Series 1406 Liquid Level Sensors - Norriseal

Series 1406 Liquid Level Sensors - Norriseal

Series 1406 Liquid Level Sensors - Norriseal

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

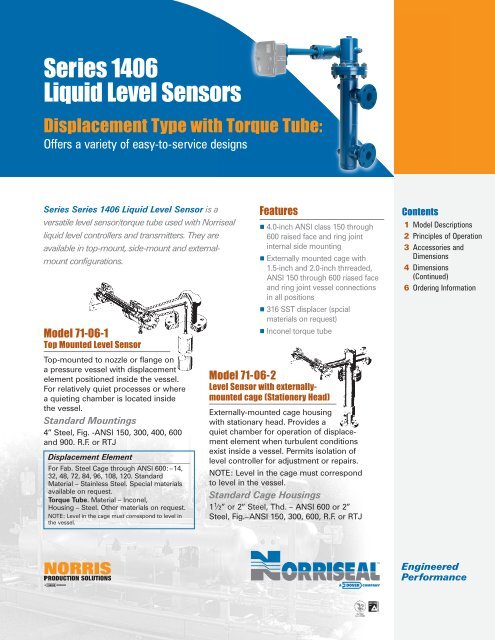

<strong>Series</strong> <strong>1406</strong><br />

<strong>Liquid</strong> <strong>Level</strong> <strong>Sensors</strong><br />

Displacement Type with Torque Tube:<br />

Offers a variety of easy-to-service designs<br />

<strong>Series</strong> <strong>Series</strong> <strong>1406</strong> <strong>Liquid</strong> <strong>Level</strong> Sensor is a<br />

versatile level sensor/torque tube used with <strong>Norriseal</strong><br />

liquid level controllers and transmitters. They are<br />

available in top-mount, side-mount and externalmount<br />

configurations.<br />

Model 71-06-1<br />

Top Mounted <strong>Level</strong> Sensor<br />

Top-mounted to nozzle or flange on<br />

a pressure vessel with displacement<br />

element positioned inside the vessel.<br />

For relatively quiet processes or where<br />

a quieting chamber is located inside<br />

the vessel.<br />

Standard Mountings<br />

4” Steel, Fig. -ANSI 150, 300, 400, 600<br />

and 900. R.F. or RTJ<br />

Displacement Element<br />

For Fab. Steel Cage through ANSI 600:–14,<br />

32, 48, 72, 84, 96, 108, 120. Standard<br />

Material – Stainless Steel. Special materials<br />

available on request.<br />

Torque Tube. Material – Inconel,<br />

Housing – Steel. Other materials on request.<br />

NOTE: <strong>Level</strong> in the cage must correspond to level in<br />

the vessel.<br />

Features<br />

4.0-inch ANSI class 150 through<br />

600 raised face and ring joint<br />

internal side mounting<br />

Externally mounted cage with<br />

1.5-inch and 2.0-inch thrreaded,<br />

ANSI 150 through 600 riased face<br />

and ring joint vessel connections<br />

in all positions<br />

316 SST displacer (spcial<br />

materials on request)<br />

Inconel torque tube<br />

Model 71-06-2<br />

<strong>Level</strong> Sensor with externally-<br />

mounted cage (Stationery Head)<br />

Externally-mounted cage housing<br />

with stationary head. Provides a<br />

quiet chamber for operation of displacement<br />

element when turbulent conditions<br />

exist inside a vessel. Permits isolation of<br />

level controller for adjustment or repairs.<br />

NOTE: <strong>Level</strong> in the cage must correspond<br />

to level in the vessel.<br />

Standard Cage Housings<br />

11 ⁄2” or 2” Steel, Thd. – ANSI 600 or 2”<br />

Steel, Fig.–ANSI 150, 300, 600, R.F. or RTJ<br />

ISO 9001<br />

Cert. #30080<br />

Contents<br />

1 Model Descriptions<br />

2 Principles of Operation<br />

3 Accessories and<br />

Dimensions<br />

4 Dimensions<br />

(Continued)<br />

6 Ordering Information<br />

Engineered<br />

Performance

2 Specifications<br />

Model 71-06-3<br />

Side Mounted <strong>Level</strong> Sensor<br />

Side-mounted to nozzle or flange on a<br />

pressure vessel with displacement element<br />

positioned inside the vessel. For relatively quiet<br />

processes or where a quieting chamber is located<br />

inside the vessel. Also used in corrosive applications<br />

where external piping cannot be used or<br />

where external cage mountings are not practical<br />

because of clogging or vapor lock.<br />

Torque arm between displacement element and<br />

torque tube is 20” long, double the length of top<br />

and external mounted units. Displacement<br />

element is correspondingly lighter and displaces<br />

less volume.<br />

NOTE: Special consideration must be given<br />

to installation of long displacements through<br />

vessel opening<br />

Standard Mountings<br />

4” Steel, Fig. -ANSI 150, 300, 400, 600<br />

and 900. R.F. or RTJ<br />

Model 71-06-6<br />

<strong>Level</strong> Sensor with externally-<br />

mounted cage (Rotatable Head)<br />

Externally-mounted cage housing with<br />

rotatable head. Permits upper cage, torque<br />

tube and controller to be rotated on the<br />

float cage for easier accessibility as<br />

required.<br />

Standard Cage Housings<br />

1 1 ⁄2” or 2” Steel, Thd. – ANSI 600 or 11⁄2” or 2”<br />

Steel, Fig.–ANSI 150, 300, 400, 600, R.F. or RTJ<br />

Torque Tube Assembly<br />

Torque tube assembly consists of a shaft inside a tube. Tube is enclosed at the connector block<br />

end, with shaft welded concentrically to end closure of the tube. At the other end, shaft rotates<br />

in a bearing and connects to a specific gravity rocker arm. No stuffing box or packing gland<br />

required in transmitting rotational movement from torque tube to a specific gravity rocker arm.<br />

Torque tube is welded construction. All critical internal parts exposed to process<br />

are either inconel or 316 stainless steel (important for corrosive services).<br />

Displacement arm is reversible for either right or left hand<br />

mounting of controller or transmitter. No additional parts<br />

required for this reversal. Complete dismantling not<br />

required. Symmetrical connector block permits<br />

mounting of torque tube in either end.<br />

Connector block has no bearing parts;<br />

It’s frictionless, free from freezing or<br />

clogging.<br />

Principles of Operation<br />

Displacement element is positioned in liquid to be<br />

measured. As liquid level changes in vessel,<br />

apparent weight of displacement element (due to<br />

fluid displacement) varies according to amount of<br />

its submergence. This change in weight is converted<br />

to variable angular rotation in torque tube<br />

and produces an output pressure from the controller<br />

that is proportional to liquid level. Output<br />

pressure then positions control valve to regulate<br />

and maintain correct liquid level for process.<br />

72-Pneumatic Controller. Specific gravity rocker<br />

arm and proportional bands are set direct for gravity<br />

ranges between 0.5 and 1.5. For gravities above<br />

1.5 or below 0.5, special elements can be used or<br />

necessary compensation made by proportional<br />

band setting.<br />

1600 Electronic Controller. FM and CSA approved<br />

Class I, Div 1 Groups C&D. Gravity ranges same as<br />

72-45. Two-wire loop powered. Available as transmitter<br />

only or transmitter with proportional plus<br />

integral control. Set point, proportional band, and<br />

integral are entered via key pad.<br />

TORQUE<br />

TUBE<br />

CAGE<br />

HOUSING<br />

DISPLACEMENT ELEMENT<br />

CONTROLLER<br />

MOUNTING END<br />

REMOVABLE<br />

PIN<br />

CONNECTOR<br />

BLOCK

3 Accessories and Dimensions<br />

Accessories<br />

Radiation Fin Torque Tube Housing. For service<br />

temperatures below 0° F and above 800° F.<br />

(Standard torque tube housing without insulation<br />

is suitable for 0° F to 800° F service temperatures if<br />

ambient temperature is below 80°F.)<br />

Side-mounted <strong>Level</strong> Controller for Hub Mounting.<br />

20” torque arm, standard. Other lengths available<br />

Dimensions<br />

For Preliminary Piping Design<br />

on special request. Displacement element, stainless<br />

steel, 50 cu. in. Available in ratings of ANSI<br />

1440 and 3600 CWP.<br />

Gage Glass Assemblies. Consult Factory.<br />

71-06-1 Top Mounted <strong>Level</strong> Sensor 71-06-3 Side Mounted <strong>Level</strong> Sensor<br />

TOP VIEW<br />

SIDE VIEW<br />

TOP VIEW<br />

SIDE VIEW<br />

Dimensions (inches)<br />

Displacement Element<br />

Length (inches)<br />

A<br />

Top Mounted<br />

Steel<br />

B<br />

Side Mounted<br />

A<br />

14 8 7 8 1 ⁄4<br />

32 8 16 17 1 ⁄4<br />

48 8 24 25 1 ⁄4<br />

60 8 30 31 1 ⁄4<br />

72 8 36 37 1 ⁄4<br />

84 8 42 43 1 ⁄4<br />

96 8 48 49 1 ⁄4<br />

108 8 54 55 1 ⁄4<br />

120 8 60 61 1 ⁄4

4 Dimensions (Continued)<br />

71-06-2 <strong>Level</strong> Sensor with externally-mounted cage (Stationary Head)<br />

With Threaded Connections With Flanged Connections<br />

MOUNTING 1 MOUNTING 2<br />

MOUNTING 3 MOUNTING 4<br />

TOP VIEW SIDE VIEW<br />

For Mountings 1, 2, 3 and 4 Cast Steel – 1 1 ⁄2” or 2” ANSI 600 lb.<br />

MOUNTING 5 MOUNTING 6<br />

MOUNTING 7 MOUNTING 8<br />

TOP VIEW SIDE VIEW<br />

Displacement<br />

Element Length<br />

Equalizing Connection Dimensions (inches) Mountings 1, 2, 3 and 4<br />

(inches)<br />

A B C D E F<br />

Steel 14 221 ⁄2 161 ⁄2 191 ⁄4 193 ⁄4 101 ⁄2 73 ⁄4<br />

32 417 ⁄8 357 ⁄8 385 ⁄8 391 ⁄8 207 ⁄8 181 ⁄8<br />

48 577 ⁄8 517 ⁄8 545 ⁄8 551 ⁄8 287 ⁄8 261 ⁄8<br />

60 697 ⁄8 637 ⁄8 665 ⁄8 671 ⁄8 347 ⁄8 321 ⁄8<br />

72 817 ⁄8 757 ⁄8 785 ⁄8 791 ⁄8 407 ⁄8 381 ⁄8<br />

84 937 ⁄8 777 ⁄8 905 ⁄8 911 ⁄8 467 ⁄8 441 ⁄8<br />

96 105 7 ⁄8 997 ⁄8 102 5 ⁄8 1031 ⁄8 527 ⁄8 501 ⁄8<br />

108 117 7 ⁄8 111 7 ⁄8 114 5 ⁄8 1151 ⁄8 547 ⁄8 561 ⁄8<br />

120 129 7 ⁄8 123 7 ⁄8 126 5 ⁄8 1271 ⁄8 647 ⁄8 621 ⁄8<br />

For Mountings 5, 6, 7 and 8 Cast Steel – 11 ⁄2” or 2” ANSI 150, 300, 400 and 600 lb. R. F.<br />

Displacement<br />

Element Length<br />

Equalizing Connection Dimensions (inches) Mountings 5, 6, 7 and 8<br />

(inches)<br />

A B C D E F<br />

14 29 161 ⁄2 221 ⁄4 23 13 3 ⁄4 73 ⁄4<br />

32 483 ⁄8 357 ⁄8 417 ⁄8 423 ⁄8 241 ⁄8 181 ⁄8<br />

48 643 ⁄8 517 ⁄8 577 ⁄8 583 ⁄8 321 ⁄8 261 ⁄8<br />

60 763 ⁄8 637 ⁄8 637 ⁄8 703 ⁄8 381 ⁄8 321 ⁄8<br />

72 883 ⁄8 757 ⁄8 817 ⁄8 823 ⁄8 441 ⁄8 381 ⁄8<br />

84 100 3 ⁄8 877 ⁄8 937 ⁄8 943 ⁄8 501 ⁄8 441 ⁄8<br />

96 112 3 ⁄8 997 ⁄8 1057 ⁄8 1063 ⁄8 561 ⁄8 501 ⁄8<br />

108 124 3 ⁄8 111 7 ⁄8 117 7 ⁄8 118 3 ⁄8 621 ⁄8 561 ⁄8<br />

120 136 3 ⁄8 123 7 ⁄8 129 7 ⁄8 130 3 ⁄8 681 ⁄8 621 ⁄8

Dimensions (Continued<br />

71-06-6 <strong>Level</strong> Sensor with externally-mounted cage (Rotatable Head)<br />

With Threaded Connections With Flanged Connections<br />

MOUNTING 9 MOUNTING 10<br />

MOUNTING 11 MOUNTING 12<br />

TOP VIEW TOP VIEW<br />

For Mountings 9 and 10 – 11 Displacement<br />

Element Length<br />

⁄2” or 2” ANSI 600 lb.<br />

Equalizing Connection Dimensions (inches) Mountings 9 and 10<br />

(inches)<br />

A B C D E F J<br />

14 335 ⁄8 18 11 14 4 7 161 ⁄2<br />

32 5211 ⁄16 373 ⁄8 213 ⁄8 32 53 ⁄8 16 357 ⁄8<br />

48 6811 ⁄16 533 ⁄8 293 ⁄8 48 53 ⁄8 24 517 ⁄8<br />

60 8011 ⁄16 653 ⁄8 353 ⁄8 60 53 ⁄8 32 637 ⁄8<br />

72 9211 ⁄16 773 ⁄8 413 ⁄8 72 53 ⁄8 36 757 ⁄8<br />

84 104 11 ⁄16 893 ⁄8 473 ⁄8 84 53 ⁄8 42<br />

96 116 11 ⁄16 1013 ⁄8 533 ⁄8 96 53 ⁄8 48<br />

108 128 11 ⁄16 113 3 ⁄8 593 ⁄8 108 53 ⁄8 54<br />

120 14011 ⁄16 125 3 ⁄8 653 ⁄8 120 53 ⁄8 60<br />

For Mountings 11 and 12 – 11 Displacement<br />

Element Length<br />

⁄2” or 2” ANSI 600 lb. R. F.<br />

Equalizing Connection Dimensions (inches) Mountings 9 and 10<br />

(inches) A B C E F G H J<br />

14 3611 ⁄16 211 ⁄4 141 ⁄4 335 ⁄16 14 4 11 161 ⁄2<br />

32 5515 ⁄16 405 ⁄8 245 ⁄8 5211 ⁄16 32 53 ⁄8 16 357 ⁄8<br />

48 7115 ⁄16 565 ⁄8 325 ⁄8 6811 ⁄16 48 53 ⁄8 24 517 ⁄8<br />

60 8315 ⁄16 565 ⁄8 385 ⁄8 8011 ⁄16 60 53 ⁄8 30 637 ⁄8<br />

72 9515 ⁄16 805 ⁄8 445 ⁄8 9211 ⁄16 72 53 ⁄8 36 757 ⁄8<br />

84 10715 ⁄16 925 ⁄8 505 ⁄8 10411 ⁄16 84 53 ⁄8 42<br />

96 11915 ⁄16 104 5 ⁄8 565 ⁄8 11511 ⁄16 96 53 ⁄8 48<br />

108 131 15 ⁄16 116 5 ⁄8 625 ⁄8 12811 ⁄16 108 53 ⁄8 54<br />

120 14315 ⁄16 1285 ⁄8 685 ⁄8 14011 ⁄16 120 53 ⁄8 60<br />

5

6<br />

1. Model Number:<br />

Top Mounted <strong>Level</strong> Sensor 71-06-1<br />

Side Mounted <strong>Level</strong> Sensor 71- 06-3<br />

<strong>Level</strong> Sensor, externally-mounted<br />

cage with rotatable head 71- 06-6<br />

2. Indicating Controller Electronic<br />

1610 pneumatic 72- 45-1<br />

3. Non-Indicating Controller Electronic 72- 45-1<br />

4. Transmitter Electronic: 1620<br />

5. Cage Housing: Size, Material, Type<br />

ANSI Rating<br />

6. Displacement Element: Length and Material<br />

7. Torque Tube: Material for tube<br />

and housing<br />

Control Signal Output: 3-15, 3-27, 6-30 psi<br />

Ordering Information<br />

©2013 Dover Corporation/<strong>Norriseal</strong> and its affiliates. This manual, including all text and<br />

images, is a copyrighted work of Dover Corporation/<strong>Norriseal</strong> and its affiliates. It may<br />

not be, in whole or in part, photocopied, scanned, or otherwise reproduced, revised,<br />

or publicly displayed, without prior written permission from <strong>Norriseal</strong>. This manual is<br />

for use only with the new <strong>Norriseal</strong> valves and/or controllers listed in the manual. It<br />

may not be distributed with, and is not for use with, any remanufactured products.<br />

Please contact your <strong>Norriseal</strong> representative<br />

for more details and assistance in specifying<br />

the optimal solution for your application.<br />

Engineered Performance<br />

11122 West Little York • Houston, Texas 77041<br />

Tel: 713·466·3552 • Fax: 713·896·7386<br />

www.norriseal.com<br />

8. Accessories: Radiation fin torque tube housing<br />

Gage glass assembly.<br />

(Specify tubular or reflex type)<br />

Side-mounted level controller for<br />

hub mounting. (Specify length of<br />

torque arm and pressure rating)<br />

When ordering 72-45 or 1600<br />

Transmitter/Controller specify:<br />

1. Minimum pressure of instrument available<br />

2. Transmitter ouptup range<br />

3. Receiver type, dial size and model number<br />

4. Availability of 24VDC power source (1600 only)<br />

Due to the continuous improvement program at <strong>Norriseal</strong>, specifications and/or prices<br />

are subject to change without notice or obligation.<br />

All trademarks contained herein are the property of their respective owners.<br />

0<strong>1406</strong>-0113T