Evershield EVERSHIELD - Metal Improvement Company

Evershield EVERSHIELD - Metal Improvement Company

Evershield EVERSHIELD - Metal Improvement Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>EVERSHIELD</strong> <strong>Evershield</strong><br />

Conductive Coatings and Plating Processes<br />

for Superior Conductive EMI/RFI Shielding<br />

Coatings and Plating Processes for Superior EMI/RFI Shielding<br />

E/M Coating Services is the industry leader in applying conductive coating and electroless plating<br />

processes for EMI/RFI shielding and semiconductive coating processes for electrostatic dissipation.<br />

Conductive Coatings for EMI/RFI Shielding<br />

E/M Coating Services applies a broad range of EMI/RFI shielding processes<br />

that ensure the reliable performance of electronic devices. As a long-time<br />

leader in applying engineered coating solutions, our cost-effective processes<br />

meet shielding and ground plane needs, ranging from FCC and European<br />

Union compliance to critical shielding and electrical bonding requirements for<br />

aircraft, missile and medical components.<br />

Semiconductive Coatings for Electrostatic Control<br />

Smaller electronic components are particularly susceptible to damage or failure<br />

due to electrostatic discharge. In the search for ways to ensure the operational<br />

integrity of new, high performance products, electronics manufacturers turn to<br />

E/M Coating Services for their application needs. E/M Coating Services can<br />

apply coatings that can provide:<br />

• Surface resistivity of 1 x 105 to 1 x 1012 • Outstanding corrosion protection<br />

• Good lubricity on high friction surfaces<br />

• Excellent wear resistance<br />

• High temperature and cryogenic stability<br />

E/M has numerous UL recognitions under QMRX2, which applies to the application<br />

of conductive coatings that conform to UL 746C adhesion test procedures.<br />

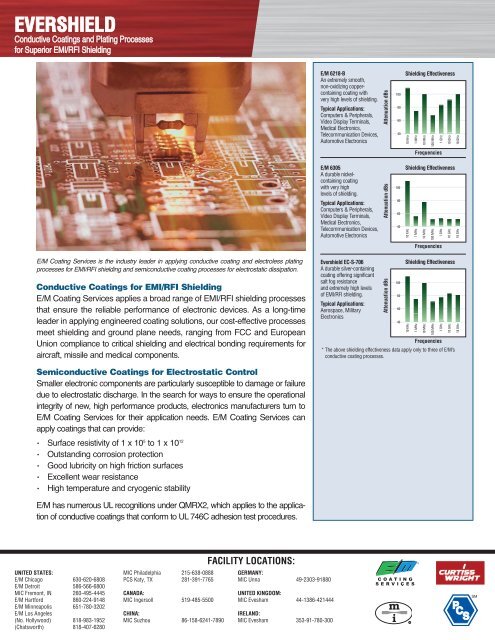

E/M 6218-B<br />

An extremely smooth,<br />

non-oxidizing coppercontaining<br />

coating with<br />

very high levels of shielding.<br />

Typical Applications:<br />

Computers & Peripherals,<br />

Video Display Terminals,<br />

Medical Electronics,<br />

Telecommunication Devices,<br />

Automotive Electronics<br />

E/M 6305<br />

A durable nickelcontaining<br />

coating<br />

with very high<br />

levels of shielding.<br />

Typical Applications:<br />

Computers & Peripherals,<br />

Video Display Terminals,<br />

Medical Electronics,<br />

Telecommunication Devices,<br />

Automotive Electronics<br />

<strong>Evershield</strong> EC-S-706<br />

A durable silver-containing<br />

coating offering significant<br />

salt fog resistance<br />

and extremely high levels<br />

of EMI/RFI shielding.<br />

Typical Applications:<br />

Aerospace, Military<br />

Electronics<br />

Frequencies<br />

* The above shielding effectiveness data apply only to three of E/M’s<br />

conductive coating processes.<br />

E/M Coating Services has over 40 years of experience in applying critical tolerance coatings and is a E/M COATING SERVICES FACILITIES<br />

pioneer and leader in solid film and dry film lubricating and coating processes. We can assist you in United States<br />

selecting the right coating to meet design challenges, lower the cost of ownership and enhance the Chicago<br />

performance and longevity of your products. E/M Coating Services is a division of the <strong>Metal</strong> <strong>Improvement</strong> Detroit<br />

