w orkplace safety & fire equipmen t - ShipServ

w orkplace safety & fire equipmen t - ShipServ

w orkplace safety & fire equipmen t - ShipServ

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

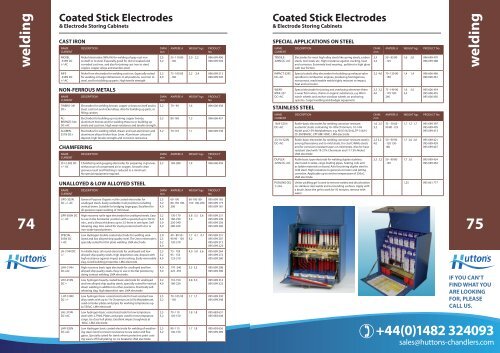

welding<br />

Coated Stick Electrodes<br />

& Electrode Storing Cabinets<br />

CAST IRON<br />

NAME<br />

CURRENT<br />

NICKEL<br />

-333N DC<br />

+/-AC<br />

NIFE<br />

-334N DC<br />

+/-AC<br />

DESCRIPTION DIAM<br />

mm<br />

Nickel electrodes (98% Ni) for welding of gray cast iron<br />

to itself or to steel. Especially good for old oil soaked and<br />

corroded cast iron, and also for joining cast iron to steel,<br />

copper, copper alloys and stainless steel<br />

Nickel-Iron electrodes for welding cast iron. Especially suited<br />

for welding on larger dimensions in all positions, cast iron to<br />

steel, and for building up parts. High tensile strength<br />

NON-FERROUS METALS<br />

NAME<br />

CURRENT<br />

TINBRO-341<br />

DC+<br />

AL-<br />

BRONZE-344<br />

DC+AC<br />

ALUMIN-<br />

351N DC+<br />

CHAMFERING<br />

NAME<br />

CURRENT<br />

CH-2-382 DC<br />

+/- AC<br />

2,5<br />

3,2<br />

3,2<br />

4,0<br />

DESCRIPTION DIAM<br />

mm<br />

Electrodes for welding bronze, copper or brass to itself and to<br />

steel, cast iron and nickel alloys. Also for building up parts, or<br />

filling cavities<br />

Electrodes for building up or joining copper bronze,<br />

aluminium bronze and for welding these to or building up<br />

steels and cast iron. High wear resistance and tensile strength.<br />

Electrodes for welding rolled, drawn and cast aluminium and<br />

aluminium alloys thicker than 2mm. Aluminium coloured<br />

deposit, high tensile strength and corrosion resistance.<br />

DESCRIPTION DIAM<br />

mm<br />

Chamfering and gouging electrodes for preparing U-grooves<br />

without use of compressed air or oxygen. Smooth clean<br />

grooves result and finishing is reduced to a minimum.<br />

No special <strong>equipmen</strong>t required.<br />

UNALLOYED & LOW ALLOYED STEEL<br />

NAME<br />

CURRENT<br />

GPO-302N<br />

DC +/- AC<br />

GPR-300H DC<br />

+/- AC<br />

AMPERE A WEIGHT kgs PRODUCT<br />

No<br />

55 -110 80<br />

-140<br />

75 -100 85<br />

-160<br />

2,0 2,2 096 699 496<br />

096 699 504<br />

2,2 2,4 096 699 512<br />

096 699 520<br />

AMPERE A WEIGHT kgs PRODUCT<br />

No<br />

3,2 70 - 90 1,4 096 606 458<br />

3,2 80-160 1,3 096 606 457<br />

3,2 70-110 1,1 096 699 538<br />

AMPERE A WEIGHT kgs PRODUCT<br />

No<br />

3,2 160-280 1,4 096 606 459<br />

Coated Stick Electrodes<br />

& Electrode Storing Cabinets<br />

74 75<br />

SPECIAL-<br />

303N DC<br />

+ AC<br />

LH-314N DC<br />

+/-<br />

LHH-314H<br />

DC+AC<br />

LHV-316N<br />

DC +<br />

LHT-318N<br />

DC +/-<br />

LHL-319N<br />

DC+AC<br />

LHR-320N<br />

DC+AC<br />

DESCRIPTION DIAM<br />

mm<br />

General Purpose Organic-rutile coated electrodes for<br />

unalloyed steels. Easily weldable in all positions including<br />

vertical down. Sutiable for bridging large gaps. Excellent for<br />

