FRONT (Page 1) - Fusite

FRONT (Page 1) - Fusite

FRONT (Page 1) - Fusite

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

®<br />

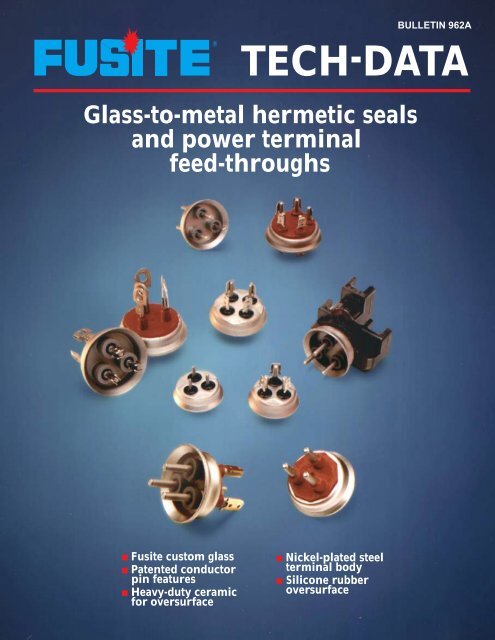

TECH-DATA<br />

Glass-to-metal hermetic seals<br />

and power terminal<br />

feed-throughs<br />

■ <strong>Fusite</strong> custom glass<br />

■ Patented conductor<br />

pin features<br />

■ Heavy-duty ceramic<br />

for oversurface<br />

■ Nickel-plated steel<br />

terminal body<br />

■ Silicone rubber<br />

oversurface<br />

BULLETIN 962A

Glass-to-metal<br />

hermetic seals<br />

and power<br />

terminal<br />

feed-throughs<br />

Terminal Models<br />

Fractional, 600<br />

and 700 Series<br />

These <strong>Fusite</strong> terminals are<br />

designed for high reliability Air<br />

Conditioning and Refrigeration<br />

Compressors. Many incorporate<br />

industry’s most innovative engineering<br />

features, including:<br />

■ Patented groove is designed to<br />

open at high in-rush currents.<br />

(This design is not a substitute<br />

for compressor safety devices<br />

and circuit protection.)<br />

■ Custom-smelted <strong>Fusite</strong> proprietory<br />

glass designed for complete and<br />

reliable hermeticity.<br />

■ Heavy-duty ceramic insulator for<br />

electrical oversurface on the<br />

inside of the compressor.<br />

■ Molded silicone rubber oversurface<br />

for the outside of the compressor,<br />

bonded to the terminal.<br />

■ Solid pin and high conductivity<br />

copper core pin models available<br />

for various applications.<br />

Minimum Ratings<br />

Hydrostatic<br />

Pressure: .................... UL - 2250 psi<br />

Hermeticity: ................1 x 10 (-7) Std.<br />

CC/Sec. of Helium<br />

Dielectric Voltage: ......Min. 2500V with<br />

10,000 Megohms<br />

at 500VDC<br />

© 1996 <strong>Fusite</strong> Division of Emerson Electric Co.<br />

<strong>Fusite</strong> is a registered trademark of Emerson Electric Co.<br />

®<br />

PART # A B C<br />

393-37 .344 [8.74] .547 [13.89] 1.281 [32.54]<br />

393-38 .266 [6.76] .406 [10.31] 1.062 [26.97]<br />

393-95 .266 [6.76] .547 [13.89] 1.203 [30.56]<br />

TERMINALS - 393 FRACTIONAL SERIES<br />

PART # A B<br />

393-694 .452 [11.48] 1.510 [38.36]<br />

393-677 .530 [13.46] 1.590 [40.39]<br />

TERMINALS - 393-600 SERIES<br />

TERMINALS - 393-700 SERIES<br />

Nonagon<br />

pad available<br />

on 393-600<br />

and 393-700<br />

Copper Core<br />

Models<br />

footnoted 4.<br />

Nonagon<br />