<strong>Company</strong>, a world leader in metal treatment technologies that include FACILITY shot and laser LOCATIONS:<br />

peening, heat treating Hartford<br />

and coatings.<br />

UNITED STATES:<br />

MIC Philadelphia 215-638-0888 GERMANY:<br />

Los Angeles (North Hollywood)<br />

E/M Chicago <strong>Metal</strong> <strong>Improvement</strong> 630-620-6808 <strong>Company</strong>PCS is Katy, a wholly-owned TX subsidiary 281-391-7765of<br />

the Curtiss-Wright MIC Unna Corporation 49-2303-91880 Los Angeles (Chatsworth)<br />

E/M Detroit (NYSE: CW), 586-566-6800 a diversified global provider of highly engineered products and services in the areas of metal Minneapolis<br />

MIC Fremont, treatment, IN motion 260-495-4445 control and flow CANADA: control.<br />

UNITED KINGDOM:<br />

Philadelphia<br />

Ph: 630-620-6808<br />

Ph: 586-566-6800<br />

Ph: 860-224-9148<br />

Ph: 818-983-1952<br />

Ph: 818-407-6280<br />

Ph: 651-780-3202<br />

Ph: 215-638-0888<br />

E/M Hartford<br />

E/M Minneapolis<br />

E/M Los Angeles<br />

(No. Hollywood)<br />

860-224-9148 MIC Ingersoll<br />

Web: 651-780-3202 www.emcoatingservices.com<br />

CHINA:<br />

818-983-1952 MIC Suzhou<br />

519-485-5500 MIC Evesham<br />

E-mail: info@emcoatingservices.com<br />

IRELAND:<br />

86-158-6241-7890 MIC Evesham<br />

44-1386-421444 United Kingdom<br />

Evesham<br />

353-91-780-300<br />

m<br />

i<br />

Ph: 44 (0) 1386-421444<br />

11/04-5K<br />

R<br />

(Chatsworth) 818-407-6280<br />

Attenuation dBs<br />

Attenuation dBs<br />

Attenuation dBs<br />

100<br />

80<br />

60<br />

40<br />

100<br />

80<br />

60<br />

40<br />

100<br />

80<br />

60<br />

40<br />

Shielding Effectiveness<br />

10 KHz<br />

10 KHz<br />

1 MHz<br />

10 MHz<br />

100 MHz<br />

1 GHz<br />

Frequencies<br />

1 MHz<br />

10 MHz<br />

100 MHz<br />

1 GHz<br />

10 GHz<br />

Shielding Effectiveness<br />

10 KHz<br />

1 MHz<br />

10 MHz<br />

100 MHz<br />

1 GHz<br />

Frequencies<br />

10 GHz<br />

Shielding Effectiveness<br />

10 GHz<br />

18 GHz<br />

18 GHz<br />

18 GHz<br />

SM

<strong>EVERSHIELD</strong><br />

<strong>Evershield</strong><br />

Conductive Coatings and Plating Processes for Superior EMI/RFI Shielding<br />

Conductive Coatings and Plating Processes for Superior EMI/RFI Shielding<br />

Electroless Plating Processes for EMI/RFI Shielding<br />

E/M Coating Services has led the development of electroless plating technology<br />

for <strong>Evershield</strong><br />

plastic, <strong>Evershield</strong><br />

plastic composite, and ceramic substrates that achieve extremely<br />

high Conductive levels Conductive of electromagnetic Coatings Coatings and Plating and shielding. Plating Processes We Processes offer for the Superior for broadest Superior EMI/RFI range Shielding of Shielding solutions<br />

to the problems faced in designing and manufacturing electronic devices and<br />

