Kalzip FC rainscreen system - brochure

Kalzip FC rainscreen system - brochure

Kalzip FC rainscreen system - brochure

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

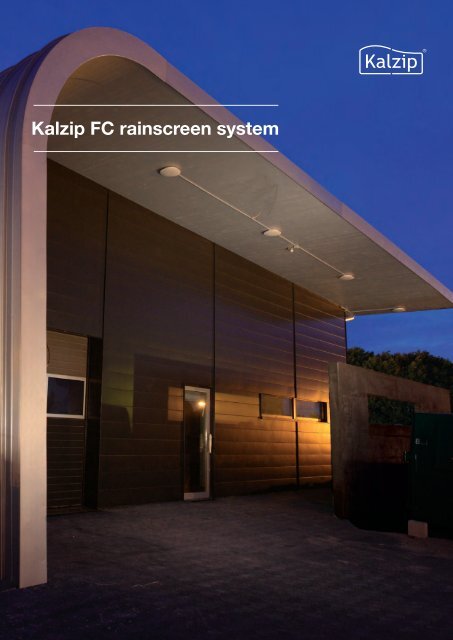

<strong>Kalzip</strong> <strong>FC</strong> <strong>rainscreen</strong> <strong>system</strong><br />

Colour your thinking

Ingenious, attractive,<br />

innovative and<br />

economical<br />

02<br />

<strong>Kalzip</strong> <strong>FC</strong> <strong>rainscreen</strong> is a non-penetrative façade <strong>system</strong> that<br />

incorporates a fast-to-install lightweight flat <strong>rainscreen</strong> panel,<br />

suitable for both new build and refurbishment projects.<br />

The main feature of the <strong>system</strong> is its flexibility which allows the<br />

installation of the profiles to be carried out in two directions,<br />

either from the top down or from the bottom up.<br />

This choice of panel mounting direction is a unique benefit<br />

which enables not only easier and faster installation compared<br />

to conventional panel <strong>system</strong>s but also allows scaffolding<br />

or subsequent construction work to be coordinated<br />

independently from the installation process.<br />

The <strong>system</strong>'s innovative design and technical capabilities also<br />

allow individual sheets to be removed and installed without<br />

compromising the adjoining panels or the overall integrity of<br />

the façade <strong>system</strong>.

Product advantages and<br />

<strong>system</strong> characteristics<br />

• Contemporary, visually stunning aesthetics<br />

• Several different standard profile widths provide flexibility and scope for design<br />

• Highly cost-effective through simple and fast installation techniques<br />

• Optimised panel geometry means low inherent weight and reduced use of materials<br />

• Variable acoustic and thermal insulation options<br />

• A wide range of colour and surface finishes with edge folding as standard<br />

• Fully integrated corner panels (optional)<br />

• High structural performance<br />

• Creation of fixed point with a specially designed fixed point clamp<br />

03

<strong>Kalzip</strong> <strong>FC</strong> <strong>rainscreen</strong> <strong>system</strong><br />

Technical information<br />

Installation and fixing<br />

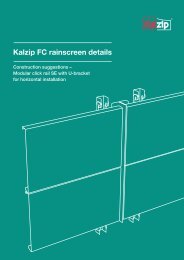

The <strong>Kalzip</strong> <strong>FC</strong> <strong>rainscreen</strong> <strong>system</strong> has been designed for horizontal installation and for use with all common substructures.<br />

The panels are fixed into either proprietary individual clips or continuous modular rails which feature integrated plastic inlays that<br />

lock the panels securely into place. The individual mono-click brackets can also be used for creating special details.<br />

The modular click rail is typically supplied in three to four metre lengths. This is not only for practical handling reasons but also<br />

where a break in the façade sub-construction is required to allow expansion between floors. A specially designed setting out tool<br />

is available to ensure the correct spacing and alignment between adjacent rails. The same tool can be adjusted to accommodate<br />

all standard profile cover widths. The <strong>system</strong> components have been optimised to enable the <strong>system</strong> to be adjusted and aligned<br />

solely via the substructure. Fully integrated corner panels add a subtle yet harmonious detail to the building geometry and<br />

enhance the overall aesthetics of the façade.<br />

Installation from the bottom upwards Installation from the top downwards<br />

Profile options and dimensions<br />

Replacing a damaged panel<br />

Panel suffers accidental<br />

or deliberate damage<br />

04<br />

Damaged panel is cut along<br />

its length<br />

Lower part of damaged panel<br />

is pulled down and removed<br />

Upper panel is unclicked. Top<br />

part of the damaged panel is<br />

unhooked<br />

Materials and finishes:<br />

<strong>FC</strong> <strong>rainscreen</strong> panels are available in stucco embossed<br />

