- Page 1 and 2: Ford Racing Performance Parts 2006

- Page 3 and 4: TABLE OF CONTENTS TIMING POINTERS .

- Page 5 and 6: Ford Racing Performance Parts is pr

- Page 7 and 8: FORD RACING PERFORMANCE PARTS CATAL

- Page 9 and 10: 2005-06 FORD GT Perhaps no performa

- Page 11 and 12: FORD GT PERFORMANCE MUFFLER KIT M-5

- Page 13 and 14: Grand Am Cup Engine Package M-6007-

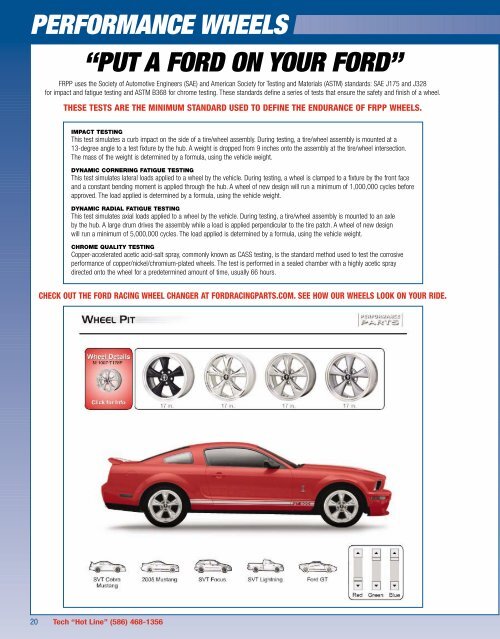

- Page 15 and 16: 2005-06 MUSTANG GT WHEEL M-1007-U18

- Page 17 and 18: DRAG PACK M-2005-FR2* Big block-lik

- Page 19 and 20: 2005-06 MUSTANG V-6 MUFFLER KIT M-5

- Page 21: STREET RODS Street Rod Gauge Sets (

- Page 25 and 26: 10TH ANNIVERSARY MUSTANG COBRA WHEE

- Page 27 and 28: 2000 SILVER MUSTANG COBRA “R” W

- Page 29 and 30: FORD GT FRONT WHEEL M-1007-GTF* •

- Page 31 and 32: FORD RACING HARLEY-DAVIDSON 20" CHR

- Page 33 and 34: 16-SPOKE FOCUS TUNER WHEEL M-1007-P

- Page 35 and 36: CENTER CAPS M-1096-C M-1096-T M-109

- Page 37 and 38: CRATE ENGINES CRATE ENGINE DEVELOPM

- Page 39 and 40: D-UP To ensure accuracy, computeriz

- Page 41 and 42: * After the short block is complete

- Page 43 and 44: 2003 MUSTANG MACH1 4.6L DOHC 4V ENG

- Page 45 and 46: ENGINE BLOCKS ALUMINUM 5.0L ENGINE

- Page 47 and 48: CYLINDER HEAD CHANGING KIT M-6067-D

- Page 49 and 50: COATED DOHC CAM COVERS 4.6/5.4L M-6

- Page 51 and 52: HI-FLOW SHORTY HEADERS These unique

- Page 53 and 54: 5.0L/302 CID SMALL BLOCK 360/390 HP

- Page 55 and 56: COMPLETE HD 5.8L/351-2V FORD RACING

- Page 57 and 58: 5.8L/351 - 392 CID SMALL BLOCK - 43

- Page 59 and 60: 7.5L/460 “SUPER COBRA JET” - 55

- Page 61 and 62: 514 CUBIC INCH “COBRA SPECIAL”

- Page 63 and 64: CORRECTION FACTORS, OBSERVED AND CO

- Page 65 and 66: 347 CID FORD RACING FORGED STROKER

- Page 67 and 68: ALUMINUM 302/351 STREET/RACE BLOCKS

- Page 69 and 70: 460 SIAMESE BORE WET OR DRY SUMP BL

- Page 71 and 72: CYLINDER HEADS GT-40X XTRA PERFORMA

- Page 73 and 74:

HIGH-PORT HEAD FOR ALL-OUT PERFORMA

- Page 75 and 76:

SUPER COBRA JET CYLINDER HEADS M-60

- Page 77 and 78:

351 FORD RACING SINGLE PLANE D3 NAS

- Page 79 and 80:

CONNECTING RODS AND PISTONS 460 CON

- Page 81 and 82:

CHECKING CAMSHAFT TIMING In order t

- Page 83 and 84:

SERPENTINE BELT HORSEPOWER PULLEY K

- Page 85 and 86:

CAMSHAFTS AND LIFTERS SMALL BLOCK V

- Page 87 and 88:

CAMSHAFT SPECIFICATIONS FORD RACING

- Page 89 and 90:

HEADERS THE BEST MUSTANG AND TRUCK

- Page 91 and 92:

EXHAUST SYSTEMS Ford Racing Perform

- Page 93 and 94:

PUSH RODS AND GUIDE PLATES VALVE PU

- Page 95 and 96:

PULLEYS SERPENTINE BELT HORSEPOWER

- Page 97 and 98:

NASCAR RACE WATER PUMP ASSEMBLY M-8

- Page 99 and 100:

ENGINE LUBRICATION PARTS FORD RACIN

- Page 101 and 102:

302 REAR SUMP OIL PAN M-6675-T302

- Page 103 and 104:

OIL PAN KITS OIL PAN CONVERSION KIT

- Page 105 and 106:

INTAKE MANIFOLD GASKETS (SOLD IN PK

- Page 107 and 108:

FASTENERS, PLUGS, DOWELS INTAKE MAN

- Page 109 and 110:

9MM SPARK PLUG WIRE SETS - “FORD

- Page 111 and 112:

DISTRIBUTOR GEAR INSTALLATION The f

- Page 113 and 114:

TURN YOUR MUSTANG INTO A STALLION

- Page 115 and 116:

INLET ADAPTER (1994-95 MUSTANG) M-9

- Page 117 and 118:

HIGH-FLOW RATE FUEL INJECTOR SETS K

- Page 119 and 120:

ENGINE DRESS-UP COMPONENTS CUSTOM V

- Page 121 and 122:

BLACK SATIN VALVE COVERS M-6582-A34

- Page 123 and 124:

Show off your engine compartment wi

- Page 125 and 126:

ENGINE COMPONENTS FORD RACING PERFO

- Page 127 and 128:

SHIFTERS B&M “RIPPER” SHIFTER M

- Page 129 and 130:

TREMEC 5-SPEED EXTRA HD TRANSMISSIO

- Page 131 and 132:

MANUAL TRANSMISSION FLYWHEEL PART N

- Page 133 and 134:

CLUTCHES PART NUMBER DESCRIPTION EN

- Page 135 and 136:

TRANSMISSION COMPONENTS CHROME AUTO

- Page 137 and 138:

HEAVY DUTY LOW STALL TORQUE CONVERT

- Page 139 and 140:

BRAKE BACKING PLATE T-BOLTS M-4002-

- Page 141 and 142:

8.8" RING & PINION INSTALLATION KIT

- Page 143 and 144:

28-TOOTH 8.8" TRACTION-LOK REAR AXL

- Page 145 and 146:

CHASSIS COMPONENTS MUSTANG REAR LOW

- Page 147 and 148:

1979-04 MUSTANG FRONT/REAR SPRING K

- Page 149 and 150:

STRUT TOWER BRACES M-20201-A50 ➀

- Page 151 and 152:

11", 5-LUG FRONT BRAKE ROTOR KIT M-

- Page 153 and 154:

5-LUG REAR BRAKE DRUM/AXLE SHAFT KI

- Page 155 and 156:

2003-04 MUSTANG COBRA PARTS 10TH AN

- Page 157 and 158:

MUSTANG COBRA “R” PARTS 2000 SI

- Page 159 and 160:

COOLING SYSTEMS HIGH TEMPERATURE BL

- Page 161 and 162:

GAUGES AND TACH DRIVER FORD RACING

- Page 163 and 164:

ACCESSORIES MUSTANG GT SPECIAL EDIT

- Page 165 and 166:

FORD RACING UMBRELLA M-77600 FORD R

- Page 167 and 168:

ACCESSORIES AND BOOKS THE OFFICIAL

- Page 169 and 170:

1,000-LB. CAPACITY ENGINE STAND M-6

- Page 171 and 172:

. FUEL LINE DISCONNECT TOOL M-9280-

- Page 173 and 174:

Header M-9430-SVTFC Supercharger M-

- Page 175 and 176:

ZETEC 4-CYLINDER DOHC 2.0L 16V STRE

- Page 177 and 178:

BRAKES FOCUS RS BRAKE AND SUSPENSIO

- Page 179 and 180:

EXHAUST COMPONENTS BORLA FOCUS MUFF

- Page 181 and 182:

SUSPENSION COMPONENTS FOCUS COILOVE

- Page 183 and 184:

ACCESSORIES TACH DRIVER M-17360-A20

- Page 185 and 186:

ACCESSORIES FOCUS SVT PARKING BRAKE

- Page 187 and 188:

FORD RACING FOCUS FLOOR MATS M-1308

- Page 189 and 190:

SVT FOCUS FRONT FASCIA M-17831-F**

- Page 191 and 192:

2.0L ZETEC ENGINE REBUILDER PARTS M

- Page 193 and 194:

HIGH-SPEED HAULERS A MESSAGE FROM T

- Page 195 and 196:

FORD RACING PERFORMANCE CRATE ENGIN

- Page 197 and 198:

EFI MASS AIR CONVERSION KIT M-9000-

- Page 199 and 200:

COOLING SYSTEMS 2004 TO PRESENT F-1

- Page 201 and 202:

ALUMINUM TRANSMISSION PAN M-7195-C6

- Page 203 and 204:

HEAVY DUTY LOW STALL TORQUE CONVERT

- Page 205 and 206:

HANDLING F-150 QUAD SHOCK BRACKETS

- Page 207 and 208:

LOWERING KIT, 2001-05 ESCAPE M-3000

- Page 209 and 210:

CHROME AUTOMATIC TRANSMISSION OIL P

- Page 211 and 212:

F-150 LIGHTNING HEADLIGHTS M-13006-

- Page 213 and 214:

HARLEY-DAVIDSON STRIPE KIT DARK RED

- Page 215 and 216:

FORD RACING MTX THUNDERFORMS AUDIO

- Page 217 and 218:

Monster Truck Traction Bars Suspens

- Page 219 and 220:

ENGINE DIMENSIONS BASIC ENGINE DIME

- Page 221 and 222:

289/302/351W/351C/351M/400 SIX WAYS

- Page 223 and 224:

BIG BLOCK V-8 ENGINES * 429/429CJ/4

- Page 225 and 226:

VALVE TRAIN When modifying producti

- Page 227 and 228:

VALVE SPRINGS AND THINGS Valve spri

- Page 229 and 230:

DEALER LIST CODES: LS = LOCAL SALES

- Page 231 and 232:

ROUSH INDUSTRIES LIVONIA, MI 48150

- Page 233 and 234:

SUGGESTED RETAIL PRICE LIST PARTS S

- Page 235 and 236:

Pg. Sugg. Part Number Description N

- Page 237 and 238:

Pg. Sugg. Part Number Description N

- Page 239 and 240:

Pg. Sugg. Part Number Description N

- Page 241 and 242:

Pg. Sugg. Part Number Description N

- Page 243 and 244:

GENERAL INFORMATION AND TECHNICAL A