at the knees and the<br />

cuffs.<br />

Picture source: KJUS<br />

Mammut Sports Group<br />

Gipfelgrat Light Jacket Men / Women<br />

The extremely abrasion-proof and light schoeller ® -WB-400 softshell<br />

jacket with coldblack ® finish and very good stretch is<br />

ideally suited for high-altitude use. The frontreach sleeve form is<br />

ergonomically tailored to climbing movements, the 3-point hood<br />

regulation system and the hood designed to accommodate a<br />

climbing helmet are only a two of the further highlights which<br />

this high-tech jacket can offer.<br />

Picture source: Mammut Sports Group

Mammut Sports Group<br />

Bluesmiths<br />

Eisfeld Pants Light Men / Women<br />

Maliko Short by Bluesmiths<br />

27.07.2012 Trademarks<br />

<strong>Schoeller</strong> Textil AG: keprotec ® schoeller®-PCM schoeller ® c_change,<br />

<strong>Schoeller</strong> Technologies AG: 3XDRY ® NanoSphere ® coldblack®<br />

bluesign technologies ag: bluesign ®<br />

DuPont: Kevlar ®<br />

Invista: Cordura ® Lycra ®<br />

PRESS INFORMATION<br />

Contact: Shannon Walton<br />

Phone: 970.260.9282<br />

shannon@schoellerusa.com<br />

www.schoeller-textiles.com<br />

The highly breathable soft-shell pants made of sturdy, highly-<br />

elastic schoeller ® -dryskin fabric is deal for tours in high-altitude<br />

terrain. The additional coldblack ® finish means that dark colors<br />

behave almost like light ones and absorb up to 80% of sunlight.<br />

A further plus point is the hem reinforcement and the crampon<br />

protection made of schoeller ® keprotec ® .<br />

Picture source: Mammut Sports Group<br />

As the sport of paddleboarding grows, so does the demand for<br />

apparel that is sublime as the sport. The Malikos have stretch,<br />

high abrasion resistance and feature both NanoSohere ® and<br />

coldblack ® for quick drying and sun protection. The shorts have<br />

seams wont rub you the wrong way, have no Velcro or metal<br />

zippers, meaning they feel fantastic on the body and will stay<br />

good looking and functional for a lifetime. The Malikos are<br />

named for the most famous downwinder course in the world<br />

and are as appropriate there as they are at the Paia Fish<br />

Market for tacos après paddleboarding or surfing.<br />

Bild-Quelle: Bluesmiths

Search and State<br />

Luna C<br />

S1-J jacket<br />

27.07.2012 Trademarks<br />

<strong>Schoeller</strong> Textil AG: keprotec ® schoeller®-PCM schoeller ® c_change,<br />

<strong>Schoeller</strong> Technologies AG: 3XDRY ® NanoSphere ® coldblack®<br />

bluesign technologies ag: bluesign ®<br />

DuPont: Kevlar ®<br />

Invista: Cordura ® Lycra ®<br />

PRESS INFORMATION<br />

Contact: Shannon Walton<br />

Phone: 970.260.9282<br />

shannon@schoellerusa.com<br />

www.schoeller-textiles.com<br />

Whether you’re on a training ride, racing a gravel century or on<br />

a mountain pass, you need apparel that is versatile and tough.<br />

The S1-J is warm when its cold, breathes when it's hot, and is<br />

built to last. It's lightweight and packs neatly into an S1-A jersey<br />

pocket. Forget about the weather; be comfortable, and focus on<br />

the ride. The S1-J is a 3 season jacket that features<br />

c_change, a bionic climate membrane that independently<br />

reacts to changing temperatures, closing when exposed to cold<br />

and opening in response to warmth. The S1-J will be the most<br />

versatile piece of technical apparel you own.<br />

Image source: Search and State<br />

The High Performance Jacket<br />

The 'High Performance Jacket' incorporates c_change, the<br />

biomimicing wind and weatherproof membrane; NanoSphere ® ,<br />

the naturally self-cleaning finishing technology; and the use of<br />

carbon fiber, which is a first in a fashion line of this type. This<br />

exclusive jacket is also machine washable and available for a<br />

limited time.<br />

Image source: Luna C Clothing

Lizard Footwear<br />

Athleta<br />

Kross Scramble<br />

The Frontier Jean<br />

27.07.2012 Trademarks<br />

<strong>Schoeller</strong> Textil AG: keprotec ® schoeller®-PCM schoeller ® c_change,<br />

