THREADS AND FASTENERS - Goodheart-Willcox

THREADS AND FASTENERS - Goodheart-Willcox

THREADS AND FASTENERS - Goodheart-Willcox

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

This sample chapter is for review purposes only. Copyright © The <strong>Goodheart</strong>-<strong>Willcox</strong> Co., Inc. All rights reserved.<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

G<br />

UNLESS OTHERWISE SPECIFIED<br />

DIMENSIONS ARE IN INCHES<br />

TOLERANCES ON<br />

DECIMALS<br />

DO NOT SCALE DRAWING<br />

I 2<br />

3 4 5<br />

DRAWN DATE<br />

CHECK<br />

DESIGN<br />

STRESS<br />

MATERIALS<br />

PRODUCTION<br />

SUPERVISOR<br />

After completing this unit, you will be able to:<br />

Define terms related to screw threads and<br />

fasteners.<br />

Identify screw thread forms.<br />

List pipe thread forms.<br />

Explain how thread types are represented and<br />

specified on prints.<br />

A screw thread or thread is a ridge of a particular<br />

shape, often a V, which follows a helical<br />

path around the surface of a cylindrical surface.<br />

A helix is like a barber pole, candy cane, or can<br />

be compared to wrapping a rope around a cylinder.<br />

By definition, a helix is formed by a point<br />

progressing uniformly along a path with a constant<br />

obliquing angle to the axis of a cone or<br />

cylinder. Threads are formed by hand, ground or<br />

rolled on a lathe, and formed using thread cutting<br />

machines.<br />

Threads are a very important feature of<br />

many industrial fasteners and machine parts.<br />

Threads such as the American National or the<br />

Unified Standard (V-type) are used for bolts,<br />

screws, and nuts; and for fastening machine<br />

parts together. Other thread forms are designed<br />

for special purposes, such as transmitting power<br />

along an axis, as in the lead screw of a machine<br />

lathe. Pipe threads are also standardized and<br />

designed for particular functions.<br />

Thread Terms and Definitions<br />

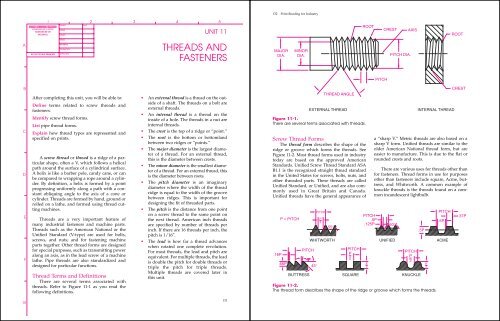

There are several terms associated with<br />

threads. Refer to Figure 11-1 as you read the<br />

following definitions.<br />

UNIT 11<br />

<strong>THREADS</strong> <strong>AND</strong><br />

<strong>FASTENERS</strong><br />

• An external thread is a thread on the outside<br />

of a shaft. The threads on a bolt are<br />

external threads.<br />

• An internal thread is a thread on the<br />

inside of a hole. The threads in a nut are<br />

internal threads.<br />

• The crest is the top of a ridge or “point.”<br />

• The root is the bottom or bottomland<br />

between two ridges or “points.”<br />

• The major diameter is the largest diameter<br />

of a thread. For an external thread,<br />

this is the diameter between crests.<br />

• The minor diameter is the smallest diameter<br />

of a thread. For an external thread, this<br />

is the diameter between roots.<br />

• The pitch diameter is an imaginary<br />

diameter where the width of the thread<br />

ridge is equal to the width of the groove<br />

between ridges. This is important for<br />

designing the fit of threaded parts.<br />

• The pitch is the distance from one point<br />

on a screw thread to the same point on<br />

the next thread. American inch threads<br />

are specified by number of threads per<br />

inch. If there are 16 threads per inch, the<br />

pitch is 1/16″.<br />

• The lead is how far a thread advances<br />

when rotated one complete revolution.<br />

For most threads, the lead and pitch are<br />

equivalent. For multiple threads, the lead<br />

is double the pitch for double threads or<br />

triple the pitch for triple threads.<br />

Multiple threads are covered later in<br />

this unit.<br />

131<br />

132 Print Reading for Industry<br />

MAJOR<br />

DIA.<br />

MINOR<br />

DIA.<br />

THREAD ANGLE<br />

Screw Thread Forms<br />

The thread form describes the shape of the<br />

ridge or groove which forms the threads. See<br />

Figure 11-2. Most thread forms used in industry<br />

today are based on the approved American<br />

Standards. Unified Screw Thread Standard ASA<br />

B1.1 is the recognized straight thread standard<br />

in the United States for screws, bolts, nuts, and<br />

other threaded parts. These threads are called<br />

Unified Standard, or Unified, and are also commonly<br />

used in Great Britain and Canada.<br />

Unified threads have the general appearance of<br />

ROOT<br />

CREST AXIS<br />

PITCH DIA.<br />

EXTERNAL THREAD INTERNAL THREAD<br />

Figure 11-1.<br />

There are several terms associated with threads.<br />

.16P<br />

P = PITCH<br />

.66P<br />

PITCH<br />

PITCH<br />

P<br />

2<br />

55°<br />

PITCH<br />

ROOT<br />

CREST<br />

a “sharp V.” Metric threads are also based on a<br />

sharp V form. Unified threads are similar to the<br />

older American National thread form, but are<br />

easier to manufacture. This is due to the flat or<br />

rounded crests and roots.<br />

There are various uses for threads other than<br />

for fasteners. Thread forms in use for purposes<br />

other than fasteners include square, Acme, buttress,<br />

and Whitworth. A common example of<br />

knuckle threads is the threads found on a common<br />

incandescent lightbulb.<br />

PITCH<br />

.5P<br />

.125P 60°<br />

PITCH<br />

WHITWORTH UNIFIED ACME<br />

45°<br />

PITCH<br />

P<br />

2<br />

BUTTRESS SQUARE KNUCKLE<br />

P<br />

2<br />

PITCH<br />

P<br />

2<br />

Figure 11-2.<br />

The thread form describes the shape of the ridge or groove which forms the threads.<br />

