Machining guideline

Machining guideline

Machining guideline

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Machining</strong> <strong>guideline</strong><br />

That‘s where<br />

Standard moulds<br />

we are strong.

Content<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

page 8<br />

page 7<br />

page 24<br />

page 10<br />

page 3–5<br />

page 27<br />

page 20<br />

page 21<br />

page 9<br />

page 19<br />

page 11<br />

page 12<br />

page 17-18<br />

page 13–16<br />

page 28<br />

page 22-23<br />

page 25-26<br />

page 6<br />

Threads<br />

Chamfers<br />

Top lock<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

Bores pattern - special<br />

Meusburger bores pattern<br />

Distorsion<br />

Cooling circuit<br />

O-ring seals<br />

Eye bolt<br />

Slide<br />

Roughing<br />

Finishing<br />

Inclined pin<br />

Interlock<br />

Insulation Board<br />

Ejector set<br />

Anti-twist protection<br />

Flame cutting<br />

www.meusburger.com<br />

office@meusburger.com<br />

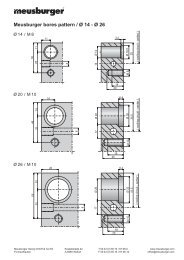

Meusburger bores pattern / Ø 14 − Ø 26<br />

Ø 14 / M 8<br />

Ø 20 / M 10<br />

Ø 26 / M 10<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

2 3<br />

36<br />

48<br />

55<br />

11<br />

25<br />

16<br />

32<br />

20<br />

35<br />

11<br />

16<br />

20<br />

6<br />

8<br />

8<br />

Ø 14<br />

14<br />

Ø 20<br />

17<br />

Ø 26<br />

17<br />

3,2<br />

14<br />

20<br />

19<br />

25<br />

19<br />

25<br />

6,4<br />

6,4<br />

Ø 16,5<br />

25<br />

M 8<br />

Ø 26<br />

M 10<br />

M 10<br />

34,5<br />

( cooling circuit - center )<br />

( cooling circuit - center )<br />

Ø 32<br />

41,5<br />

( cooling circuit - center )

Meusburger bores pattern / Ø 30 − Ø 42<br />

Ø 30 / M 12<br />

63<br />

83<br />

24<br />

39<br />

Ø 42 / M 16<br />

36<br />

47<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

24<br />

36<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

10<br />

10<br />

Ø 30<br />

18<br />

Ø 42<br />

18<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

25<br />

32<br />

34<br />

26<br />

6,4<br />

6,4<br />

Ø 36<br />

48<br />

( cooling circuit - center )<br />

M 12<br />

Ø 48<br />

M 16<br />

( cooling circuit - center )<br />

66<br />

www.meusburger.com<br />

office@meusburger.com<br />

Meusburger bores pattern / Ø 54<br />

Ø 54 / M 20<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

4 5<br />

103<br />

44<br />

59<br />

44<br />

12<br />

Ø 54<br />

22<br />

43<br />

32<br />

10,4<br />

Ø 60<br />

82<br />

M 20<br />

( cooling circuit - center )

