CHECKLIST RUBBLE MASTER “AWCM” - Rubble Master HMH GmbH

CHECKLIST RUBBLE MASTER “AWCM” - Rubble Master HMH GmbH

CHECKLIST RUBBLE MASTER “AWCM” - Rubble Master HMH GmbH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

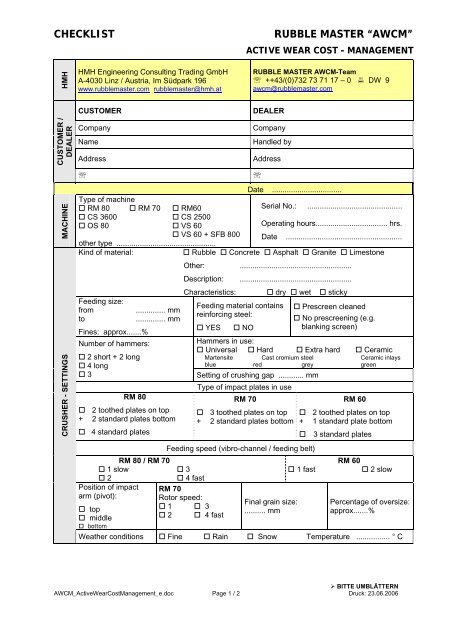

<strong>CHECKLIST</strong> <strong>RUBBLE</strong> <strong>MASTER</strong> <strong>“AWCM”</strong><br />

<strong>HMH</strong><br />

CUSTOMER /<br />

DEALER<br />

MACHINE<br />

CRUSHER - SETTINGS<br />

<strong>HMH</strong> Engineering Consulting Trading <strong>GmbH</strong><br />

A-4030 Linz / Austria, Im Südpark 196<br />

www.rubblemaster.com rubblemaster@hmh.at<br />

CUSTOMER DEALER<br />

Company Company<br />

Name Handled by<br />

Address Address<br />

℡ ℡<br />

ACTIVE WEAR COST - MANAGEMENT<br />

<strong>RUBBLE</strong> <strong>MASTER</strong> AWCM-Team<br />

℡ ++43/(0)732 73 71 17 – 0 DW 9<br />

awcm@rubblemaster.com<br />

Type of machine<br />

RM 80 RM 70 RM60<br />

Date .................................<br />

Serial No.: .............................................<br />

CS 3600<br />

OS 80<br />

CS 2500<br />

VS 60<br />

Operating hours.................................. hrs.<br />

VS 60 + SFB 800<br />

other type ...............................................<br />

Date .......................................................<br />

Kind of material: <strong>Rubble</strong> Concrete Asphalt Granite Limestone<br />

Feeding size:<br />

from .............. mm<br />

to .............. mm<br />

Other: .....................................................<br />

Description: .....................................................<br />

Characteristics: dry wet sticky<br />

Feeding material contains<br />

reinforcing steel:<br />

YES NO<br />

Prescreen cleaned<br />

No prescreening (e.g.<br />

blanking screen)<br />

Fines: approx.......%<br />

Number of hammers:<br />

2 short + 2 long<br />

4 long<br />

Hammers in use:<br />

Universal Hard Extra hard<br />

Martensite Cast cromium steel<br />

blue red grey<br />

Ceramic<br />

Ceramic inlays<br />

green<br />

3 Setting of crushing gap ............ mm<br />

Type of impact plates in use<br />

RM 80<br />

RM 70<br />

RM 60<br />

2 toothed plates on top<br />

+ 2 standard plates bottom<br />

3 toothed plates on top<br />

+ 2 standard plates bottom<br />

2 toothed plates on top<br />

+ 1 standard plate bottom<br />

4 standard plates<br />

3 standard plates<br />

RM 80 / RM 70<br />

1 slow 3<br />

2 4 fast<br />

Position of impact<br />

arm (pivot):<br />

top<br />

middle<br />

bottom<br />

Feeding speed (vibro-channel / feeding belt)<br />

RM 70<br />

Rotor speed:<br />

1 3<br />

2 4 fast<br />

Final grain size:<br />

.......... mm<br />

RM 60<br />

1 fast 2 slow<br />

Percentage of oversize:<br />

approx.......%<br />

Weather conditions Fine Rain Snow Temperature ................ ° C<br />

BITTE UMBLÄTTERN<br />

AWCM_ActiveWearCostManagement_e.doc Page 1 / 2 Druck: 23.06.2006

WEAR PARTS<br />

NOTES / REMARKS<br />

Service life of hammers:<br />

(both sides)<br />

Service life of impact plates<br />

(on impact arm)<br />

Service life of side linings …............ hours<br />

Please outline any points of particular interest :<br />

…............ hours Tons ........... t.<br />

................ hours Tons ........... t.<br />

YOU DEFINE YOUR APPLICATION – WE MINIMISE YOUR WEAR COSTS!<br />

Dear <strong>RUBBLE</strong> <strong>MASTER</strong> customer,<br />

we know that <strong>RUBBLE</strong> <strong>MASTER</strong> crushers achieve superior wear periods at their optimum<br />

settings. Our new <strong>RUBBLE</strong> <strong>MASTER</strong> AWCM program – Active Wear Cost Management – is<br />

designed to proactively optimise the service life of your wear parts.<br />

1. With a comprehensive product range <strong>RUBBLE</strong> <strong>MASTER</strong> supports its customers in<br />

achieving the maximum possible performance from our crushers and screens by<br />

processing various materials cost effectively.<br />

2. Using the questionnaire, you provide us with details of the parameters for your specific<br />

applications, specifying the kind of material, crusher settings and the desired properties<br />

of the final grain.<br />

3. A team of experts at <strong>HMH</strong> Engineering-Consulting-Trading <strong>GmbH</strong> assesses the<br />

optimisation of the crushing process for each specific application and provides you<br />

with advice on how to optimise your crushing operations to maximise throughput<br />

and keep running costs low. Our suggestions relate to specific crusher settings,<br />

adjusting crusher geometry, selecting the right materials for wear parts and keeping you<br />

up-to-date with the latest news, field experience and innovations from <strong>HMH</strong>.<br />

4. Together with you we will develop a plan of action to be implemented in several<br />

stages: starting with an estimate of your potential savings from implementing the<br />

suggested measures immediately, without additional cost, delivering higher performance<br />

and less wear – through to the implementation of efficient <strong>RUBBLE</strong> <strong>MASTER</strong> retrofit<br />

modules where required.<br />

5. After 100 operating hours we assess the results and analyse an alternative plan of<br />

action if necessary.<br />

The details you have provided will be analysed by a team of experts at <strong>HMH</strong>. We will discuss<br />

our findings with you in order to implement the most suitable plan of action. Your future in<br />

achieving the best results with the lowest possible wear – for even more success with<br />

<strong>RUBBLE</strong> <strong>MASTER</strong> Compact Recycling.<br />

Many thanks for your assistance. We look forward to giving you our full support.<br />

Your <strong>RUBBLE</strong> <strong>MASTER</strong> AWCM Team<br />

AWCM_ActiveWearCostManagement_e.doc Seite 2 / 2 Druck: 23.06.2006