all-purpose repair welding of mild steel.<br />

High recovery rutile type electrodes for unalloyed steels. Easy<br />

to use in the horizontal position with a speed of up to 50cm/<br />

min., and a throat thickness up to 3.5-6mm in one layer. Self<br />

releasing slag. Also suited for steels protected with zinc or<br />

iron-oxide based primers.<br />

Low Hydrogen double coated electrode for welding unalloyed<br />

and low alloyed ship quality steel. The 2mm electrode is<br />

specially suited for thin plate welding. LMA electrode<br />

A reliable basic all round electrode for unalloyed and low<br />

alloyed ship quality steels, high deposition rate, deposit with<br />

high resistance against impact and cracking. Easily removable<br />

slag, Good building properties. LMA electrode<br />

High recovery basic type electrode for unalloyed and low<br />

alloyed ship quality steels. Easy to use in the flat position by<br />

doing contact welding, LMA electrode.<br />

Low hydrogen heavily coated basic electrode for unalloyed<br />

and low alloyed ship quality steels, specially suited for vertical<br />

down welding in addition to other positions. Practically selfreleasing<br />

slag, high deposition rate. LMA electrode<br />

Low hydrogen basic coated electrode for heat resistant low<br />

alloy steels with up to 1% Chromium an 0.5% Molybdenum,<br />

used on boiler plates and pipes for working tempratures up<br />

to 550oC. LMA electrode<br />

Low hydrogen basic coated electrode for low temprature<br />

steel with 2,7%Ni. Plates and pipes used for low temprature<br />

cargo. Ice class hull plates. Excellent impact toughness at<br />

-80oC. LMA electrode.<br />

Low Hydrogen basic coated electrode for welding of weathering<br />

steel. Good corrosion resistance to sea water and flue<br />

gases. Specially suited for steels where protective paint coating<br />

wears off (hull plating on ice breakers) LMA electrode.<br />

2,5<br />

3,2<br />

4,0<br />

3,2<br />

4,0<br />

5,0<br />

6,0<br />

2,0<br />

2,5<br />

3,2<br />

4,0<br />

2,5<br />

3,2<br />

4,0<br />

4,0<br />

5,0<br />

3,2<br />

4,0<br />

2,5<br />

3,2<br />

2,5<br />

3,2<br />

2,5<br />

3,2<br />

AMPERE A WEIGHT kgs PRODUCT<br />

No<br />

60-100<br />

80-150 100-<br />

200<br />

130-170<br />

180-230<br />

250-340<br />

280-430<br />

40 - 80 50 -<br />

90 90 - 150<br />

120-210<br />

75 - 105<br />

95 - 155<br />

125-210<br />

170 -240<br />

225 -355<br />

110-150<br />

180-220<br />

70 -105 95<br />

-150<br />

70 -110<br />

105-150<br />

80 -115<br />

100-150<br />

60-100 80-<br />

150 100-200<br />

5,8 5,5 5,6<br />

5,3<br />

1,7 4,1 4,1<br />

5,2<br />

095 699 165<br />

095 699 173<br />

095 699 181<br />

095 699 231<br />

095 699 249<br />

095 699 256<br />

095 699 260<br />

095 699 231<br />

095 699 207<br />

095 699 215<br />

095 699 223<br />

4,0 5,0 5,6 095 699 264<br />

095 699 272<br />

095 699 280<br />

5,5 5,5 095 699 298<br />

095 699 306<br />

4,8 5,0 095 699 314<br />

095 699 322<br />

1,7 1,7 095 699 330<br />

095 699 348<br />

1,8 1,8 095 683 631<br />

095 683 649<br />

