A laser-based water level sensor and robust insulated and heated ...

A laser-based water level sensor and robust insulated and heated ...

A laser-based water level sensor and robust insulated and heated ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

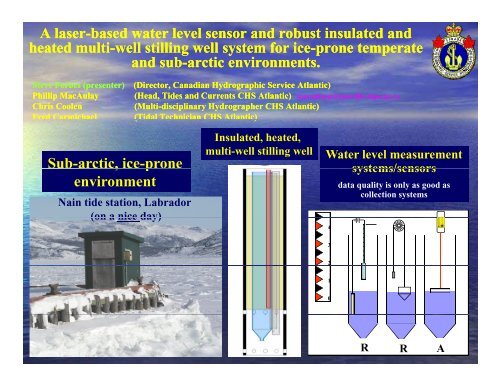

A <strong>laser</strong>-<strong>based</strong> <strong>water</strong> <strong>level</strong> <strong>sensor</strong> <strong>and</strong> <strong>robust</strong> <strong>insulated</strong> <strong>and</strong><br />

<strong>heated</strong> multi-well stilling well system for ice-prone temperate<br />

<strong>and</strong> sub-arctic sub-arctic environments.<br />

Steve Forbes (presenter) (Director, Canadian Hydrographic Service Atlantic)<br />

Phillip MacAulay (Head, Tides <strong>and</strong> Currents CHS Atlantic) macaulayp@mar.dfo-mpo.gc.ca<br />

Chris Coolen (Multi-disciplinary Hydrographer CHS Atlantic)<br />

Fred Carmichael (Tidal ( Technician CHS Atlantic) )<br />

Sub-arctic, , ice-prone p<br />

environment<br />

Nain tide station, Labrador<br />

(on a nice day)<br />

Insulated, <strong>heated</strong>,<br />

multi-well stilling well<br />

Water <strong>level</strong> measurement<br />

systems/<strong>sensor</strong>s<br />

4<br />

3<br />

2<br />

1<br />

0<br />

data quality is only as good as<br />

collection systems<br />

R R<br />

A

Introduction<br />

• Tide gauges measure <strong>water</strong> <strong>level</strong>s (the obvious)<br />

• Uses of tide gauge data<br />

- Basic sounding reduction<br />

Hd Hydrography h [

CHS Atlantic’s Permanent Water Level Network<br />

(many are ice-prone)<br />

16 tide gauges, 000’s kms of coastline<br />

1430<br />

Long Term Sea Level (GLOSS)<br />

Multi-well Laser systems - 08<br />

New Multi-well Laser Sites - 09<br />

2145<br />

0065<br />

0365<br />

2000<br />

1805<br />

0490<br />

1700<br />

0491<br />

1680<br />

0612<br />

0665<br />

0755<br />

0990<br />

0905<br />

0835

Water <strong>level</strong> <strong>sensor</strong>s (no magic solution)<br />

Total error estimates ignoring stilling well effects<br />

(Perspective) Wharf thermal expansion, expansion order +/- +/ 5mm 5 mm<br />

$.2K $.5K $1K<br />

+/- ~5-10 cm +/- ~2-3 mm +/- ~2-3 cm<br />

1) Tide Board<br />

4<br />

2) Tape Drop: st<strong>and</strong>ard t d d<br />

device used to set relative<br />

<strong>sensor</strong>s, (<strong>sensor</strong>s with offsets)<br />

CHS <strong>sensor</strong>s<br />

$5K $.8K $1.5K $5K $5K<br />

+/- 1% +/- 1% +/- ~2-3 mm +/- ~1-2 cm<br />

+/- 1%<br />

~2-3 cm ~2-3 cm<br />

~2-3 cm<br />

3) Float <strong>and</strong> PPulley lle 4) Bubbler<br />

5) SSubmersible bmersible pressure press re 6) Laser <strong>sensor</strong>: 7) Radar <strong>sensor</strong>:<br />

CHS Legacy <strong>sensor</strong> Sutron continuous fast<br />

response bubbler<br />

<strong>sensor</strong> Spectre Sensor Dimetix DLS-B15<br />

pump<br />

P atm<br />

8) Acoustic <strong>sensor</strong>:<br />

Single 3 manual<br />

Sound speed<br />

measurement Mech chain <strong>and</strong> Water density Relatively untested<br />

variation<br />

2<br />

weight errors<br />

variation stilling well required<br />

C(t,h, …)<br />

1<br />

0<br />

Stilling gwell required q – R<br />

Stilling well Optional – O<br />

Relative Measurement – R (must be set relative to a known)<br />

Absolute Measurement – A (direct measurement)<br />

h<br />

o<br />

o<br />

o<br />

o<br />

P= wgh<br />

o 0 0 0<br />

P=wgh R, A R, R<br />

O, R O, R R, A<br />

Surface integration<br />

measurement<br />

bias<br />

O, A<br />

O, A<br />

Require stilling well in the<br />

presence of ice

The stilling well (a necessary evil)<br />

• Provides <strong>sensor</strong> protection <strong>and</strong> act as an analog mechanical<br />

filter via small dia entrance to large dia pipe (by area ~1/100 to 1/150)<br />

- Frequency dependent dependent filter filter, stills high high frequency frequency <strong>water</strong> motions<br />