Electroless Electroless Plating Plating Processes Processes for EMI/RFI for EMI/RFI Shielding<br />

components. While achieving extremely high levels of attenuation, our electro-<br />

E/M Coating E/M Coating Services Services has led has the led development the development of electroless of electroless plating plating technology<br />

less plating processes meet stringent environmental requirements.<br />

for plastic,<br />

for plastic,<br />

plastic<br />

plastic<br />

composite,<br />

composite,<br />

and ceramic<br />

and ceramic<br />

substrates<br />

substrates<br />

that<br />

that<br />

achieve<br />

achieve<br />

extremely<br />

extremely<br />

high levels of electromagnetic shielding. We offer the broadest range of solutions<br />

Advantages:<br />

high levels of electromagnetic shielding. We offer the broadest range of solutions<br />

to the problems faced in designing and manufacturing electronic devices and<br />

•to the High problems levels of faced shielding in designing at very thin and plating manufacturing thicknesses—as electronic low devices as and<br />

components. While achieving extremely high levels of attenuation, our electro-<br />

components. 0.000020" less plating<br />

While (1/2 processes micron) achieving<br />

meet<br />

extremely<br />

stringent<br />

high<br />

environmental<br />

levels of attenuation,<br />

requirements.<br />

our electro-<br />

•less Extreme plating processes uniformity meet of plating stringent thicknesses environmental and EMI/RFI requirements. shielding<br />

Advantages:<br />

•<br />

Advantages:<br />

Ability to achieve excellent grounding for lightning protection while<br />

• High levels of shielding at very thin plating thicknesses—as low as<br />

withstanding heavy corrosion<br />

• High levels 0.000020" of shielding (1/2 micron) at very thin plating thicknesses—as low as<br />

• Toughness<br />

0.000020" • Extreme (1/2<br />

and<br />

micron) uniformity durability—excellent of plating thicknesses results in drop and EMI/RFI testing shielding<br />

• Applicable to almost any advanced engineering thermoset, thermoplastic<br />

• Extreme • Ability uniformity to achieve of plating excellent thicknesses grounding for and lightning EMI/RFI protection shielding while<br />

or composite<br />

• Ability to withstanding achieve excellent heavy corrosion grounding for lightning protection while<br />

•<br />

Quality withstanding<br />

Toughness<br />

Assurance heavy<br />

and<br />

corrosion<br />

durability—excellent results in drop testing<br />

• Applicable to almost any advanced engineering thermoset, thermoplastic<br />

To • Toughness maintain the and highest durability—excellent standards of quality, results E/M in drop Coating testing Services employs<br />

or composite<br />

Statistical • Applicable Process to almost Control any (SPC) advanced methods. engineering We’ve developed thermoset, a thermoplastic wide variety of<br />

pretreatment or composite Quality techniques Assurance that ensure the adhesion of <strong>Evershield</strong> plating processes<br />

to virtually<br />

To<br />

all<br />

maintain<br />

plastic,<br />

the<br />

glass,<br />

highest<br />

or carbon<br />

standards<br />

reinforced<br />

of quality,<br />

plastics<br />

E/M<br />

and<br />

Coating<br />

composite<br />

Services<br />

materials.<br />

employs<br />

Quality Statistical Assurance Process Control (SPC) methods. We’ve developed a wide variety of<br />

To maintain pretreatment the highest techniques standards that ensure of quality, the adhesion E/M Coating of <strong>Evershield</strong> Services plating processes employs<br />

Statistical to virtually Process all Control plastic, glass, (SPC) or methods. carbon reinforced We’ve plastics developed and composite a wide variety materials. of<br />

pretreatment techniques that ensure the adhesion of <strong>Evershield</strong> plating processes<br />

to virtually all plastic, glass, or carbon reinforced plastics and composite materials.<br />