.5P<br />

P<br />

2<br />

.5P<br />

.37P

Thread Representation<br />

A true projection view of a screw thread is<br />

not used due to the helical shape. Instead,<br />

threads are represented on a print in conventional<br />

ways. The three conventional methods in<br />

which threads may be represented on drawings<br />

are the detailed, schematic, and simplified methods.<br />

See Figure 11-3.<br />

The detailed convention most closely represents<br />

screw threads as they actually appear. This<br />

convention is sometimes used to show the<br />

geometry of a thread form as a portion of a<br />

greatly enlarged detail on a drawing. A rule of<br />

thumb is to draw detailed threads if the major<br />

diameter appears larger than 1″ on the drawing.<br />

The schematic convention and simplified<br />

convention are representations of the thread and<br />

are easier to draw. These conventions are recommended<br />

when the major diameter is less than 1″<br />

on the drawing. Both conventions are commonly<br />

used to save drafting time. The simplified<br />

convention is the easiest convention to use with<br />

most CAD systems.<br />

EXTERNAL <strong>THREADS</strong><br />

REGULAR VIEWS SECTION VIEWS<br />

DETAILED REPRESENTATION<br />

SCHEMATIC REPRESENTATION<br />

SIMPLIFIED REPRESENTATION<br />

Unit 11 Threads and Fasteners 133<br />

Thread Series<br />

There are four series of Unified screw<br />

threads—coarse, fine, extra fine, and constantpitch.<br />

See Figure 11-4 and Figure 11-5. Each<br />

series has its own designation. There are also<br />

three special thread series designated UNS, NS,<br />

and UN. These series cover special combinations<br />

of diameter, pitch, and length of engagement.<br />

The Unified coarse thread series is designated<br />

UNC. It is used for nuts, bolts, screws, and<br />

general uses where a fine thread is not required.<br />

The Unified fine thread series is designated<br />

UNF. It is used where the length of the threaded<br />

engagement is short and where a small lead<br />

angle is desired.<br />

The Unified extra fine series is designated<br />

UNEF. It is used for very short lengths of thread<br />

engagement and for thin-wall tubes, nuts, ferrules,<br />

and couplings.<br />

The Unified constant-pitch series is designated<br />

UN with the number of threads per inch<br />

INTERNAL <strong>THREADS</strong><br />

Figure 11-3.<br />

The three conventional methods for representing threads are detailed, schematic, and simplified.<br />