• Filter parameters change with fouling/plugging example<br />

• Can be expensive to install <strong>and</strong> replace<br />

• Requires significant significant vertical vertical infrastructure infrastructure for for support<br />

support<br />

• To achieve true independence each <strong>sensor</strong> requires its own well<br />

• Known potential sources of error<br />

- <strong>water</strong> density inside well may may not not be/stay the same as outside resulting<br />

in different <strong>water</strong> surface <strong>level</strong> inside vs outside the well example<br />

- Inlet/exit flow non-linearity can introduce <strong>level</strong> offset under active<br />

wave conditions (in-out ( flow resistance hysteresis y effect) )<br />

• Cold weather issues<br />

- direct damage of well by ice (crushing) Nain well failures in 02 <strong>and</strong> 08<br />

- Ice formation in <strong>water</strong> in well (freezing) ( g)<br />

- ice/frost buildup above <strong>water</strong> along inside of well (not a frost-free appliance)<br />

- heating costs for un-<strong>insulated</strong> systems<br />

All persistent Nain problems

Stilling Well Filtering (a relative example)<br />

Data from three <strong>sensor</strong>s, , <strong>laser</strong>, , bubbler, , submersible pressure p <strong>sensor</strong>, ,<br />

in three wells, same location, one well experiencing brief period of minor plugging<br />

pressure<br />

<strong>sensor</strong><br />

bubbler<br />

<strong>laser</strong><br />

phase lag<br />

amplitude<br />

reduction<br />

Well developing minor plugging (dirty harbor): amplitude<br />

Well developing minor plugging (dirty harbor): amplitude<br />

reduction <strong>and</strong> phase lag develop for 20 min period wave energy,<br />

energy at longer tidal periods uneffected

Stilling Well Entrainment of Fresh Water<br />

Example, extreme rain event late in winter in the presence of significant pack<br />

ice leading leading to to deep deep penetration penetration of of fresh fresh <strong>water</strong> <strong>and</strong> infiltration into stilling well<br />

According to float <strong>and</strong> pulley <strong>sensor</strong><br />

<strong>water</strong> <strong>level</strong> inside well rises<br />

All three <strong>sensor</strong><br />

read the same<br />

Fresh <strong>water</strong><br />

infiltration<br />

WL According to bubbler <strong>and</strong> pressure<br />

<strong>sensor</strong> reading pressure at depth<br />

Water surface <strong>level</strong> potentially not equivalent<br />

inside <strong>and</strong> outside the well<br />

(error persistent until well is physically flushed)

Heated Multi-well stilling well<br />

Thermostat<br />

Heat tape<br />

line <strong>water</strong><br />

6)<br />

1) 14” 14 HDPE tough tough protective outer outer casing casing ( (~1 1 inch thick)<br />

2) 6” PVC Main well for <strong>laser</strong> float or float <strong>and</strong> pulley<br />

Thermocouple<br />

<strong>sensor</strong><br />

3) Three 2” satellite wells,<br />

3)<br />

– t two with ith stilling tilli orifices ifi for f a backup b k bubbler b bbl<br />

<strong>sensor</strong> <strong>and</strong> gnomen tape drop<br />

– one free flowing for a fast response pressure<br />

5)<br />

4)<br />

<strong>sensor</strong><br />

1)<br />

4) Two 1-1/4” heater tubes filled with environmentally<br />

2)<br />

friendly anti-freeze<br />

5) Insulation, marine grade slow expansion polyurethane<br />

2lb/ft foam foam from top of well to below low low <strong>water</strong><br />

<strong>water</strong><br />

6) 120 v self-regulating (heat output drops as temperature<br />

rises) submersible heat tapes (10 W/ft) in heater tubes,<br />

with additional thermostatic control<br />

(shut off at ~ 6 C)<br />

1) )<br />

4)<br />

Pros:<br />

• Heating distributed along full length of well<br />

prevents both ice <strong>and</strong> frost frost formation<br />

• Insulation reduces heating costs<br />

• Multi-well design requires only one installation<br />

for multiple truly independent <strong>sensor</strong>s<br />

5)<br />

3)<br />

2) 3)<br />

3)<br />

4)<br />

Low w

Well Construction Overview<br />

1) Assemble <strong>and</strong> align pipe bundle bundle using<br />

316 SS hose clamps<br />

2) Construct <strong>and</strong> fit foam spacers at predetermined<br />

(~ 28 inch) intervals along<br />

pipe bundle bundle, secure in place with<br />

polyurethane spray foam<br />

3) Drill 2 inch holes in outer HDPE pipe<br />

to correspond with mid points<br />

b between f foam spacers<br />

4) Slide pipe bundle into outer casing<br />

5) Spray in slow-expansion polyurethane<br />

foam thru 2 inch access holes starting<br />

starting<br />

at one end of pipe <strong>and</strong> working<br />

sequentially to other end. Use lots,<br />

bleeds past spacers filling all voids,<br />

excess exp<strong>and</strong>s exp<strong>and</strong>s out access holes<br />

Fully assembled 25 ft multi-well<br />

- Cost ~ $ 2.5-3 K<br />

- Weight ~ 3 - 400 lbs, easily<br />

t transported t d on l long trailer, t il possible ibl to t<br />

carefully man-h<strong>and</strong>le into place<br />

without heavy machinery<br />

2) 2)<br />

)<br />

1)<br />

4)<br />

3)<br />

5)