Plated Substrates<br />

ABS (Acrylonitrile-<br />

Plated Substrates<br />

Butadiene-Styrene)<br />

PAS (Polyarylsulfone–<br />

30% Glass Filled)<br />

PPS (Polyphenylene Sulfide)<br />

• Unfilled<br />

Acetals ABS (Acrylonitrile- PC (Polycarbonate) PAS (Polyarylsulfone– • Long PPS (Polyphenylene Fiber Carbon Sulfide)<br />

Butadiene-Styrene) •<br />

BMI (Bismaleimide–<br />

20%, 30% 30%, Glass Filled)<br />

Reinforced<br />

• Unfilled<br />

Plated Substrates<br />

•<br />

Carbon Reinforced)<br />

40% Glass Filled<br />

30%, • 50% Glass Filled<br />

Acetals<br />

PC (Polycarbonate)<br />

Long Fiber Carbon<br />

•<br />

BMI (Bismaleimide–<br />

20%, 30%,<br />

Reinforced<br />

DAP (Diallyl Phthalate)<br />

PEEK (Polyetheretherketone)<br />

PS (Polystyrene)<br />

ABS (Acrylonitrile-<br />

PAS (Polyarylsulfone– PPS •(Polyphenylene Sulfide)<br />

Carbon Reinforced)<br />

40% Glass Filled<br />

30%, 50% Glass Filled<br />

• Butadiene-Styrene)<br />

30% 30% Glass Glass Filled) Filled<br />

PSO (Polysulfone)<br />

• Unfilled<br />

Epoxy/Glass<br />

DAP (Diallyl Phthalate) • 30%, PEEK 40% (Polyetheretherketone)<br />

PS (Polystyrene)<br />

Phenolics •<br />

Acetals<br />

PC<br />

Glass<br />

Carbon<br />

(Polycarbonate)<br />

Long Fiber Carbon<br />

• 30% Glass Filled<br />

PSO (Polysulfone)<br />

Epoxy/Glass<br />

Filled<br />

•<br />

BMI (Bismaleimide–<br />

20%, • 30%, 40%<br />

Reinforced<br />

Polyester Phenolics<br />

HDPE (High Glass Density<br />

PEI (Polyetherimide)<br />

• Carbon Reinforced)<br />

40% Glass Carbon Filled Filled<br />

• 30%, 50% Glass Filled<br />

Thermoplastic<br />

Polyethylene)<br />

• 30% Glass Filled<br />

Polyester<br />

HDPE (High Density<br />

• Thermoset<br />

DAP (Diallyl Phthalate)<br />

PEEK<br />

• 40%<br />

(Polyetheretherketone)<br />

PEI (Polyetherimide) PS (Polystyrene)<br />

•<br />

Carbon Filled<br />

Thermoplastic<br />

LCP (Liquid Polyethylene) Crystal<br />

• 30% Glass Filled<br />

• 30% Glass Filled<br />

RIM PSO •(Urethane) (Polysulfone) Thermoset<br />

Polymer–Mineral Epoxy/Glass & Glass Filled) PEK (Polyetherketone)<br />

• 40% Carbon Filled<br />

LCP (Liquid Crystal • 30%, 40%<br />

SMC Phenolics RIM (Sheet (Urethane) Molding<br />

Nylons–Polyamide<br />

Glass Polymer–Mineral & Glass Filled) PES Carbon (Polyethersulfone–<br />

PEK Filled (Polyetherketone)<br />

Compound)<br />

•HDPE 6/6 (High 30%, Density 40%,<br />

30% PEI (Polyetherimide)<br />

Glass)<br />

Polyester<br />

SMC (Sheet Molding<br />

Nylons–Polyamide<br />

PES (Polyethersulfone–<br />

Compound)<br />

Polyethylene) 50% Glass • 6/6 Filled 30%, 40%,<br />

30% Glass)<br />

• Thermoplastic<br />

PP • 30% (Polypropylene) Glass Filled<br />

• Thermoset<br />

• 6/6 40% Carbon 50% Glass Filled Filled<br />