<strong>Schoeller</strong> Technologies AG: 3XDRY ® NanoSphere ® coldblack®<br />

bluesign technologies ag: bluesign ®<br />

DuPont: Kevlar ®<br />

Invista: Cordura ® Lycra ®<br />

PRESS INFORMATION<br />

Contact: Shannon Walton<br />

Phone: 970.260.9282<br />

shannon@schoellerusa.com<br />

www.schoeller-textiles.com<br />

The Kross is designed to adapt to a variety of outdoor activities<br />

and settings. Featuring LIZARD’s proprietary Kyodo Vibram ®<br />

sole made with flexible, low-profile and lightweight Vibram ®<br />

rubber, the Kross shoes promote natural barefoot posturing and<br />

provide a self-cleaning, multi-directional tread pattern for<br />

optimal grip on rock, mud and wet surfaces. This new style also<br />

boasts the soft and flexible QuickFit fastening system and a<br />

3Dair mesh upper and lining for maximum ventilation. The<br />

upper is constructed of leather and schoeller ® -keprotec ® to be<br />

extremely abrasion proof.<br />

Image source: Aicad<br />

Your favorite-fitting jean just turned super technical in an urban<br />

style that offers full mobility out on the trails. Semi-fitted and<br />

mid-rise. Straight leg, zip/snap fly, and internal drawstring.<br />

Plenty of pockets to stash your stuff (even hidden pockets<br />

within pockets).Ergonomic built-out gusset & inseam are<br />

shaped for stride and mobility <strong>Schoeller</strong> 3XDRY ® Technology<br />

wicks from inside (evaporating sweat) to keep you cool and dry;<br />

durable outer fabric resists nicks, tears and dirt (read: a rugged<br />

jean truly made for the trails).

Outlier<br />

Image source: Athleta<br />

The FreeShell<br />

27.07.2012 Trademarks<br />

<strong>Schoeller</strong> Textil AG: keprotec ® schoeller®-PCM schoeller ® c_change,<br />

<strong>Schoeller</strong> Technologies AG: 3XDRY ® NanoSphere ® coldblack®<br />

bluesign technologies ag: bluesign ®<br />

DuPont: Kevlar ®<br />

Invista: Cordura ® Lycra ®<br />

PRESS INFORMATION<br />

Contact: Shannon Walton<br />

Phone: 970.260.9282<br />

shannon@schoellerusa.com<br />

www.schoeller-textiles.com<br />

Deceptively simple, the FreeShell is an incredibly versatile<br />

jacket with a streamlined silhouette. Truly a go-anywhere piece,<br />

it travels seamlessly through cool nights and light rain, but won't<br />

overheat when the sun peeks through. The 4Season fabric from<br />

<strong>Schoeller</strong> <strong>Textiles</strong> allows for freedom of movement and<br />

breathability, so you stay comfortable in a range of<br />

temperatures. Discreet front pockets and a hidden mega stash<br />

pocket make sure you can carry what you need while an<br />

extended back keeps you covered in any situation.<br />

Image source: Outlier

Press Information<br />

Season Summer 2014<br />

ESCHLER – a schoeller® brand: Bike Collection Summer 2014<br />

INDIVIDUAL, FAST & FOCUSED<br />

Eschler – a schoeller® brand presents a highly ambitious and<br />

focused summer bike collection 2014! The warp knits for rec-<br />

reationsal bikewear is strongly influenced by the high-tech<br />

textiles developed for the elite segment. The collection high-<br />

lights include the complex two-layer knit “Flash”, which<br />

unites outstanding aerodynamics with a fantastic moisture<br />

management. Eschler offers the fabrics with integrated car-<br />

bon fibres as well as coldblack ® – the special finishing tech-<br />

nology for textiles by <strong>Schoeller</strong> Switzerland that reduces heat<br />

build-up and provides reliable protection from UV rays. Yet,<br />

Eschler and the <strong>Schoeller</strong> Textil AG do not only cooperate,<br />