Laser Sensor<br />

• Dimetix DLS-B15 Laser (+/- 1.5 mm accuracy)<br />

• Adjustable <strong>laser</strong> <strong>level</strong>ing mount <strong>and</strong> <strong>level</strong>ing-in<br />

reference plate (<strong>laser</strong> 0 ref is to front face): <strong>laser</strong><br />

is <strong>level</strong>ed <strong>level</strong>ed in in from from bench bench-marks marks to ref plate<br />

• Sutron Xpert logger using st<strong>and</strong>ard RS232<br />

input/decoder software block (6 second sample<br />

repeat period, 1 minute average)<br />

• Laser Float: 1” PVC foam board, 5” diameter,<br />

rounded edges (spec grav ~ .6) floats ~8mm<br />

above <strong>water</strong> surface<br />

- Edges grooved to improve <strong>water</strong> shedding<br />

- Embedded rare-earth magnets for float<br />

placement <strong>and</strong> retrieval (see float tool)<br />

- Top p surface p painted to p prevent <strong>laser</strong> p penetration<br />

into PVC <strong>and</strong> to thus provide clear reflection<br />

• Potential Improvements<br />

- Thicker float (1-1/2 or 2 inch) greater above<br />

<strong>water</strong> ater height ~12-16 12 16 mm<br />

- Electrostatic paint application for smoother top<br />

surface (surface must be smooth over length<br />

scale of <strong>laser</strong> dot for data-spike-free operation)<br />

Ref plate<br />

Float placement tool<br />

steel disc with eye bolt

Weight g enters <strong>water</strong><br />

F+P Float sinks (data offset low)<br />

Weight enters<br />

<strong>water</strong><br />

Laser vs Float <strong>and</strong> Pulley<br />

(weight entering <strong>water</strong> error)<br />

Laser<br />

Fl Float t <strong>and</strong> d pulley ll (F+P)<br />

Chain <strong>and</strong> weight wet<br />

F+P Float time lag (data offset high)<br />

Weight exits<br />

<strong>water</strong>

Nain Installation (piling mount)<br />

Installing<br />

Stilling well<br />

Laser spot<br />

Laser Float<br />

(<strong>laser</strong> on)<br />

Heaters <strong>and</strong><br />

heater control<br />

Heater tube<br />

<strong>laser</strong><br />

Bubbler<br />

<strong>laser</strong><br />

Tape<br />

drop<br />

Tape<br />

drop<br />

Stilling<br />

well<br />

Pressure<br />

<strong>sensor</strong><br />

Heater tube

St John’s Installation (wharf mount)<br />

heater<br />

Tape<br />

Bubbler drop<br />

<strong>laser</strong><br />

hheater t<br />

<strong>laser</strong><br />

Pressure<br />

<strong>sensor</strong><br />

Tape<br />

drop

Nain Sensor Comparison<br />

Each <strong>sensor</strong> independent, in own stilling well<br />

Laser checked against g tape p drop p( (in own stilling g well) ) time-averaged g test ggood<br />

to +/- 1 to 3 mm<br />

Bubbler <strong>and</strong> pressure <strong>sensor</strong> least-squares calibrated to <strong>laser</strong> for slope (<strong>water</strong> density) <strong>and</strong> offset<br />

Errors between <strong>sensor</strong>s explainable <strong>based</strong> on stilling well behavior: pressure <strong>sensor</strong> in well with little<br />

stilling, bubbler exhibits minor spiking at ~15 min interval (software bug in auto-zero process,<br />

manufacturer to provide p fix )

Summary<br />

• Two example <strong>insulated</strong> <strong>and</strong> <strong>heated</strong> multi-well installations operational<br />

for 8 months: only minor teething issues experienced<br />

• Following multi-well installation heating costs at Nain Labrador<br />

significantly reduced<br />

reduced<br />

• Multi-well system relatively simple, inexpensive, <strong>and</strong> easy to construct<br />

<strong>and</strong> install: system <strong>robust</strong>ness, longevity <strong>and</strong> system maintenance<br />

issues still to be determined<br />

• Laser-float <strong>sensor</strong> accuracy appears stable at ~ 2-3 mm, further<br />

confirmation required but clearly better than a st<strong>and</strong>ard float <strong>and</strong><br />

pulley system: minor data-spiking (occasionally a few data spikes per<br />

day, easily cleaned) suspected source, float surface imperfections.<br />

Suggested solution, thicker float, better painted surface QC<br />

• Stilling well errors still a factor: a possible solution to counteract<br />

inside inside-outside outside <strong>water</strong> <strong>water</strong> density density generated generated errors errors is under consideration<br />

consideration