• 40% PP Carbon (Polypropylene) Filled<br />

LCP<br />

• 6/10<br />

(Liquid •<br />

30%<br />

Crystal 6/6 40% Carbon Filled<br />

Glass Filled<br />

PPE (Polyphenylene Ester) RIM (Urethane)<br />

Polymer–Mineral • 6/10<br />

• 6/12 30% Glass<br />

& 30%<br />

Filled<br />

Glass Glass Filled) Filled<br />

PPE (Polyphenylene Ester)<br />

PEK (Polyetherketone)<br />

PPO (Polyphenylene Oxide-<br />

• 6/12 30% Glass Filled PPO (Polyphenylene Oxide- SMC (Sheet Molding<br />

PAI<br />

Nylons–Polyamide<br />

(Polyamide-Imide)<br />

Styrene PES (Polyethersulfone–<br />

Copolymers) Compound)<br />

• Unfilled<br />

6/6 30%,<br />

PAI<br />

40%,<br />

(Polyamide-Imide)<br />

Styrene Copolymers)<br />

30% Glass)<br />

• Unfilled<br />

• 30%<br />

50%<br />

Glass<br />

Glass<br />

Filled<br />

Filled<br />

• 30% Glass Filled PP (Polypropylene)<br />

• 6/6 40% Carbon Filled<br />

• 6/10 30% Glass Filled<br />

PPE (Polyphenylene Ester)<br />

• 6/12 30% Glass Filled PPO (Polyphenylene Oxide-<br />

PAI (Polyamide-Imide)<br />

Web: www.emcoatingservices.com Web: www.emcoatingservices.com Styrene Copolymers) E-mail: E-mail: info@emcoatingservices.com<br />

• Unfilled<br />

• 30% Glass Filled<br />

<strong>Evershield</strong> 3501<br />

This most cost-effective<br />

system achieves high<br />

Shielding Effectiveness<br />

levels of EMI shielding<br />

by copper and nickel<br />

100<br />

plating all surfaces.<br />

80<br />

Typical <strong>Evershield</strong> Applications: 3501<br />

Computers This most cost-effective<br />

This most cost-effective & Peripherals,<br />

Video system Terminals, achieves high<br />

system achieves high<br />

Medical levels of EMI Electronics, shielding<br />

levels of EMI shielding<br />

Telecommunications,<br />

by copper and nickel<br />

by plating copper all surfaces. and nickel<br />

Automotive plating all surfaces. Electronics<br />

Typical Applications:<br />

60 Shielding Shielding Effectiveness<br />

Effectiveness<br />

40<br />

100<br />

100<br />

80<br />

Frequencies<br />

80<br />

60<br />

Typical Computers Applications: & Peripherals,<br />

<strong>Evershield</strong> Computers Video Terminals, 5100-T & Peripherals,<br />

60<br />

40 Shielding Effectiveness<br />

Increased Video Medical Terminals, Electronics, thicknesses of<br />

40<br />

copper Medical Telecommunications, plating Electronics, achieve levels<br />

of Telecommunications,<br />

Automotive signal attenuation Electronics in<br />

compliance Automotive with Electronics NACSIM<br />

5100A/ <strong>Evershield</strong> TEMPEST 5100-T and<br />

Frequencies<br />

100<br />

Frequencies<br />

80<br />

Shielding Effectiveness<br />

MIL-STD Increased 461B thicknesses DESIGN of<br />

requirements. <strong>Evershield</strong> copper plating 5100-T achieve levels<br />

