epros®DrainLiner Program - Trelleborg

epros®DrainLiner Program - Trelleborg

epros®DrainLiner Program - Trelleborg

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

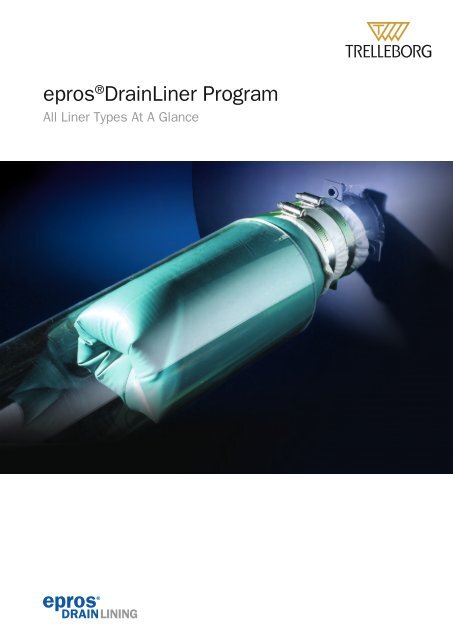

epros ® DrainLiner <strong>Program</strong><br />

All Liner Types At A Glance<br />

DRAIN LINING

<br />

DRAIN LINING

epros ® DrainLinerPP (mit PP-Beschichtung)<br />

In trenchless rehabilitation methodology, a general distinction is made between<br />

sectional or part repairs by means of patch or short liners and complete (full-length)<br />

renovation of sewer and pipe runs using cured-in-place pipe lining (CIPP) techniques.<br />

The renovation of non-man-entry sewer lines with full-length CIPP liners has<br />

established itself as a sophisticated economical and technical alternative to<br />

traditional repair techniques involving digging up the ground.<br />

This method has become a proven and reasonable-cost solution for the basic<br />

renovation of service lines in need of repair by extending their service lives for<br />

another life cycle of at least 50 years.<br />

A basic condition is that the materials used in CIPP operations are suitable for this<br />

type of application and that the installation process meets stringent quality criteria.<br />

<strong>Trelleborg</strong> Pipe Seals Duisburg provide all liners for the rehabilitation and repair of<br />

main lines, lateral pipes, vertical pipes and diverse pipe lines with or without bends.<br />

Various product lines geared to the particular needs are available:<br />

epros <br />

® DrainFlexLiner * with PP coating/installation aid<br />

epros ® DrainSteamLiner with integrated PP coating<br />

epros ® DrainPlusLiner (PUR) with PUR film/installation aid<br />

epros ® DrainPlusLiner (TPU) with TPU film/installation aid<br />

epros ® DrainLiner with PVC coating/installation aid<br />

* (= epros ® DrainLiner with PP coating/installation aid)<br />

All epros ® DrainLiners are approved<br />

by Deutsches Institut für Bautechnik (DIBt)<br />

In connection with the use of certain epoxy resin systems,<br />

the following General Technical Approvals apply:<br />

Pipe size Resin system DIBt Approval No.<br />

DN 100 - DN 250 epros ® EPROPOX FC15/FC30 Z-42.3-366<br />

DN 100 - DN 400 epros ® EPROPOX HC60 Z-42.3-375<br />

DN 100 - DN 600 epros ® EPROPOX HC120 Z-42.3-368<br />

DN 100 - DN 1000 epros ® EPROPOX HC2640 coming soon<br />

For the installation technique and specifications according to the German Institute for<br />

Construction Enginnering (DIBt) please refer to the latest Method Statement manual.<br />

Preliners and calibration hoses additionally needed in some of the installation techniques<br />

are also briefly described in the following.<br />

DRAIN LINING<br />

3

epros ® DrainFlexLiner *<br />

max. 120 °C<br />

Benefits Applications<br />

Many times superior to conventional<br />

PP liners due to<br />

• maximal elasticity of the<br />

coating<br />

• ease to handle<br />

• easy to install<br />

• user-friendly wetting<br />

characteristics<br />

• absolute dimensional stability<br />

during inversion<br />

• superior price-performance<br />

ratio<br />

* (= epros ® DrainLiner with PP coating/<br />

installation aid)<br />

** greater pipe sizes and wall thicknesses<br />

available on request<br />

DRAIN LINING<br />

• e p r o s ® DrainFlexLiner * for pipe lines and sewers having diameters from<br />