aluminium EN AW 6025 (AIMg2.5SiMnCu) and painted<br />

aluminium EN AW 3004 (AIMn1Mg1) or EN AW 3005<br />

(AIMn1Mg0.5) The profiles are available as standard in<br />

a range of RAL / PVDF colours. Other surface finishes<br />

are available on request including stucco-embossed,<br />

AluPlusPatina, micro-ribbed, perforated and with<br />

integrated recessed seams.<br />

Protective foil:<br />

All material is provided with protective film. Please<br />

check with our Technical Services Department for further<br />

information.<br />

Replacement panel is<br />

hooked on<br />

Panels are clicked into place to<br />

finish repair

Flexible for all sub-structures in new<br />

build or refurbishment<br />

The <strong>Kalzip</strong> <strong>FC</strong> <strong>rainscreen</strong> <strong>system</strong> is suitable for all common sub-constructions. Adjustment<br />

of the panels takes place solely via the sub-construction. The <strong>Kalzip</strong> <strong>FC</strong> <strong>rainscreen</strong> panels<br />

can therefore be installed quickly and easily without the need for additional alignment.<br />

The following <strong>system</strong>s are recommended:<br />

1. Structurally effective modular click<br />

rail SEL-40 on L-section (figure 1a)<br />

or SE on U-section wall bracket<br />

(figure 1b) The advantage of these<br />

sub-constructions are that they require<br />

very few compo nents. Quick and<br />

economical installation is there fore<br />

possible. Installation experi en ce is an<br />

essential requirement here as the<br />

components need to be aligned in<br />

several directions at the same time.<br />

figure 4<br />

figure 1a<br />

2. Adjustable aluminium<br />

sub-construction pre-punched<br />

mono-click brackets (figure 2)<br />

The advantage of this sub-construction<br />

is that it uses conventional <strong>system</strong>s,<br />

onto which mono-click brackets can<br />

be fixed in modular positions. This<br />

sub-construction is recom mended<br />

e.g. when there is a change in panel<br />

cover width within the façade.<br />

figure 1b figure 2<br />

figure 3<br />

3. Adjustable aluminium sub-construction installed<br />

hori zon tally with structurally effective modular click<br />

rail (figures 4 and 5)<br />

In this case, there is a standard sub-construction (figure 4)<br />

which is installed horizontally. The wall brackets may<br />

require additional reinforcement (figure 5).<br />

This sub-construction can be used in projects where<br />

horizontal members are more economical for structural<br />

reasons, e.g. in the case of ribbon windows. The<br />

structurally effective modular click rail enables the<br />

arrangement of the sub-construction to take place<br />

independently from panel alignment and is therefore<br />

the simplest installation solution.<br />

figure 5<br />

figure 6<br />

<strong>Kalzip</strong> <strong>FC</strong> <strong>rainscreen</strong> <strong>system</strong><br />

Adjustable aluminium subconstruction<br />

with modular<br />

click rail (figure 3)<br />

This option uses commercially<br />

available <strong>system</strong>s without additional<br />

modifications. The advantage is<br />

economical and simple installation<br />

(alignment takes place in two steps)<br />

The structurally non-effective<br />

modular click rail must be fixed to<br />

the vertical L-section and at every<br />

panel support.<br />

4. Structurally effective modular click rail on steel<br />

cassettes (figures 6 and 7)<br />

This design is often used in industrial buildings. The<br />

structurally effective modular click rail should be used<br />

to accommodate different cover widths of the panels<br />

and cassettes (figure 6).<br />

Alternatively for higher thermal performance requirements<br />

a continuously insulated steel cassette <strong>system</strong> can be used<br />

as the backing wall (figure 7). When installing the modular<br />

click rail on this <strong>system</strong>, please observe the steel cassette<br />

manu facturer’s installation recommendations to achieve a<br />

thermal break.<br />

figure 7<br />

05

<strong>Kalzip</strong> <strong>FC</strong> <strong>rainscreen</strong> <strong>system</strong><br />

06<br />

Precision right down to the<br />

very last detail<br />

All <strong>Kalzip</strong> <strong>FC</strong> façade <strong>system</strong> components are developed to accommodate a<br />

wide range of requirements and are harmoniously coordinated.<br />

Detail example: joint<br />

1 <strong>Kalzip</strong> <strong>FC</strong> <strong>rainscreen</strong> panel<br />

2 Mono-click bracket<br />

3 Angle profile<br />

4 Wall bracket<br />

5 Thermal break<br />

6 Thermal insulation<br />

7 Brickwork/concrete<br />

8 Vertical joint flashing<br />

Detail example: external corners non right-angled<br />

1 <strong>Kalzip</strong> <strong>FC</strong> <strong>rainscreen</strong> panel<br />

