MAINTENANCE NOV 2011.pdf

MAINTENANCE NOV 2011.pdf

MAINTENANCE NOV 2011.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

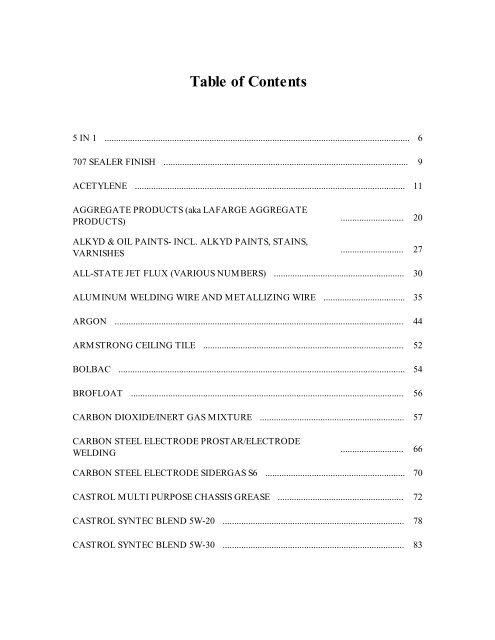

Table of Contents<br />

5 IN 1 ................................................................................................................................... 6<br />

707 SEALER FINISH ......................................................................................................... 9<br />

ACETYLENE .................................................................................................................... 11<br />

AGGREGATE PRODUCTS (aka LAFARGE AGGREGATE<br />

PRODUCTS)<br />

ALKYD & OIL PAINTS- INCL. ALKYD PAINTS, STAINS,<br />

VARNISHES<br />

........................... 20<br />

........................... 27<br />

ALL-STATE JET FLUX (VARIOUS NUMBERS) ........................................................ 30<br />

ALUMINUM WELDING WIRE AND METALLIZING WIRE ................................... 35<br />

ARGON ............................................................................................................................ 44<br />

ARMSTRONG CEILING TILE ...................................................................................... 52<br />

BOLBAC ........................................................................................................................... 54<br />

BROFLOAT ..................................................................................................................... 56<br />

CARBON DIOXIDE/INERT GAS MIXTURE .............................................................. 57<br />

CARBON STEEL ELECTRODE PROSTAR/ELECTRODE<br />

WELDING<br />

........................... 66<br />

CARBON STEEL ELECTRODE SIDERGAS S6 ............................................................ 70<br />

CASTROL MULTI PURPOSE CHASSIS GREASE ...................................................... 72<br />

CASTROL SYNTEC BLEND 5W-20 .............................................................................. 78<br />

CASTROL SYNTEC BLEND 5W-30 .............................................................................. 83

CASTROL SYNTEC BLEND 10W-30 ............................................................................ 88<br />

CASTROL SYNTEC BLEND 10W-40 ............................................................................ 94<br />

CASTROL SYNTEC BLEND 20W-50 .......................................................................... 100<br />

CASTROL SYNTEC BLEND TRUCK 15W-40 ........................................................... 106<br />

CGC PLASTERS-BASECOAT AND GAUGING ....................................................... 112<br />

CHEVRON SRI GREASE .............................................................................................. 120<br />

COMET DISINFECTANT CLEANSER W CHLORINAL<br />

(PROFESSIONAL LINE)<br />

......................... 129<br />

COMPUCESSORIES POWER DUSTER (AKA DYMEL) .......................................... 134<br />

CRETE ............................................................................................................................ 139<br />

DEEP LUBE .................................................................................................................... 141<br />

DYMEL (AKA COMPUCESSORIES POWER DUSTER) .......................................... 144<br />

ESAB MILD STEEL COVERED ELECTRODES ......................................................... 149<br />

GRINDING & CUTTING WHEELS, RESINOID, CUP WHEELS,<br />

MOUNTED POINTS (RESINOID BINDED ABRASIVES)<br />

......................... 155<br />

HELIUM ......................................................................................................................... 160<br />

INDUSTRIAL ASPHALT BUR TYPE I, II, III, IV ...................................................... 167<br />

KOOL KUT 24 B ........................................................................................................... 173<br />