Increased of signal attenuation thicknesses in of<br />

Typical copper Applications:<br />

compliance plating with achieve NACSIMlevels<br />

TEMPEST of 5100A/ signal TEMPEST attenuation Electronics,<br />

and in<br />

Military compliance MIL-STD Electronics 461B with DESIGN NACSIM<br />

5100A/ requirements. TEMPEST and<br />

60<br />

100<br />

40<br />

80 100<br />

60<br />

80<br />

Shielding Effectiveness<br />

Frequencies<br />

MIL-STD Typical Applications: 461B DESIGN<br />

<strong>Evershield</strong> SP-4000<br />

requirements.<br />

TEMPEST Electronics,<br />

With<br />

Military<br />

shielding<br />

Electronics<br />

effectiveness<br />

comparable Typical Applications: to <strong>Evershield</strong><br />

40<br />

60<br />

40<br />

Shielding Effectiveness<br />

Frequencies<br />

3501, TEMPEST eliminates Electronics, harsh<br />

100<br />

chemical Military <strong>Evershield</strong> Electronics and SP-4000 mechanical<br />

pretreatments, With shielding effectiveness selectively<br />

Shielding<br />

80 Frequencies<br />

Effectiveness<br />

plating comparable and protecting to <strong>Evershield</strong><br />

100 60<br />

molded-in <strong>Evershield</strong> 3501, eliminates decorative SP-4000 harsh surfaces. Shielding Effectiveness<br />

With chemical shielding and mechanical effectiveness<br />

80 40<br />

Typical comparable pretreatments, Applications: to selectively <strong>Evershield</strong><br />

Computers 3501, plating eliminates and protecting<br />

100<br />

& Peripherals, harsh Video 60<br />

Terminals, chemical<br />

molded-in<br />

and<br />

decorative<br />

Medical mechanical<br />

surfaces.<br />

Electronics,<br />

Frequencies<br />

40 80<br />

Telecommunications, pretreatments, Typical Applications: selectively Automotive Electronics<br />

plating Computers and & protecting Peripherals, Video<br />

60<br />

molded-in Terminals, Medical decorative Electronics, surfaces.<br />

Frequencies<br />

<strong>Evershield</strong><br />

Telecommunications,<br />

5880<br />

Automotive Electronics 40 Shielding Effectiveness<br />

Copper/nickel Typical Applications: plating provides<br />

high Computers levels of & electromagnetic<br />

Peripherals, Video<br />

shielding,<br />

<strong>Evershield</strong><br />

Terminals, electrical<br />

5880<br />

Medical bonding, Electronics, 100 Shielding Frequencies Effectiveness<br />

Copper/nickel plating provides<br />

and Telecommunications, wear and corrosion Automotive Electronics<br />

high levels of electromagnetic<br />

80<br />

resistance. Plating thickness<br />

shielding, electrical bonding,<br />

100<br />

can<br />

and<br />

be<br />

wear<br />

adjusted<br />

and corrosion<br />

to electronic<br />

60<br />

and <strong>Evershield</strong> environmental 5880 conditions. 80 Shielding Effectiveness<br />

resistance. Plating thickness<br />

Adheres Copper/nickel to virtually plating all provides<br />

can be adjusted to electronic<br />

40<br />

advanced high levels thermosets of electromagnetic 60<br />

and environmental conditions. and<br />

thermoplastics.<br />

shielding, electrical bonding,<br />

100<br />

Adheres to virtually all<br />

40<br />

and advanced wear thermosets and corrosion and<br />

Frequencies<br />

Typical resistance. Applications: Plating thickness Aerospace Electronics, 80<br />

thermoplastics.<br />

Military can be adjusted Electronics, to electronic Medical Electronics, Telecommunications,<br />

