Controls and Flow Meters - Chemline Plastics Limited

Controls and Flow Meters - Chemline Plastics Limited

Controls and Flow Meters - Chemline Plastics Limited

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

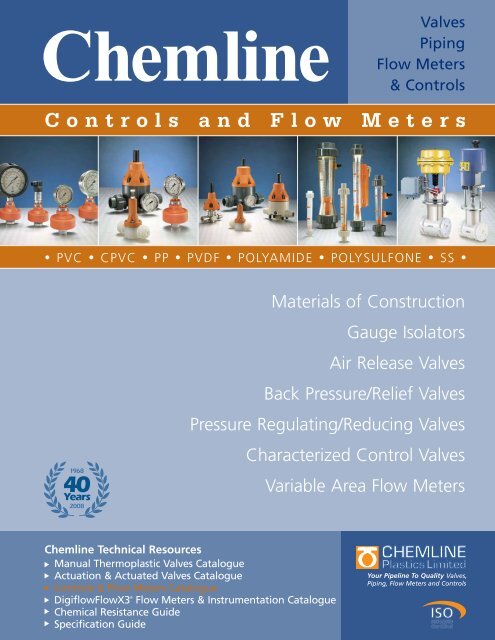

<strong>Chemline</strong><br />

Valves<br />

Piping<br />

<strong>Flow</strong> <strong>Meters</strong><br />

& <strong>Controls</strong><br />

<strong>Controls</strong> <strong>and</strong> <strong>Flow</strong> <strong>Meters</strong><br />

PVC CPVC PP PVDF POLYAMIDE POLYSULFONE SS<br />

Materials of Construction<br />

Gauge Isolators<br />

Air Release Valves<br />

Back Pressure/Relief Valves<br />

Pressure Regulating/Reducing Valves<br />

<strong>Chemline</strong> Technical Resources<br />

Manual Thermoplastic Valves Catalogue<br />

Actuation & Actuated Valves Catalogue<br />

<strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> Catalogue<br />

Digiflow<strong>Flow</strong>X3 ®<br />

<strong>Flow</strong> <strong>Meters</strong> & Instrumentation Catalogue<br />

Chemical Resistance Guide<br />

Specification Guide<br />

▼<br />

▼<br />

▼<br />

▼<br />

▼<br />

▼<br />

Characterized Control Valves<br />

Variable Area <strong>Flow</strong> <strong>Meters</strong><br />

Your Pipeline To Quality Valves,<br />

Piping, <strong>Flow</strong> <strong>Meters</strong> <strong>and</strong> <strong>Controls</strong>

New<br />

New<br />

New<br />

New<br />

<strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> Page<br />

Gauge Isolators 4-5<br />

Air Release Valves<br />

AR Series Air Release Valves 6-7<br />

AA Series Air & Vacuum Release Valves 8-9<br />

Back Pressure/Relief Valves<br />

SB17 Mini Back Pressure/Relief Valves 10-11<br />

SB10/11 Back Pressure/Relief Valves 12-15<br />

SB12 Back Pressure/Relief Valves 16-19<br />

SR50 Pressure Regulating/Reducing Valves 20-23<br />

ChemFlare TM End Connectors 24-25<br />

Characterized Control Valves 26-28<br />

EK Series Pneumatically Actuated 29-30<br />

EE Series Electrically Actuated 31-32<br />

Variable Area <strong>Flow</strong> <strong>Meters</strong> 33-36<br />

2 <strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08<br />

Gauge Isolators<br />

AR Series Air Release Valves<br />

AA Series Air&Vacuum Release Valves SB17 Mini Back Pressure/Relief Valves<br />

SB/SR50 Series Sizes: 3/8" to 2" SB/SR50 Series Sizes: 2-1/2" to 4"<br />

ChemFlare TM End Connectors EK Series Characterized Control<br />

EE Series Characterized Control Variable Area <strong>Flow</strong> <strong>Meters</strong><br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008

Materials of Construction<br />

Thermoplastics<br />

PVC (Polyvinyl Chloride)<br />

The most economical <strong>and</strong> largest selection of <strong>Chemline</strong><br />

valves are moulded from PVC. It offers excellent mechanical<br />

<strong>and</strong> chemical resistance properties at low cost. The working<br />

temperature range of PVC valves is 0 to 60°C (30 to 140°F).<br />

PVC used for <strong>Chemline</strong> valves is identified by cell classification<br />

number 11564-A as per ASTM St<strong>and</strong>ard D 1784. The suffix<br />

“A” refers to the highest chemical resistance rating. Most<br />

other PVC valves as well as pipe <strong>and</strong> fittings have only a “B”<br />

chemical resistance rating.<br />

The special PVC “A” compound used in <strong>Chemline</strong> valves<br />

resists attack of most acids, strong alkalais, salts <strong>and</strong> many<br />

other chemicals. High chemical resistance of this material<br />

allows its application on aggressive services such as 98%<br />

H2 SO4 , dry chlorine <strong>and</strong> low pressure wet chlorine gas. PVC<br />

is attacked by chlorinated hydrocarbons, ketones, esters <strong>and</strong><br />

some aromatic compounds. It can be used on solutions<br />

containing up to 1000 ppm solvents.<br />

<strong>Chemline</strong> PVC valves are non-toxic. They meet CSA st<strong>and</strong>ard<br />

B137.0 for toxicity.<br />

They are resistant to damaging effects of sunlight <strong>and</strong><br />

weathering, thus painting is not necessary.<br />

CPVC (Chlorinated Polyvinyl Chloride)<br />

CPVC is very similar to PVC in mechanical properties <strong>and</strong><br />

chemical resistance. It is suitable for applications from<br />

0 to 95°C (30 to 200°F).<br />

The special CPVC compound used for <strong>Chemline</strong> valves is<br />

classified as 23567-A as per ASTM D 1784. The suffix “A”<br />

denotes conformance to the highest chemical resistance<br />

rating. The compound is non-toxic, conforming to CSA<br />

toxicity st<strong>and</strong>ard B137.0.<br />

CPVC valves have proven to be an excellent choice for<br />

applications at temperatures too high for PVC or when an<br />

extra margin of safety is required.<br />

PP (Polypropylene)<br />

PP is light weight <strong>and</strong> high in chemical resistance. Valves are<br />

suitable for service from –20 to 90°C (–5° to 195°F). PP is<br />

unaffected by alkalais, salts, organic solvents <strong>and</strong> most acids,<br />

particularly hydrochloric <strong>and</strong> phosphoric acid. It is unsuitable<br />

on strong acids, chlorinated hydrocarbons, aromatic<br />

compounds <strong>and</strong> high concentrations of free chlorine.<br />

PP is very inert thus popular for high purity applications such<br />

as deionized water, etc. The material comes normally<br />

opaqued by addition of grey-beige pigment to prevent<br />

ultraviolet light penetration. Natural translucent material<br />

without pigment will degrade if exposed to UV light (sun<br />

light). <strong>Chemline</strong> offers PP pipe, fittings <strong>and</strong> valves in<br />

pigmented <strong>and</strong> unpigmented PP, both approved by the FDA<br />

for contact with food.<br />

PVDF (Polyvinylidene Fluoride)<br />

PVDF is superior to other valve thermoplastics in chemical<br />

resistance <strong>and</strong> abrasion resistance. It has remarkable strength<br />

over the largest working temperature range. The working<br />

temperature range of PVDF valves is –40 to 120°C (–40 to<br />

250°F).<br />

PVDF’s impact strength is over twice that of PVC. The valves<br />

are extremely durable under mechanical abuse even at –40°F.<br />

They also offer the highest abrasion resistance of<br />

thermoplastic valves.<br />

PVDF has excellent chemical resistance against halogens such<br />

as chlorine <strong>and</strong> bromine, strong acids such as hydrofluoric<br />

<strong>and</strong> nitric acids, organic solvents <strong>and</strong> oils. PVDF is not<br />

resistant to hot bases.<br />

It is also non toxic <strong>and</strong> imparts no odours or tastes into the<br />

fluid. Our PVDF conforms with USDA Title 21, P121.2593<br />

requirements for contact with food.<br />

Gas permeability of PVDF is extremely low. A patented PVDF<br />

gas permeability barrier is available on Type 14 <strong>and</strong> DV Series<br />

Diaphragm Valves. It is a backing to the Teflon ® diaphragm<br />

<strong>and</strong> has proven to increase the life of diaphragm valves on<br />

chlorine <strong>and</strong> strong acid services.<br />

Teflon ® PTFE (Polytetrafluoroethylene)<br />

PTFE is almost totally insoluble <strong>and</strong> chemically inert. It has<br />

high temperature resistance. Teflon ® PTFE ball seats, because<br />

of natural lubricity, require no lubrication. Teflon ® PTFE<br />

diaphragms <strong>and</strong> flange gaskets are used in the most severe<br />

chemical resistance applications.<br />

Elastomers<br />

EPDM (Ethylene Propylene Terpolymer)<br />

EPDM is a synthetic rubber used as the st<strong>and</strong>ard seal material<br />

for most <strong>Chemline</strong> valves. It is the most economical choice of<br />

elastomer <strong>and</strong> has excellent chemical resistance on the great<br />

majority of applications including acids, alkalais, salts <strong>and</strong><br />

many others at temperatures up to 90°C. EPDM is weak on<br />

organic compounds <strong>and</strong> cannot be used on oils <strong>and</strong> fats.<br />

<strong>Chemline</strong> valves seals of EPDM meet CSA st<strong>and</strong>ard B137.0 for<br />

non-toxicity.<br />

FKM or FPM (“Viton ® “ Fluorocarbon Rubber)<br />

FKM/FPM is more expensive than EPDM so is used as an<br />

alternate elastomer when required. It has excellent resistance<br />

to mineral acids, oils <strong>and</strong> many aliphatic <strong>and</strong> aromatic<br />

hydrocarbons. FKM/FPM (Viton ®) is weak on sodium<br />

hydroxide.<br />

FKM-C is a special formulation with higher resistance to<br />

chlorine services.<br />

FKM-F offers better chemical resistance on inorganic acids<br />

than st<strong>and</strong>ard FKM. Ratings are included for hydrochloric,<br />

nitric <strong>and</strong> sulphuric acids.<br />

CPE (Chlorinated Polyethylene)<br />

CPE is superior to all other elastomers on sodium<br />

hypochlorite. It resists hypochlorite up to full strength (13%).<br />

Ball valves supplied with CPE seals are very price competitive<br />

on this service.<br />

NITRILE (Acrylonitrile-Butadiene Copolymer, abv. NBR)<br />

Nitrile is also know as Buna-N. It has high chemical resistance to<br />

oil <strong>and</strong> petroleums but is weak on oxidizing media i.e. acids.<br />

