ALJOIN Final Technical Report - Transport Research & Innovation ...

ALJOIN Final Technical Report - Transport Research & Innovation ...

ALJOIN Final Technical Report - Transport Research & Innovation ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Contract N° G3RD-CT-2002-00829<br />

<strong>Final</strong> <strong>Technical</strong> <strong>Report</strong> – draft 1<br />

<strong>ALJOIN</strong> o 3mm (no oversizing of the weld – normal skin thickness used on<br />

the Ladbroke Grove vehicles)<br />

o 4.2mm (oversizing factor 1.4)<br />

o 4.8mm (oversizing factor 1.6)<br />

• 3 Welding Processes<br />

o MIG welded demonstrators with 5356 welding wire<br />

o LASER welded demonstrators<br />

o FSW demonstrators<br />

• Initiator location:<br />

o 1: no initiator<br />

o 4: initiator located in correspondence of the parent material and<br />

the HAZ<br />

For the final test programme, three specimens each with or without initiator were<br />

prepared for each combination of conditions. For each combination of aluminium grade<br />

and welding process, test would stop when all six samples (3 each with or without<br />

initiator) fractured in the parent material.<br />

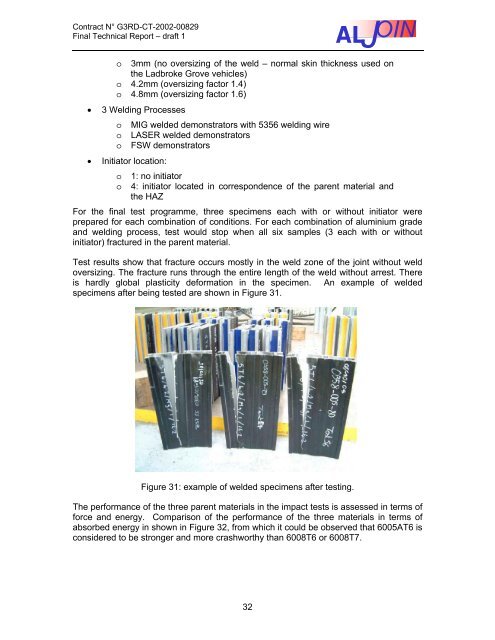

Test results show that fracture occurs mostly in the weld zone of the joint without weld<br />

oversizing. The fracture runs through the entire length of the weld without arrest. There<br />

is hardly global plasticity deformation in the specimen. An example of welded<br />

specimens after being tested are shown in Figure 31.<br />

Figure 31: example of welded specimens after testing.<br />

The performance of the three parent materials in the impact tests is assessed in terms of<br />

force and energy. Comparison of the performance of the three materials in terms of<br />

absorbed energy in shown in Figure 32, from which it could be observed that 6005AT6 is<br />

considered to be stronger and more crashworthy than 6008T6 or 6008T7.<br />

32