134 Print Reading for Industry<br />

NORMAL<br />

DIAMETER<br />

BASIC<br />

DIAMETER<br />

COARSE<br />

NC & UNC<br />

THDS<br />

PER<br />

IN<br />

TAP<br />

DRILL<br />

DIA<br />

FINE<br />

NF & UNF<br />

THDS<br />

PER<br />

IN<br />

TAP<br />

DRILL<br />

DIA<br />

EXTRA FINE<br />

NEF & UNEF<br />

THDS TAP<br />

PER DRILL<br />

IN DIA NORMAL<br />

0 .060 80 .0469<br />

1 .073 64 No.53 72 No.53<br />

2 .086 56 No.50 64 No.50<br />

3 .099 48 No.47 56 No.45<br />

4 .112 40 No.43 48 No.42<br />

5 .125 40 No.38 44 No.37<br />

6 .138 32 No.36 40 No.33<br />

8 .164 32 No.29 36 No.29<br />

10 .190 24 No.25 32 No.21<br />

12 .216 24 No.16 28 No.14 32 No.13<br />

1/4 .250 20 No.7 28 No.3 32 .2189<br />

5/16 .3125 18 F 24 I 32 .2813<br />

3/8 .375 16 .3125 24 Q 32 .3438<br />

7/16 .4375 14 U 20 .3906 28 .4062<br />

1/2 .500 13 .4219 20 .4531 28 .4688<br />

9/16 .5625 12 .4844 18 .5156 24 .5156<br />

5/8 .625 11 .5313 18 .5781 24 .5781<br />

11/16 .6875 ... ... ... ... 24 .6406<br />

3/4 .750 10 .6563 16 .6875 20 .7031<br />

13/16 .8125 ... ... ... ... 20 .7656<br />

7/8 .875 9 .7656 14 .8125 20 .8281<br />

15/16 .9375 ... ... ... ... 20 .8906<br />

Figure 11-4.<br />

Thread specifications for NC, UNC, NF, UNF, NEF, and UNEF threads.<br />

NORMAL<br />

DIAMETER<br />

8 PITCH<br />

8N & 8UN<br />

THDS<br />

PER<br />

IN<br />

TAP<br />

DRILL<br />

DIA<br />

12 PITCH<br />

12N & 12UNF<br />

THDS<br />

PER<br />

IN<br />

TAP<br />

DRILL<br />

DIA<br />

16 PITCH<br />

16N & 16UN<br />

THDS<br />

PER<br />

IN<br />

TAP<br />

DRILL<br />

.500 ... ... 12 .422 ... ...<br />

.563 ... ... 12 .484 ... ...<br />

.625 ... ... 12 .547 ... ...<br />

.688 ... ... 12 .609 ... ...<br />

.750 ... ... 12 .672 16 .688<br />

.813 ... ... 12 .734 16 .750<br />

.875 ... ... 12 .797 16 .813<br />

.934 ... ... 12 .869 16 .875<br />

1.000 8 .875 12 .922 16 .938<br />

1.063 ... ... 12 .984 16 1.000<br />

1.125 8 1.000 12 1.047 16 1.065<br />

1.188 ... ... 12 1.109 16 1.125<br />

1.250 8 1.125 12 1.72 16 1.188<br />

1.313 ... ... 12 1.234 16 1.250<br />

1.375 8 1.250 12 1.297 16 1.313<br />

1.434 ... ... 12 1.359 16 1.375<br />

1.500 8 1.375 12 1.422 16 1.438<br />

1.563 ... ... ... ... 16 1.500<br />

1.625 8 1.500 12 1.547 16 1.563<br />

1.688 ... ... ... ... 16 1.625<br />

1.750 8 1.625 12 1.672 16 1.688<br />

1.813 ... ... ... ... 16 1.750<br />

1.875 8 1.750 12 1.797 16 1.813<br />

1.934 ... ... ... ... 16 1.875<br />

2.000 8 1.875 12 1.922 16 1.938<br />

Figure 11-5.<br />