KRYLON INDUSTRIAL TOUGH COAT SANDABLE<br />

PRIMER-RED OXIDE<br />

LAFARGE AGGREGATE PRODUCTS (AKA AGGREGATE<br />

PRODUCTS)<br />

......................... 180<br />

......................... 185<br />

LAFARGE COLD PATCH ASPHALT ........................................................................ 192

LAFARGE HOT MIX ASPHALT (HMA) .................................................................. 198<br />

LAFARGE QPR - ASPHALT REPAIR ........................................................................ 204<br />

LAFARGE READY MIX CONCRETE (CONCRETE) ............................................... 209<br />

LAFARGE SAND AND GRAVEL ............................................................................... 215<br />

LATEX PAINTS (ALL)- INCL. LOW VOC LATEX SEMI GLOSS,<br />

ULTRA 9600 LATEX INTERIOR SEMI GLOSS, ENAMEL LOW<br />

ODOUR LOW VOC<br />

......................... 221<br />

LEPAGE PRES-TITE CONTACT CEMENT .............................................................. 224<br />

LUBRIPLATE NON-DETERGENT MOTOR OIL 30 ................................................ 227<br />

MAGNALAC PRECATALYZED LACQUER - BLACK SATIN .............................. 232<br />

MAGNALAC PRECATALYZED LACQUER - SATIN 35 ........................................ 238<br />

MAN-MADE VITREOUS CEILINGS AND WALL PANELS<br />

(CLASS A)<br />

......................... 244<br />

METAL ALLOY (AKA WELCO 15/WELCO 15FC) ................................................... 246<br />

MICROFLO .................................................................................................................... 255<br />

NATUREWOOD TREATED WOOD (AKA OSMOSE PRESSURE<br />

TREATED WOOD)<br />

......................... 258<br />

OXYGEN ........................................................................................................................ 263<br />

POLY FILLER RT .......................................................................................................... 271<br />

POLY PLASTER OF PARIS .......................................................................................... 273<br />

PORTLAND CEMENT ................................................................................................. 275<br />

POWERFLO ................................................................................................................... 282<br />

PRES-TITE CONTACT CEMENT ............................................................................... 284

PROPANE ...................................................................................................................... 287<br />

QPR - ASPHALT REPAIR ............................................................................................ 295<br />

RAIN-X DE-ICER WINDSHIELD WASHER FLUID ................................................. 300<br />

SAND AND GRAVEL ................................................................................................... 307<br />

SOLIDAIRE CITRUS ..................................................................................................... 313<br />

SOLIDAIRE GOLD ........................................................................................................ 318<br />

SOLIDAIRE RED ........................................................................................................... 323<br />

SOLIDAIRE SILVER ...................................................................................................... 328<br />

SOLIDAIRE SPEARMINT ............................................................................................ 333<br />

SOLDER ALLOYS CONTAINING LEAD ................................................................... 338<br />

STATICIDE INDUSTRIAL WIPES .............................................................................. 340<br />

SUPER GLAZE ALUMINUM ELECTRODES AND RODS<br />

(VARIOUS NUMBERS)<br />

......................... 345<br />

SYNKOOL 1200 ............................................................................................................. 347<br />

SYNTHETIC RESINOID TECHNOLOGY .................................................................. 349<br />

TALON RODENTICIDE PELLETS ............................................................................. 353<br />

TITEBOND II PREMIUM WOOD GLUE ................................................................... 359<br />

TREMCLAD FAST DRY PAINT- AEROSOL ............................................................ 366<br />

TREMCLAD FAST DRY PAINT- BRUSH ................................................................ 368<br />

TUBULAR ARC WELDING ELECTRODES FOR FLUX CORED,<br />

METAL CORED & SUBMERGED ARC WELDING<br />

......................... 370<br />

ULTRA LIFT-OFF ......................................................................................................... 373

UNIVERSAL STONE ..................................................................................................... 374<br />

UNLEADED GASOLINE .............................................................................................. 377<br />

VALVE ACTION PAINT MARKER (VARIOUS COLOURS) .................................. 390<br />

VALVOLINE SAE 30 NON-DETERGENT MOTOR OIL (3047) .............................. 397<br />

VARSOL DX 3139 SOLVENT ...................................................................................... 406<br />

WD-40 AEROSAL .......................................................................................................... 417<br />