pad available<br />

on 393-600<br />

and 393-700<br />

Copper Core<br />

Models<br />

footnoted 4.<br />

PART # A B<br />

3B3-635 .765 [19.43] 1.700 [43.18]<br />

3B3-637 .875 [22.23] 1.810 [45.97]<br />

TERMINALS - 3B3-600 SERIES<br />

TERMINALS - 3K3-600 SERIES<br />

0.459<br />

0.125 [3.18]<br />

0.059 [1.50]<br />

[11.66]<br />

1.282 [32.56]<br />

0.059 [1.50]<br />

0.469<br />

[11.66]<br />

0.937 [23.80]<br />

MAX.<br />

AROUND<br />

INSULATORS<br />

A<br />

B<br />

0.125 [3.18]<br />

0.459<br />

[11.66]<br />

0.937 [23.80]<br />

0.125 [3.18]<br />

45˚<br />

0.390 [9.91]<br />

0.250 [6.35]<br />

90˚<br />

A<br />

1.282 [32.56]<br />

45 ˚<br />

1.282 [32.56]<br />

B<br />

C<br />

1.510 [38.36]<br />

0.391 [9.93]<br />

0.250 [6.35]<br />

1.112 [28.24]<br />

0.090 [2.29]<br />

0.238 [6.05]<br />

1.112 [28.24]<br />

0.260 [6.60]<br />

0.670 REF. [17.02]<br />

0.059 [1.50] 0.250 [6.35]<br />

MAX.<br />

AROUND<br />

INSULATORS<br />

45 ˚<br />

0.059 [1.50]<br />

45˚ 1.480 [37.59]<br />

0.452<br />

[11.48]<br />

0.391 [9.93]<br />

0.670<br />

REF.<br />

0.391 [9.93]<br />

0.250 [6.35]<br />

0.238 [6.05]<br />

[13.46]<br />

1.112 [28.24]<br />

0.260 [6.60]<br />

[17.02]<br />

1.312 [33.32]<br />

0.272 [6.91]<br />

J P<br />

90<br />

[13.46]<br />

˚<br />

F<br />

U<br />

R<br />

T<br />

S I E<br />

0.530<br />

PAT' D<br />

C<br />

PAT'D<br />

C<br />

FU S<br />

R<br />

C<br />

I T E<br />

0.530<br />

0.5954<br />

[15.123]<br />

1.100 [27.94]<br />

MAX.<br />

AROUND<br />

INSULATORS<br />

0.530<br />

[13.46]<br />

B<br />

A<br />

0.421 [10.69]<br />

[17.45] 0.687<br />

0.085 [2.16]<br />

0.125 [3.18] 45°<br />

0.7057<br />

[17.925]<br />

1.920 [48.77]<br />

0.505<br />

[12.83]<br />

1.820 [46.23]<br />

0.500 [12.70]<br />

0.280 [7.11] 1.700 [43.18]<br />

0.812<br />

REF.<br />

0.280 [7.11]<br />

0.405 [10.29]<br />

[20.70]<br />

[20.62]<br />

Note: Dimensions shown are in inches with millimeter dimensions in parentheses.<br />

Ceramic Steel<br />

Glass Rubber<br />

90<br />

˚<br />

PAT ' D<br />

C<br />

0.815<br />

Drawings are representative of <strong>Fusite</strong> models.<br />

All data is subject to change. Consult latest<br />

<strong>Fusite</strong> engineering drawings for current<br />

specifications.<br />

PAT' D<br />

C<br />

R<br />

F US I<br />

F US<br />

F U S<br />

T E<br />

R<br />

I T E<br />

0.530<br />

U R<br />

R<br />

I T E<br />

U R<br />

U R<br />

U R<br />

[13.46]