Thread specifications for constant pitch threads.<br />

DIA NORMAL<br />

DIAMETER<br />

BASIC<br />

DIAMETER<br />

COARSE<br />

NC & UNC<br />

THDS<br />

PER<br />

IN<br />

TAP<br />

DRILL<br />

DIA<br />

FINE<br />

NF & UNF<br />

THDS<br />

PER<br />

IN<br />

TAP<br />

DRILL<br />

DIA<br />

EXTRA FINE<br />

NEF & UNEF<br />

THDS<br />

PER<br />

IN<br />

TAP<br />

DRILL<br />

DIA<br />

1 1.000 8 .875 12 .922 20 .953<br />

1–1/16 1.063 ... ... ... ... 18 1.000<br />

1–1/8 1.125 7 .904 12 1.046 18 1.070<br />

1–3/16 1.188 ... ... ... ... 18 1.141<br />

1–1/4 1.250 7 1.109 12 1.172 18 1.188<br />

1–5/16 1.313 ... ... ... ... 18 1.266<br />

1–3/8 1.375 6 1.219 12 1.297 18 1.313<br />

1–7/16 1.438 ... ... ... ... 18 1.375<br />

1–1/2 1.500 6 1.344 12 1.422 18 1.438<br />

1–9/16 1.563 ... ... ... ... 18 1.500<br />

1–5/8 1.625 ... ... ... ... 18 1.563<br />

1–11/16 1.688 ... ... ... ... 18 1.625<br />

1–3/4 1.750 5 1.563 ... ... ... ...<br />

2 2.000 4.5 1.781 ... ... ... ...<br />

2–1/4 2.250 4.5 2.031 ... ... ... ...<br />

2–1/2 2.500 4 2.250 ... ... ... ...<br />

2–3/4 2.750 4 2.500 ... ... ... ...<br />

3 3.000 4 2.750 ... ... ... ...<br />

3–1/4 3.250 4 ... ... ... ... ...<br />

3–1/2 3.500 4 ... ... ... ... ...<br />

3–3/4 3.750 4 ... ... ... ... ...<br />

4 4.000 4 ... ... ... ... ...<br />

DIAMETER<br />

8 PITCH<br />

8N & 8UN<br />

THDS<br />

PER<br />

IN<br />

TAP<br />

DRILL<br />

DIA<br />

12 PITCH<br />

12N & 12UNF<br />

THDS<br />

PER<br />

IN<br />

TAP<br />

DRILL<br />

DIA<br />

16 PITCH<br />

16N & 16UN<br />

THDS<br />

PER<br />

IN<br />

TAP<br />

DRILL<br />

DIA<br />

2.063 ... ... ... ... 16 2.000<br />

2.125 ... ... 12 2.047 16 2.063<br />

2.188 ... ... ... ... 16 2.125<br />

2.250 8 2.125 12 2.172 16 2.188<br />

2.313 ... ... ... ... 16 2.250<br />

2.375 ... ... 12 2.297 16 2.313<br />

2.438 ... ... ... ... 16 2.375<br />

2.500 8 2.375 12 2.422 16 2.438<br />

2.625 ... ... 12 2.547 16 2.563<br />

2.750 8 2.625 12 2.717 16 2.688<br />

2.875 ... ... 12 ... 16 ...<br />

3.000 8 2.875 12 ... 16 ...<br />

3.125 ... ... 12 ... 16 ...<br />

3.250 8 ... 12 ... 16 ...<br />

3.375 ... ... 12 ... 16 ...<br />

3.500 8 ... 12 ... 16 ...<br />

3.625 ... ... 12 ... 16 ...<br />

3.750 8 ... ... ... 16 ...<br />

3.875 ... ... 12 ... 16 ...<br />

4.000 8 ... ... ... 16 ...<br />

4.250 8 ... 12 ... 16 ...<br />

4.500 8 ... ... ... 16 ...<br />

4.750 8 ... 12 ... 16 ...<br />

5.000 8 ... ... ... 16 ...<br />

5.250 8 ... 12 ... 16 ...