2 Mono-click bracket<br />

3 Angle profile<br />

4 Wall bracket<br />

5 Thermal break<br />

6 Thermal insulation<br />

7 Brickwork/concrete<br />

8 Flashing<br />

9 External corner flashing<br />

Corner panels<br />

Both internal and external corner panels are produced in the factory to suit project<br />

requirements. This gives maximum flexibility when detailing and fixing panels.<br />

Corner panels with angles other than 90° can also be produced. For wind loading<br />

and stability reasons, panels fitted in corners require additional supports. Please<br />

contact our Technical Services Department for further information.<br />

Accessories<br />

A full range of <strong>Kalzip</strong> <strong>FC</strong> <strong>rainscreen</strong> accessories is available.<br />

Mono click bracket<br />

Modular click rail ME<br />

Modular click rail SE Modular click rail SEL<br />

<strong>FC</strong> <strong>rainscreen</strong> flashing support <strong>FC</strong> <strong>rainscreen</strong> fixed point clamp <strong>FC</strong> <strong>rainscreen</strong> guidance snapper

Project case studies<br />

Louisiana Superdome,<br />

New Orleans, USA<br />

Architect: Trahan Architects<br />

Façade area: 34,000 square metres<br />

Profile: <strong>Kalzip</strong> <strong>FC</strong> <strong>rainscreen</strong> 30/305R<br />

Surface finish: AluPlusPatina finish in natural<br />

aluminium coated with RAL 7016<br />

The pictures were shown all around the world and the building<br />

became the epitome of rescue from the forces of nature, when<br />

Hurricane Katrina swept across the south east of the USA as<br />

a devastating natural catastrophe in 2005. The city of New<br />

Orleans was particularly badly hit and 30,000 citizens took<br />

refuge inside the Superdome, the city’s largest building, in<br />

order to survive the raging storm outside.<br />

The Superdome, which still today is the largest permanently<br />

installed dome construction in the world, only suffered minor<br />

damage to its outer skin.<br />

The refurbishment included an area of 34,000 square metres of<br />

the innovative <strong>Kalzip</strong> <strong>FC</strong> <strong>rainscreen</strong> <strong>system</strong>. Further details are<br />

available on our website www.kalzip.com<br />

Spirit of Spice Warehouse, Willich, Germany<br />

Architect: Dewey + Blohm-Schroder Achitekten<br />

Façade area: 330 square metres<br />

Profile: <strong>Kalzip</strong> <strong>FC</strong> <strong>rainscreen</strong> 30/300<br />

Surface finish: polyester coated<br />

The owners of the spice factory in Willich, Germany turned<br />

their hobby into an occupation and established a company for<br />

the manufacture and sales of spices in 2005. By 2010 its huge<br />

success had made it necessary for them to construct a new<br />

building, which houses rooms for production, administration<br />

and also an apartment.<br />

The open side of the elongated structure (in a recumbent<br />

U- shape) faces to the north and west overlooking a nature<br />

conservation area whilst the south side, which is clad with<br />

<strong>Kalzip</strong> profiles, backs onto a 'mixed use' industrial estate.<br />

The roof and wall surfaces merge into one another through<br />

the building's shape and design. The standing seams and the<br />

AluPlusPatina finish give the building a characteristic surface<br />

that conveys quality and durability. The building, which was<br />

conceived as a 'passive' house, is equipped with a geothermal<br />

<strong>system</strong>, solar hot water production, controlled forced<br />

ventilation and a 600 square metre photovoltaic plant making<br />

it as independent of external energy supplies as possible. The<br />

<strong>Kalzip</strong> profiled sheets enable the non-penetrative installation<br />

of the solar modules. For the external façade, the architects<br />

chose the <strong>Kalzip</strong> <strong>FC</strong> <strong>rainscreen</strong> <strong>system</strong>. Characteristic of this<br />

<strong>system</strong> are the large panels, which provide the façade with a<br />

calm and highly aesthetic surface.<br />

<strong>Kalzip</strong> <strong>FC</strong> <strong>rainscreen</strong> <strong>system</strong><br />

07

www.kalzip.com<br />

Care has been taken to ensure that this information<br />

is accurate, but Tata Steel Europe Limited – including<br />

its subsidiaries – does not accept responsibility for<br />

information which is found to be misleading.<br />

Copyright 2011<br />

<strong>Kalzip</strong> Ltd<br />

TATA STEEL INTERNATIONAL<br />

KALZIP OFFICE<br />

PO Box 18294<br />

Jebel Ali<br />

Dubai<br />

United Arab Emirates<br />

T +971 (0) 488 73 23 2<br />

F +971 (0) 488 73 97 7<br />

E enquiries.me@kalzip.com<br />

www.kalzip.com