the two Swiss companies – the pioneer of stretch wovens<br />

<strong>Schoeller</strong> and the warp knit specialist Eschler – have merged<br />

in June 2012 under the leadership of <strong>Schoeller</strong> Textil AG.<br />

Market Segments: Elite Sports & Recreational Sports<br />

The market segment ‘Elite Sports’ concentrates on sponsors and<br />

racesuit manufacturers for alpine skiing and ski jumping – Eschler is<br />

market leader in both disciplines, equipping more or less all national<br />

teams with sports specific, high performance fabrics. Yet, Eschler<br />

also supplies elite summer sports athletes with warp knits for racewear,<br />

in particular cyclists and triathletes. The market segment ‘Recreational<br />

Sports’, of course, strongly profits from the expertise<br />

gained from the professional sports fabrics.

Structured for Speed<br />

Determined to develop innovations and to enhance the performance<br />

of athletes, Eschler has put a lot of time and research in optimising<br />

the aerodynamics of its high performance textiles. When<br />

speed counts, Eschler presents fast knitwear fine-tuned to the detail.<br />

Wind channel studies showed that special structured surfaces<br />

reduce wind resistance up to 10% compared to smooth surfaces.<br />

The tests of highly elastic knitwear specifically focused on the speed<br />

range of over 100 km/h for alpine skiwear and 35–75 km/h for<br />

bikewear. They proved that on structured surfaces the airflow is<br />

more streamlined, leading to less air turbulence and thus improving<br />

the aerodynamics. The test results are of high relevance for disciplines<br />

such as mountainbiking, road cycling as well as triathlon<br />

Eschler – a schoeller® brand transfers its expertise to the fabrics for<br />

non-professional sports apparel and expands its range of elastic,<br />

structured knitwear. One of the highlights in this product category<br />

is the double layer “Flash” material merging a Polyamide/Elastane<br />

outer and a Polyester material on the inside: a unique combination<br />

of outstanding moisture management, abrasion resistance and<br />

aerodynamics. For added comfort, Eschler, on client request, integrates<br />

carbon fibres that further optimise temperature management.<br />

A further option: the Swiss brand offers Flash fabrics with<br />

coldblack ® by <strong>Schoeller</strong> Switzerland which reduces heat build-up<br />

and provides reliable protection from UV rays. The technology reflects<br />

infrared heat rays, the textiles heat up less and thus significantly<br />

optimise heat management.<br />

Eschler also tests and classifies the compression properties of the<br />

two-way stretch knitwear (the range includes weight classes from<br />

150–180 g/m² to 200–250 g/m²).<br />

CERAMIC PRINTING: fine, yet diamond hard<br />

It certainly is a hard task to fulfil: the demand of fine, soft sportswear<br />

fabrics, which simultaneously offer tough durability – even<br />

with extreme rubbing friction. Eschler is known as a specialist for<br />

ceramic printed fabrics that offer the perfect synergy of high wearing<br />

comfort and resistance to mechanical wear. The Polyurethanebased<br />

coating embedded with diamond-hard ceramic particles is<br />

printed in a fine pentagon shape with small dots. Thus, Eschler can<br />

keep the fabrics’ soft feel and high elasticity. This particularly environmentally<br />

friendly innovation is completely free of solvents. Furthermore,<br />

the ceramic particles remain permanently embedded in<br />

the polyurethane.

A Far-Sighted Business Move<br />

In June 2012, the Eschler Group merged with <strong>Schoeller</strong> Textil AG –<br />

a far-sighted business move and a logical consequence in terms of<br />

market positioning. The combination of Eschler’s highly functional<br />

knitted fabrics and the innovative range of <strong>Schoeller</strong> textiles and<br />

technologies is absolutely unique on the market and will meet the<br />

future requirements of joint customers even more precisely, more<br />

individually and more creatively. Thus, the two traditional Swiss<br />

companies make it possible to place the product range on an even<br />

broader footing on the global market.<br />

Peter Eschler, CEO of the brand which was founded in 1927, states:<br />

“The synergy of woven and knitted fabrics is the only one of its<br />

kind in the textile sector. But it is also a coming together of two<br />

companies that have fostered the same values and cultures! We are<br />

both Swiss, family-owned brands with a a strong and dedicated<br />

ambition to always deliver top performance.”<br />

Siegfried Winkelbeiner, CEO <strong>Schoeller</strong> Textil AG, adds: We are convinced<br />