preceding the designation, such as 8UN. This series<br />

of threads is for special purposes, such as highpressure<br />

applications. Constant-pitch threads are<br />

also used for large diameters where the other<br />

thread series do not meet the requirements.<br />

Thread Classes<br />

After classification by form and series,<br />

threads are further classified by manufacturing<br />

tolerance. These classes are 1A, 2A, and 3A for<br />

external threads and 1B, 2B, and 3B for internal<br />

threads. On some older drawings, classes 2 and<br />

3 may appear without a letter designation.<br />

Classes 1A and 1B replace the older<br />

American Standard class 1. They are used in<br />

applications requiring minimum binding and<br />

allow for frequent and quick assembly or disassembly<br />

of parts.<br />

Classes 2A and 2B are threads with tighter<br />

tolerances. They are used for general purposes<br />

such as for nuts, bolts, screws, and normal applications<br />

by mass production industries.<br />

Class 3A and 3B are threads with very stringent<br />

and close tolerances. They are used for<br />

applications in industries requiring tighter tolerances<br />

than the preceding classes of 1A and 1B, or<br />

2A and 2B.<br />

Multiple Threads<br />

Threads can have two or three ridges running<br />

side-by-side. These are called double threads or<br />

triple threads. It may help to think of rope<br />

wrapped around a pole. If one rope is wrapped, it<br />

is like a single thread. If two ropes are wrapped,<br />

they are like double threads. Three ropes<br />

wrapped around the pole are like triple threads.<br />

Simply looking at the thread generally will<br />

not indicate if it is single, double, or triple.<br />

However, a close inspection should reveal a<br />

greater slope to double and triple threads than<br />

that found on single threads. Due to the greater<br />

slope angle of the thread, the “holding power”<br />

of a double or triple thread is less.<br />

Remember, the lead of a double thread is<br />

twice the pitch. One revolution of the threaded<br />

Unit 11 Threads and Fasteners 135<br />

cylinder advances two pitches because there are<br />

two ridges. Likewise, a triple thread advances<br />

three pitches.<br />

Left-Hand Threads<br />

Threads are most commonly created so that<br />

clockwise revolutions advance the threaded<br />

parts together. Common nuts and bolts tighten<br />

with clockwise turns. These threads are called<br />

right-hand threads. However, some applications<br />

require threads which tighten with counterclockwise<br />

movement. These threads are referred<br />

to as left-hand or reverse threads.<br />

Left-hand threads are usually found on<br />

items where right-hand threads may produce<br />

unwanted loosening, perhaps due to motion.<br />

Examples include bicycle pedal threads, threads<br />

on a flush handle, arbor nut on a table saw<br />

blade, and similar applications. Left-hand<br />

threads are indicated in a print using a callout.<br />

Detailed representations should also reflect a<br />

slope angle opposite that of right-hand threads.<br />

See Figure 11-6.<br />

CLOCKWISE<br />

RIGHT–H<strong>AND</strong> THREAD<br />

LEFT–H<strong>AND</strong> THREAD<br />

Figure 11-6.<br />

Right-hand and left-hand threads.<br />

COUNTERCLOCKWISE<br />

136 Print Reading for Industry<br />

Specification of Screw Threads<br />

A screw thread is specified on a drawing<br />

using a standard note with a leader and an<br />

arrow pointing to the thread. The note contains<br />

specific information for the specific thread. The<br />

note in Figure 11-7 is interpreted as follows.<br />

A) Nominal size (major diameter or screw<br />

number)<br />

B) Number of threads per inch<br />

C) Thread form<br />