DN 100 to DN 1200 ** .<br />

For installations according to DIBt specifications use the nominal pipe sizes<br />

given therein.<br />

• Use for lines with bends up to 45° - without changes in nominal size.<br />

• Suitable for being installed in circular, egg-shaped and special sections.<br />

• Qualifies for steam curing thanks to its high temperature resistance.<br />

Specifications<br />

Material<br />

Polyester needle-felt tube (PES tube) with a polypropylene coating (PP).<br />

The coating (approx. 300 µm) is deemed an installation aid. The special<br />

formulation gives the new PP liner its extraordinary elasticity (DN 225 -<br />

DN 1200). This particular flexibility is also true for smaller diameters<br />

(DN 100 - DN 200) due to a special PP-based coating used for this specific<br />

purpose only. Undersize; 10%<br />

Wall thickness<br />

Wall thicknesses between 3 and 21 mm can be selected, depending on the<br />

results of the design calculations.<br />

Suitable resins<br />

The epros ® DrainFlexLiner can be used with epoxy, silicate or polyester resin<br />

systems.<br />

Curing method<br />

Ambient cure<br />

Hot water<br />

Steam cure<br />

World first<br />

Available from August 2012 –<br />

the most flexible PP liner<br />

of all time.

epros ® DrainSteamLiner<br />

max. 120 °C<br />

Benefits Applications<br />

• Robust CIPP liner for<br />

heavier-duty applications.<br />

• Guaranteed waterproof by its<br />

integrated coating.<br />

• No cutting in APS leakage<br />

tests<br />

• Very good hydraulic<br />

characteristics.<br />

DRAIN LINING<br />

• e p r o s ® DrainSteamLiner for pipe lines and sewers having diameters from<br />

DN 150 to DN 1200 *) . For installation acc. to DIBt specifications use the<br />

nominal pipe sizes given therein.<br />

• Use for lines with bends up to 45° - without changes in nominal size.<br />

• Suitable for being installed in circular, egg-shaped and special sections.<br />

• Specially recommended for steam cures<br />

Specifications<br />

Material<br />

Polyester needle-felt tube (PES tube) with a polypropylene (PP) coating,<br />

but as an integral part of the liner in the case of the epros ® DrainSteamLiner<br />

(approx. 600 µm). Undersize; 10 %<br />

Wall thickness<br />

Wall thicknesses between 3 and 21 mm can be selected, depending on the<br />

results of the design calculations.<br />

Suitable resins<br />

Epoxy, silicate and polyester resin systems can be used.<br />

Curing method<br />

Ambient cure<br />

Hot water<br />

Steam cure<br />

5

epros ® DrainPlusLiner (PUR)<br />

max. 30 °C<br />

Benefits Applications<br />

• Extremely flexible liner type,<br />

negotiates bends easily<br />

• Allows for bends up to 90°<br />

• Allows for up to 2 changes in<br />

diameter (DN 50 or higher).<br />

• Almost no wrinkling<br />

• Very little reduction in<br />

cross-section of the pipe.<br />

• Easy to handle even in case of<br />

low ambient temperatures<br />

DRAIN LINING<br />

• e p r o s ® DrainPlusLiner (PUR) for pipe runs including house connections with<br />

diameters from DN 30 to 250 DN.<br />

The General Technical Approvals by DIBt apply to pipe sizes from<br />

DN 100 to DN 250.<br />

• For lines with up to two changes in diameter.<br />

• For lines with bends up to 90°.<br />

• Suitable for being installed in circular, egg-shaped and special sections.<br />