WD-40 BULK LIQUID .................................................................................................. 421<br />

WD-40 SMART STRAW AEROSOL ........................................................................... 425<br />

WELCO 15/WELCO 15FC (AKA METAL ALLOY) ................................................... 429<br />

WELDING CONSUMABLES (VARIOUS-DURANICKEL,<br />

INCOLOY, INCONEL, INCO-CORED, MONEL, NICKEL, NILO,<br />

NIMONIC, NI-ROD, INCOFLUX, INCO-WELD)<br />

......................... 438<br />

WELDING ELECTRODES ............................................................................................ 456<br />

WELDING ELECTRODES - CARBON STEEL PROSTAR ........................................ 459<br />

WELDING ELECTRODES - CARBON STEEL SIDERGAS S6 .................................. 463<br />

WELDING ELECTRODES - MILD STEEL COVERED .............................................. 465<br />

WELDING ELECTRODES/RODS - ALUMINUM .................................................... 471<br />

WELDING RODS - W1060 (R45)-W1200 (R60) .......................................................... 473<br />

WELDING WIRE - ALUMINUM WELDING & METALLIZING<br />

WIRE<br />

......................... 481<br />

WINTERGREEN ARTIFICIAL FLAVOURING ......................................................... 490

00007443 MATERIAL SAFETY DATA SHEET Page 1<br />

BRODI SPECIALTY PRODUCTS LTD<br />

250 COCHRANE DRIVE, UNIT 9<br />

MARKHAM; ONTARIO; L3R 8E5<br />

CANADA<br />

PRODUCT: 5 in 1<br />

Section 01: CHEMICAL PRODUCT AND COMPANY IDENTIFICATION<br />

MANUFACTURER ................................................. Brodi Specialty Products Ltd.<br />

250 Cochrane Drive, Unit 9<br />

Markham,<br />

Ontario<br />

Canada<br />

L3R 8E5<br />

905-475-6084<br />

PRODUCT NAME................................................... 5 in 1<br />

CHEMICAL FAMILY................................................ HYDROCARBONS.<br />

MOLECULAR WEIGHT........................................... NOT APPLICABLE.<br />

CHEMICAL FORMULA........................................... NOT APPLICABLE.<br />

TRADE NAMES & SYNONYMS.............................. 5 in 1<br />

PRODUCT USES.................................................... MOISTURE BARRIER.<br />

LAB BOOK NUMBER.............................................. F 01-093.<br />

Sec tio n 02: COMPOSITION/INFORMATION INGREDIENTS<br />

Hazardous Ingredients % Exposure Limit C.A.S.# LD/50, Route,Species LC/50 Route,Species<br />

HYDROTREATED MIDDLE<br />

DISTILLATE<br />

60-90 N/A 64742-46-7 NOT AVAILABLE NOT AVAILABLE<br />

MINERAL OIL 10-30 N/A 8042-47-5 NOT AVAILABLE NOT AVAILABLE<br />

DIPROPYLENE GLYCOL METHYL<br />

ETHER<br />

1-5 100 ppm 34590-94-8 5135 mg/kg ORAL - RAT NOT AVAILABLE<br />

PROPRIETARY COMPONENTS 1-5<br />

ACETONE 1-5 750 ppm 67-64-1 >9750 mg/kg ORAL - RAT >16,000 ppm (4 hr) INHAL -<br />

RAT<br />

CARBON DIOXIDE 1 - 5 5000 ppm 124-38-9 NOT APPLICABLE NOT AVAILABLE<br />

Sec tion 03: HAZARDS IDENTIFICATION<br />

ROUTE OF ENTRY:<br />

INGESTION............................................................. MAY CAUSE HEADACHE, NAUSEA, VOMITING AND WEAKNESS.<br />

INHALATION........................................................... INHALATION OF SOLVENTS MAY CAUSE IRRITATION. PROPELLANT IS A SIMPLE<br />

ASPHYXIANT.<br />

EYE CONTACT....................................................... VAPORS MAY IRRITATE.<br />

SKIN ABSORPTION................................................ NO DATA AVAILABLE FOR THIS PRODUCT MIXTURE.<br />

SKIN CONTACT...................................................... MAY CAUSE IRRITATION.<br />

EFFECTS OF ACUTE EXPOSURE........................ DIZZINESS, NAUSEA. IRRITATION TO SKIN & EYES.<br />

EFFECTS OF CHRONIC EXPOSURE................... SOLVENTS MAY CAUSE DEFATTING DERMATITIS .<br />

EXPOSURE LIMIT OF MATERIAL......................... SEE SECTION 2.<br />

Section 04: FIRST AID MEASURES<br />

EMERGENCY FIRST AID PROCEDURE .............. IN CASE OF EYE CONTACT, FLUSH IMMEDIATELY WITH PLENTY OF WATER FOR AT LEAST 15<br />

MINUTES AND GET MEDICAL ATTENTION. FOR SKIN, WASH THOROUGHLY WITH SOAP AND<br />

WATER. IF AFFECTED BY INHALATION OF VAPOUR OR SPRAY MIST, REMOVE TO FRESH AIR.<br />

IF SWALLOWED; DO NOT INDUCE VOMITING, GET MEDICAL ATTENTION.<br />

Sec tio n 05: FIRE FIGHTING MEASURES<br />

AUTO IGNITION TEMPERATURE (°C).................. 465.<br />

SPECIAL PROCEDURES....................................... WATER FROM FOGGING NOZZLES MAY BE USED TO COOL CLOSED CONTAINERS TO<br />

PREVENT BUILD-UP IF EXPOSED TO EXTREME TEMPERATURES. FULL PROTECTIVE<br />

EQUIPMENT INCLUDING SELF CONTAINED BREATHING APPARTATUS SHOULD BE WORN IN A<br />

FIRE INVOLVING THIS MATERIAL.<br />

FLAMMABILITY....................................................... NOT A FLAMMABLE PRODUCT (AS PER CANADIAN AEROSOL REGULATIONS).<br />

IF YES, UNDER WHICH CONDITIONS ................ EXCESSIVE HEAT, SPARKS AND OPEN FLAME.<br />

EXTINGUISHING MEDIA........................................ WATER, CARBON DIOXIDE, DRY CHEMICAL, FOAM.<br />

UPPER FLAMMABLE LIMIT................................... 12.8.<br />

(% BY VOLUME)<br />

LOWER FLAMMABLE LIMIT.................................. 2.6.<br />

(% BY VOLUME)<br />

EXPLOSION DATA<br />

SENSITIVITY TO STATIC DISCHARGE........... NOT APPLICABLE.<br />

SENSITIVITY TO IMPACT................................. NOT APPLICABLE.<br />

HAZARDOUS COMBUSTION

00007443 MATERIAL SAFETY DATA SHEET Page 2<br />

PRODUCT: 5 in 1<br />

Sec tio n 05: FIRE FIGHTING MEASURES<br />

PRODUCTS............................................................ HYDROCARBON FUMES AND SMOKE. CARBON MONOXIDE WHERE COMBUSTION IS<br />

INCOMPLETE.<br />

AEROSOL FLAME PROJECTION<br />

CLASSIFIED AS:..................................................... 0 cm.<br />

FLASHBACK........................................................... NONE.<br />

FLASH POINT(°C),TAG CLOSED-CUP ................. LOWEST KNOWN VALUE IS ACETONE @ -18C.<br />

(CONCENTRATE)<br />

Section 06: ACCIDENTAL RELEASE MEASURES<br />

LEAK/SPILL............................................................. REMOVE ALL SOURCES OF IGNITION. USE AN INERT ABSORBENT MATERIAL, AND<br />

NON-SPARKING TOOLS. VENTILATE AREA. PREVENT FROM ENTERING A WATERCOURSE.<br />

Sec tio n 07: HANDLING AND STORAGE<br />

STORAGE NEEDS.................................................. KEEP AWAY FROM HEAT, SPARKS, AND OPEN FLAMES.<br />

ENGINEERING CONTROLS.................................. VENTILATION - LOCAL (MECHANICAL IF USED INDOORS ON A CONTINUOUS BASIS).<br />

HANDLING PROCEDURES AND EQUIPMENT..... STORE IN A COOL, WELL VENTILATED AREA NOT TO EXCEED 50 DEG C.<br />

SYNERGISTIC MATERIALS................................... NONE KNOWN.<br />

Section 08: EXPOSURE CONTROLS/PERSONAL PROTECTION<br />

GLOVES/ TYPE...................................................... NOT NORMALLY REQUIRED.<br />

RESPIRATORY/TYPE............................................ IF USED INDOORS ON A CONTINUOUS BASIS, USE OF A CARTRIDGE TYPE RESPIRATOR<br />

(NIOSH/MSHATC 23C OR EQUIVALENT) IS RECOMMENDED.<br />

EYE/TYPE............................................................... SAFETY GLASSES.<br />

FOOTWEAR/TYPE................................................. NOT NORMALLY REQUIRED.<br />

OTHER/TYPE.......................................................... NOT REQUIRED.<br />

Section 09: PHYSICAL AND CHEMICAL PROPERTIES<br />

PHYSICAL STATE.................................................. LIQUID.<br />

APPEARANCE........................................................ CLEAR AMBER LIQUID.<br />

ODOR...................................................................... HYDROCARBON.<br />

ODOR THRESHOLD............................................... NOT AVAILABLE.<br />

VAPOUR PRESSURE(PSIG)-AEROSOL............... 90-110.<br />

@ 20 C<br />

BOILING POINT (°C)(CONC).................................. >260 deg C.<br />

EVAPORATION RATE............................................ LESS THAN 1.<br />

n-BUTYL ACETATE = 1<br />

VAPOUR DENSITY (AIR=1)................................... GREATER THAN 1.<br />

(BY WEIGHT)<br />

SOLUBILITY IN WATER g/L (20°C)........................ NEGLIGIBLE.<br />

pH............................................................................ NOT APPLICABLE.<br />

SPECIFIC GRAVITY (LIQUID)................................ 0.80-0.86.<br />

COEFFICIENT OF WATER\OIL DIST..................... NOT AVAILABLE.<br />

FREEZING POINT: (°C).......................................... NOT AVAILABLE.<br />

AEROSOL PERCENT VOLATILE........................... NOT AVAILABLE.<br />

(BY WEIGHT).<br />

Section 10: STABILITY AND REACTIVITY<br />

HAZARDOUS PRODUCTS OF<br />

DECOMPOSITION.................................................. HYDROCARBON FUMES AND SMOKE. CARBON MONOXIDE WHERE COMBUSTION IS<br />

INCOMPLETE.<br />

CHEMICAL STABILITY:<br />

YES......................................................................... UNDER NORMAL CONDITIONS.<br />

NO, WHICH CONDITIONS ................................... NOT APPLICABLE.<br />

COMPATIBILITY WITH OTHER SUBSTANCES:<br />

NO, WHICH ONES ................................................ STRONG OXIDIZING AGENTS.<br />

REACTIVITY CONDITIONS .................................. NOT APPLICABLE.<br />

Section 11: TOXICOLOGICAL INFORMATION<br />

REPRODUCTIVE EFFECTS................................... NO INFORMATION IS AVAILABLE AND NO ADVERSE REPRODUCTIVE EFFECTS ARE<br />

ANTICIPATED.<br />

IRRITANCY OF MATERIAL.................................... SKIN/EYE IRRITANT.<br />

SENSITIZING CAPABILITY OF MATERIAL........... UNKNOWN.<br />

CARCINOGENICITY OF MATERIAL...................... THE INGREDIENTS OF THIS PRODUCT ARE NOT LISTED AS CARCINOGENS BY NTP,<br />

(NATIONAL TOXICOLOGY PROGRAM), NOT REGULATED AS CARCINOGENS BY OSHA,<br />

(OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION), AND HAVE NOT BEEN EVALUATED<br />

BY IARC,(INTERNATIONAL AGENCY FOR RESEARCH ON CANCER), NOR BY ACGIH<br />

(AMERICAN CONFERENCE OF GOVERNMENTAL INDUSTRIAL HYGIENISTS).<br />

TERATOGENICITY................................................. NO INFORMATION IS AVAILABLE AND NO ADVERSE TERATOGENIC EFFECTS ARE<br />

ANTICIPATED.<br />

MUTAGENICITY..................................................... NO INFORMATION IS AVAILABLE AND NO ADVERSE MUTAGENIC EFFECTS ARE<br />

ANTICIPATED.