D) Thread class number or symbol<br />

E) Left-hand (LH), double threads (DOUBLE)<br />

Threads are right-hand and single lead<br />

unless otherwise specified. The letters LH after<br />

the class symbol specify the thread as left hand.<br />

The word DOUBLE indicates double thread. The<br />

word TRIPLE indicates triple thread. Single<br />

threads and right-hand threads do not require<br />

RH or SINGLE to be specified.<br />

Schematic and simplified thread representations<br />

are not impacted by the thread form, the<br />

pitch, left-hand, or multiple thread status. The<br />

schematic spacing is usually just a factor of the<br />

major diameter, and nothing more.<br />

MAJOR DIAMETER IN INCHES<br />

NUMBER OF<br />

<strong>THREADS</strong> PER INCH<br />

THREAD<br />

FORM<br />

THREAD<br />

CLASS<br />

1/2 – 13 UNC 2A<br />

Figure 11-7.<br />

A screw thread is specified in a local note.<br />

Other specifications for threads may be<br />

given. These additional specifications may<br />

include thread length, hole size (for internal<br />

threads), or chamfer. See Figure 11-8.<br />

If the tolerance of the thread pitch diameter<br />

is given, it is placed at the end of the specification<br />

for the thread as follows.<br />

3<br />

− 10UNC − 2B PD 0.6850 TO 0.6927<br />

4<br />

The specification for a constant-pitch series<br />

thread with a tolerance for the pitch diameter<br />

would be listed as follows.<br />

1<br />

− 8UN − 3A PD 2.1688 TO 2.1611<br />

4 2<br />

Metric Threads<br />

Metric threads are graphically represented<br />

in the same manner as Unified and American<br />

National Standard. However, the format of the<br />

associated note is different. In a note for metric<br />

threads, the letter M is followed by the diameter<br />

and pitch. The M designates the thread as a<br />

metric series. Thread designation is for a<br />

coarse thread unless otherwise noted. Metric<br />

A B C D E<br />

1 – 5 ACME – 2A LH DOUBLE

17/32 – 1.25<br />

5/8 X 82°<br />

5/8 – 11UNC – 2B .75<br />

Figure 11-8.<br />

Additional specifications for a thread may<br />

include thread length, hole size, or chamfer.<br />

fine threads are designated by listing the pitch<br />

as a suffix.<br />

For example, in Figure 11-9, M8 is a coarse<br />

thread designation representing a nominal<br />

M8<br />

Figure 11-9.<br />

Metric threads are specified slightly different than other threads.<br />

Unit 11 Threads and Fasteners 137<br />

thread diameter of 8mm with a standardized<br />

pitch of 1.25mm understood. A fine thread designation<br />

for the part is M8×1.0. This indicates an<br />

8mm diameter with a pitch of 1.0mm. The most<br />

common metric thread is coarse. Metric coarse<br />

threads are generally between Unified coarse<br />

and fine series for a comparable diameter.<br />

The specification for metric series threads<br />

does not indicate the number of threads per unit<br />

of length, such as threads per millimeter. Instead,<br />

the pitch is indicated in the specification. For<br />

example, M8×1.0 designates the pitch is 1mm.<br />

The tolerance and class of fit for metric<br />

threads are designated by adding numbers and<br />

letters in a certain sequence to the callout. The<br />

thread designation in Figure 11-10 calls for a<br />

20mm diameter fine thread with a pitch of<br />

.75mm. In addition, the thread has a pitch diameter<br />

tolerance of grade 6 with an allowance “h”<br />

and a crest diameter tolerance grade 6 with an<br />

allowance “g.” See Unit 13 for a discussion of<br />

these tolerancing symbols.<br />

Pipe Threads<br />

The three forms of pipe threads used in<br />

industry are regular, aeronautical, and dryseal<br />

M8 X 1.0<br />

138 Print Reading for Industry<br />

METRIC THREAD<br />