that there is a global demand for Swiss quality, Now, the<br />

power of this concentrated expertise opens up entirely new dimensions<br />

for further exciting developments!“<br />

For further information please visit:<br />

www.eschler.com<br />

www.schoeller-textiles.com<br />

High-Res images ready for download:<br />

http://www.k-g-k.com/download/Eschler_Flash_HR.jpg<br />

http://www.k-g-k.com/download/Eschler_Keramik_HR.jpg<br />

http://www.k-g-k.com/download/Eschler-Keramik-1_HR.jpg<br />

http://www.k-g-k.com/download/Eschler_Balingen_HR.jpg<br />

ESCHLER – a schoeller ® brand: Founded in 1927, the family-owned brand quickly<br />

advanced to become one of the world’s leading manufacturers of functional knit<br />

fabrics. Today, Eschler specialises in sportswear, workwear, technical textiles and<br />

lingerie. Eschler produces its sportswear textiles in Balingen/Germany. In 2012, the<br />

brand merged with the <strong>Schoeller</strong> Textil AG – as Eschler a Swiss, family-owned<br />

brand. Each of the two enterprises is among the market leaders in their respective<br />

segment.<br />

PR Contact<br />

KGK –Kern Gottbrath Kommunikation<br />

Sissi Pärsch<br />

+49 – 89 – 30 76 66-3<br />

eschler@K-G-K.com

Press Information Outdoor 2012<br />

contact: Shannon Walton �phone: 970-260-9282 �pr@schoeller-tech.com �www.ecorepel.ch<br />

ecorepel ® – an ideal combination of function and sustainability<br />

by <strong>Schoeller</strong> Technologies.<br />

Seattle, July 2012: Following its launch in January 2012, ecorepel ® , the<br />

water repelling high-tech finish from <strong>Schoeller</strong> Technologies, is firmly on<br />

course for major success. Companies such as Mammut and Adidas Porsche<br />

Design have shown great interest in textiles that are ecologically water<br />

repelling. What makes ecorepel ® the right choice is not only its<br />

environmentally friendly aspect, but also the wide range of possible uses on<br />

different fibers and materials.<br />

In the development of ecorepel ® , <strong>Schoeller</strong> found inspiration in nature. All waterfowl,<br />

for example ducks, produce an oily secretion to make their feathers water repelling.<br />

ecorepel ® imitates exactly this sort of impregnation as it is based on long,<br />

biodegradable paraffin chains that wrap themselves as a spiral around the individual<br />

fibers, filaments or yarns in a very fine film. This reduces surface tension so that<br />

water droplets and even mud with significantly higher surface tension run off simply.<br />

The breathability is not affected and the feel remains pleasantly soft.<br />

Among those enthusiastic about the benefits of ecorepel ® is Daniela Schuermann,<br />

Teamleader Fabric Apparel, from Mammut, “We consider ecorepel ® a really exciting<br />

technology and are currently testing it. It is fascinating to see how an<br />

environmentally friendly finish can also achieve terrific results. “Materials Manager<br />

Claudia Gockel from Adidas Porsche Design, “ecorepel ® is an ideal alternative to<br />

existing solutions. We can very well envision using ecorepel ® for selected items in<br />

our new collection.”<br />

The possible uses for ecorepel ® are wide-ranging. Applications on various fiber types<br />

such as wool, cotton and synthetic fibers have already tested successfully. Its<br />

effectiveness on fabrics like denim, soft-shell and fleece has also been proven.<br />

ecorepel ® is a wash resistant high-tech finish that does not negatively affect our<br />

environment, either in its production or in its use. As no fluorocarbons are used, it is<br />

biodegradable (in accordance with OECD 302 B (80 – 100 %)), passes the Oeko-<br />