Flame cutting<br />

B<br />

b<br />

Z<br />

Allowance and tolerance<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

L<br />

l<br />

S = thickness<br />

B / L S Zug. B/L Tol. B/L Mat.<br />

b / l max. 200 Zug. b/l Tol. b/l<br />

400<br />

600<br />

600<br />

140<br />

140<br />

140<br />

140<br />

140<br />

140<br />

Y 1,0 / 100<br />

Z 0,2 / 100<br />

6,0 - 2,0 1.1730<br />

8,0 - 2,0<br />

1.2311<br />

1.2312<br />

7,0 - 2,0<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

9,0 - 2,0<br />

8,0 - 2,0<br />

10,0 - 3,0<br />

R2 min.<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

Y<br />

Z Y<br />

Y<br />

S<br />

www.meusburger.com<br />

office@meusburger.com<br />

Bores pattern − special<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

6 7<br />

t2<br />

t1<br />

d1<br />

Ø 20<br />

Ø 26<br />

Ø 30<br />

Ø 42<br />

Ø 54<br />

Ø 66<br />

Ø 80<br />

t1<br />

96<br />

136<br />

156<br />

196<br />

216<br />

296<br />

d2<br />

+0,4<br />

d1 +0,8<br />

d1<br />

d2 t2<br />

Ø 26<br />

Ø 32<br />

Ø 36<br />

Ø 48<br />

Ø 60<br />

Ø 72<br />

Ø 86<br />

6,4<br />

10,4

Threads<br />

t1<br />

d1<br />

d2<br />

t2<br />

Metric threads Imperial threads (inches)<br />

pitch in<br />

pitch in<br />

d1 mm d2 t1 t2 d3 d4 t4 d1 pitch mm d2<br />

M 3 0,50 2,5 6 10 3,5 6,5 3,5 G 1/8" 28G/" 0,91 8,70<br />

M 4 0,70 3,3 8 12 4,5 8,0 4,5 G 1/4" 19G/" 1,34 11,60<br />

M 5 0,80 4,2 10 14 5,5 9,5 6,0 G 3/8" 19G/" 1,34 15,00<br />

M 6 1,00 5,0 11 15 6,6 11,0 7,0 G 1/2" 14G/" 1,81 19,00<br />

M 8 1,25 6,8 14 20 9,0 15,0 9,0 G 3/4" 14G/" 1,81 24,25<br />

M10 1,50 8,5 19 25 11,0 18,0 11,0 G 7/8" 14G/" 1,81 28,00<br />

M12 1,75 10,2 25 32 14,0 20,0 13,0 G 1" 11G/" 2,31 30,00<br />

M14 2,00 12,0 25 32 16,0 24,0 15,0 G 11/4" 11G/" 2,31 39,00<br />

M16 2,00 14,0 28 34 18,0 26,0 17,0 G 11/2" 11G/" 2,31 45,00<br />

M18 2,50 15,5 32 40 20,0 29,0 19,5<br />

M20 2,50 17,5 33 42 22,0 32,0 21,5<br />

M22 2,50 19,5 37 48 24,0 35,0 23,5<br />

M24 3,00 21,0 38 52 26,0 38,0 25,5<br />

M27 3,00 24,0 46 60 29,0 42,0 28,5<br />

M30 3,50 26,5 55 70 32,0 48,0 32,0<br />

M36 4,00 32,0 65 85 39,0 57,0 38,0<br />

M42 4,50 37,5 75 95 45,0 66,0 44,0<br />

M48 5,00 43,0 85 110 52,0 76,0 50,0<br />

Fine threads<br />

d1 d2 d1 d2 d1 d2<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

d4<br />

M 4x0,5 3,5<br />

M 14x1,5 12,5<br />

M 5x0,5 4,5<br />

M 16x1 15,0<br />

M 6x0,5 5,5<br />

M 16x1,5 14,5<br />

M 6x0,75 5,2<br />

M 18x1,5 16,5<br />

M 8x0,5 7,5<br />

M 20x1,5 18,5<br />

M 8x0,75 7,2<br />

M 22x1 21,0<br />

M 8x1 7,0<br />

M 22x1,5 20,5<br />

M 9x1 8,0 M 24x1 23,0<br />

M 10x1 9,0 M 24x1,5 22,5<br />

M 10x1,25 8,8 M 24x2 22,0<br />

M 10x1,5 8,5 M 26x1,5 24,5<br />

M 11x1 10,0 M 27x1,5 25,5<br />

M 12x1 11,0<br />

M 27x2 25,0<br />

M 12x1,25 10,8<br />

M 28x1,5 26,5<br />

M 12x1,5 10,5<br />

M 30x1 29,0<br />

M 14x1 13,0<br />

M 30x1,5 28,5<br />

t4<br />

d3<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

M 30x2 28,0<br />

M 32x1,5 30,5<br />

M 33x2 31,0<br />

M 34x1,5 32,5<br />

M 35x1,5 33,5<br />

M 36x1,5 34,5<br />

M 36x2 34,0<br />

M 38x1,5 36,5<br />

M 40x1,5 38,5<br />

M 42x1,5 40,5<br />

M 42x2 40,0<br />

M 48x2 46,0<br />

M 48x3 45,0<br />

M 50x1,5 48,5<br />

M 52x2 50,0<br />

www.meusburger.com<br />

office@meusburger.com<br />

Eye bolt<br />

If plate weight > 800 kg,<br />

provide threads for eye bolts!<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