Model 1<br />

Pin<br />

Material<br />

400 Series<br />

SS<br />

393-794 Solid Pins Pins 35 1.510 (38.36)<br />

For over<br />

393-774 Cu Core 4 Pins Pins 2000 VA & 50 3/8 (9.5) 3/16 (4.8) 1/4 (6.4) 1/8 (3.2) .125 (3.18) 1.510 (38.36)<br />

up to 300 V<br />

393-798 Cu Core 4 Pins Tabs 50 1.510 (38.36)<br />

1 Models listed are representative models.<br />

2 Terminals are recognized by Underwriters Laboratories File SA3716 -<br />

Per UL Standard 984<br />

3 Maximum Operating Current values were established under laboratory<br />

conditions and serve as guidelines only. Individual applications must be<br />

tested to determine the effect of specific variables. Tests were conducted<br />

using standard gauge wire and high conductivity connectors, rated for their<br />

applications. It is very important to use the proper wire size for a given<br />

compressor operating current. Wire size and connector type greatly influence<br />

the pin temperature, especially in over-current conditions.<br />

4 These terminals are available with nonagon pads (shown at left).<br />

Terminations<br />

Outside Inside<br />

UL Rating<br />

2<br />

Maximum<br />

Operating<br />

Current<br />

Amps 3<br />

Minimum Spacing Inches (mm)<br />

Oversurface Through Air<br />

Outside Inside Outside Inside<br />

Pin Dia.<br />

Inches (mm)<br />

Pin Length<br />

Inches (mm)<br />

393-38 Solid Pins Pins For up to 20 1.062 (26.97)<br />

2000 VA &<br />

393-95 Solid Tabs Pins up to 300 V, 22 1/8 (3.2) 3/32 (2.4) 1/8 (3.2) 1/16 (1.6) .090 (2.29) 1.203 (30.56)<br />

and for over<br />

393-37 Solid Tabs Tabs 2000 VA 25 1.281 (32.54)<br />

& up to<br />

150V<br />

393-677 Cu Core 4 Tabs Pins 50 1.590 (40.39)<br />

For over<br />

393-694 Solid Tabs Pins 2000 VA & 35 1.510 (38.36)<br />

up to 300 V<br />

393-674 Cu Core 4 Tabs Pins 50 3/8 (9.5) 3/16 (4.8) 1/4 (6.4) 1/8 (3.2) .125 (3.18) 1.510 (38.36)<br />

393-698 Cu Core 4 Tabs Tabs 50 1.510 (38.36)<br />

3B3-640 Solid Tabs Pins 35 1.810 (45.97)<br />

3B3-637 Cu Core Tabs Pins 55 1.810 (45.97)<br />

For over<br />

3B3-634T Solid Tabs Tabs 2000 VA 35 1.810 (45.97)<br />

& up to<br />

3B3-619 Cu Core Tabs Tabs 600 V 55 1/2 (12.7) 1/4 (6.4) 3/8 (9.5) 3/16 (4.8) .125 (3.18) 1.810 (45.97)<br />

3B3-635 Cu Core Straps Pins 65 1.700 (43.18)<br />

3B3-620 Cu Core Straps Tabs 60 1.700 (43.18)<br />

3K3-602 Cu Core Double Pins 80 .187 (4.75) 1.820 (46.23)<br />

Straps<br />

For over<br />

3K3-601 Cu Core Double Double 2000 VA 125 1/2 (12.7) 1/4 (6.4) 3/8 (9.5) 3/16 (4.8) .187 (4.75) 1.820 (46.23)<br />

Straps Tabs & up to<br />

600V<br />

3K3H-600 Cu Core Double Double 130 .243 (6.17) 1.820 (46.23)<br />

Straps Tabs<br />

0.062 [1.57]<br />

0.312 [7.92]<br />

0.160 [4.06]<br />

TAB DETAIL STRAP DETAIL<br />

0.656 [16.66]<br />

ø0.065/0.080 [1.65/2.03]<br />

0.344 [8.74]<br />

0.040 [1.02] x 45˚<br />

0.250 [6.35]<br />

0.307 [7.80] MIN.<br />

0.032 [0.81]<br />

0.104 [2.64]<br />

0.218 [5.54]<br />

0.437 [11.10]<br />

0.030 [0.76]