Frequencies<br />

Automotive<br />

Typical Applications:<br />

and environmental Electronics,<br />

Aerospace<br />

conditions. Connectors<br />

Electronics, 60<br />

Military Electronics, Medical Electronics, Telecommunications,<br />

Adheres Automotive to virtually Electronics, all Connectors 40<br />

<strong>Evershield</strong> advanced thermosets Mil-Plate 1000 and<br />

Shielding Effectiveness<br />

Based thermoplastics.<br />

<strong>Evershield</strong> on copper/nickel/tin<br />

Mil-Plate 1000<br />

Shielding Effectiveness<br />

plating<br />

Typical Based on technology,<br />

Applications: copper/nickel/tin provides<br />

Frequencies<br />

Aerospace Electronics,<br />

100<br />

extreme<br />

Military plating technology, Electronics,<br />

levels of corrosion provides Medical Electronics, Telecommunications,<br />

100<br />

resistance<br />

Automotive<br />

extreme levels and<br />

Electronics,<br />

of signal corrosion<br />

Connectors 80<br />

attenuation resistance and comparable signal to<br />

80<br />

<strong>Evershield</strong> attenuation 5880. comparable to<br />

60<br />

<strong>Evershield</strong> 5880. Mil-Plate 1000<br />

Shielding Effectiveness<br />

60<br />

Typical Based on Applications:<br />

Typical Applications: copper/nickel/tin<br />

40<br />

Aerospace plating technology, Electronics,<br />

Aerospace Electronics, provides 40<br />

Military extreme Electronics,<br />

100<br />

Military Electronics, levels of corrosion<br />

Connectors resistance Connectorsand<br />

signal<br />

Frequencies<br />

80 Frequencies<br />

attenuation comparable to<br />

<strong>Evershield</strong> 5880.<br />

Typical Applications:<br />

60<br />

Aerospace Electronics,<br />

Military Electronics,<br />

40<br />

Connectors<br />

Frequencies11/04-5K<br />

11/04-5K<br />

Attenuation dBs<br />

Attenuation dBs<br />

Attenuation dBs<br />

Attenuation dBs<br />

Attenuation dBs Attenuation dBs<br />

Attenuation dBs<br />

Attenuation dBs Attenuation dBs<br />

Attenuation dBs<br />

Attenuation dBs Attenuation dBs<br />

Attenuation dBs<br />

Attenuation dBs<br />

Attenuation dBs<br />

10 KHz<br />

10 KHz<br />

10 KHz<br />

10 KHz<br />

10 KHz<br />

10 KHz1<br />

MHz<br />

10 KHz<br />

10 KHz<br />

10 KHz<br />

10 KHz<br />

10 KHz<br />

10 KHz<br />

10 KHz<br />

1 MHz 10 KHz<br />

1 MHz<br />

1 MHz<br />

1 MHz<br />

10 KHz<br />

1 MHz<br />

1 MHz 10 MHz<br />

1 MHz<br />

10 MHz<br />

1 MHz<br />

1 MHz<br />

10 MHz<br />

1 MHz<br />

1 MHz<br />

10 MHz<br />

1 MHz<br />

10 MHz 1 MHz<br />

1 MHz<br />

10 MHz<br />

10 MHz 100 MHz<br />

10 MHz<br />

100 MHz<br />

10 MHz<br />

10 MHz<br />

100 MHz<br />

10 MHz<br />

10 MHz<br />

100 MHz<br />

10 MHz<br />

100 10 MHz MHz<br />

10 MHz<br />

100 MHz<br />

100 MHz<br />

100 MHz<br />

100 MHz<br />

100 MHz<br />

100 MHz<br />

100 MHz<br />

1 GHz<br />

1 GHz<br />

1 GHz<br />

1 GHz<br />

1 GHz<br />

1 GHz<br />

1 GHz<br />

10 GHz<br />

100 MHz<br />

1 GHz<br />

10 GHz<br />

1 GHz<br />

18 GHz<br />

10 GHz<br />

1 GHz<br />

1 GHz<br />

1 GHz<br />

10 GHz<br />

10 GHz<br />

10 GHz<br />

10 GHz<br />

10 GHz<br />

10 GHz<br />

100<br />

1 GHz<br />

MHz<br />

10 GHz<br />

1 GHz<br />

18 GHz<br />

10 GHz<br />

100 MHz<br />

10 GHz<br />

10 GHz<br />

10 GHz<br />

1 GHz<br />

18 GHz<br />

18 GHz<br />

18 GHz<br />

10 GHz<br />

18 GHz<br />

18 GHz<br />

18 GHz<br />

18 GHz<br />

18 GHz<br />

18 GHz<br />

18 GHz<br />

18 GHz<br />

18 GHz<br />

18 GHz