8 9<br />

b4<br />

d2<br />

l3<br />

d1<br />

l1<br />

E 1272<br />

E 1274<br />

d1<br />

l1<br />

< 90°<br />

d1 d2 l1 max. kg max. kg max. kg max. kg<br />

M 10 25 15 1000 400 800 560<br />

M 12 30 18 2000 750 1500 1000<br />

M 16 35 24 4000 1500 3000 2100<br />

M 20 40 30 6000 2300 4600 3200<br />

M 24 48 36 8000 3200 6400 4500<br />

M 30 60 45 12000 4500 9000 6300<br />

M 36 75 54 16000 7000 14000 9800<br />

< 90°<br />

d1 b4 l1 l3 max. kg max. kg max. kg max. kg<br />

M 10 29 17 33 900 450 900 630<br />

M 12 35 21 51 1200 600 1200 840<br />

M 16 38 25 47 2600 1300 2600 1820<br />

M 20 35 33 56 4000 2000 4000 2800<br />

M 24 40 40 68 7000 3500 7000 4900<br />

M 30 50 50 93 10000 5000 10000 7000

Top lock<br />

0.2<br />

Pocket<br />

type<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

c<br />

E 1304/34<br />

E 1304/40<br />

E 1304/50<br />

E 1304/64<br />

E 1304/72<br />

l<br />

18<br />

22<br />

30<br />

40<br />

52<br />

E 1304<br />

34<br />

40<br />

50<br />

64<br />

72<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

R<br />

10/18<br />

12/22<br />

15/30<br />

18/40<br />

20/46<br />

l<br />

+0.2<br />

0<br />

= =<br />

a<br />

M 4<br />

M 5<br />

M 6<br />

M 8<br />

M 8<br />

+0.015<br />

+0.005<br />

b<br />

b t M a c<br />

22<br />

26<br />

34<br />

42<br />

48<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

M<br />

t<br />

7<br />

9<br />

13<br />

17<br />

19<br />

+0.1<br />

0<br />

Take note of<br />

clearance “c”<br />

R<br />

8<br />

10<br />

www.meusburger.com<br />

office@meusburger.com<br />

Roughing<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

10 11<br />

-2<br />

-3<br />

b<br />

Pocket milled with insert cutters<br />

Corner radius / Depth<br />

b / l R t<br />

< 100/100 17,5 -100<br />

< 300/300 26 -150<br />

> 300/300 33 -210<br />

Bottom radius r = 3 mm − 6 mm depending on the tool used<br />

l<br />

R<br />

max. t )*<br />

-<br />

-240<br />

-300<br />

max. t )* Avoid max. depth if possible (higher machining costs)<br />

For complex forms:<br />

Provide:<br />

- pre-work drawing<br />

- 2D-data: DXF, DWG<br />

- 3D-data: Parasolid, STEP<br />

-2<br />

-3<br />

-2<br />

-3<br />

b<br />

t<br />

-1<br />

-1,5<br />

r<br />

t -1<br />

-1,5

Finishing<br />

b<br />

Corner radius / Depth<br />

depth ( t ) std. F 53 ( t ) min. corner radius (R) bottom radius (r)<br />

< 35<br />

4<br />

0, 1, 2<br />

< 45<br />

5<br />

< 55<br />

6<br />

0, 1, 2, 4<br />

< 80<br />

8<br />

< 90<br />

50<br />

10<br />

< 100<br />

60<br />

12<br />

0, 1, 2, 4, 6<br />

< 105<br />

80<br />

16<br />

< 125<br />

100<br />

20<br />

< 150<br />

25<br />

< 200<br />

30<br />

< 250<br />

35<br />

Avoid max. depth if possible (higher machining costs)<br />

Pocket<br />

b / l<br />

200<br />

400<br />

600<br />

600<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Clearance in the angles<br />

Tol. b / l Tol. t<br />

+0,04 +0<br />

+0,01 - 0,02<br />

+0,05<br />

+0,01<br />

+0,06 +0<br />

+0,01 - 0,04<br />

+0,07<br />

+0,01<br />

l<br />

b<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

l<br />

In case of a small radii the clearances are drilled deeper than the pocket bottom.<br />

R<br />

b<br />

Pocket for top lock<br />

Tol. b Tol. l Tol. t<br />

+0,015<br />

+0,005<br />

+0,2<br />

0<br />

+0,1<br />

0<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

t<br />

r<br />

t<br />

www.meusburger.com<br />

office@meusburger.com<br />

Interlock<br />

Cylindric pocket<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

12 13<br />

R<br />

b<br />

+0,02<br />

0<br />

+0,02<br />

0<br />

t<br />

+0,02<br />

0<br />

l<br />

Corner radius / Depth<br />

depth ( t )<br />

min. corner radius (R) bottom radius (r)<br />

< 25<br />

4<br />

0, 1, 2<br />

< 35<br />

6<br />

0, 1, 2, 4<br />

< 45 8

Interlock<br />

Pocket with one inclined surface<br />

l1<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

R<br />

+0.02<br />

- 0.02<br />

Corner radius / Depth<br />

depth ( t ) min. corner radius (R) bottom radius (r) angle (w)<br />

< 25<br />

4<br />

0, 1, 2 variable<br />

< 35<br />

6<br />

0, 1, 2, 4<br />

< 45 8<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

l1<br />

+0.02<br />

- 0.02<br />

b<br />

A<br />

+0.02<br />

0<br />

w<br />

0<br />

-0,02<br />

+0.02<br />

l 0<br />

t<br />

0,03/100 A<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

Interlock<br />

Type 1: pocket - conical HS-tool<br />

depth ( t ) min. corner radius (R) bottom radius (r) angle (w)<br />

< 50<br />

10<br />

0, 1, 2 3, 5, 10, 15, 20<br />

< 70<br />

0, 1, 2, 4 3, 5, 10<br />

< 100<br />

0, 1, 2, 4, 6 3, 5<br />

< 120<br />

3<br />

Type 2: pocket - line milling<br />

depth ( t ) min. corner radius (R) bottom radius (r) angle (w)<br />

< 70<br />

8<br />

0, 1, 2, 4 variable<br />

< 100<br />

10<br />

12,5 0, 1, 2, 4, 6<br />

< 125<br />

16<br />

< 150<br />

20<br />

< 180<br />

25<br />

< 230<br />

28<br />

< 300<br />

35<br />

Depending on production time and costs, angle radius will be machined with type 1 or 2.<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

14 15<br />

l<br />

H7<br />

R - type 1 R - type 2<br />

H7<br />

b<br />

t<br />

A<br />

w<br />

+0.04<br />

0<br />

0,03/100 A

Interlock<br />

Pocket - conical HS-tool<br />

Clearance recommended but not necessary!<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