Tex ® - Standard 100 test and complies with bluesign ® .<br />

Discover more at Outdoor Retailer, Booth #39051

Press Information Outdoor 2012<br />

contact: Shannon Walton �phone: 970.260.9282 �pr@schoeller-tech.com �www.energear.ch<br />

energear – Efficiently using your own energy<br />

energear textile technology from <strong>Schoeller</strong> ensures that the radiated<br />

energy is reflected back to the body. Following preliminary in-house<br />

testing, including the growth of bean seeds, the efficacy of energear<br />

has been confirmed in an innovative test process of the Hohenstein<br />

Institute.<br />

All living creatures constantly radiate energy in the form of Far Infrared Rays. A<br />

titanium-mineral matrix especially developed for energear, allows the body’s<br />

own Far Infrared Rays to be reflected back to it. This reflection can increase<br />

circulation and oxygen levels in the blood. The additional energy can result in<br />

performance enhancement and the reduction of premature fatigue, improved<br />

regeneration, shorter warm-ups, and an increase in balance and concentration<br />

as well as wellbeing.<br />

A simple experiment with beans plausibly demonstrates the positive effects of<br />

energear. Nestling in fabric covers – one with and one without energear -<br />

the growth of these plants which react sensitively to environmental influences<br />

was tested. After just eight days, a distinct difference could be observed. The<br />

beans grew significantly faster and in greater numbers that those without<br />

energear.<br />

Hohenstein also examines the influence of clothing on mental performance<br />

capacity in order to corroborate the positive experience. Testers wearing an<br />

energear shirt or an identical “placebo” shirt were subjected to a new test<br />

process. The test recorded the age-related mean reaction time to visual and<br />

audio stimuli as well as the rate of errors per test model. The results show that<br />

testers wearing an energear shirt displayed a shorter reaction time to both<br />

visual and audio stimuli corresponding to increased information processing.<br />

These measurements taken by a neutral institute corroborate the positive effect<br />

of energear.<br />

energear is a trademark of <strong>Schoeller</strong> Technologies AG/Switzerland.

The energear textile technology was developed in 2010 for <strong>Schoeller</strong> textiles<br />

and integrated into membranes and coatings. Since 2011, it has been available<br />

at the licensing level for further markets as it can be applied to textiles via a<br />

printing paste. Depending on the blend, the printing paste with energear<br />

results in a grey to silver-metallic look. Regardless of the substrate, it can be<br />

used on the first, second or third clothing layer.<br />

Radiated energy reflects back to the body.<br />

The experiment with beans demonstrates the positive<br />

effects of energear.<br />

Discover more at Outdoor Retailer <strong>Schoeller</strong> Booth #39051<br />

energear is a trademark of <strong>Schoeller</strong> Technologies AG/Switzerland.

Press Information Outdoor 2012<br />

contact: Shannon Walton �phone: 970-260-9282 �pr@coldblack.ch �www.coldblack.ch<br />

coldblack ® : Sun Reflector – UV Protector<br />

Dark colors heat up more when exposed to direct sunlight than light ones.<br />

coldblack ® is a special finishing technology for textiles developed by <strong>Schoeller</strong><br />

Technologies AG that alters the heat management of textiles and offers reliable<br />

protection from UV rays.<br />

Light colored textiles reflect both visible and invisible rays of sunlight, meaning both heat<br />

and light. Dark colored textiles absorb both types of rays and therefore absorb heat.<br />

coldblack ® technology reduces this absorption of heat rays, particularly for darker colors.<br />

The result is tangibly better heat management, because textiles with coldblack ® remain<br />

significantly cooler than the same material without coldblack ® . Furthermore, the<br />

coldblack ® technology guarantees a UPF of at least 30, without affecting the look or feel<br />

of the product. This means that textiles with coldblack ® effectively protect from UV rays.<br />

As the heat absorption of the fabric when exposed to direct sunlight can be significantly<br />

reduced thanks to coldblack ® , the wearer feels fresher in clothing with coldblack ® and is<br />

therefore capable of greater performance. When the body makes less effort to cool down,<br />

the energy can be then be applied to the actual physical performance.<br />

New products 2012 with coldblack ®<br />

Under Armour coldblack ® collection<br />

http://www.underarmour.com/shop/us/en/cold-black<br />

http://www.youtube.com/watch?v=LF9vl2kjIAo<br />

http://www.youtube.com/watch?v=LF9vl2kjIAo<br />

coldblack ® is a registered trademark of <strong>Schoeller</strong> Technologies AG/Switzerland.