DESIGNATION<br />

M20X1.5–6h6g<br />

MAJOR<br />

DIAMETER<br />

Figure 11-10.<br />

The tolerance class is added as a suffix to the thread note.<br />

pipe threads. The regular pipe thread is the standard<br />

for the plumbing trade. The aeronautical<br />

pipe thread is the standard in the aerospace<br />

industry. Regular and aeronautical pipe thread<br />

forms must be filled with a lute or sealer to prevent<br />

leakage in the joint. The dryseal pipe thread<br />

is the standard for automotive, refrigeration,<br />

and hydraulic tube/pipe fittings. Dryseal pipe<br />

threads do not allow leakage, even without the<br />

use of sealer. This is due to the metal-to-metal<br />

contact at the crest and root of the threads.<br />

Representation and Specification<br />

Straight and taper pipe threads are represented<br />

graphically in a similar manner as other<br />

screw threads. However, pipe threads are shown<br />

tapered at an angle of approximately 3° to the<br />

A B C D<br />

1/4 – 18 DRYSEAL NPTF<br />

Figure 11-11.<br />

Pipe threads are drawn similar to normal threads,<br />

but at a slight angle to the centerline axis.<br />

PITCH<br />

(FINE THREAD)<br />

PITCH DIAMETER TOLERANCE<br />

6 = GRADE<br />

g = POSITION (ALLOWANCE)<br />

CREST DIAMETER TOLERANCE<br />

6 = GRADE<br />

g = POSITION (ALLOWANCE)<br />

TOLERANCE CLASS<br />

centerline axis. See Figure 11-11.<br />

The specifications for American Standard<br />

Pipe Threads are listed in sequence of the nominal<br />

size, number of threads per inch, and the symbols<br />

for the thread series and form. For example,<br />

the thread specification 1/2-14NPT designates a<br />

1/2″ nominal size, 14 threads per inch, and an<br />

American Standard taper pipe thread.<br />

Pipe Thread Symbols<br />

The following symbols are used to designate<br />

American Standard pipe threads.<br />

• NPT. American Standard taper pipe<br />

thread.<br />

• NPTR. American Standard taper pipe<br />

thread for railing joints.<br />

• NPSC. American Standard pipe thread<br />

for couplings.<br />

• NPSM. American Standard pipe thread<br />

for free-fitting mechanical joints.<br />

• NPSL. American Standard pipe thread<br />

for loose-fitting mechanical joints with<br />

locknuts.<br />

• NPSH. American Standard pipe thread<br />

for hose couplings.<br />

Symbols for dryseal pipe threads are designated

as follows:<br />

• NPTF. Dryseal American Standard pipe<br />

thread.<br />

• PTF-SAE SHORT. Dryseal SAE short<br />

taper pipe thread.<br />

• NPSF. Dryseal American Standard fuel<br />

internal straight pipe thread.<br />

• NPSI. Dryseal American Standard intermediate<br />

internal straight pipe thread.<br />

A typical specification for dryseal pipe<br />

thread is shown in Figure 11-11. This specification<br />

includes:<br />

A) Nominal size<br />

B) Number of threads per inch<br />

C) Form (dryseal)<br />

D) Symbol<br />

Unit 11 Threads and Fasteners 139<br />

Print Reading Activities<br />

In the activities in this unit, you will read<br />

some actual industry prints. Many companies<br />

have their own drafting standards. As such, some<br />

items shown on industry prints may not exactly<br />

conform to the standards taught in this text.<br />

However, an important aspect of print reading is<br />

being able to correctly interpret all prints, including<br />

prints drawn to older or company-specific<br />

standards. Additional advanced print activities<br />

for this unit, APR11-1 and APR11-2, are located at<br />

the back of the book.<br />

140 Print Reading for Industry<br />

Print Reading Activity 11-1<br />

External Threads<br />

Refer to the print in PR11-1 and answer the<br />

following questions.<br />

1. What is the name of the part?<br />