R<br />

depth ( t )<br />

< 50<br />

< 70<br />

< 100<br />

< 120<br />

+0.02<br />

Pocket - line milling<br />

l 0<br />

l<br />

clearance<br />

+0.02<br />

0<br />

min. corner radius (R) bottom radius (r)<br />

10<br />

0, 1, 2<br />

0, 1, 2, 4<br />

0, 1, 2, 4, 6<br />

depth ( t ) min. corner radius (R) bottom radius (r) angle (w)<br />

< 70<br />

8<br />

0, 1, 2, 4 variable<br />

< 100<br />

10<br />

12,5<br />

0, 1, 2, 4, 6<br />

< 125<br />

16<br />

< 150<br />

20<br />

< 180<br />

25<br />

< 230<br />

28<br />

< 300<br />

35<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

+0.02<br />

0<br />

b<br />

angle (w)<br />

3, 5, 10, 15, 20<br />

3, 5, 10<br />

3, 5<br />

3<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

t<br />

A<br />

w<br />

+0.04<br />

0<br />

0,03/100 A<br />

www.meusburger.com<br />

office@meusburger.com<br />

Inclined pin<br />

d tol. d<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

16 17<br />

Ø 6<br />

Ø 8<br />

Ø 9<br />

Ø 10<br />

Ø 12<br />

Ø 14<br />

Ø 16<br />

Ø 18<br />

max.<br />

2 x d<br />

+0,012<br />

- 0<br />

+0,015<br />

- 0<br />

+0,018<br />

- 0<br />

d<br />

d<br />

d<br />

pos. tol. angle<br />

+/-0,2 5° - 30°<br />

E 1030<br />

E 1032<br />

d tol. d<br />

Ø 20<br />

+0,021<br />

- 0<br />

Ø 22<br />

Ø 24<br />

Ø 30<br />

Ø 32<br />

Ø 40<br />

d<br />

+0,025<br />

- 0<br />

E 1034<br />

pos. tol. angle<br />

+/-0,2 5° - 30°

Retainer for inclined pin<br />

+0,03<br />

+0,01<br />

b<br />

b1<br />

Position and angle to be selected.<br />

Pocket<br />

d1<br />

Typ<br />

E 3060/ 6<br />

E 3060/ 8<br />

E 3060/10<br />

E 3060/12<br />

E 3060/14<br />

E 3060/16<br />

E 3060/18<br />

E 3060/20<br />

E 3060/22<br />

E 3060/24<br />

E 3060/30<br />

l1<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

l<br />

E 3060<br />

+0,03<br />

+0,01<br />

M<br />

+0,05<br />

0<br />

t<br />

d1<br />

6<br />

8<br />

10<br />

12<br />

14<br />

16<br />

18<br />

20<br />

22<br />

24<br />

30<br />

0<br />

R -0,2<br />

b l t b1 l1 M<br />

32<br />

36<br />

40<br />

44<br />

52<br />

54<br />

56<br />

62<br />

66<br />

74<br />

18<br />

22<br />

26<br />

30<br />

34<br />

38<br />

42<br />

46<br />

50<br />

52<br />

62<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

12<br />

14<br />

18<br />

24<br />

28<br />

32<br />

36<br />

38<br />

42<br />

44<br />

52<br />

20<br />

22<br />

24<br />

26<br />

28<br />

34<br />

36<br />

38<br />

42<br />

44<br />

52<br />

8<br />

9<br />

8,5<br />

10<br />

12<br />

14<br />

16<br />

18<br />

20<br />

22<br />

24<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

M 4<br />

M 5<br />

M 6<br />

M 8<br />

M10<br />

R<br />

10<br />

12<br />

16<br />

www.meusburger.com<br />

office@meusburger.com<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

18 19<br />

Slide<br />

0<br />

-0,02<br />

t3<br />

a<br />

a t3<br />

11 3<br />

12 2<br />

15 3<br />

19 4<br />

24<br />

+0,015<br />

0<br />

b<br />

+0,015<br />

0<br />

+0,02<br />

0<br />

t<br />

E 3116<br />

E 3118

Cooling circuit<br />

2x45°<br />

+0,2<br />

d2 0<br />

M<br />

t2<br />

+0,2<br />

0<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

t1 +1<br />

- 1<br />

Feasible diameters and depths<br />

d1<br />

4<br />

5<br />

6<br />

6,1<br />

6,55<br />

7<br />

7,5<br />

8,05<br />

8,25<br />

8,5<br />

9<br />

9,5<br />

9,55<br />

10,05<br />

10,1<br />

10,2<br />

11<br />

11,2<br />

11,5<br />

12,05<br />

12,2<br />

12,55<br />

12,7<br />

12,85<br />

13<br />

14<br />

14,2<br />

15<br />

15,85<br />

16<br />

t1 max.<br />

560<br />

860<br />

760<br />

560<br />

560<br />

760<br />

760<br />

1360<br />

960<br />

1360<br />

960<br />

960<br />

1360<br />

1360<br />

960<br />

1360<br />

1360<br />

1360<br />

1560<br />

1460<br />

1360<br />

1360<br />

1560<br />

1160<br />

1360<br />

1460<br />

1360<br />

1560<br />

1360<br />

1560<br />

d1<br />

16,05<br />

16,25<br />

16,32<br />

17,2<br />

17,6<br />

18<br />

18,25<br />

19<br />

20,05<br />

20,25<br />

22<br />

22,1<br />

24<br />

24,2<br />

25<br />

26<br />

28<br />

30<br />

32<br />

d1 +0,05<br />

- 0,02<br />

Standard machining from two sides<br />

(machining for heat cartridge from one side)<br />

t1 max.<br />

1560<br />

1160<br />

1160<br />

1160<br />

1160<br />

1560<br />

1360<br />