Installation,Operation and Shipping<br />

1. Excessive shocks to the terminal<br />

must be avoided since mechanical<br />

stress can damage the glass and/or<br />

ceramic. Damage may result in hermetic<br />

failure or loss of terminal performance.<br />

2. Precautions are required to prevent<br />

striking or bending of pins. Bent or<br />

damaged pins may result in loss of<br />

hermeticity or terminal performance.<br />

3. Terminals must not be overheated<br />

during brazing or welding operations.<br />

The temperature of the metal adjacent<br />

to the glass must not exceed 400°F.<br />

4. It is important to select the proper<br />

terminal for each application. Considerations<br />

include maximum operating<br />

currents, locked rotor currents,<br />

time and protection circuitry. Since<br />

customer designs vary as to terminal<br />

location, lead size, return line locations<br />

and compressor types, <strong>Fusite</strong><br />

cannot provide specific data on every<br />

compressor configuration. The<br />

attached data tables are general<br />

guidelines only and not specific<br />

application recommendations. For<br />

assistance in terminal selection, contact<br />

<strong>Fusite</strong> Engineering.<br />

Bulletin 962A<br />

Hermetic Terminal Precautions<br />

5. Compressors and systems should<br />

be designed with appropriate electrical<br />

overload and thermal overload protection.<br />

Locked rotor currents often run 5<br />

times as high as operating currents,<br />

and in some cases even higher. If<br />

such high currents are allowed to continue<br />

for any length of time, severe<br />

damage or personal injury may result.<br />

High currents raise the terminal pin<br />

temperatures, which may result in failure<br />

of wire insulation, breakdown of<br />

coolant-oil mixture causing possible<br />

electrical contamination, or softening<br />

of the glass seal resulting in hermetic<br />

failure.<br />

6. Lead size and connector configuration<br />

can effect terminal operating<br />

temperature. Using larger wires<br />

increases the heat sink effect and lowers<br />

pin temperatures. Proper connector<br />

selection also reduces contact<br />

resistance and lowers pin temperatures.<br />

General Instructions<br />

Improper handling or servicing may<br />

cause hermetic terminal failure. The<br />

glass seal of the terminal may be<br />

damaged and allow leakage of oil and<br />

Where Glass Seals Metal<br />

®<br />

FUSITE DIVISION<br />

EMERSON ELECTRIC CO.<br />

6000 FERNVIEW AVENUE<br />

CINCINNATI, OHIO 45212 U.S.A.<br />

Telephone 513-731-2020 • Fax 513-631-6456<br />

International Locations: GOTEMBA, JAPAN •<br />

ALMELO, HOLLAND • BAO’AN, CHINA<br />

refrigerant. If electrical power is<br />

applied under these conditions, a hazardous<br />

condition can be initiated and<br />

may result in serious personal injury<br />

and/or property damage.<br />

To protect against this potential hazard,<br />

personnel should be advised of<br />

these conditions and take the following<br />

precautions:<br />

1. Always refer to compressor manufacturer’s<br />

installation, operating and<br />

service instructions.<br />

2. <strong>Fusite</strong> terminals are not field serviceable<br />

or repairable. Replace compressor<br />

if required.<br />

3. Do not remove the junction box<br />

cover until electrical power to the unit<br />

has been turned off.<br />

4. Do not start the compressor without<br />

the junction box cover properly locked<br />

in place.<br />

To protect further against compressor<br />

failure hazards, consult factory technical<br />

manuals. In addition, consult and<br />

follow all manufacturers’ warning<br />

labels mounted adjacent to the compressor<br />

junction box. Contact <strong>Fusite</strong><br />

for other information regarding<br />

Terminal Precautions.<br />

All sales are subject to <strong>Fusite</strong>’s Terms & Conditions in effect at the time of shipment. A copy will be provided upon request.<br />

Printed in U.S.A.