Check out our NEW Catalog! - kolorMATRIX Screenprint Supply

Check out our NEW Catalog! - kolorMATRIX Screenprint Supply

Check out our NEW Catalog! - kolorMATRIX Screenprint Supply

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

404-691-0055 404-691-0037fax www.kolormatrix.com 800-935-2121 404-691-0055 www.kolormatrix.com<br />

Graphic Ink<br />

2<br />

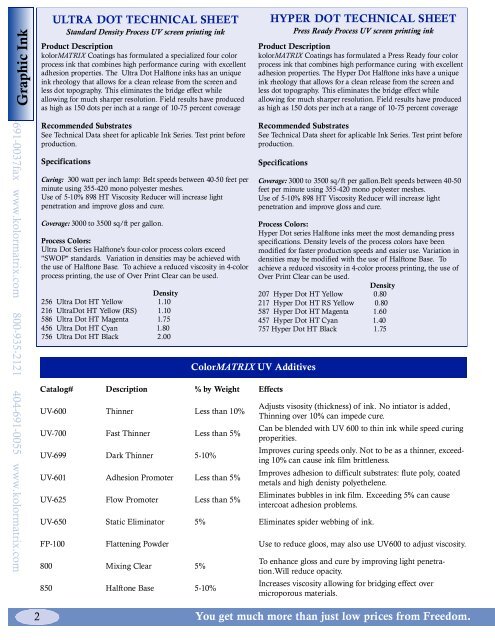

ULTRA DOT TECHNICAL SHEET<br />

Standard Density Process UV screen printing ink<br />

Product Description<br />

<strong>kolorMATRIX</strong> Coatings has formulated a specialized f<strong>our</strong> color<br />

process ink that combines high performance curing with excellent<br />

adhesion properties. The Ultra Dot Halftone inks has an unique<br />

ink rheology that allows for a clean release from the screen and<br />

less dot topography. This eliminates the bridge effect while<br />

allowing for much sharper resolution. Field results have produced<br />

as high as 150 dots per inch at a range of 10-75 percent coverage<br />

Recommended Substrates<br />

See Technical Data sheet for aplicable Ink Series. Test print before<br />

production.<br />

Specifications<br />

Curing: 300 watt per inch lamp: Belt speeds between 40-50 feet per<br />

minute using 355-420 mono polyester meshes.<br />

Use of 5-10% 898 HT Viscosity Reducer will increase light<br />

penetration and improve gloss and cure.<br />

Coverage: 3000 to 3500 sq/ft per gallon.<br />

Process Colors:<br />

Ultra Dot Series Halftone's f<strong>our</strong>-color process colors exceed<br />

"SWOP" standards. Variation in densities may be achieved with<br />

the use of Halftone Base. To achieve a reduced viscosity in 4-color<br />

process printing, the use of Over Print Clear can be used.<br />

Density<br />

256 Ultra Dot HT Yellow 1.10<br />

216 UltraDot HT Yellow (RS) 1.10<br />

586 Ultra Dot HT Magenta 1.75<br />

456 Ultra Dot HT Cyan 1.80<br />

756 Ultra Dot HT Black 2.00<br />

HYPER DOT TECHNICAL SHEET<br />

Press Ready Process UV screen printing ink<br />

Product Description<br />

<strong>kolorMATRIX</strong> Coatings has formulated a Press Ready f<strong>our</strong> color<br />

process ink that combines high performance curing with excellent<br />

adhesion properties. The Hyper Dot Halftone inks have a unique<br />

ink rheology that allows for a clean release from the screen and<br />

less dot topography. This eliminates the bridge effect while<br />

allowing for much sharper resolution. Field results have produced<br />

as high as 150 dots per inch at a range of 10-75 percent coverage<br />

Recommended Substrates<br />

See Technical Data sheet for aplicable Ink Series. Test print before<br />

production.<br />

Specifications<br />

ColorMATRIX UV Additives<br />

<strong>Catalog</strong># Description % by Weight Effects<br />

UV-600 Thinner Less than 10%<br />

UV-700 Fast Thinner Less than 5%<br />

UV-699 Dark Thinner 5-10%<br />

UV-601 Adhesion Promoter Less than 5%<br />

UV-625 Flow Promoter Less than 5%<br />

Coverage: 3000 to 3500 sq/ft per gallon.Belt speeds between 40-50<br />

feet per minute using 355-420 mono polyester meshes.<br />

Use of 5-10% 898 HT Viscosity Reducer will increase light<br />

penetration and improve gloss and cure.<br />

Process Colors:<br />

Hyper Dot series Halftone inks meet the most demanding press<br />

specifications. Density levels of the process colors have been<br />

modified for faster production speeds and easier use. Variation in<br />

densities may be modified with the use of Halftone Base. To<br />

achieve a reduced viscosity in 4-color process printing, the use of<br />

Over Print Clear can be used.<br />

Density<br />

207 Hyper Dot HT Yellow 0.80<br />

217 Hyper Dot HT RS Yellow 0.80<br />

587 Hyper Dot HT Magenta 1.60<br />

457 Hyper Dot HT Cyan 1.40<br />

757 Hyper Dot HT Black 1.75<br />

Adjusts visosity (thickness) of ink. No intiator is added,<br />

Thinning over 10% can impede cure.<br />

Can be blended with UV 600 to thin ink while speed curing<br />

properities.<br />

Improves curing speeds only. Not to be as a thinner, exceeding<br />

10% can cause ink film brittleness.<br />

Improves adhesion to difficult substrates: flute poly, coated<br />

metals and high denisty polyethelene.<br />

Eliminates bubbles in ink film. Exceeding 5% can cause<br />

intercoat adhesion problems.<br />

UV-650 Static Eliminator 5% Eliminates spider webbing of ink.<br />

FP-100 Flattening Powder Use to reduce gloos, may also use UV600 to adjust viscosity.<br />

800 Mixing Clear 5%<br />

850 Halftone Base 5-10%<br />

To enhance gloss and cure by improving light penetration.Will<br />

reduce opacity.<br />

Increases viscosity allowing for bridging effect over<br />

microporous materials.<br />

You get much more than just low prices from Freedom.