Nitrile has excellent abrasion resistance <strong>and</strong> is less expensive<br />

than FKM/FPM (Viton ®).<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008 <strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08 3

Gauge Isolators<br />

<strong>Chemline</strong> SG Series Gauge Isolators allow inexpensive<br />

pressure gauges, or any other pressure instrument to be<br />

used in corrosive services. The upper chamber (gauge<br />

side) is filled with a stable fluid such as glycol or<br />

glycerine‡. A diaphragm separates it from the lower<br />

chamber which receives the media under pressure.<br />

The 1/2" gauge connection allows use of the popular 4"<br />

<strong>and</strong> 4-1/2" diameter gauges. Pressure switches or<br />

transmitters may also be installed. Customers can easily<br />

fill isolators <strong>and</strong> install their own gauges.<br />

Isolate Pressure Instruments<br />

from Corrosive Media<br />

Teflon ® Diaphragm<br />

Features<br />

Easy to Mount Gauges<br />

● It is easy to fill an isolator <strong>and</strong> field mount a gauge.<br />

No special equipment is required.<br />

● Will accept popular 4" <strong>and</strong> 4-1/2" diameter gauges<br />

Provision for Fill Port<br />

● Housing may be drilled <strong>and</strong> tapped by <strong>Chemline</strong> or<br />

customer for a threaded fill port. This is used for<br />

filling isolator using a vacuum filling station<br />

High Chemical Resistance<br />

● Choice of body materials for a wide range of<br />

applications<br />

● Teflon ® PTFE bonded EPDM dished diaphragm for<br />

high chemical resistance <strong>and</strong> sensitivity<br />

Heavy Duty Design for Safety<br />

● PPG* top chamber<br />

● Heavy wall connection ports<br />

A<br />

B<br />

A With 2" gauge<br />

B With 4-1/2" gauge<br />

C With 2" back mount gauge<br />

D With pressure transmitter<br />

† Other available inlet connections are 1/2" socket or 1/2" to 1" flanged.<br />

‡ Other fluids are available for special applications such as chlorine service.<br />

* Glass reinforced polypropylene.<br />

4 <strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08<br />

C<br />

D<br />

Your Pipeline To Quality<br />

Optional Gauge Isolators are<br />

available alone or with gauge<br />

mounted <strong>and</strong> prefilled with glycol‡<br />

Stainless Steel<br />

B<strong>and</strong>s Prevent<br />

FNPT ports from<br />

splitting<br />

Provision<br />

for Fill Port<br />

PVC, PP, PVDF<br />

SERIES: SG<br />

INLET<br />

CONNECTION: 1/4" or 1/2" Threaded†<br />

INSTRUMENT<br />

CONNECTION: 1/4" or 1/2" Threaded<br />

DIAPHRAGM: Teflon ®<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008

Gauge Isolators<br />

C<br />

3.38"<br />

WORKING PRESSURES PSI<br />

Material<br />

10 – 20°C<br />

50 – 68°F<br />

30°C<br />

86°F<br />

D<br />

3.15" Dia.<br />

ORDERING EXAMPLE<br />

<strong>Chemline</strong> Gauge Isolators SG<br />

40°C<br />

104°F<br />

50°C<br />

122°F<br />

Body Material A – PVC B – PP K – PVDF<br />

Inlet Size 002 – 1/4" 005 – 1/2"(St<strong>and</strong>ard)<br />

Instrument Connection 002 – 1/4" 005 – 1/2"<br />

Diaphragm P – Teflon ® PTFE bonded EPDM<br />

6<br />

5<br />

4<br />

3<br />

1<br />

2<br />

5<br />

60°C<br />

140°F<br />

OPTIONAL GAUGES<br />

● <strong>Chemline</strong> offers the gauges listed below mounted to<br />

isolator <strong>and</strong> prefilled with glycol, glycerine or special<br />

fluid for chlorine applications. These gauges have<br />

dials <strong>and</strong> cases filled with either glycol (st<strong>and</strong>ard),<br />

glycerine or silicon for corrosion resistance <strong>and</strong><br />

dampening.<br />

OTHER OPTIONS<br />

● Flanged inlet connections<br />

Example: <strong>Chemline</strong> SG Series Gauge Isolator, PVC, 1/2" x 1/4" FNPT inlet x instrument connections, Teflon ® .<br />

● Threaded Fill Port – drilled, tapped <strong>and</strong> plugged<br />

● <strong>Chemline</strong> will mount any pressure instrument supplied<br />

free issue by customer<br />

DIMENSIONS INCHES<br />

Gauge<br />

Connection Housing<br />

1/4" 316 SS<br />

1/4" 316 SS<br />

1/4" 316 SS<br />

1/4" 316 SS<br />

1/2" 316 SS<br />

1/2" PBTP Plastic 1<br />

Gauge<br />

Bourdon<br />

Dimensions<br />

Diameter<br />

Item No.<br />

Tube Window Accuracy C D(max.)<br />

2-1/2"<br />

P025-xx<br />

Brass Polycarbonate ±1.5% of span 3.1 2.5<br />

2-1/2"<br />

P025-xx-SS<br />

316 SS Polycarbonate ±1.5% of span 3.1 2.5<br />

2-1/2" Back Mount P025-xx-SS/BM<br />

316 SS Polycarbonate ±1.5% of span 1.6 2.5<br />

2-1/2" Back Mount P025-xx-BM<br />

Brass Polycarbonate ±1.5% of span 1.6 2.5<br />

4"<br />

P040-xx-SS<br />

316 SS Safety Glass ±1% of span 4.5 4.0<br />

4-1/2"<br />

P045-xx-SS<br />

316 SS Acrylic ±0.5% of span 6.3 5.8<br />

xx denotes the maximum gauge pressure i.e., 30, 60, 100, 160 or 200 psi. See data page for recommended working pressures.<br />

1 PBTP = glass filled polyester.<br />

PVC 150 100 80 45 15 – – – – –<br />

PP 150 125 100 80 65 45 – – – –<br />

PVDF 150 150 150 125 105 85 70 60 45 30<br />

Temperature Ranges: PVC –10 to 60°C (14 to 140°F), PP: 8 to 80°C (46 to 176°F), PVDF: –30 to 120°C (–22 to 248°F).<br />

NR = Not Recommended. * Weights are for unfilled 1/2" x 1/2" isolators without gauges. 1/2" x 1/4" isolators are 20% lighter.<br />

WEIGHTS<br />

A 005- 002 P G<br />

Filling & Mounting G –Add only if isolator is supplied filled with glycol <strong>and</strong> gauge or pressure instrument<br />

is mounted by <strong>Chemline</strong>. Separate gauge item numbers are listed above.<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008 <strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08 5<br />