Properties<br />

Material<br />

Polyester needle-felt tube (PES tube) with a polyurethane film<br />

coating (PUR). The coating (approx. 200 µm) is deemed an installation aid.<br />

Optionally available with an undersize of 9% or 18%.<br />

Wall thickness<br />

Uniform thickness of 3 mm - the liner takes the required material from the<br />

length, not from the wall thickness.<br />

Suitable resins<br />

The epros ® DrainPlusLiner must always be used with epoxy resin<br />

systems, preferably epros ® EPROPOX variants.<br />

Curing method<br />

Ambient cure<br />

Hot-water and steam cure only in connection with a calibration hose<br />

(see p. 9ff).

epros ® DrainPlusLiner (TPU)<br />

max. 100 °C<br />

Benefits Applications<br />

• Extremely flexible liner type,<br />

negotiates bends easily<br />

• Allows for bends up to 90°<br />

• Allows for up to 2 changes in<br />

diameter (DN 70 or higher).<br />

• Minimal wrinkling<br />

• Almost no reduction in<br />

cross-section of host pipe.<br />

• Easy to handle even in case<br />

of low ambient temperatures<br />

DRAIN LINING<br />

• e p r o s ® DrainPlusLiner (TPU) for pipe runs including house connections with<br />

diameters from DN 70 to DN 250.<br />

The General Technical Approvals by DIBt apply to pipe sizes from<br />

DN 100 to DN 250.<br />

• For lines with up to two changes in diameter.<br />

• For lines with bends up to 90°.<br />

• Suitable for being installed in circular, egg-shaped and special sections.<br />

Properties<br />

World first<br />

Available from August 2012 –<br />

the new steam-resistant<br />

DrainPlusLiner (TPU) –<br />

without calibration hose and with<br />

guaranteed wall thickness.<br />

Material<br />

Polyester needle-felt tube (PES tube) with a polyurethane film coating (TPU).<br />

The coating (approx. 180 µm) is deemed an installation aid. Undersize; 10%<br />

Wall thickness<br />

Uniform thickness of 4.5 mm - 3 mm guaranteed in overexpansion area.<br />

Suitable resins<br />

The epros ® DrainPlusLiner must always be used with epoxy resin<br />

systems, preferably epros ® EPROPOX variants.<br />

Curing method<br />

Ambient cure<br />

Hot-water and steam cure without calibration hose (see p. 11).<br />

7

epros ® DrainLiner (PVC)<br />

max. 80 °C<br />

(hot water)<br />

Benefits Applications<br />

• Almost no wrinkling.<br />

• Due to the elasticity of the<br />

liner, the installation pressure<br />

can be low.<br />

• Optimal for installation with a<br />

water column.<br />

* greater pipe sizes and wall thicknesses<br />

available on request<br />

DRAIN LINING<br />

• e p r o s ® DrainLiner (PVC) for pipe lines and sewers with diameters from<br />

DN 100 to DN 1200 * . For installations acc. to DIBt specifications use the<br />

nominal pipe sizes given therein.<br />

• Use for lines with bends up to 45° - without changes in nominal size.<br />

• Suitable for being installed in circular, egg-shaped and special sections.<br />

Specifications<br />

Material<br />

Polyester needle-felt tube (PES tube) with a polyurethane film<br />

coating (TPU). The coating (approx. 450 µm) is deemed an installation aid.<br />

Undersize; 10 %<br />

Designs (2 qualities)<br />

Sewn (from DN 100 to DN 250)<br />

Sewn & welded (from DN 150 to DN 600)<br />

Wall thickness<br />

Wall thicknesses between 3 and 21 mm can be selected, depending on the<br />

results of the design calculations.<br />

Suitable resins<br />

The epros ® DrainFlexLiner can be used with epoxy, silicate or polyester<br />

resin systems.<br />

Curing method<br />

Ambient cure<br />

Hot water up to 80 °C<br />

No steam cure

epros ® DrainPreLiner<br />

Ideal for protecting resins from infiltration. 9<br />

DRAIN LINING<br />

The preliner is a thin but resistant protective PE film tube (approx. 200 µm).<br />