Louis Garneau Triathlon Elite Lazer Tek Suit 2 new with coldblack ®<br />

http://www.louisgarneau.com<br />

Discover more at ORSM12, booth #39051<br />

coldblack ® is a registered trademark of <strong>Schoeller</strong> Technologies AG/Switzerland.

Press Information Outdoor 2012<br />

contact: Shannon Walton �phone: 970.260.9282 �pr@schoeller-tech.com �www.nanosphere.ch<br />

NanoSphere ® - top results in stain, water and oil repellence<br />

NanoSphere ® is a textile finish based on nanotechnology and achieves top<br />

results in terms of the self-cleaning effect, abrasion resistance and washing<br />

permanence.<br />

The nanoparticles in the NanoSphere ® finish form a fine structure on the surface of the<br />

fabric. In contrast to classic, smooth textile surfaces, which offer water and dirt particles<br />

a larger contact surface and therefore allow greater adhesion, water and dirt on a<br />

NanoSphere ® surface lie only on the peaks. For this reason, even such substances as oil<br />

or ketchup run off the NanoSphere ® surface. Any residue can be simply washed off with<br />

a little water. NanoSphere ® meets the most demanding washing and dry cleaning<br />

requirements. The finish is highly abrasion resistant and the protective function remains<br />

lastingly active, even when exposed to considerable load and after frequent washings.<br />

The functional finish does not alter the feel, appearance, breathability or the elasticity of<br />

a material. NanoSphere ® corresponds with the criteria of the bluesign ® standard, the<br />

world's most stringent production for Environment, Health and Safety specifications<br />

(EHS). NanoSphere ® guarantees the highest possible freedom from harmful substances<br />

and the most economical use of resources in the manufacturing process.<br />

NanoSphere ® is ideal for such areas as outdoor wear, sportswear, men’s fashion,<br />

women’s wear, career apparel and work wear; as well as shoes, home furnishings, and<br />

commercial textiles.<br />

Levi’s® Commuter with NanoSphere ® /Urban Cycling<br />

http://www.levi.com<br />

Discover More at Outdoor Retailer <strong>Schoeller</strong> Booth# 38051<br />

NanoSphere® is a registered trademark of <strong>Schoeller</strong> Technologies AG/Switzerland (patent protected technology).

Press Information Outdoor 2012<br />

contact: Shannon Walton �phone: 970.260.9282�pr@3XDRY.com �www. 3XDRY.com<br />

3XDRY ® - 1 fabric, 2 finishes, 3 functions<br />

Sevelen, July 2012: The 3XDRY ® function finish combines two technologies in one<br />

fabric: On the outside, the finish is water repelling and on the inside water<br />

absorbing. Thanks to this combination, the 3XDRY feelgood technology improves<br />

the dirt and water repelling properties, reduces visible perspiration marks and<br />

generates a pleasant cooling effect. Clothing with 3XDRY ® transports the<br />

perspiration speedily to the outside and dries quickly.<br />

New with 3XDRY ® technology<br />

¨<br />

Levi’s ® Commuter Shirt/Urban Cycling<br />

http://www.levi.com<br />

Discover More at Outdoor Retailer <strong>Schoeller</strong> Booth #39051<br />

3XDRY ® is a registered trademark of <strong>Schoeller</strong> Technologies AG/Switzerland (patent protected technology).

PRESS INFORMATION<br />

Contact: Shannon Walton<br />

Phone: 206.265.2421<br />

shannon@schoellerusa.com<br />

www.schoeller-textiles.com<br />

bluesign® roots, responsible manufacturing and long term thinking<br />

<strong>Schoeller</strong> Textil became the first bluesign® partner<br />

in 2001 and won the first bluesign® award in 2008.<br />

The independent bluesign® standard was created in<br />

response to growing environmental concerns in<br />

terms of health and safety throughout the textile<br />

production chain without compromising functionality,<br />

quality or design. bluesign® certified fabrics and<br />

products ensure confidence at each stage, from raw<br />

material to final product and from chemical supplier to<br />

consumer. In the last 10+ years, more than 700<br />

bluesign® approved fabrics have been developed at<br />

<strong>Schoeller</strong> <strong>Textiles</strong>.<br />

For humans and the environment: "pure ideas + pure materials = benefit".<br />

bluesign® approved textiles are found throughout the <strong>Schoeller</strong> range including stretch fabrics, soft-shells,<br />

lifestyle, protective and workwear fabrics; each constructed of different yarn combinations and coating processes.<br />