70°C<br />

158°F<br />

PARTS ▲ Recommended Spare Parts<br />

No. Part Pcs. Materials<br />

1 Body 1 PVC, PP, PVDF<br />

2▲ Diaphragm 1 Teflon ® PTFE<br />

3 Bonnet 1 PPG<br />

4 Gasket 1 EPDM<br />

5 Stainless Steel B<strong>and</strong>s 2 304 SS<br />

6 Optional Gauge 1 See below<br />

PPG = Glass reinforced polypropylene<br />

80°C<br />

176°F<br />

90°C<br />

194°F<br />

100°C<br />

212°F<br />

120°C<br />

248°F<br />

Net Weights<br />

Pounds*<br />

1.0<br />

0.7<br />

1.3

AR Series<br />

Air Release<br />

Valves<br />

The <strong>Chemline</strong> AR Series Air Release Valve allow gases<br />

to escape from unpressurized pipe lines. It must be<br />

installed vertically at the highest point in the piping<br />

system with the “Air” arrow up. As the unpressurized<br />

air vents, liquid rises to the float (an inverted cup),<br />

which lifts the float up against the seat, holding liquid<br />

pressure. The float will not release until the pressure on<br />

the inlet side of the valve is equal to the outlet pressure<br />

of the valve (normally atmospheric).<br />

Low Cost<br />

Sizes up to 3"<br />

Features<br />

Full Size Range<br />

● 1/2" to 3"<br />

Large <strong>Flow</strong> Capacities<br />

● Valves have full port liquid capacities, so for air flow<br />

they may be chosen several sizes smaller than the<br />

liquid pipeline.<br />

Outlet Cap Available<br />

● For non-hazardous fluids, the optional removeable PE<br />

outlet cap prevents tampering with the union nut.<br />

Eliminates possible splashing during quick closure <strong>and</strong><br />

covers the open end.<br />

● For hazardous fluids, a 3 foot pipe should be installed<br />

on the outlet side or the outlet should be piped to a<br />

containment area.<br />

With Outlet Cap<br />

6 <strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08<br />

Your Pipeline To Quality<br />

PVC<br />

SERIES: AR<br />

SIZES: 1/2" – 3"<br />

ENDS: Socket, Threaded or Flanged<br />

SEALS: EPDM, FKM (Viton ®<br />

)<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008

AR Series Air Release Valves<br />

L S<br />

12<br />

7<br />

11<br />

5<br />

1<br />

lS<br />

5<br />

1<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008<br />

D<br />

Without Outlet Cap<br />

With Outlet Cap<br />

Valves shown in closed position<br />

1<br />

D2<br />

D1<br />

4<br />

9<br />

6<br />

3<br />

10<br />

2<br />

9<br />

6<br />

3<br />

10<br />

2<br />

A<br />

L F<br />

PARTS ▲ Recommended Spare Parts<br />

No. Part Pcs. Materials<br />

1 Body 1 PVC<br />

2 Float 1 PVC<br />

3▲ Seat O-Ring 1 EPDM, FKM (Viton ®)<br />

4 End Connector 1 PVC<br />

5 Union Nut 1 PVC<br />

6 Seat Carrier 1 PVC<br />

7 Foot Valve Screen 1 PP<br />

9▲ Face O-Ring 1 EPDM, FKM (Viton ®)<br />

10▲ Carrier O-Ring 1 EPDM, FKM (Viton ®)<br />

11 Outlet Cap 1 PE<br />

12 Countersunk Bolt 1 304 SS<br />

WORKING PRESSURES PSI<br />

Size<br />

1/2" – 2"<br />

2-1/2" – 3"<br />

20ºC<br />

68ºF<br />

150<br />

150<br />

30ºC<br />

94ºF<br />

150<br />

120<br />

40ºC<br />

105ºF<br />

150<br />

90<br />

Maximum Temperature: 60 o C (140 o F).<br />

ORDERING EXAMPLE<br />

<strong>Chemline</strong> Air<br />

Release Valves<br />

Body Material A –PVC<br />

DIMENSIONS INCHES WEIGHTS LB.<br />

Socket Threaded<br />

Without<br />

Size A D1 D2 LS LF lS LT LF lT Cap<br />

1/2" 3.27 2.0 2.48 3.54 4.88 0.89 3.03 4.61 0.63 0.17<br />

3/4" 3.58 2.3 2.95 3.98 5.43 1.00 3.46 5.43 0.75 0.26<br />

1" 4.21 2.7 3.54 4.38 6.10 1.13 3.86 6.10 0.87 0.39<br />

1-1/4" 4.88 3.2 4.33 5.04 6.85 1.26 4.41 6.77 0.94 0.57<br />

1-1/2" 5.37 3.7 4.92 5.67 7.99 1.38 4.80 7.60 0.94 0.88<br />

2" 5.67 4.5 5.51 6.51 9.06 1.50 5.71 8.66 1.10 1.54<br />

2-1/2" 7.15 6.6 7.87 7.72 12.40 1.75 6.81 11.89 1.30 4.96<br />

3" 7.15 6.6 7.87 9.13 11.69 2.00 7.95 11.10 1.42 4.41<br />

50ºC<br />

120ºF<br />

90<br />

45<br />

60ºC<br />

140ºF<br />

35<br />

15<br />

AR A 020 E S<br />

Size 005 –1/2" 007 –3/4"<br />

010 –1" 012 – 1-1/4"<br />

015 – 1-1/2" 020 –2"<br />

025 – 2-1/2" 030 –3"<br />

Seals E – EPDM V – FKM (Viton<br />

Example: <strong>Chemline</strong> Type AR Air Release Valve, PVC, 2", with<br />

EPDM seals, socket ends.<br />

®)<br />

Ends S – Socket T – Threaded F – Flanged<br />

With<br />

Cap<br />

0.34<br />

0.51<br />

0.81<br />

1.35<br />

1.85<br />

2.85<br />

8.33<br />

7.78<br />

<strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08 7

AA Series<br />

Air & Vacuum<br />

Release Valves<br />

The <strong>Chemline</strong> AA Series Air <strong>and</strong> Vacuum Release Valve<br />

provides a controlled venting solution for larger<br />

diameter piping systems. This valve reduces the<br />

potential for water hammer incidents that occur when<br />

pressure builds up due to entrapped air. A unique twostage<br />

ball stop prevents liquids from escaping while<br />

allowing high volume air release while the pipeline is<br />

under pressure, also at low pressure when it is being<br />

filled.<br />

The vacuum release function allows air to re-enter the<br />

pipeline to prevent vacuum collapse.<br />

PDCPD (Polydicyclopenthadiene) is a polyolefin<br />

thermoset plastic. Valve parts are manufactured by a<br />

process called reaction injection moulding (RIM).<br />

PDCPD has excellent corrosion resistance <strong>and</strong><br />

temperature ratings, very similar to those of<br />

polypropylene. It is durable material offering very high<br />

impact strength <strong>and</strong> a fraction of the weight of cast<br />

iron.<br />

Light Weight<br />

Durable<br />

Features<br />

High Impact Strength<br />

Superior Exhaust Performance<br />

● High discharge capacities<br />

● Two-stage (high/low) exhaust function<br />

Works at Low Pressures<br />

● Half the minimum pressure compared to cast iron<br />

Wide Operating Temperature Range<br />

● –40 o C (–40 o F) to 50 o C (122 o F)<br />

Excellent Corrosion Resistance<br />

● PDCPD (polydicyclopenthadiene) material has<br />

chemical resistance similar to polypropylene<br />

Top Entry<br />

● Easy access to internal parts while valve is in line<br />

1 PDCPD = Polydicyclopenthadiene<br />

8 <strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08<br />

Your Pipeline To Quality<br />

PDCPD 1<br />

SERIES: AA<br />

SIZES: 1-1/4" & 3"<br />

ENDS: Threaded or Flanged<br />

SEALS: EPDM<br />

Removeable<br />

Cover<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008

Air & Vacuum Release Valves<br />

H<br />

DIMENSIONS INCHES WORKING PRESSURES PSI<br />

Size Connection<br />

D H<br />

Range<br />

1-1/4" Female Threaded 8.0 7.5<br />

0.7 to 110<br />

3"<br />

Flanged<br />

9.5 9.0<br />

0.7 to 185<br />

OPERATION<br />

First Stage – High <strong>Flow</strong><br />

Air Exhaust<br />

ORDERING EXAMPLE<br />

<strong>Chemline</strong> Air<br />

Release Valves<br />

Body Material D – PDCPD<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008<br />

/ D<br />

Second Stage – Low <strong>Flow</strong><br />

Air Exhaust prior to shut-off<br />

AA D 012 E T<br />

Size 012 – 1-1/4" 030 –3"<br />

Seals E – EPDM<br />

Ends T – Threaded F – Flanged<br />

Example: <strong>Chemline</strong> Type AA Air Release Valve, PDCPD, 1-1/4", with EPDM<br />

seals, threaded end.<br />

3<br />

2<br />

4<br />

5<br />

6<br />

8<br />

7<br />

1<br />

9<br />

10<br />

PARTS ▲ Recommended Spare Parts<br />

No. Part Pcs. Materials<br />

1 Body 1 PDCPD 1<br />

2 Bonnet 1 PDCPD 1<br />

3 Cover 1 PDCPD 1<br />

4▲ Bonnet Seal 1 EPDM<br />

5 Bolt & Nut Set 4 304 SS<br />

6▲ Body O-Ring 1 EPDM<br />

7▲ Float Seat 1 EPDM<br />

8 Disc 1 PP<br />

9 Float 1 PP<br />

10 Guide 1 HI-PVC 2<br />

1 PDCPD = Polydicyclopenthadiene<br />

2 High Impact PVC<br />

MAXIMUM<br />

AIR DISCHARGE<br />

CAPACITY CFM<br />

CFM@1.42 psi △P/m3/h 185<br />

1,250<br />

WEIGHTS<br />

LB. KG<br />

6.5 2.95<br />

15.0 6.80<br />

Shut-off Air Intake (vacuum release)<br />

Function<br />

<strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08 9

SB 17 Mini<br />

Back Pressure/<br />

Relief Valves<br />

The <strong>Chemline</strong> SB Series Back Pressure/Relief Valve<br />

has two functions. As a back pressure valve, installed<br />

in-line downstream of a pump, the back pressure<br />

below the metering pump is maintained. When<br />

installed in the branch of a tee it is a pressure relief<br />

valve. The valve stays closed until inlet pressure<br />

reaches the set pressure which is adjusted by turning<br />

the spring tensioning bolt. The “Mini” SB17 size<br />

relief valves offer high performance in a compact<br />

package.<br />

True Union Ends<br />

Ideal for Chemical Dosing Systems<br />

Features<br />

True Union Ends<br />

● Easy installation <strong>and</strong> maintenance<br />

● Eliminate chemical leakage problems common with<br />

old fashioned threaded connections<br />

<strong>Flow</strong> Rates<br />

● Up to 500 l/hr<br />

Recommended Viscosity<br />

● Recommended for services with a maximum viscosity<br />

of 400cP<br />

Technical<br />

Set Pressure Range:<br />

● 7.5 to 150 psi<br />

<strong>Flow</strong> Rates<br />

● Up to 500 l/hr (2.2 USGPM)<br />

Maximum Viscosity:<br />

● 400cP is maximum recommended service viscosity<br />

Optional ChemFlare TM End Connections<br />

1 For details on ChemFlare TM End Connectors, consult <strong>Chemline</strong>.<br />

10 <strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08<br />

Your Pipeline To Quality<br />

PVC, PP, PVDF<br />

SIZES: 1/4" – 3/8"<br />

ENDS: Socket, Threaded or ChemFlare TM1<br />

DIAPHRAGM: Teflon ® Bonded EPDM<br />

O-Rings: EPDM, FPM (Viton ®)<br />

Spring Tensioning Bolt<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008

SB 17 Back Pressure/Relief Valves<br />

7<br />

8<br />

6<br />

4<br />

5<br />

2<br />

9<br />

3<br />

13<br />

15<br />

12<br />

DIMENSIONS INCHES<br />

Size<br />

1/4" 0.80<br />

3/8" 0.80<br />

† For socket or threaded.<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008<br />

1 14<br />

L<br />

B H<br />

3.50 4.72<br />

3.50 4.72<br />

A IS<br />

0.67<br />

0.67<br />

10<br />

11<br />

I S<br />

1.26"<br />

L†<br />

4.70<br />

4.70<br />

B<br />

A<br />

H<br />

PARTS ▲ Recommended Spare Parts<br />

No. Part Pcs. Materials<br />

1 Body 1 PVC, PP, PVDF<br />

2 Bonnet 1 PPG<br />

3▲ Diaphragm 1 Teflon ® PTFE<br />

bonded EPDM<br />

4 Spring Plate 1 Cadmium Plated<br />

Steel<br />

5 Spring 2 Galvanized Steel<br />

6 Ball 1 304 SS<br />

7 Spring 1 304 SS<br />

Tensioning Bolt<br />

8 Lock Nut 1 304 SS<br />

9 Pressure Plate 1 Cadmium Plated<br />

Steel<br />

10 Socket Head 4 304 SS<br />

Bolt<br />

11 Washer 4 304 SS<br />

12 Nut 4 304 SS<br />

13 End Connector 2 PVC, PP, PVDF<br />

14 Union Nut 2 PVC, PP, PVDF<br />

15▲ Face O-Ring 2 EPDM, FPM(Viton ®)<br />

MAXIMUM PRESSURES PSI<br />

PVC PP PVDF<br />

20°C 30°C 40°C 50°C 20°C 30°C 40°C 50°C 60°C 70°C 30°C 50°C 70°C<br />

Size 68°F 86°F 104°F 122°F 68°F 86°F 104°F 122°F 140°F 158°F 86°F 122°F 158°F<br />