Generally, its use is not mandatory, because it provides no structural stability<br />

to the liner. The preliner will remain in place and cannot be removed.<br />

Under certain circumstances, however, a preliner is pulled or inverted into the<br />

host pipe prior to liner installation in order to form a barrier between the pipe<br />

wall and the liner to prevent the resin from direct contact with the host pipe,<br />

or avoid damage to the liner.<br />

Applications (examples)<br />

• Absolutely necessary e.g. in groundwater-saturated zones<br />

(groundwaterinfiltration).<br />

• For rehabilitation of displaced joints where water accumulations before liner<br />

installation cannot be avoided.<br />

• Absolutely necessary if using the rapid ambient curing epoxy resin systems<br />

epros ® EPROPOX FC15 or FC30.<br />

Available sizes: DN 100 to DN 1000

Calibration Hoses<br />

The rehabilitation of pipe runs according to the epros ® DrainLiner open-end<br />

method always requires a calibration hose to be inverted. This is necessary to<br />

support and expand the liner, which is loose in the line due to the open end,<br />

and to hold it expanded until final cure.<br />

The supporting calibration hose can be inverted along with the liner, e. g. if a<br />

head of water (water column) is used for installation. However, if an inversion<br />

drum is used, it is advisable to invert the calibration hose in a second step<br />

after liner inversion only in order to use the inversion drum‘s full capacity in<br />

terms of lining length. The subsequent installation of the calibration hose is<br />

also required in case of dimensional changes, because simultaneous inversion<br />

would not allow the liner to be optimally expanded to the largest host pipe<br />

diameter.<br />

On the other hand, if vertical pipe runs like drop pipes are to be lined, it is<br />

important to invert the calibration hose together with the liner tube, because<br />

the hose will stabilize the length of the liner during installation and prevent<br />

the liner from getting too long by its sole dead weight or from being contracted<br />

„from the bottom to the top“ during the lining operation. What is important is<br />

to keep the liner under pressure in order to maintain a minimum stability.<br />

The <strong>Trelleborg</strong> Pipe Seals product program offers various models for each<br />

particular application:<br />

epros ® DrainCali Typ „Light Duty“ (DN 65 – DN 200)<br />

epros ® DrainCali Typ „Heavy Duty“ (DN 100 – DN 300)<br />

epros ® DrainCali Typ „Heavy Weight“ (DN 350 – DN 600)<br />

They are described in more detail in the following.<br />

DRAIN LINING

epros ® DrainCali 11<br />

„Light Duty“<br />

• Calibration hose preferred for ambient curing resins<br />

• Mainly used for house connection pipes<br />

• Negotiates bends easily, welded design<br />

• Sizes: DN 65 to DN 200<br />

max. 45 °C<br />

„Heavy Duty“<br />

• Calibration hose for hot curing resins<br />

• Used in main sewers and for house connections<br />

• Negotiates bends up to 90°<br />

• Sewn<br />

• Lightweight design<br />

• Sizes: DN 100 to DN 300<br />

max. 80 °C water<br />

max. 100 °C steam<br />

„Heavy Weight“<br />

• Calibration hose for hot curing resins<br />

• Mainly used in main sewers<br />

• Negotiates bends up to 45°<br />

• Sewn and welded<br />

• Robust heavyweight design<br />

• Sizes: DN 350 to DN 600<br />

max. 80 °C water<br />

DRAIN LINING

<strong>Trelleborg</strong> Pipe Seals Milford Inc<br />

250 Elm Street Milford<br />

New Hampshire 03055<br />

USA<br />

Tel: +1 800 626 2180<br />

Fax: +1 603 673 7271<br />

<strong>Trelleborg</strong> Pipe Seals Duisburg GmbH<br />

Dr. Alfred-Herrhausen-Allee 36<br />

47228 Duisburg<br />

Germany<br />

Tel: +49 2065 999 0<br />

Fax: +49 2065 999 111<br />

www.trelleborg.com/epros<br />

<strong>Trelleborg</strong> Pipe Seals Sales Office<br />

c/o <strong>Trelleborg</strong> Singapore Pte Ltd.<br />

4 Jalan Pesawat<br />

Singapore 619 362<br />

Singapore<br />

Tel: +65 6265 9613<br />

Fax: +65 6265 9902<br />

Version 1.0 – 2012-04-15<br />

Änderungen und Ergänzungen vorbehalten.