Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Drill Jigs Principles of Design Machinery ... - Evenfall Studios

Drill Jigs Principles of Design Machinery ... - Evenfall Studios

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

24 No. sDRILL JIGS<br />

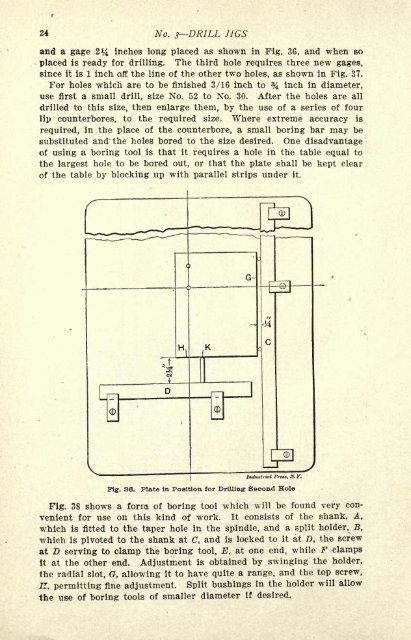

and a gage 2^ inches long placed as shown in Fig. 36, and when so<br />

placed is ready for drilling. The third hole requires three new gages,<br />

since it is 1 inch <strong>of</strong>f the line <strong>of</strong> the other two holes, as shown in Fig. 37.<br />

For holes which are to be finished 3/16 inch to % inch in diameter,<br />

use first a small drill, size No. 52 to No. 30. After the holes are all<br />

drilled to this size, then enlarge them, by the use <strong>of</strong> a series <strong>of</strong> four<br />

lip counterbores, to the required size. Where extreme accuracy is<br />

required, in the place <strong>of</strong> the counterbore, a small boring bar may be<br />

substituted and the holes bored to the size desired. One disadvantage<br />

<strong>of</strong> using a boring tool is that it requires a hole in the table equal to<br />

the largest hole to be bored out, or that the plate shall be kept clear<br />

<strong>of</strong> the table by blocking up with parallel strips under it.<br />

G-<br />

Induttrial /'/, N.Y.<br />

Fig. 36. Plate in Position for <strong>Drill</strong>ing- Second Hole<br />

Fig. 38 shows a form <strong>of</strong> boring tool which will be found very convenient<br />

for use on this kind <strong>of</strong> work. It consists <strong>of</strong> the shank, A,<br />

which is fitted to the taper hole in the spindle, and a split holder, B,<br />

which is pivoted to the shank at C, and is locked to it at D, the screw<br />

at D serving to clamp the boring tool, E, at one end, while F clamps<br />

It at the other end. Adjustment is obtained by swinging the holder,<br />

the radial slot, G, allowing it to have quite a range, and the top screw,<br />

IT, permitting fine adjustment. Split bushings in the holder will allow<br />

the use <strong>of</strong> boring tools <strong>of</strong> smaller diameter if desired.