2. What is the drawing number?<br />

3. As given in the title block, what is the<br />

scale of the drawing?<br />

4. What material is required?<br />

5. What is the maximum allowed finished<br />

length?<br />

6. What size is the hole drilled through<br />

the piece?<br />

7. Interpret the thread specification for A.<br />

.750<br />

10<br />

UNC<br />

2A<br />

8. Give the dimensions for the groove on<br />

the left-hand side of the part.<br />

9. Interpret the thread specification for B.<br />

1<br />

8<br />

UNC<br />

2A<br />

1.25 LG<br />

10. What does UNC stand for?<br />

1. ______________________________________<br />

2. ______________________________________<br />

3. ______________________________________<br />

4. ______________________________________<br />

5. ______________________________________<br />

6. ______________________________________<br />

7.<br />

______________________________________<br />

______________________________________<br />

______________________________________<br />

______________________________________<br />

8. ______________________________________<br />

9.<br />

______________________________________<br />

______________________________________<br />

______________________________________<br />

______________________________________<br />

______________________________________<br />

10. ______________________________________

B<br />

A<br />

PR11-1.<br />

Print supplied by Rockwell Manufacturing Company.<br />

Unit 11 Threads and Fasteners 141<br />

142 Print Reading for Industry<br />

A<br />

PR11-2.<br />

Print supplied by Johnson and Towers, Inc.

Print Reading Activity 11-2<br />

Internal Thread<br />

Refer to the print PR11-2 and answer the following<br />

questions.<br />

1. What is the name of the part?<br />

2. What is the number of the part?<br />

3. What material is specified?<br />

4. How many counterbored holes (C-BORE)<br />

are there on the part?<br />

5. What is the overall outside diameter of<br />

the part?<br />

6. How many threaded holes are there on<br />

this part?<br />

7. What is the diameter of the bolt circle<br />

that serves as a reference for the location<br />

of the threaded holes?<br />

8. What are the location dimensions for the<br />

hole at A?<br />

9. What is the size of the large center<br />

“through” hole?<br />

10. What type of thread representation is<br />

used in this drawing?<br />

Unit 11 Threads And Fasteners 143<br />

1. ______________________________________<br />

2. ______________________________________<br />

3. ______________________________________<br />

4. ______________________________________<br />

5. ______________________________________<br />

6. ______________________________________<br />

7. ______________________________________<br />

8. ______________________________________<br />

9. ______________________________________<br />

10. ______________________________________<br />

144 Print Reading for Industry<br />

Threads Activity 11-3<br />

Thread Interpretation<br />

For numbers 1–9, fill in the blanks for the<br />

sample threads shown in the drawings A–D. Use<br />

the colored lines as guidelines for lettering. Also,<br />

answer A, B, and C for number 10.<br />

1 1<br />

2 – 8 UNC – 2A<br />

FULL SCALE<br />

HALF SCALE<br />

A B C D<br />

.625 – 18UNF–2A LH TRIPLE<br />

LETTER THE INFORMATION FOR FIGURES A THROUGH D IN THE SPACES BELOW:<br />

A B C D<br />

1. NO <strong>THREADS</strong>/INCH<br />

2. PITCH OF THREAD<br />

3. THREAD FORM<br />

4. RH/LH?<br />

5. SINGLE OR WHICH?<br />

6. LEAD OF THREAD<br />

7. MAJOR DIAMETER<br />

8. INTERNAL/EXTERNAL?<br />

9. HOW REPRESENTED?<br />

M12 X 1.75<br />

10. FOR THE METRIC THREAD:<br />

A. WHAT IS THE MAJOR DIAMETER?<br />

B. WHAT IS THE PITCH?<br />

C. HOW IS IT REPRESENTED?