1,7 1,8 095 693 656<br />

095 699 389<br />

SPECIAL APPLICATIONS ON STEEL<br />

NAME<br />

CURRENT<br />

TENSILE-<br />

328N DC+AC<br />

IMPACT-329S<br />

DC+AC<br />

WEAR-<br />

MAX-327<br />

DC+AC<br />

STAINLESS STEEL<br />

NAME<br />

CURRENT<br />

18/8-321N<br />

DC+AC<br />

23/14-322N<br />

DC+AC<br />

DUPLEX-<br />

325N DC+AC<br />

PICKLING GEL<br />

1 Litre<br />

DESCRIPTION DIAM<br />

mm<br />

Electrodes for most high-alloy steels like spring-steels, carbon<br />

steels, tool steels etc. High resistance against cracking, heat<br />

and corrosion. Extremely hard wearing , polishes to high gloss<br />

with low friction.<br />

Special cobolt alloy electrodes for building up exhaust valve<br />

spindles in combustion engines, producing homogenous,<br />

non-porous, machineable welds highly resistant to impact,<br />

heat and corrosion.<br />

Special electrode for joining and overlaying whenever there<br />

is wear from wires, chains or organic substances, e.g. Worn<br />

winch wheels and anchor windlass wheels on anchoring<br />

systems. Cargo handling and dredger <strong>equipmen</strong>t.<br />

2,5<br />

3,2<br />

AMPERE A WEIGHT kgs PRODUCT No<br />

50 - 85 80<br />

-125<br />

3,2 4,0 70 -120 90<br />

-150<br />

2,5 3,2<br />

4,0<br />

DESCRIPTION DIAM<br />

mm<br />

Rutile-basic electrodes for welding corrosion-resistant<br />

austenitic steels containing 16-18% Chromium, 10-14%<br />

Nickel and 2-3% Molybdenum, e.g. AISI:316/316L,TP-316/H,<br />

CF-3M/8M/8C, CPF 8M/10MC. LMA electrode<br />

Rutile-basic electrodes for welding corrosion-resistant steel is<br />

among themselves and to mild steels, for clad CrNiMo steels<br />

and for corrosion-resistant layers on mild steels. Also for heat<br />

resistant steel with 19-21% Chromium and 11-13% Nickel.<br />

LMA electrode<br />

Rutile basic type electrode for welding duplex stainless<br />

steel used in tanks, cargo loading pipes, heating coils and<br />

as ladder materials on board. Aslo for joining duplex steel to<br />

mild steel. High resistance to general corrosion and pitting<br />

corrosion. Applicable up to service temperature of 250oC.<br />

LMA electrode.<br />

Unitor pickling gel is used to remove oxides and discoloration<br />

on stainless steel welds and surrounding surfaces. Apply with<br />

a brush, leave the gel to work for 50 minutes, remove with<br />

water<br />

1,6 2,5<br />

3,2<br />

2,5 3,2<br />

4,0<br />

75 -140 90<br />

-170 120-<br />

240<br />

1,6 2,0 096 699 470<br />

096 699 488<br />

1,4 1,4 096 606 460<br />

096 606 461<br />

1,6 3,5<br />

3,4<br />

095 606 454<br />

095 606 455<br />

095 606 456<br />

AMPERE A WEIGHT kgs PRODUCT No<br />

35 - 50 60 -<br />

90 80 -125<br />

50 - 90 90<br />

-120 130-<br />

180<br />

2,5 3,2 50 - 90 80<br />

-120<br />

1,7 1,7 1,7 095 699 397<br />

095 699 405<br />

095 699 413<br />

1,7 2,0 2,0 095 669 421<br />

095 699 439<br />

095 699 447<br />

1,7 2,0 095 699 454<br />

095 699 462<br />

1,25 095 661 777<br />

welding<br />

IF YOU CAN’T<br />

FIND WHAT YOU<br />

ARE LOOKING<br />

FOR, PLEASE<br />

CALL US.