1460<br />

1560<br />

1160<br />

1560<br />

1160<br />

1560<br />

1160<br />

1560<br />

1560<br />

1160<br />

1560<br />

1160<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

Example:<br />

Standard cooling circuits and counter bores<br />

d1 d2 M t2<br />

6<br />

8<br />

10<br />

19<br />

22<br />

24<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

M 8x0,75<br />

M10x1<br />

R1/8”<br />

M14x1,5<br />

R1/4”<br />

M14x1,5<br />

R1/4”<br />

M16x1,5<br />

R3/8”<br />

18<br />

Two-axis inclined holes can also be<br />

bored without problems<br />

www.meusburger.com<br />

office@meusburger.com<br />

O-ring seals - counterbore<br />

counterbore<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

E 2130/ 7,5 x1,5<br />

E 2130/ 8 x1,5<br />

E 2130/ 9,8 x1,5<br />

E 2130/ 10 x2<br />

E 2130/ 10 x2,4<br />

E 2130/ 11,8x2,4<br />

E 2130/ 12 x2<br />

E 2130/ 13,9x2,4<br />

E 2130/ 15,3x2,4<br />

E 2130/ 17,5x2,4<br />

E 2130/ 19,3x2,4<br />

E 2130/ 21,3x2,4<br />

E 2130/ 23,3x2,4<br />

E 2130/ 25,3x2,4<br />

E 2130/ 27,3x2,4<br />

E 2130/ 28 x3<br />

E 2130/ 30,2x3<br />

E 2130/ 32,2x3<br />

E 2130/ 34,2x3<br />

E 2130/ 35 x2,5<br />

E 2130/ 36 x2<br />

E 2130/ 36 x3<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

20 21<br />

O-ring seal<br />

D1 D2 T d1 d2 d4<br />

7,0<br />

7,5<br />

9,3<br />

11,0<br />

13,2<br />

14,5<br />

16,8<br />

18,5<br />

20,5<br />

22,5<br />

24,5<br />

26,5<br />

27,0<br />

29,3<br />

31,3<br />

33,3<br />

35,0<br />

D 0<br />

+0,1<br />

D 2 0<br />

1 -0,1<br />

11,0<br />

12,5<br />

15,5<br />

17,3<br />

19,5<br />

20,8<br />

23,0<br />

24,8<br />

26,8<br />

28,8<br />

30,8<br />

32,8<br />

35,0<br />

37,0<br />

39,0<br />

41,0<br />

43,0<br />

1,2<br />

1,2<br />

1,2<br />

1,6<br />

1,9<br />

1,9<br />

1,6<br />

1,9<br />

1,9<br />

1,9<br />

1,9<br />

1,9<br />

1,9<br />

1,9<br />

1,9<br />

2,4<br />

2,4<br />

2,4<br />

2,4<br />

2,0<br />

1,6<br />

2,4<br />

+0,05<br />

0<br />

T<br />

d4<br />

d2<br />

d1<br />

7,5<br />

8,0<br />

9,8<br />

10,0<br />

10,0<br />

11,8<br />

12,0<br />

13,9<br />

15,3<br />

17,5<br />

19,3<br />

21,3<br />

23,3<br />

25,3<br />

27,3<br />

28,0<br />

30,2<br />

32,2<br />

34,2<br />

35,0<br />

36,0<br />

36,0<br />

10,5<br />

11,0<br />

12,8<br />

14,0<br />

14,8<br />

16,6<br />

16,0<br />

18,7<br />

20,1<br />

22,3<br />

24,1<br />

26,1<br />

28,1<br />

30,1<br />

32,1<br />

34,0<br />

36,2<br />

38,2<br />

40,2<br />

40,0<br />

40,0<br />

42,0<br />

1,5<br />

1,5<br />

1,5<br />

2,0<br />

2,4<br />

2,4<br />

2,0<br />

2,4<br />

2,4<br />

2,4<br />

2,4<br />

2,4<br />

2,4<br />

2,4<br />

2,4<br />

3,0<br />

3,0<br />

3,0<br />

3,0<br />

2,5<br />

2,0<br />

3,0

Auswerferplatten Ejector set - guiding − Führungen<br />

2 Bohrungen<br />

guiding bores<br />

4 Bohrungen<br />

guiding bores<br />

Position Postition und and Anzahl number der of Bohrungen guiding bores sind to frei be wählbar selected.<br />

Toleranz Tolerance für for die the Position position der of Bohrungen bores +/- 0,01. +/-0,01<br />

d2H7<br />

d2<br />

H7<br />

E 1100<br />

E 1105<br />

d1<br />

d1<br />

+0,3<br />

d2<br />

+0,1<br />

E 1120<br />

E 1125<br />

d2<br />

E 1325<br />

E 1330<br />

d1 d3 t3 d1 d3 t3 d1 d2 d3 t3<br />

Ø 20<br />

+0,018<br />

+0,006 Ø 26 6,4<br />

Ø 26 Ø 32<br />

Ø 30<br />

+0,020<br />

+0,008 Ø 36<br />

Ø 42<br />

+0,022<br />

+0,010 Ø 48<br />

Ø 54<br />

+0,026<br />

+0,012 Ø 60<br />

10.4<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Ø 14<br />

+0,018<br />

+0,006 Ø 18<br />

Ø 16 Ø 20<br />

Ø 18 Ø 22<br />

Ø 24 Ø 28<br />

Ø 28 Ø 32<br />

Ø 30<br />

+0,020<br />

+0,008 Ø 34<br />

Ø 38<br />

+0,022<br />

+0,010 Ø 42<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

t3<br />

6,4 Ø 22<br />

+0,018<br />

+0,006 Ø 12 Ø 26 6,4<br />

Ø 30<br />

+0,020<br />

+0,008 Ø 18 Ø 34<br />

Ø 38<br />

+0,022<br />

+0,010 Ø 24 Ø 42<br />

Ø 46 Ø 30 Ø 50<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

d1<br />

d3<br />

E 1144<br />

d1 d2 d3 t3<br />

Ø 17<br />

+0,018<br />

+0,006 Ø 10 Ø 21<br />

Ø 22 Ø 12 Ø 26<br />

Ø 30<br />

+0,020<br />

+0,008 Ø 18 Ø 34<br />

Ø 38<br />

+0,022<br />

+0,010 Ø 24 Ø 42<br />

Ø 46 Ø 30 Ø 50<br />

www.meusburger.com<br />

office@meusburger.com<br />

6,4<br />

Ejector set - thread insert<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

d1 d3 b1 l3<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

22 23<br />

+1<br />

+0.5<br />

d3 R10<br />

d1<br />

Ø 30<br />

Ø 40<br />

+0.4<br />

b1 +0.2<br />

46<br />

56<br />

E 1515<br />

34<br />

46<br />

6<br />

6<br />

d1 +1<br />

+2<br />

d1 H7<br />

l3 0<br />

+0.02

Chamfers<br />

F/P − Plates and risers<br />

Chamfer sizes / Standard<br />

l a min. a max.<br />

396<br />

596<br />

> 596<br />

1,0<br />

1,4<br />

1,8<br />

Recommended chamfer sizes: 1<br />

1,5<br />

2<br />

3<br />

4<br />

5<br />

6<br />

8<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

l<br />

1,2<br />

1,6<br />

2,0<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

a<br />

45°<br />

www.meusburger.com<br />

office@meusburger.com<br />

Anti-twist protection ejector<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

24 25<br />

+1 0<br />

+0.10<br />

h3 0<br />

h4<br />

+0.02<br />

b3 0<br />

d1<br />

3<br />

3.2<br />

3.5<br />

3.7<br />

4<br />

4.2<br />

4.5<br />

4.7<br />

5<br />

5.2<br />

5.5<br />

6<br />

6.2<br />

6.5<br />

7<br />

7.5<br />

8<br />

8.2<br />

8.5<br />

9<br />

10<br />

12<br />

14<br />

16<br />

20<br />

l3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

7<br />

7<br />

7<br />

8<br />

R3<br />

0<br />

-0.2<br />

b3<br />

4<br />

4<br />

5<br />

5<br />

6<br />

6<br />

6<br />

6<br />

7<br />

7<br />

7<br />

9<br />

9<br />

9<br />

9<br />

9<br />

11<br />

11<br />

11<br />

11<br />

13<br />

15<br />

18<br />

18<br />

22<br />

h3<br />

2.5<br />

2.5<br />

3<br />

3<br />

3.5<br />

3.5<br />

3.5<br />

3.5<br />

4<br />

4<br />

4<br />

5<br />

5<br />

5<br />

5<br />

5<br />

6<br />

6<br />

6<br />

6<br />

7<br />

8<br />

9.5<br />

9.5<br />

11.5<br />

h4<br />

3<br />

3<br />

3.5<br />

3.5<br />

4<br />

4<br />

4<br />

4<br />

5<br />

5<br />

5<br />

6<br />

6<br />

6<br />

6<br />

6<br />

7<br />

7<br />

7<br />

7<br />

8<br />

9<br />

11<br />

11<br />

13<br />

+0.20<br />

+0.10<br />

d1<br />

+0.02<br />

l3 0<br />

R3<br />

1.5<br />

1.5<br />

1.5<br />

1.5<br />

2<br />

2<br />

2<br />

2<br />

2.5<br />

2.5<br />

2.5<br />

2.5<br />

2.5<br />

2.5<br />

2.5<br />

2.5<br />

3<br />

3<br />

3<br />

3<br />

4<br />

5<br />

6<br />

6<br />

8

Anti-twist protection contour core Distortion<br />

Verzug<br />

b3<br />

+0.015<br />

0<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

b<br />

d1<br />

1.5<br />

1.6<br />

1.8<br />

2<br />

2.2<br />

2.5<br />

2.7<br />

3<br />

3.2<br />

3.5<br />

3.7<br />

4<br />

4.2<br />

4.5<br />

5<br />

5.2<br />

5.5<br />

6<br />

6.2<br />

6.5<br />

7<br />

8<br />

8.2<br />

8.5<br />

9<br />

10<br />

10.2<br />

10.5<br />

11<br />

11.5<br />

12<br />

12.5<br />

b<br />

1.05<br />

1.1<br />

1.2<br />

1.5<br />

1.6<br />

1.75<br />

1.85<br />

2<br />

2.1<br />

2.25<br />

2.35<br />

2.5<br />

2.6<br />

2.75<br />

3.5<br />

3.6<br />

3.75<br />

4<br />

4.1<br />

4.25<br />

4.5<br />

5<br />

5.1<br />

5.25<br />

5.5<br />

6<br />

6.1<br />

6.25<br />

6.5<br />

6.75<br />

7<br />

7.25<br />

l3<br />

f<br />

0.3<br />

0.3<br />

0.3<br />

0.5<br />

0.5<br />

0.5<br />

0.5<br />

0.5<br />

0.5<br />

0.5<br />

0.5<br />

0.5<br />

0.5<br />

0.5<br />

0.5<br />

0.5<br />

0.5<br />

0.7<br />

0.7<br />

0.7<br />

0.7<br />

0.7<br />

0.7<br />

0.7<br />

0.7<br />

0.7<br />

0.7<br />

0.7<br />

0.7<br />

0.7<br />

1<br />

1<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

R3<br />

R1<br />

l3 b3<br />

5<br />

5<br />

5<br />

6<br />

6<br />

7<br />

7<br />

8<br />

8<br />

9<br />

9<br />

10<br />

10<br />

10<br />

12<br />

12<br />

12<br />

14<br />

14<br />

14<br />

14<br />

16<br />

16<br />

16<br />

16<br />

18<br />

18<br />

18<br />

18<br />

18<br />

20<br />

20<br />

3.55<br />

3.6<br />

3.7<br />

4.5<br />

4.6<br />

5.25<br />

5.35<br />

6<br />

6.1<br />

6.75<br />

6.85<br />

7.5<br />

7.6<br />

7.75<br />

9.5<br />

9.6<br />

9.75<br />

11<br />

11.1<br />

11.25<br />

11.5<br />

13<br />

13.1<br />

13.25<br />

13.5<br />

15<br />

15.1<br />

15.25<br />

15.5<br />

15.75<br />

17<br />

17.25<br />

f x 45°<br />

+0.025<br />

t3 0<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

H7<br />

d1<br />

R1 R3 t3<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1<br />

1.5<br />

1.5<br />

1.5<br />

1.5<br />

1.5<br />

1.5<br />

1.5<br />

1.5<br />

1.5<br />

1.5<br />

2.5<br />

2.5<br />

2.5<br />

2.5<br />

2.5<br />

2.5<br />

2.5<br />

2.5<br />

2.5<br />

2.5<br />

2.5<br />

2.5<br />

2.5<br />

3<br />

3<br />

2<br />

2<br />

2<br />

2<br />

2<br />

2.5<br />

2.5<br />

3<br />

3<br />

4<br />

4<br />

4<br />

4<br />

4<br />

5<br />

5<br />

5<br />

6<br />

6<br />

6<br />

6<br />

7<br />

7<br />

7<br />

7<br />

8<br />

8<br />

8<br />

8<br />

8<br />

9<br />

9<br />

1.5<br />

1.5<br />

1.5<br />

2<br />

2<br />

2<br />

2<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

3<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

5<br />

7<br />

7<br />

www.meusburger.com<br />

office@meusburger.com<br />

<strong>Machining</strong><br />

Verzugsarme<br />

with<br />

Verzugsarme<br />

Bearbeitung<br />

little distortion<br />

Bearbeitung<br />

Distortion Möglicher<br />

Möglicher possible Verzug<br />

Verzug<br />

durch<br />

durch due to folgende<br />

folgende the following Bearbeitung<br />

Bearbeitung machining<br />

Take Auf<br />

Auf<br />

Verzug special<br />

Verzug<br />

besonders care<br />

besonders of distorsion zu<br />

zu<br />

achten<br />

achten with ist<br />

ist steel bei<br />

bei<br />

Material<br />

Material type 1.2085, 1.2085,<br />

1.2085,<br />

bei<br />

bei<br />

offenen<br />

offenen<br />

Konturen<br />

Konturen<br />

open oder<br />

oder outlines bei<br />

bei<br />

Wärmebehandlungen<br />

Wärmebehandlungen or heat-treatment wie<br />

wie e.g. z.B.<br />

z.B. nitriding.<br />

nitrieren.<br />

nitrieren.<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

26 27

BB<br />

BB<br />

Insulation board<br />

Milled<br />

Milled<br />

P<br />

(max. perm. contact P pressure)<br />

(max. perm. contact pressure)<br />

B<br />

L<br />

S<br />

330<br />

330<br />

or<br />

or<br />

600<br />

600<br />

N/mm²<br />

N/mm²<br />

1200<br />

1200<br />

2400<br />

2400<br />

5<br />

6<br />

8<br />

10<br />

10<br />

Parallel<br />

Parallel<br />

ground<br />

ground<br />

thickness<br />

thickness<br />

B<br />

400<br />

400<br />

L<br />

<strong>Machining</strong><br />

<strong>Machining</strong><br />

data:<br />

data:<br />

3D:<br />

3D:<br />

STEP<br />

STEP<br />

preferred,<br />

preferred,<br />

Parasolid<br />

Parasolid<br />

2D:<br />

2D:<br />

DXF<br />

DXF<br />

or<br />

or<br />

DWG<br />

DWG<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

L<br />

S<br />

600<br />

600<br />

as<br />

as<br />

specified<br />

specified<br />

by<br />

by<br />

customer<br />

customer<br />

L S<br />

L S<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

0.02/100<br />

0.02/100<br />

0.02<br />

0.02<br />

S<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

Roughing 3D<br />

Data import<br />

Stress-relieving heat<br />

treatment<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

28 29<br />

<strong>Machining</strong><br />

WKF - from VISI, Parasolid, Step<br />

direct interfaces (Catia V4, V5, Unigraphics, Pro-E)<br />

Max. size Width: 1,100 mm<br />

Length: 1,600 mm<br />

Weight: 2,500 kg<br />

For exceeding dimensions, the feasibility will be determined accordingly<br />

(clamping, weight, job execution).<br />

Allowance to be selected:<br />

Smallest possible tool Ø:<br />

Angle radius (pocket bottom):<br />

standard 1 - 2 mm<br />

35 mm (R 17,5)<br />

R 3 - R 6<br />

Support areas for subsequent machining to customer specifications.<br />

Any plate which has been massively roughed will be stress-relieved again.<br />

After this process the reference surface will be finished and the<br />

2D machining achieved (e.g. holes, threads, pockets etc.)<br />

Data export We supply the customers with STL files for subsequent machining.

Data transfer via internet or medium<br />

In-house CAD: VISI-CAD (wkf)<br />

2D interfaces: wkf / dxf / dwg<br />

pdf only when combined with wkf / dxf or dwg<br />

Split icons, patterns and blocks in single elements, change polylines into line segments and curves.<br />

3D interfaces: x_t / stp<br />

Direct interfaces: Catia, Pro-E, Unigraphics<br />

No processing: igs<br />

Required data<br />

» Parts list with design details (tolerances, surface roughness, colour tables, ...)<br />

» Detailed drawings, with dimensions and tolerances<br />

» Assembly drawing including accessories<br />

» 3D data<br />

» Complete standard moulds split in single layers<br />

» Thread details (metric, inch, pitch)<br />

Send data to: av@meusburger.com<br />

The contours drawn must be in accordance with the dimensioning (for processing with a CAM workstation)<br />

With respect to 2D+3D data, we assume they are identical.<br />

Subsequent modifications or amendments have to be identified by an amendment index.<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

Stress-relieving heat treatment<br />

A special service for all our customers<br />

Inside our furnaces with a total capacity of 240 tons, the steel we process is heat treated for stress relief. All the<br />

steel we process are subjected to this treatment that creates the best pre-requisites for subsequent machining<br />

with low risk of warping. The critical factor in this process is the long furnace cooling period of 14 hours (35°C<br />

/ hour). If required, machined parts are subjected to stress-relieving heat treatment even between one machining<br />

step and another.<br />

100<br />

20<br />

0 1<br />

2 3 4 5 5 6 6 7 7 8 8 9 9 10 10 11 11 12 12 13 13 14 14 15 16 17 18 19 20 21 22 23 24<br />

30 31<br />

700<br />

600<br />

500<br />

400<br />

300<br />

200<br />

°C<br />

Anwärmzeit heating up Haltezeit maintain Abkühlzeit<br />

cooling period<br />

4 Stunden hours 6 6 Stunden hours 14 Stunden 14 hours= = 35°C / Stunde / hour<br />

h

Grinding<br />

Precision and segment grinding<br />

After machining, the plates are given their final touch on precision grinding machines. Our experienced<br />

staff and state-of-the-art grinding machines ensure absolute precision and top surface qualities.<br />

Maximum workpiece dimensions:<br />

Precision grinding<br />

Max. width: max. 1,500 mm<br />

Max. length: max. 3,000 mm<br />

Max. weight of plate: max. 3,000 kg<br />

Segment grinding<br />

Max. width: max. 846 mm<br />

Max. length: max. 996 mm<br />

Max. weight of plate: max. 3,000 kg<br />

Our sales team is at your service<br />

Meusburger is represented in all European countries by its own field representatives or distribution<br />

partners in order to be able to guarantee competent and friendly service on site. A multi-lingual sales<br />

team and numerous product experts provide additional service from the head office in Wolfurt.<br />

These statistics confirm the company‘s excellent work:<br />

» Supplies to 51 countries<br />

» Over 8,000 customers<br />

» Export rate of 92%<br />

Field service<br />

We have somebody near you<br />

Product managers<br />

We provide excellent practical know-how<br />

In-house customer service<br />

We communicate in 14 languages<br />

Experts<br />

We support you in all specialist areas<br />

32 33

Index<br />

Meusburger Georg GmbH & Co KG<br />

Standard molds<br />

Anti-twist protection ................................................. 25-26<br />

Bores pattern - special ................................................. 7<br />

Chamfers ................................................. 24<br />

Content ................................................. 2<br />

Cooling circuit ................................................. 20<br />

Data transfer ................................................. 30<br />

Distortion ................................................. 27<br />

Ejector set ................................................. 22-23<br />

Eye bolt ................................................. 9<br />

Finishing ................................................. 12<br />

Flame cutting ................................................. 6<br />

Grinding ................................................. 32<br />

Inclined pin ................................................. 17-18<br />

Insulation board ................................................. 28<br />

Interlock ................................................. 13-16<br />

Meusburger bores pattern ....................................... 3-5<br />

O-ring seals ................................................. 21<br />

Roughing ................................................. 11<br />

Roughing 3D ................................................. 29<br />

Slide ................................................. 19<br />

Stress-relieving heat-treatment .................................. 31<br />

Threads ................................................. 8<br />

Top lock ................................................. 10<br />

Kesselstraße 42<br />

A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0<br />

F 00 43 (0) 55 74 / 67 06-11<br />

www.meusburger.com<br />

office@meusburger.com<br />

Your reliable partner<br />

for tool and mould making<br />

Lubricating<br />

» Large range of high-performance<br />

lubricants for all kinds of use in<br />

tool and mould making<br />

Protecting<br />

» Preservatives for reliable<br />

corrosion protection<br />

Cleaning<br />

» Cleaning agents for effective and<br />

fast cleaning of your tools and<br />

moulds<br />

Meusburger Georg GmbH & Co KG | Standard molds | Kesselstr. 42 | A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0 | F -11 | sales@meusburger.com | www.meusburger.com<br />

34 35

© 2012/I Meusburger Georg GmbH & Co KG. All rights reserved. No extract of these documents may<br />

be duplicated or transmitted for whatever purposes without the explicit and written authorization of<br />

Meusburger Georg GmbH & Co KG. Printing or other errors excepted. Technical details subject to changes.<br />

Meusburger Georg GmbH & Co KG | Standard moulds | Kesselstr. 42 | A-6960 Wolfurt<br />

T 00 43 (0) 55 74 / 67 06-0 | F -11 | sales@meusburger.com | www.meusburger.com