1/4" 150 100 60 15 150 120 90 60 37.5 15 150 100 60 40<br />

3/8" 150 100 60 15 150 120 90 60 37.5 15 150 100 60 40<br />

Temperature Ranges: PVC 0 to 50°C (32 to 122°F), PP –20 to 70°C (–4 to 158°F), PVDF –40 to 100°C (–40 to 212°F).<br />

ORDERING EXAMPLE<br />

<strong>Chemline</strong> Mini Back<br />

Pressure/Relief Valves<br />

Body Material A –PVC B –PP K – PVDF<br />

Size 002 –1/4" 003 –3/8"<br />

O-Ring E – EPDM V – FPM (Viton ®)<br />

LCF<br />

5.84<br />

6.00<br />

SB17 A 003 E UT<br />

ChemFlare TM<br />

Ends T – Threaded S – Socket B – Butt<br />

CF4 – ChemFlareTM 1/4" tube CF6 – ChemFlareTM 3/8" tube<br />

Example: <strong>Chemline</strong> SB17 Series, PVC, 3/8" diameter, Teflon ® bonded EPDM diaphragm,<br />

EPDM O-rings, True Union threaded ends.<br />

Tube ID<br />

1/4"<br />

3/8"<br />

WEIGHTS LBS.<br />

PVC PP PVDF<br />

0.5 0.4 0.6<br />

0.5 0.4 0.6<br />

80°C<br />

176°F<br />

90°C<br />

194°F<br />

25<br />

25<br />

100°C<br />

212°F<br />

15<br />

15<br />

<strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08 11

SB 10/11 Series<br />

Back Pressure/<br />

Relief Valves<br />

The <strong>Chemline</strong> SB Series Back Pressure/Relief Valve has<br />

two functions. As a back pressure valve, installed in-line<br />

downstream of a pump, the back pressure below the<br />

metering pump is maintained. When installed in the<br />

branch of a tee it is a pressure relief valve. The valve stays<br />

closed until inlet pressure reaches the set pressure which<br />

is adjusted by turning the spring tensioning bolt. Inlet<br />

pressure acts on the Teflon ®control diaphragm opening<br />

the valve, allowing excess pressure to flow downwards<br />

through the orifice.<br />

The SB10/11 Series is very sensitive to pressure changes<br />

<strong>and</strong> requires low overpressure to fully open. It is<br />

designed for clean fluids only.<br />

Sensitive <strong>and</strong> Reliable<br />

Designed for Long Life<br />

True Union Ends<br />

Features<br />

True Union Ends<br />

● Easy installation <strong>and</strong> maintenance<br />

● Eliminate chemical leakage problems common with<br />

old fashioned threaded connections<br />

Long Cycling Life<br />

● Dynamic seal is Teflon ® bonded EPDM for high<br />

chemical resistance<br />

● This moulded diaphragm is designed for superior<br />

sealing <strong>and</strong> flex life<br />

Designed for Superior Performance<br />

● Valves are hydraulically designed for low hysteresis<br />

(“backlash”) <strong>and</strong> to eliminate chatter<br />

● Low overpressure to fully open<br />

● Sensitive to pressure changes<br />

Technical<br />

Set Pressure Ranges:<br />

● SB10 – 3 to 60 psi<br />

● SB11 – 7 to 150 psi<br />

– The only difference between SB10 <strong>and</strong> SB11 is the<br />

strength of spring<br />

Maximum Viscosity:<br />

● 120cP is maximum recommended service viscosity<br />

1 For ChemFlare TM end connectors, consult <strong>Chemline</strong>.<br />

2 PP <strong>and</strong> PVDF spigot ends have DIN dimensions <strong>and</strong> will butt fuse<br />

directly to <strong>Chemline</strong> PP <strong>and</strong> PVDF piping systems.<br />

12 <strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08<br />

Your Pipeline To Quality<br />

PVC, PP, PVDF<br />

SERIES: SB10 <strong>and</strong> SB11<br />

SIZES: 3/8" – 2"<br />

ENDS: True Union Socket, Threaded or<br />

ChemFlare TM1<br />

Spigot 2 Bodies with Plain, Socket,<br />

Threaded or Flanged ends<br />

DIAPHRAGM: Teflon ® Bonded EPDM<br />

SEALS: EPDM, FPM (Viton ®)<br />

Spring<br />

Tensioning<br />

Bolt<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008

Over Pressure (psi)<br />

SB 10/11 Back Pressure/Relief Valves<br />

OVER PRESSURE VS. FLOW RATE<br />

The curves show the relationship between the over<br />

pressure (inlet pressure above the set pressure) <strong>and</strong><br />

the approximate flow rate through the valve for<br />

water at 20 O C (68 O F). These values vary depending on:<br />

● The configuration of the piping <strong>and</strong> the pressure<br />

losses associated with it.<br />

● The fluid if not water at 20 O C (68 O F).<br />

● Whether the pressure is rising or falling. Hysteresis is<br />

approximately 4 psi.<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

VALVE SIZES 3/4" <strong>and</strong> 1"<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008<br />

SB 11<br />

SB 10<br />

5 10 15 20 25 30 35 40 45 50 55<br />

Over Pressure (psi)<br />

Over Pressure (psi)<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

VALVE SIZES 3/8" <strong>and</strong> 1/2"<br />

SB 10<br />

1 2 3 4 5 6 7 8 9 10 11 12 13 14<br />

<strong>Flow</strong> Rate (USGPM)<br />

VALVE SIZES 1-1/4", 1-1/2" <strong>and</strong> 2"<br />

5 10 15 20 25 30 35 40 45 50 55 60 65 70<br />

<strong>Flow</strong> Rate (USGPM) <strong>Flow</strong> Rate (USGPM)<br />

ChemFlare TM Ends<br />

● For connection to<br />

Teflon ® tube. Leak-free<br />

connections for<br />

difficult services such as<br />

sodium hypochlorite<br />

Optional Pressure Gauge<br />

● For inlet <strong>and</strong>/or outlet<br />

SB 11<br />

SB 11<br />

SB 10<br />

TYPICAL DOSING SYSTEM SCHEMATIC<br />

<strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08 13

SB 10/11 Back Pressure/Relief Valves<br />

8<br />

H<br />

A<br />

2<br />

3<br />

11b<br />

12b<br />

4<br />

14<br />

11a<br />

16<br />

12a<br />

14 <strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08<br />

D<br />

12c 12d 5c 1<br />

L<br />

TU<br />

True Union Body<br />

L SP L L S L T<br />

F<br />

18<br />

I<br />

s<br />

10<br />

9<br />

7a<br />

7b<br />

6<br />

5a<br />

13<br />

5b<br />

17<br />

OTHER ENDS<br />

PARTS ▲ Recommended Spare Parts<br />

No. Part Pcs. Materials<br />

1 Body 1 PVC, PP, PVDF<br />

2 Bonnet 1 PPG<br />

3 Spring 1 Galvanized Steel<br />

4▲ Control 1 Teflon ® PTFE<br />

Diaphragm bonded EPDM<br />

5a▲ Piston 1 PVC, PP, PVDF<br />

5b▲ Seat 1 EPDM, FPM(Viton ®)<br />

5c▲ Seat Retainer 1 PVC, PP, PVDF<br />

6 Lower Spring 1 Cad. Plated<br />

Retainer Steel<br />

7a Upper Spring 1 Cad. Plated<br />

Retainer Steel<br />

7b Ball 1 304 SS<br />

8 Spring Tensioning 1 304 SS<br />

Bolt<br />

9 Lock Nut 1 304 SS<br />

10 Spring Bolt Cap 1 PE<br />

11a▲ Piston Bolt 1 304 SS<br />

11b Ball 1 304 SS<br />

12a Bolt/Nut Cap 8/12 1 PE<br />

12b Hex Bolt 4/6 1 304 SS<br />

12c Hex Nut 4/6 1 304 SS<br />

12d Washer 8/12 1 304 SS<br />

13 Spacer Disc 1 PVC, PP, PVDF<br />

14 Pressure Plate 1 Cad. Plated<br />

Steel<br />

16 Union Nut 2 PVC, PP, PVDF<br />

17 End Connector 2 PVC, PP, PVDF<br />

18▲ Face O-Ring 2 EPDM, FPM(Viton ®)<br />

11/2" size / 3/4" to 2" sizes<br />

Spigot Body ChemFlareTM Socket<br />

Threaded<br />

Flanged<br />

DIMENSIONS INCHES<br />

Size D H A ISLSP LCF A<br />

3/8" 3.2 6.9 1.0 0.6 5.7<br />

–<br />

1/2" 3.2 6.9 1.0 0.6 5.7<br />

8.3<br />

3/4" 4.2 8.0 1.5 0.7 6.9<br />

1" 4.2 8.0 1.5 0.9 6.9<br />

1-1/4" 5.8 10.3 2.2 1.0 8.8<br />

1-1/2" 5.8 10.3 2.2 1.2 8.8<br />

2" 5.8 10.3 2.2 1.5 9.6<br />

‡<br />

WEIGHTS LB. Cv VALUES<br />

PVC PP <strong>and</strong> PVDF<br />

USGPM <strong>Flow</strong><br />

LTU†<br />

LS LT LF<br />

LSP* LTU† PVC PP PVDF at 1 psi △P<br />

6.5<br />

7.4 7.2 4.5<br />

0.9 5.7 ** 1.8 1.5 2.2 2.1<br />

6.8<br />

8.0 7.8 6.3<br />

0.9 5.7 7.1 1.9 1.6 2.4 3.0<br />

8.3<br />

9.3 8.9 7.4 9.7 1.4 6.9 8.4 4.1 3.5 4.6 6.6<br />

8.5<br />

9.6 9.3 7.4 10.2 1.4 6.9 8.7 4.2 3.5 4.7 8.7<br />

10.9 11.6 11.2 9.2 – 2.1 8.8 10.9 11.0 9.0 12.0 18.0<br />

11.1 12.2 11.5 9.5 – 2.1 8.8 11.2 11.2 9.2 12.2 20.0<br />

11.3 12.9 12.0 10.0 – 2.1 9.6 13.2 11.4 9.4 12.4 21.4<br />

†True Union Bodies come st<strong>and</strong>ard with socket ends. Threaded union ends are available. ** Consult <strong>Chemline</strong>.<br />

*Spigot bodies are used for non union socket, threaded or flanged ends. All spigot ends have metric dimensions <strong>and</strong> the PP <strong>and</strong> PVDF spigots<br />

butt fuse directly to <strong>Chemline</strong> PP <strong>and</strong> PVDF piping. ‡ Tube size can be reduced to 1/4" tube, LCF = 7.74" for 1/4", 8.26" for 3/8".<br />

L CF<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008

SB 10/11 Back Pressure/Relief Valves<br />

MAXIMUM PRESSURES PSI<br />

PVC PP PVDF<br />

20°C 30°C 40°C 50°C 30°C 40°C 50°C 60°C 70°C 30°C 50°C 70°C 80°C<br />

Size 68°F 86°F 104°F 122°F 86°F 104°F 122°F 140°F 158°F 86°F 122°F 158°F 176°F<br />

3/8" 150 105 60 15 150 90 60 37 15 150 100 60 45<br />

1/2" 150 105 60 15 150 90 60 37 15 150 100 60 45<br />

3/4" 150 105 60 15 150 90 60 37 15 150 100 60 45<br />

1" 150 105 60 15 150 90 60 37 15 150 100 60 45<br />

1-1/4" 150 105 60 15 150 90 60 37 15 150 100 60 45<br />

1-1/2" 150 105 60 15 150 90 60 37 15 150 100 60 45<br />

2" 150 105 60 15 150 90 60 37 15 150 100 60 45<br />

Temperature Ranges: PVC 0 to 50°C (32 to 122°F), PP –20 to 70°C (–4 to 158°F), PVDF –40 to 100°C (–40 to 212°F).<br />

ORDERING EXAMPLE<br />

<strong>Chemline</strong> Back<br />

Pressure/Relief Valves<br />

Pressure SB10 – 3 to 60 psi<br />

Range SB11 – 7 to 150 psi<br />

Body Material A –PVC B –PP K – PVDF<br />

Example: <strong>Chemline</strong> SB 11 Series, PVC, 1/2" diameter, FPM (Viton ®) seals, Union socket ends.<br />

x = 4 for 1/4", 6 for 3/8", 8 for 1/2", 12 for 1" ID tube connections.<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008<br />

SB11 A 005 V U<br />

Size 003 –3/8" 005 –1/2" 007 –3/4" 010 –1"<br />

012 – 1-1/4" 015 – 1-1/2" 020 –2"<br />

Elastomers E – EPDM V – FPM (Viton ®)<br />

Ends S – Socket T – Threaded F – Flanged U – Union Socket<br />

CFx – ChemFlare TM Blank – Spigot (Butt)<br />

90°C<br />

194°F<br />

30<br />

30<br />

30<br />

30<br />

30<br />

30<br />

30<br />

OPTION<br />

● Integral Pressure Gauge – for inlet<br />

<strong>and</strong>/or outlet<br />

100°C<br />

212°F<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

15<br />

SAMPLE SPECIFICATION<br />

– All Back Pressure/Relief Valves in PVC, PP or PVDF shall be <strong>Chemline</strong> SB10 or SB11 Series or equal in sizes 1/2" to 2". SB10<br />

shall have inlet set pressure range of 3 to 60 psi <strong>and</strong> SB11 shall have an inlet set pressure range of 7 to 150 psi. All valves<br />

shall have a maximum inlet pressure rating of 150 psi. Valves shall be suitable for aggressive clean non scaling chemicals.<br />

– All exposed external metal parts including spring tensioning bolt <strong>and</strong> body bolts shall be 304 stainless steel covered with<br />

polyethylene caps.<br />

– All valves shall have a large Teflon ® coated control diaphragm to fully open at no more than 10-15% over pressure.<br />

– Static seals shall be EPDM or FPM (Viton ®).<br />

– Socket ends 1/2" to 2" shall be Schedule 80 <strong>and</strong> conform to ASTM D-2467.<br />

– Threaded ends 1/2" to 2" shall be Schedule 80 <strong>and</strong> conform to ASTM D-2464.<br />

– Butt fusion ends in PP <strong>and</strong> PVDF shall be compatible with <strong>Chemline</strong> metric polypropylene <strong>and</strong> PVDF piping systems.<br />

– Flanged ends shall be ANSI Class 150.<br />

– PVC compound shall have an ASTM cell classification 13463-A, with minimum suffix "A" designation for chemical<br />

resistance as per ASTM D-1784.<br />

– All polypropylene material shall conform to ASTM D-4101 PP 0211B67272 material requirements.<br />

– All PVDF material shall be unpigmented conforming to ASTM D-3222 Type 2 suspension resin material requirements <strong>and</strong><br />

also with USDA Title 21, Chapter I, Part 177.2510 requirements for contact with food.<br />

– All valves shall have chemical resistant labels permanently marked with manufacturing number to provide production level<br />

traceability.<br />

<strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08 15

SB 12 Series<br />

Back Pressure/<br />

Relief Valves<br />

The <strong>Chemline</strong> SB Series Back Pressure/Relief Valve has two<br />

functions. As a back pressure valve, installed in-line<br />

downstream of a pump, the back pressure below the<br />

metering pump is maintained. When installed in the<br />

branch of a tee it is a pressure relief valve. The valve stays<br />

closed until inlet pressure reaches the set pressure which<br />

is adjusted by turning the spring tensioning bolt. Inlet<br />

pressure acts upward against the piston allowing excess<br />

pressure to flow upwards through the orifice.<br />

The SB12 Series has a built-in check valve function,<br />

desirable for dosing applications. It is not so sensitive as<br />

to open with every pulsation from a metering pump.<br />

Designed for Long Life<br />

Ideal for Chemical Dosing Systems<br />

Built-in Check Feature<br />

Features<br />

True Union Ends<br />

● Easy installation <strong>and</strong> maintenance<br />

● Eliminate chemical leakage problems common with<br />

old fashioned threaded connections<br />

Long Cycling Life<br />

● Dynamic seal is Teflon ® bonded EPDM for high<br />

chemical resistance<br />

● This moulded diaphragm is designed for superior<br />

sealing <strong>and</strong> flex life<br />

Superior Performance in Dosing Systems<br />

● Valves are hydraulically designed for very low<br />

hysteresis (“backlash”) <strong>and</strong> to eliminate chatter<br />

● Built-in check (non-return) function<br />

● Valve opening depends on inlet pressure only <strong>and</strong> is<br />

uneffected by changes in downstream (back) pressure<br />

Technical<br />

Set Pressure Ranges:<br />

● 1/2" to 2" – 5 to 150 psi<br />

● 2-1/2" <strong>and</strong> 3" – 7.5 to 150 psi*<br />

● 4" – 7.5 to 90 psi*<br />

Maximum Viscosity:<br />

● 120cP is maximum recommended service viscosity<br />

* Optional 4 to 60 psi range springs are available for 2-1/2" to 4" sizes.<br />

1 For ChemFlare TM end connectors, consult <strong>Chemline</strong>.<br />

2 PP <strong>and</strong> PVDF spigot ends have DIN dimensions <strong>and</strong> will butt fuse<br />

directly to <strong>Chemline</strong> PP <strong>and</strong> PVDF piping systems.<br />

16 <strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08<br />

Your Pipeline To Quality<br />

PVC, PP, PVDF<br />

SIZES: 3/8" – 4"<br />

ENDS: True Union Socket, Threaded or<br />

ChemFlare TM1<br />

Spigot 2 Bodies with Plain, Socket,<br />

Threaded or Flanged ends<br />

DIAPHRAGM: Teflon ® Bonded EPDM<br />

SEALS: EPDM, FPM (Viton ®)<br />

Spring<br />

Tensioning<br />

Bolt<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008

Over Pressure (psi) Over Pressure (psi) Over Pressure (psi)<br />

SB 12 Back Pressure/Relief Valves<br />

OVER PRESSURE VS. FLOW RATE<br />

The curves show the relationship between the over<br />

pressure (inlet pressure above the set pressure) <strong>and</strong><br />

the approximate flow rate through the valve for<br />

water at 20 O C. These values will vary depending on:<br />

● The configuration of the piping <strong>and</strong> the pressure<br />

losses associated with it.<br />

● The fluid if not water at 20 O C.<br />

● Whether the pressure is rising or falling. Hysteresis<br />

is approximately 4 psi.<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

VALVE SIZES 3/8" <strong>and</strong> 1/2"<br />

1 2 3 4 5 6 7 8 9 10 11<br />

2 4 6 8 10 12 14 16 18 20 22<br />

5 10 15 20 25 30 35 40 45 50 55<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008<br />

<strong>Flow</strong> Rate (USGPM)<br />

VALVE SIZES 3/4" <strong>and</strong> 1"<br />

<strong>Flow</strong> Rate (USGPM)<br />

VALVE SIZES 1-1/4", 1-1/2" <strong>and</strong> 2"<br />

<strong>Flow</strong> Rate (USGPM)<br />

Over Pressure (psi)<br />

Over Pressure (psi)<br />

Over Pressure (psi)<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

VALVE SIZE 2-1/2"<br />

st<strong>and</strong>ard 7.5 to150 psi spring<br />

optional 4 to 60 psi spring<br />

10 20 30 40 50 60 70 80 90 100 110 120 130 140<br />

VALVE SIZE 3"<br />

st<strong>and</strong>ard 7.5 to 150 psi spring<br />

<strong>Flow</strong> Rate (USGPM)<br />

optional 4 to 60 psi spring<br />

20 40 60 80 100 120 140 160 180 200 220 240 260 280<br />

VALVE SIZE 4"<br />

st<strong>and</strong>ard 7.5 to 90 psi spring<br />

<strong>Flow</strong> Rate (USGPM)<br />

optional 4 to 60 psi spring<br />

20 40 60 80 100 120 140 160 180 200 220 240 260 280<br />

<strong>Flow</strong> Rate (USGPM)<br />

ChemFlare TM Ends<br />

● For connection to<br />

Teflon ® tube. Leak-free<br />

connections for difficult<br />

services such as sodium<br />

hypochlorite<br />

Optional Pressure Gauge<br />

● For inlet <strong>and</strong>/or outlet<br />

<strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08 17

SB 12 Relief Valves 1/2" – 2"<br />

H<br />

A<br />

8<br />

9<br />

12a<br />

12b<br />

14<br />

13<br />

5a<br />

18 <strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08<br />

17 16 12c 12d 5b 1 18<br />

D<br />

L TU<br />

True Union Body<br />

MAXIMUM PRESSURES PSI<br />

PVC PP PVDF<br />

Size<br />

L SP L L S L T<br />

F<br />

20°C<br />

68°F<br />

30°C<br />

86°F<br />

40°C<br />

104°F<br />

50°C<br />

122°F<br />

30°C<br />

86°F<br />

40°C<br />

104°F<br />

7b<br />

IS<br />

10<br />

2<br />

7a<br />

3<br />

6<br />

4<br />

OTHER ENDS<br />

DIMENSIONS INCHES<br />

WEIGHTS LB. Cv VALUES<br />

PVC PP <strong>and</strong> PVDF<br />

USGPM <strong>Flow</strong><br />

Size D H A ISLTU† LSP* LS LT LF LCF A LSP* LTU† PVC PP PVDF at 1 psi △P<br />

3/8" 3.2 6.9 1.0 0.6 6.5 5.7 7.4 7.2 4.5 – 0.9 5.7 ** 1.8 1.5 2.2 2.1<br />

1/2" 3.2 6.9 1.0 0.6 6.8 5.7 8.0 7.8 6.3 8.3 0.9 5.7 7.1 1.9 1.6 2.4 3.0<br />

3/4" 4.2 8.0 1.5 0.7 8.3 6.9 9.3 8.9 7.4<br />

1.4 6.9 8.4 4.1 3.5 4.6 6.6<br />

1" 4.2 8.0 1.5 0.9 8.5 6.9 9.6 9.3 7.4<br />

1.4 6.9 8.7 4.2 3.5 4.7 8.7<br />

1-1/4" 5.8 10.3 2.2 1.0 10.9 8.8 11.6 11.2 9.2<br />

2.1 8.8 10.9 11.0 9.0 12.0 18.0<br />

1-1/2" 5.8 10.3 2.2 1.2 11.1 8.8 12.2 11.5 9.5<br />

2.1 8.8 11.2 11.2 9.2 12.2 20.0<br />

2" 5.8 10.3 2.2 1.5 11.3 9.6 12.9 12.0 10.0<br />

2.1 8.8 13.2 11.4 9.4 12.4 21.4<br />

† True Union bodies come st<strong>and</strong>ard with socket ends. Threaded union ends are available. ** Consult <strong>Chemline</strong>.<br />

* Spigot bodies are used for non union socket, threaded or flanged ends. All spigot ends have metric dimensions <strong>and</strong> the PP <strong>and</strong> PVDF spigots<br />

butt fuse directly to <strong>Chemline</strong> PP <strong>and</strong> PVDF piping. ‡ Tube size can be reduced to 1/4" tube, LCF = 7.74" for 1/4", 8.26" for 3/8".<br />

‡<br />

9.7<br />

10.2<br />

–<br />

–<br />

–<br />

50°C<br />

122°F<br />

1/2"- 2" 150 105 60 15 150 90 60 37.5 15 150 100 60 45 30 15<br />

60°C<br />

140°F<br />

70°C<br />

158°F<br />

30°C<br />

86°F<br />

50°C<br />

122°F<br />

Temperature Ranges: PVC 0 to 50°C (32 to 122°F), PP –20 to 70°C (–4 to 158°F), PVDF –40 to 100°C (–40 to 212°F).<br />

PARTS ▲ Recommended Spare Parts<br />

No. Part Pcs. Materials<br />

1 Body 1 PVC, PP, PVDF<br />

2 Bonnet 1 PPG<br />

3 Spring 1 Galvanized Steel<br />

4▲ Control 1 Teflon<br />

1 1/2" size / 3/4" to 2" sizes<br />

® PTFE<br />

Diaphragm bonded EPDM<br />

5a▲ Piston 1 PVC, PP, PVDF<br />

5b▲ Seat 1 EPDM, FPM(Viton ®)<br />

6 Lower Spring<br />

Retainer<br />

1 PPG<br />

7a Upper Spring 1 Cad. Plated<br />

Retainer Steel<br />

7b Ball 1 304 SS<br />

8 Spring Tensioning<br />

Bolt<br />

1 304 SS<br />

9 Lock Nut 1 304 SS<br />

10 Spring Bolt Cap 1 PE<br />

12a Bolt/Nut Cap 8/121 PE<br />

12b Hex Bolt 4/61 304 SS<br />

12c Hex Nut 4/61 304 SS<br />

12d Washer 8/121 304 SS<br />

13 Spacer Disc 1 PVC, PP, PVDF<br />

14 Pressure Plate 1 PP<br />

16 Union Nut 2 PVC, PP, PVDF<br />

17 End Connector 2 PVC, PP, PVDF<br />

18▲ Face O-Ring 2 EPDM, FPM(Viton ®)<br />

Spigot Body ChemFlareTM Socket<br />

Threaded<br />

Flanged<br />

70°C<br />

158°F<br />

80°C<br />

176°F<br />

L CF<br />

90°C<br />

194°F<br />

100°C<br />

212°F<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008

SB 12 Relief Valves 2-1/2" – 4"<br />

H<br />

A<br />

L S<br />

10<br />

12a<br />

12b<br />

Ends S – Socket T – Threaded F – Flanged U – Union Socket<br />

CFx – ChemFlare TM Blank – Spigot (Butt)<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008<br />

2<br />

6<br />

13<br />

14<br />

1<br />

5b<br />

D<br />

5c<br />

12c<br />

LSP<br />

Spigot Body<br />

Socket Threaded<br />

DIMENSIONS INCHES<br />

PVC PP <strong>and</strong> PVDF<br />

Size A D H LS LT LF ISP LSP*<br />

2-1/2" 2.7 6.9 11.1 14.5 14.0 10.9 2.1 11.2<br />

3" 3.0 7.9 12.2 16.0 15.5 12.2 3.1 14.2<br />

4" 3.7 9.8 14.2 – – 13.8 3.3 16.5<br />

L T<br />

I<br />

SP<br />

8<br />

9<br />

7<br />

3<br />

12d<br />

4<br />

5a<br />

L F<br />

Flanged<br />

PARTS ▲ Recommended Spare Parts<br />

No. Part Pcs. Materials<br />

1 Body 1 PVC, PP, PVDF<br />

2 Bonnet 1 PPG<br />

3 Spring 1 Galvanized Steel<br />

4▲ Control 1 Teflon ® PTFE<br />

Diaphragm bonded EPDM<br />

5a▲ Piston 2 PVC, PP, PVDF<br />

5b▲ Seat 1 EPDM, FPM(Viton ®)<br />

5c▲ Seat Retainer 1 PVC, PP, PVDF<br />

6 Lower Spring 1 PPG<br />

Retainer<br />

7 Upper Spring 1 304 SS<br />

Retainer<br />

8 Spring Tensioning 1 304 SS<br />

Bolt<br />

9 Lock Nut 1 304 SS<br />

10 Spring Bolt Cap 1 PE<br />

12a Hex Bolt/Nut Cap 20 PE<br />

12b Hex Bolt/Stud 12* 304 SS<br />

12c Hex Nut 20 304 SS<br />

12d Washer 20 304 SS<br />

13 Spacer Disc 1 PVC, PP, PVDF<br />

14 Spacer O ring 1 EPDM, FPM(Viton ®)<br />

* 2 large upper bolts, 2 shorter lower bolts, 8 studs.<br />

WEIGHTS LB. Cv VALUES<br />

USGPM <strong>Flow</strong><br />

PVC PP PVDF at 1 psi △P<br />

20.9 15.4 24.6 41<br />

26.4 23.8 30.8 63<br />

33.0 26.4 37.4 98<br />

* All spigot ends have DIN dimensions <strong>and</strong> the PP <strong>and</strong> PVDF spigots may be butt fused directly to <strong>Chemline</strong> PP <strong>and</strong> PVDF piping systems.<br />

ORDERING EXAMPLE<br />

<strong>Chemline</strong> Back<br />

Pressure/Relief Valves<br />

Body Material A –PVC B –PP K – PVDF<br />

SB12 A<br />

005 V U<br />

Size 003 –3/8" 005 –1/2" 007 –3/4"<br />

010 –1" 012 – 1-1/4" 015 – 1-1/2"<br />

020 –2" 025 – 2-1/2" 030 –3" 040 –4"<br />

Elastomers E – EPDM V – FPM (Viton ®)<br />

Example: <strong>Chemline</strong> SB 12 Series, PVC, 1/2" diameter, FPM (Viton ®) seals, Union socket ends.<br />

x = 4 for 1/4", 6 for 3/8", 8 for 1/2", 12 for 1" ID tube connections.<br />

OPTIONS<br />

● 4–60 psi Pressure Range springs for<br />

2-1/2" to 4" valves<br />

● Integral Pressure Gauge – for inlet <strong>and</strong>/or<br />

outlet<br />

● Bodies in 316 Stainless Steel <strong>and</strong> Teflon ® PTFE<br />

<strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08 19

Pressure<br />

Regulating<br />

(Reducing)<br />

Valves<br />

The <strong>Chemline</strong> SR 50 Series Pressure Regulating<br />

(Reducing) Valves maintains a set downstream<br />

pressure independent of higher variable upstream<br />

pressures. As downstream pressure increases<br />

reaching the set pressure, the valve closes. It opens<br />

as soon as the downstream pressure decreases<br />

below set pressure.<br />

The SR 50 is sensitive <strong>and</strong> provides precise control.<br />

One application is to protect filters from damaging<br />

pressure surges.<br />

True Union Ends<br />

Designed for Long Life<br />

Sensitive <strong>and</strong> Reliable<br />

Features<br />

True Union Ends<br />

● Easy installation <strong>and</strong> maintenance<br />

● Eliminate chemical leakage problems common with<br />

old fashioned threaded connections<br />

Long Cycling Life<br />

● Dynamic seal is Teflon ® bonded EPDM for high<br />

chemical resistance<br />

● This moulded diaphragm is designed for superior<br />

sealing <strong>and</strong> flex life<br />

Designed for Superior Performance<br />

● Designed for minimum hysteresis<br />

● Seat is hydraulically designed to eliminate chatter<br />

Technical<br />

Downstream Set Pressure Ranges:<br />

● 1/2" to 2" – 15 to 130 psi<br />

● 2-1/2" <strong>and</strong> 3" – 15 to 90 psi<br />

Maximum Viscosity:<br />

● 120cP is maximum recommended service viscosity<br />

1 For ChemFlare TM end connectors, consult <strong>Chemline</strong>.<br />

2 PP <strong>and</strong> PVDF spigot ends have DIN dimensions <strong>and</strong> will butt fuse<br />

directly to <strong>Chemline</strong> PP <strong>and</strong> PVDF piping systems.<br />

3 316 SS <strong>and</strong> Teflon ® PTFE bodies are also available. Consult <strong>Chemline</strong>.<br />

20 <strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08<br />

Your Pipeline To Quality<br />

PVC, PP, PVDF 3<br />

SERIES: SR50<br />

SIZES: 3/8" – 3"<br />

ENDS: True Union Socket, Threaded or<br />

ChemFlare TM1<br />

Spigot 2 Bodies with Plain, Socket,<br />

Threaded or Flanged ends<br />

DIAPHRAGM: Teflon ® Bonded EPDM<br />

SEALS: EPDM, FPM (Viton ®)<br />

Spring<br />

Tensioning<br />

Bolt<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008

Pressure below Set Value (psi) Pressure below Set Value (psi)<br />

Pressure Regulating Valves<br />

HOW THEY WORK<br />

The SR 50 controls downstream pressure, which must<br />

always be below the inlet pressure. It is normally<br />

open until the downstream pressure (which acts on<br />

the control diaphragm) reaches the set pressure,<br />

adjustable with the spring tensioning bolt. At this<br />

point the valve closes. It opens again as soon as<br />

downstream pressure decreases slightly below the<br />

set pressure.<br />

The large diaphragm provides for sensitive <strong>and</strong><br />

precise control. The valve seat opens <strong>and</strong> closes until<br />

a balance is achieved between the spring force (set<br />

pressure) <strong>and</strong> the downstream pressure.<br />

WORKING PRESSURE VS. FLOW RATE<br />

The curves show the relationship between the<br />

downstream pressure below set pressure <strong>and</strong> the<br />

approximate flow rate through the valve for water<br />

at 20 O C (68 O F). These values will vary depending on:<br />

● The configuration of the piping <strong>and</strong> the pressure<br />

losses associated with it.<br />

● The fluid if not water at 20 O C (68 O F).<br />

● Whether the pressure is rising or falling. Hysteresis<br />

is approximately 3 psi.<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

0<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

0<br />

VALVE SIZES 1/2"<br />

0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5<br />

2 4 6 8 10 12 14 16 18 20 22<br />

<strong>Flow</strong> Rate (USGPM)<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008<br />

<strong>Flow</strong> Rate (USGPM)<br />

VALVE SIZES 3/4" <strong>and</strong> 1"<br />

Pressure below Set Value (psi)<br />

Downstream Pressure below Set Value (psi)<br />

Downstream Pressure below Set Value (psi)<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

0<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0 0<br />

50<br />

45<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0 0<br />

VALVE SIZES 1-1/4", 1-1/2" <strong>and</strong> 2"<br />

5 10 15 20 25 30 35 40 45 50 55<br />

VALVE SIZE 2-1/2"<br />

<strong>Flow</strong> Rate (USGPM)<br />

10 20 30 40 50 60 70 80 90 100 110 120 130 140<br />

VALVE SIZE 3"<br />

<strong>Flow</strong> Rate (USGPM)<br />

20 40 60 80 100 120 140 160 180 200 220 240 260 280<br />

<strong>Flow</strong> Rate (USGPM)<br />

<strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08 21

Pressure Regulating Valves 1/2" – 2"<br />

H<br />

A<br />

L SP<br />

12d<br />

13<br />

5a<br />

22 <strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08<br />

8<br />

9<br />

7b<br />

12a<br />

Spigot Body<br />

12b<br />

17 16 12c 12d 5c 5b 14c 14b<br />

L F<br />

D<br />

LTU<br />

True Union Body<br />

OTHER ENDS<br />

L S<br />

Socket<br />

1<br />

L CF<br />

18<br />

Flanged ChemFlare TM<br />

10<br />

2<br />

7a<br />

3<br />

11a<br />

11b<br />

6<br />

4<br />

14a<br />

14d<br />

l S<br />

PARTS ▲ Recommended Spare Parts<br />

No. Part Pcs. Materials<br />

1 Body 1 PVC, PP, PVDF<br />

2 Bonnet 1 PPG<br />

3 Spring 1 Galvanized Steel<br />

4▲ Control 1 Teflon ® PTFE<br />

Diaphragm bonded EPDM<br />

5a▲ Piston 1 PVC, PP, PVDF<br />

5b▲ Seat 1 EPDM,FPM(Viton ®)<br />

5c▲ Seat Retainer 1 PVC, PP, PVDF<br />

6 Lower Spring 1 PPG<br />

Retainer<br />

7a Upper Spring 1 Cad. Plated<br />

Retainer Steel<br />

7b Ball 1 304 SS<br />

8 Spring Tensioning 1 304 SS<br />

Bolt<br />

9 Lock Nut 1 304 SS<br />

10 Spring Bolt Cap 1 PE<br />

11a Piston Bolt 1 304 SS<br />

11b Piston Bolt Washer 1 304 SS<br />

12a Bolt/Nut Caps 8/12 1 PE<br />

12b Hex Bolt 4/6 1 304 SS<br />

12c Hex Nut 4/6 1 304 SS<br />

12d Washer 8/12 1 304 SS<br />

13 Piston Guide 1 PVC, PP, PVDF<br />

14a▲ Small Guide O-Ring 1 EPDM,FPM(Viton ®)<br />

14b▲ Large Guide O-Ring 1 EPDM,FPM(Viton ®)<br />

14c▲ Med. Guide O-Ring 1 EPDM,FPM(Viton ®)<br />

14d▲ Pilot Port O-Ring 1 EPDM,FPM(Viton ®)<br />

16 Union Nut 2 PVC, PP, PVDF<br />

17 End Connector 2 PVC, PP, PVDF<br />

18▲ Face O-Ring 2 EPDM,FPM(Viton ®)<br />

11/2" size / 3/4" to 2" sizes.<br />

DIMENSIONS INCHES<br />

WEIGHTS LB. Cv VALUES<br />

PVC PP <strong>and</strong> PVDF<br />

USGPM <strong>Flow</strong><br />

Size D H A ISLTU† LSP* LS LT LF LCF A LSP* LTU† PVC PP PVDF at 1 psi △P<br />

3/8" 3.2 6.9 1.0 0.6 6.5 5.7 7.4 7.2 4.5 – 0.9 5.7 ** 1.8 1.5 2.2 2.1<br />

1/2" 3.2 6.9 1.0 0.6 6.8 5.7 8.0 7.8 6.3 8.3 0.9 5.7 7.1 1.9 1.6 2.4 3.0<br />

3/4" 4.2 8.0 1.5 0.7 8.3 6.9 9.3 8.9 7.4<br />

1.4 6.9 8.4 4.1 3.5 4.6 6.6<br />

1" 4.2 8.0 1.5 0.9 8.5 6.9 9.6 9.3 7.4<br />

1.4 6.9 8.7 4.2 3.5 4.7 8.7<br />

1-1/4" 5.8 10.3 2.2 1.0 10.9 8.8 11.6 11.2 9.2<br />

2.1 8.8 10.9 11.0 9.0 12.0 18.0<br />

1-1/2" 5.8 10.3 2.2 1.2 11.1 8.8 12.2 11.5 9.5<br />

2.1 8.8 11.2 11.2 9.2 12.2 20.0<br />

2" 5.8 10.3 2.2 1.5 11.3 9.6 12.9 12.0 10.0<br />

2.1 9.6 13.2 11.4 9.4 12.4 21.4<br />

† True Union bodies come st<strong>and</strong>ard with socket ends. Threaded union ends are available. ** Consult <strong>Chemline</strong>.<br />

* Spigot bodies are used for non union socket, threaded or flanged ends. All spigot ends have metric dimensions <strong>and</strong> the PP <strong>and</strong> PVDF spigots<br />

butt fuse directly to <strong>Chemline</strong> PP <strong>and</strong> PVDF piping. ‡ Tube size can be reduced to 1/4" tube, LCF = 7.74" for 1/4", 8.26" for 3/8".<br />

MAXIMUM PRESSURES PSI<br />

PVC PP PVDF<br />

20°C 30°C 40°C 50°C 30°C 40°C 50°C 60°C 70°C 30°C 50°C 70°C 80°C 90°C 100°C<br />

Size 68°F 86°F 104°F 122°F 86°F 104°F 122°F 140°F 158°F 86°F 122°F 158°F 176°F 194°F 212°F<br />

1/2"– 2" 150 105 60 15 150 90 60 37.5 15 150 100 60 45 30 15<br />

Temperature Ranges: PVC 0 to 50°C (–32 to 122°F), PP –20 to 70°C (–4 to 158°F), PVDF –40 to 100°C (–40 to 212°F).<br />

‡<br />

9.7<br />

10.2<br />

–<br />

–<br />

–<br />

L T<br />

Threaded<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008

Pressure Regulating Valves 2-1/2", 3"<br />

H<br />

A<br />

10<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008<br />

2<br />

3a<br />

3b<br />

6<br />

4<br />

14<br />

13<br />

DIMENSIONS INCHES<br />

Size<br />

2-1/2"<br />

1<br />

12b<br />

D<br />

16 5c 5d 11c 5e 11b<br />

L SP<br />

Spigot Body<br />

3" 5.6 9.8 13.4 16.0 15.5 12.2 2.2 14.2 2.2<br />

† Plain spigot ends in PP <strong>and</strong> PVDF may be butt fused directly to <strong>Chemline</strong> PP <strong>and</strong> PVDF piping systems.<br />

ORDERING EXAMPLE<br />

<strong>Chemline</strong> Pressure<br />

Regulating Valves<br />

NON UNION ENDS<br />

12d<br />

I SP<br />

8<br />

9<br />

7a<br />

7b<br />

12d<br />

12b<br />

Socket Threaded Flanged<br />

A D H LS LT LF lS<br />

4.8 7.7 10.4 14.5 14.0 10.9 1.7<br />

Body Material A –PVC B –PP K – PVDF<br />

11a<br />

5a<br />

5b<br />

15<br />

12a<br />

PVC PP <strong>and</strong> PVDF<br />

SR50 A 005 V U<br />

Size 003 –3/8" 005 –1/2" 007 –3/4"<br />

010 –1" 012 – 1-1/4" 015 – 1-1/2"<br />

020 –2" 025 – 2-1/2" 030 –3"<br />

Elastomers E – EPDM V – FPM (Viton ®)<br />

Ends S – Socket T – Threaded F – Flanged U – Union Socket<br />

CFx – ChemFlare TM Blank – Spigot (Butt)<br />

Example: <strong>Chemline</strong> SR 50 Series, PVC, 1/2" diameter, FPM (Viton ®) seals, union socket ends.<br />

x = 4 for 1/4", 6 for 3/8", 8 for 1/2", 12 for 1" ID tube connections.<br />

LSP†<br />

11.2<br />

PARTS ▲ Recommended Spare Parts<br />

No. Part Pcs. Materials<br />

1 Body 1 PVC, PP, PVDF<br />

2 Bonnet 1 PPG<br />

3a/3b Spring Set 2 Galvanized Steel<br />

4▲ Control 1 Teflon ® PTFE<br />

Diaphragm bonded EPDM<br />

5a▲ Piston 1 PVC, PP, PVDF<br />

5b▲ Seat 1 EPDM,FPM(Viton ®)<br />

5c▲ Seat Retainer 1 PVC, PP, PVDF<br />

5d▲ Retainer Plug 1 PVC, PP, PVDF<br />

5e▲ Plug O-Ring 1 EPDM,FPM(Viton ®)<br />

6 Lower Spring 1 PPG<br />

Retainer<br />

7a Upper Spring 1 Cad. Plated<br />

Retainer Steel<br />

7b Ball 1 304 SS<br />

8 Tensioning Bolt 1 304 SS<br />

9 Lock Nut 1 304 SS<br />

10 Spring Bolt Cap 1 PE<br />

11a Piston Bolt 1 304 SS<br />

11b Piston Bolt Washer 1 304 SS<br />

11c Piston Nut 1 304 SS<br />

12a Bolt/Nut Cap 20 PE<br />

12b Bolt/Stud Set 121 304 SS<br />

12c Hex Nut 16 304 SS<br />

12d Washer 20 304 SS<br />

13 Piston Guide 1 PVC, PP, PVDF<br />

14▲ Guide O-Ring 1 EPDM,FPM(Viton ®)<br />

15 Base 1 PVC, PP, PVDF<br />

16 Base O-Ring 1 EPDM,FPM(Viton ®)<br />

1 2 large upper bolts, 2 shorter lower bolts, 8 studs.<br />

lSP<br />

1.7<br />

WEIGHTS LB.<br />

OPTIONS<br />

Optional Pressure Gauge<br />

● For inlet <strong>and</strong>/or outlet<br />

PVC PP PVDF<br />

27.5 26.2 31.0<br />

33.0 29.7 37.8<br />

ChemFlare TM Ends<br />

● For connection<br />

to Teflon ® tube.<br />

Leak-free<br />

connections for<br />

difficult services<br />

such as sodium<br />

hypochlorite<br />

<strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08 23

ChemFlareTM<br />

End Connectors<br />

All <strong>Chemline</strong> valves with True Union ends are<br />

available with ChemFlare TM end connections.<br />

ChemFlare TM is a long term leak-free connection<br />

design for difficult applications such as sodium<br />

hypochlorite 1 . These flared end connections are easy<br />

to install <strong>and</strong> allow for compact plumbing <strong>and</strong> a<br />

small footprint.<br />

They are available on <strong>Chemline</strong> True Union valves,<br />

flow meters <strong>and</strong> controls up to1" <strong>and</strong> will connect<br />

Teflon ® PFA tubing down to 1/4" size.<br />

Tubing must be flared using a mechanical flare tool<br />

or by heating <strong>and</strong> using a forming flare tool<br />

(preferred method). Consult <strong>Chemline</strong> for flare<br />

tools.<br />

Full Valve Working Pressure<br />

Easy Installation<br />

Low Down Time<br />

Features<br />

Weldless Design<br />

● Eliminates all fusion welds <strong>and</strong> glued joints<br />

● Threaded connection between flared end <strong>and</strong><br />

tube nut is not wetted<br />

Easy Installation<br />

● Flaring the tube ends is easy<br />

● Assembly is by h<strong>and</strong> 2<br />

Low Down Time<br />

● No welding or curing waiting time. The system<br />

may be pressure tested immediately.<br />

Minimum Dead Volume<br />

● The flared tubing connection has minimum dead<br />

volume desirable on sodium hypochlorite <strong>and</strong><br />

ultrapure applications<br />

1 For sodium hypochlorite applications <strong>Chemline</strong> recommends venting ball valves by<br />

drilling a hole on the upstream side of the ball in the closed position.<br />

2 ChemFlare TM fitting nuts should be h<strong>and</strong> tightened only.<br />

Use of a wrench can result in excessive tightening <strong>and</strong> stripped threads.<br />

24 <strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08<br />

Your Pipeline To Quality<br />

PVC, CPVC, PP, PVDF<br />

SERIES: ChemFlareTM SIZES: 1/2", 3/8", 3/4" <strong>and</strong> 1"<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008

ChemFlareTM End Connectors<br />

H1<br />

ITEM NUMBER SUFFIX<br />

ChemFlare TM<br />

End Connections<br />

Tube Size 2 4 –1/4" 6 –3/8"<br />

8 –1/2" 12 –3/4"<br />

16 –1"<br />

Example: ChemFlare TM end connections for 1/2" tubing.<br />

2 Tube size must be equal or smaller than the valve size.<br />

©<strong>Chemline</strong> <strong>Plastics</strong> <strong>Limited</strong> 2008<br />

A<br />

H2<br />

LCF<br />

MAXIMUM PRESSURES PSI<br />

PVC PP PVDF<br />

Valve Tube 20°C 30°C 40°C<br />

30°C 40°C 50°C<br />

50°C 70°C 80°C 90°C 100°C<br />

Size Size 68°F 86°F 104°F<br />

86°F 104°F 122°F<br />

122°F 158°F 176°F 194°F 212°F<br />

1/2"<br />

1/2"<br />

1/2"<br />

3/4"<br />

1"<br />

1<br />

DIMENSIONS INCHES<br />

Valve<br />

Size<br />

Tube<br />

Size A<br />

1/2"<br />

1/2"<br />

1/2"<br />

3/4"<br />

1"<br />

50°C<br />

60°C 70°C 30°C<br />

122°F<br />

140°F 158°F 86°F<br />

1/4" 150 105 60 15 150 90 60 37 15 150 100 60 45 30 15<br />

3/8" 150 105 60 15 150 90 60 37 15 150 100 60 45 30 15<br />

1/2" 150 105 60 15 150 90 60 37 15 150 100 60 45 30 15<br />

3/4" 111 105 60 15 107 90 60 37 15 107 100 60 45 30 15<br />

1" 77 72 60 15 72 67 60 37 15 72 62 52 43 30 15<br />

Temperature Ranges: PVC 0 to 60°C (32 to 140°F), PP –20 to 90°C (–4 to 194°F), PVDF –40 to 100°C (–40 to 212°F).<br />

1ChemFlareTM ends are available for reduced tube sizes down to 1/4". Tube nuts are always supplied with end connectors.<br />

1<br />

H1<br />

H2<br />

PVC<br />

H2<br />

PP/PVDF LCF<br />

1/4" 3.2 6.9 1.0 0.9 7.74<br />

3/8" 3.2 6.9 1.0 0.9 8.26<br />

1/2" 3.2 6.9 1.0 0.9 8.34<br />

3/4" 4.2 8.0 1.5 1.4 9.72<br />

1" 4.2 8.0 1.5 1.4 10.20<br />

SAMPLE SPECIFICATION<br />

– All Back Pressure/Relief Valves in PVC, PP or PVDF shall be <strong>Chemline</strong> SB10 or SB11 Series or equal in sizes 1/2" to 2". SB10<br />

shall have inlet set pressure range of 3 to 60 psi <strong>and</strong> SB11 shall have an inlet set pressure range of 7 to 150 psi. All valves<br />

shall have a maximum inlet pressure rating of 150 psi. Valves shall be suitable for aggressive, clean, non-scaling chemicals.<br />

– All valves shall have a large Teflon ® coated control diaphragm to fully open at 10-15% over pressure, provide low hysteresis<br />

(“backlash”) <strong>and</strong> no flutter.<br />

– Static seals shall be EPDM or FPM (Viton ® ).<br />

– End connections shall be ChemFlare TM design for connection to flared Teflon ® PFA tubing.<br />

– PVC compound shall have an ASTM cell classification 13463-A, with minimum suffix "A" designation for chemical resistance<br />

as per ASTM D-1784.<br />

– All polypropylene material shall conform to ASTM D-4101 PP 0211B67272 material requirements.<br />

– All PVDF material shall be unpigmented conforming to ASTM D-3222 Type 2 suspension resin material requirements <strong>and</strong><br />

also with USDA Title 21, Chapter I, Part 177.2510 requirements for contact with food.<br />

– All valves shall have chemical resistant labels permanently marked with manufacturing number to provide production level<br />

traceability.<br />

CF 8<br />

PVDF Tube<br />

Nuts not<br />

shown<br />

<strong>Controls</strong> & <strong>Flow</strong> <strong>Meters</strong> CFM 5-08 25

Characterized<br />

Control Valves<br />

The <strong>Chemline</strong> E Series Characterized Control Valves provide<br />

extremely precise flow control of aggressive fluids. Valves<br />

flow characteristics (Cv vs. lift) follow theoretical linear or<br />

equal percentage curves through the entire range of stem<br />

travel. This is accomplished with precision made<br />

replaceable seats <strong>and</strong> plugs in a wide variety of Cv values.<br />

The Teflon ® bellows shaft seal provides almost frictionless<br />

stem movement <strong>and</strong> provides over 10 years of<br />

maintenance-free operation on aggressive chemical<br />

services1 .<br />

Precise & Sensitive Control<br />

Changeable Plugs & Seats<br />