"bluesign® reviewed each thread, each dye and each chemical or nanoparticle in regard to health systems," said<br />

Detlef Fischer, VP of bluesign®. "For a company with a low complexity, it is relatively easy to work according to<br />

our specifications. However, as complex as <strong>Schoeller</strong> is, this partnership proves that a model of sustainability is<br />

(almost) universally possible when each new idea begins with sustainability and/or ecology”.<br />

With hundreds of different articles, <strong>Schoeller</strong> has an incredible depth and breadth in this field. "Our designers and<br />

developers always first consider bluesign® when developing new fabrics and technologies," says <strong>Schoeller</strong> CEO<br />

Hans-Jürgen Hübner. "Yet, there are always new items such as some crazy fabric creations or very complex,<br />

highly technical protection fabrics that do not meet the standard in one way or another. Here is where our<br />

customers have the chance to decide if a look or performance is maybe more important than the textiles being<br />

bluesign® certified”. Currently 80% of the <strong>Schoeller</strong> Textile range is bluesign®. Thus, sports enthusiasts, furniture<br />

manufacturers, fashion designers and workwear specialists may find many beautiful and highly functional<br />

<strong>Schoeller</strong> fabrics that can be worked with or worn in good conscience.<br />

28.01.2010

<strong>Schoeller</strong> products are sustainable<br />

28.01.2010<br />

PRESS INFORMATION<br />

Contact: Shannon Walton<br />

Phone: 206.265.2421<br />

shannon@schoellerusa.com<br />

www.schoeller-textiles.com<br />

Two aspects that <strong>Schoeller</strong> always considers are the influence of production on the environment and a product’s<br />

ecological footprint. Our textiles are of a high quality and "live longer" than cheaply produced goods. They can<br />

therefore remain in use for a long time. Due to water and dirt repelling finishes, they stay clean longer and<br />

therefore need less frequent washing and can be washed at lower temperatures. This reduces water, detergents<br />

and energy use.<br />

<strong>Schoeller</strong> takes a long-term and networked view<br />

We are not one of those companies hopping aboard the bandwagon of the "eco trend". <strong>Schoeller</strong> thinks in terms<br />

of both the beginning and end of the product lifecycle. This requires, among other things, the appropriate<br />

infrastructure, major organizational input and precise eco audits. For years, <strong>Schoeller</strong> has been proactively<br />

making its own contribution including continual environmental updates to the mill and reworking formulas to take<br />

advantage of ecological advancements in chemistry and we will carry on doing so in the future. We continue to<br />

put responsibility into practice.<br />

The focus of all schoeller developments and actions is people and the planet. We aim to support our customers<br />

at work, in leisure and during sporting activities with sophisticated, intelligent and ecologically safe textiles. At<br />

every product development step, the questions we ask ourselves relate not only to functional enhancement but<br />

also, and of equal importance, to ecology. As a Swiss company, we have been living these two aspects for<br />

many years, and doing so every day, powering our every innovation.<br />

bluesign® in practice<br />

In 1994, we launched our first 100% recyclable stretch fabric and no PFOS-containing products are used in our<br />

manufacturing. With the installation of state of the art dyeing machines and a solvent washing machine<br />

permitted a further 65% water reduction from 2001. In addition, we have considerably reduced the CO2 –<br />

emissions since 2002 and achieved further energy savings by converting to natural gas and recovering energy<br />

from exhaust air and wastewater. Moreover, we have succeeded in increasing production capacity and saving<br />

energy with an expansion project and the installation of modern tentering frames, an exhaust air purification<br />

plant and air weaving looms. All of these are just some examples of how the five tenants of bluesign®:<br />

resource productivity, occupational health and safety, consumer safety, air emissions and water emissions are<br />

put into practice at <strong>Schoeller</strong>.

<strong>Schoeller</strong> Textil USA sponsors the following organizations: