Ebbtide documentation

Ebbtide documentation

Ebbtide documentation

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

A<br />

It’s not the only way, but it is the best way to build boats. If mass<br />

production were our goal, we’d need to alter the way we build each boat. But since<br />

our goal is to build the best boat money can buy, we’ve taken the less traveled course.<br />

ebbtide’s exclusive unitized grid stringer system with perma-panel core combined with<br />

our exclusive DUra-COre hull construction are two examples. the results are a stable<br />

ride and very little noise through rough water. these are things the discriminating boat<br />

buyer demands. we’ve chosen quality over quantity. why aren’t other boats built this<br />

way? simple. It takes longer and costs more. you can feel the difference. you can hear the<br />

difference. you can see the difference. It’s the ebbtide difference... and why our boats ride<br />

better, handle better, look better and last longer.<br />

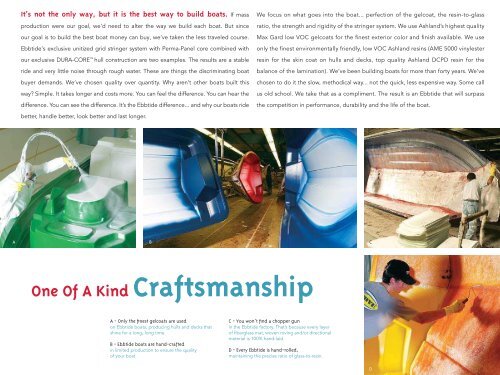

One Of A Kind Craftsmanship<br />

A - Only the finest gelcoats are used<br />

on ebbtide boats, producing hulls and decks that<br />

shine for a long, long time.<br />

B - <strong>Ebbtide</strong> boats are hand-crafted<br />

in limited production to ensure the quality<br />

of your boat.<br />

we focus on what goes into the boat... perfection of the gelcoat, the resin-to-glass<br />

ratio, the strength and rigidity of the stringer system. we use ashland’s highest quality<br />

max Gard low vOC gelcoats for the finest exterior color and finish available. we use<br />

only the finest environmentally friendly, low vOC ashland resins (ame 5000 vinylester<br />

resin for the skin coat on hulls and decks, top quality ashland DCpD resin for the<br />

balance of the lamination). we’ve been building boats for more than forty years. we’ve<br />

chosen to do it the slow, methodical way... not the quick, less expensive way. some call<br />

us old school. we take that as a compliment. the result is an ebbtide that will surpass<br />

the competition in performance, durability and the life of the boat.<br />

B C<br />

C - You won’t find a chopper gun<br />

in the ebbtide factory. that’s because every layer<br />

of fiberglass mat, woven roving and/or directional<br />

material is 100% hand-laid.<br />

D - Every <strong>Ebbtide</strong> is hand-rolled,<br />

maintaining the precise ratio of glass-to-resin.<br />

D<br />

The Hull: Boat for boat, you won’t find a stronger hull with more layers of hand-laid<br />

glass mat, core mat, woven roving, directional material and resin. each successive layer<br />

of glass mat, woven roving and directional material is fitted into the entire length of the<br />

boat, bow to stern. It is hand-rolled into place removing air voids and creating a solid,<br />

high glass-to-resin ratio laminate. the hull sides are foamed and glassed over, creating<br />

ebbtide’s exclusive DUra-COre hull-side construction. you won’t find many (maybe<br />

not any) other boats that go this extra mile. the perma-panel unitized grid stringer<br />

system and integrated transom are completely glassed into place, hand-rolled and<br />

each grid is filled with the proper amount of flotation foam before the sole is attached<br />

E F G<br />

<strong>Ebbtide</strong>’s Exclusive DurA-COrE Hull-Side Construction<br />

E - You can’t buy a boat<br />

with a more solid transom and perma-panel<br />

cored grid stringer system.<br />

F - We spray the hull sides<br />

with closed-cell flotation foam for sound deadening<br />

and structural integrity.<br />

G - <strong>Ebbtide</strong> boats have some of the<br />

smoothest gunwale lines in the industry.<br />

triple fastened, a sign of our extreme<br />

attention to detail.<br />

Bulk Lay-ups of Alternating Layers of Mat, Woven<br />

Roving or Other Composite Materials<br />

(Most Competitors Stop Here)<br />

Skin Coat – Glass Mat and<br />

Ashland AME 5000 Resin<br />

Gelcoat<br />

(yet another difference between ebbtide and the rest). this combination creates our<br />

exclusive Dyna-plane hull, one of the strongest and most solid you can buy.<br />

The Deck: each deck is hand-laid. every layer of glass mat, core mat, woven roving<br />

and directional material is hand-laid... every corner and radius hand-rolled. Once the<br />

deck is laminated, the locations for bow rails, ladders, grab rails and cleats are reinforced<br />

with aluminum mounting plates and heavy traffic areas are strengthened with cored<br />

construction panels. the finished product fits like a glove over the hull and is triple<br />

fastened along the reinforced rubrail with stainless steel attaching screws, creating some<br />

of the smoothest lines in the industry.<br />

Core Mat<br />

1/2” - 3/4” Closed-Cell<br />

Flotation Foam<br />

Glass Lay-Up<br />

Glass Lay-Up<br />

ebbtideboats.com6