00007443 MATERIAL SAFETY DATA SHEET Page 3<br />

PRODUCT: 5 in 1<br />

Section 12: ECOLOGICAL CONSIDERATIONS<br />

ENVIRONMENTAL.................................................. NOT AVAILABLE.<br />

Section 13: DISPOSAL CONSIDERATIONS<br />

WASTE DISPOSAL................................................. DO NOT PUNCTURE OR INCINERATE CONTAINERS, EVEN WHEN EMPTY. DISPOSE OF IN<br />

ACCORDANCE WITH LOCAL, PROVINCIAL AND FEDERAL REGULATIONS.<br />

Section 14: TRANSPORTATION INFORMATION<br />

T.D.G. CLASSIFICATION....................................... CONSUMER COMMODITY (AEROSOLS, UN1950, CLASS 2.2).<br />

D.O.T. CLASSIFICATION....................................... CONSUMER COMMODITY, ORM-D.<br />

Sec tion 15: REGULATORY INFORMATION<br />

CANADIAN REGULATIONS:<br />

---------------------------------------<br />

WHMIS CLASSIFICATION...................................... A,D2B.<br />

CNFC SECTION 3.3.5............................................. LEVEL 3.<br />

CEPA (Canadian Enviromental Protection Act) ALL SUBSTANCES IN THIS PRODUCT ARE LISTED ON THE CANADIAN DOMESTIC<br />

SUBSTANCES LIST (DSL) OR ARE NOT REQUIRED TO BE LISTED.<br />

U.S. REGULATIONS:<br />

------------------------------<br />

HMIS RATING HEALTH.......................................... 1 SLIGHT HAZARD.<br />

HMIS RATING FLAMMABILITY.............................. 1 SLIGHT HAZARD.<br />

HMIS RATING REACTIVITY................................... 0 MINIMAL HAZARD.<br />

HMIS RATING PERSONAL PROTECTION............ B.<br />

NFPA CODE 30B.................................................... LEVEL 3.<br />

SARA 313 INFORMATION:..................................... THIS PRODUCT CONTAINS NO INGREDIENTS SUBJECT TO THE REPORTING REQUIREMENTS<br />

OF SECTION 313 OF THE EMERGENCY PLANNING AND COMMUNITY RIGHT-TO-KNOW ACT OF<br />

1986 AND OF 40 CFR 372. .<br />

CAS #: CHEMICAL NAME: .<br />

N/A.<br />

CALIFORNIA PROPOSITION 65:........................... THE FOLLOWING STATEMENT IS MADE IN ORDER TO COMPLY WITH THE CALIFORNIA SAFE<br />

DRINKING WATER AND TOXIC ENFORCEMENT ACT OF 1986: .<br />

WARNING: THIS PRODUCT DOES NOT INTENTIONALLY CONTAIN ANY CHEMICALS KNOWN<br />

TO THE STATE OF CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS OR OTHER<br />

REPRODUCTIVE HARM.<br />

. CAS #: CHEMICAL NAME:<br />

. N/A.<br />

TSCA (Toxic Substances Control Act).................... ALL COMPONENT OF THIS PRODUCT ARE LISTED ON THE TSCA INVENTORY. ANY<br />

IMPURITIES PRESENT IN THIS PRODUCT ARE EXEMPT FROM LISTING.<br />

VOC (w/w%)............................................................ 5.<br />

Section 16: OTHER INFORMATION<br />

NOTICE FROM BRODI SPECIALTY PRODUCTS THE INFORMATION ON THIS MATERIAL SAFETY DATA SHEET IS PROVIDED BY BRODI<br />

LTD. SPECIALTY PRODUCTS LTD. FREE OF CHARGE. WHILE BELIEVED TO BE RELIABLE, IT IS<br />

INTENDED FOR USE BY SKILLED PERSONS AT THEIR OWN RISK. BRODI SPECIALTY<br />

PRODUCTS LTD. ASSUMES NO RESPONSIBILITY FOR EVENTS RESULTING OR DAMAGES<br />

INCURRED FROM ITS USE. THE INFORMATION ON THIS MATERIAL SAFETY DATA SHEET<br />

RELATES ONLY TO THE SPECIFIC MATERIAL DESIGNATED HEREIN AND DOES NOT RELATE<br />

TO USE IN COMBINATION WITH ANY OTHER MATERIAL OR IN ANY PROCESS.<br />

PREPARED BY....................................................... MSDS Co-ordinator, (877-744-0751) ext 205, Brodi Specialty Products Ltd.<br />

PREPARATION DATE ........................................... Jan01/09

707 Sealer Finish<br />

MATERIAL SAFETY DATA SHEET Page of<br />

SECTION 1 - COMPANY INFORMATION<br />

Product usage: Floor finish<br />

Product type: Water based acrylic copolymer emulsion<br />

WHMIS Class: Not Controlled<br />

Hazard Rating: Health: (1) Slight; Fire (0) Insignificant; Reactivity: (0) Insignificant<br />

TDG Class: Not Regulated.<br />

TDG Class: Not Controlled<br />

Supplier name and address: Manufacturer’s name and address<br />

Corporate Chemicals & Equipment Refer to Supplier<br />

7 Neilson Street<br />

St. Catharines, ON L2M 5V9<br />

(905) 682-8888 Emergency Telephone# CANUTEC (613) 996-6666<br />

SECTION 2 - HAZARDOUS INGREDIENTS<br />

INGREDIENT % CAS# TOXICITY<br />

Diethylene Glycol Ethyl Ether < 5 111-90-0 LD50 (oral-rat) 6500 mg/kg. LC50 1820 ppm<br />

Tributoxyethyl Phosphate < 5 78-51-3 LD50 (oral) 6730 mg/kg/<br />

Ammonia < 0.2 7664-41-7 LD50 (oral rats) 340 mg/kg. LCLo (inhalationrat)<br />

2000 ppm/4h. TLV (NH3) 25 ppm<br />

SECTION 3 - HAZARDS IDENTIFICATION<br />

Physical state : Liquid. Product is sold ready to use.<br />

Emergency overview<br />

MAY CAUSE EYE IRRITATION.<br />

Avoid contact with eyes. Wash thoroughly after handling.<br />

Routes of entry : Skin contact, Eye contact, Inhalation, Ingestion<br />

Potential acute health effects<br />

Eyes : Slightly irritating to the eyes. Product is sold ready to use.<br />

Skin : Slightly irritating to the skin.<br />

Inhalation : No known significant effects or critical hazards.<br />

Ingestion : No known significant effects or critical hazard<br />

Effects of Acute Exposure to:<br />

First Aid Procedures...<br />

SECTION 4 - FIRST AID MEASURES<br />

Skin: May cause irritation of sensitive skin<br />

Eyes: May cause irritating, watering of eyes and inflammation of conjunctiva.<br />

Ingestion: G. I. tract upsets, nausea, vomiting.<br />

Inhalation: If misted, may cause irritation of mucous membranes, coughing.<br />

Skin: Remove contaminated clothing. Wash exposed areas with running water.<br />

Eyes: Flush with water running water for 30 minutes lifting the upper and lower eyelids<br />

occasionally. Remove contact lenses. Get medical attention.<br />

Ingestion: Do not induce vomiting. If victim is alert and not convulsing, give 1-2 glasses of water to<br />

dilute material. Immediately contact local poison control centre. Vomiting should be<br />

induced under the direction of a physician or a poison control centre. If spontaneous

MATERIAL SAFETY DATA SHEET Page of<br />

vomiting occurs, have victim lean forward with head down to avoid breathing in of<br />

vomitus, rinse mouth and administer more water. Immediately transport victim to an<br />

emergency facility.<br />

Inhalation: Move victim to fresh air. Give artificial respiration only if breathing has stopped. Give<br />

cardiopulmonary resuscitation (cpr) if there is no is no breathing and no pulse.<br />

Obtain medical attention immediately.<br />

SECTION 5 - FIRE FIGHTING MEASURES<br />

Flash point: Over 120 Deg. C. after drying<br />

Flammability: Non-Flammable<br />

Combustion products: After drying, oxides of carbon, nitrogen and incomplete combustion products<br />

To Extinguish: Water fog, carbon dioxide, dry chemical<br />

Other: None<br />

SECTION 6 - ACCIDENTAL RELEASE MEASURES<br />

Personal precautions : Use personal protective equipment as required. Product is sold ready to use.<br />

Environmental precautions : Avoid contact of large amounts of spilt material and<br />

runoff with soil and surface waterways.<br />

Methods for cleaning up : Use a water rinse for final clean-up.<br />

SECTION 7 - HANDLING AND STORAGE<br />

As with all chemicals there are known and unknown effects on humans. Minimize<br />

exposure of all chemicals, including this product, to skin, respiratory system, and eyes.<br />

Keep out of reach of children. Avoid contamination of food.<br />

Wash thoroughly after handling. Store in cool dry area. Do not freeze.<br />

SECTION 8 - EXPOSURE CONTROLS & PROTECTIVE EQUIPMENT<br />

Ventilation: Normal building ventilation is adequate.<br />

Breathing Protection: Not usually necessary<br />

Skin Protection: Not usually necessary<br />

Eye Protection: Not usually necessary<br />

SECTION 9 - PHYSICAL AND CHEMICAL PROPERTIES<br />

Appearance: White milk-like emulsion Density (g/ml): 1.01<br />

pH as is: 8.0 - 9.0 Freezing point: 0 Deg. C.<br />

pH use dilution: 8.0 - 9.0 Boiling Point: 100 Deg. C.<br />

Solubility in water: Dispersible in all proportions Evaporation Rate: Same as water.<br />

Odour: Slight ammonia Viscosity: As water.<br />

SECTION 10 - REACTIVITY & STABILITY DATA<br />

Product is stable. Do not mix with strong acids, alkalis; oxidizing and reducing agents.<br />

Do not mix with chlorine bleach. Hazardous polymerization will not occur.<br />

SECTION 11 - TOXICOLOGICAL INFORMATION<br />

Potential acute health effects<br />

Product AS SOLD Product AT USE DILUTION<br />

Eyes : Slightly irritating to the eyes. Product is sold ready to use.<br />

Skin : Slightly irritating to the skin.<br />

Inhalation : No known significant effects or critical hazards.<br />

Ingestion : No known significant effects or critical hazards

MATERIAL SAFETY DATA SHEET Page of<br />

Potential chronic health effects<br />

Carcinogenic effects : No known significant effects or critical hazards.<br />

Mutagenic effects : No known significant effects or critical hazards.<br />

Teratogenic effects : No known significant effects or critical hazards.<br />

Reproductive effects : No known significant effects or critical hazards.<br />

Sensitization to Product : No known significant effects or critical hazards.<br />

Synergistic products<br />

(toxicologically)<br />

: Not available.<br />

Toxicity data<br />

Product/ingredient name Test Route Result Species<br />

ethanol, 2-(2-ethoxyethoxy)- LD50 Dermal >32 g/kg Guinea pig<br />

LD50 Oral 7500 mg/kg Rat<br />

LD50 Oral 7250 mg/kg Mouse<br />

LC50 Inhalation >5240 mg/m3 Rat<br />

Other adverse effects<br />

Target organs : Not available<br />

Ecotoxicity : Not reported<br />

SECTION 12 - ECOLOGICAL INFORMATION<br />

SECTION 13 - WASTE DISPOSAL<br />

Disposal method: Sanitary sewer or dry absorbent material.<br />

For large quantities, check with local environmental department, and government authorities.<br />

SECTION 14 - TRANSPORTATION INFORMATION<br />

Certain shipping modes or package sizes may have exceptions from the transport regulations. The classification<br />

provided may not reflect those exceptions and may not apply to all shipping modes or package sizes.<br />

Product AS SOLD<br />

TDG Classification Not regulated.<br />

For transport in bulk or using IMDG regulations, see shipping documents for specific transportation information<br />

SECTION 15 - REGULATORY INFORMATION<br />

MSDS Prepared by: Technical Dept. Telephone: (905) 682-8888<br />

SECTION 16 - OTHER INFORMATION<br />

References: Suppliers Material Safety Data Sheets. Preparation Date: July 1/2011<br />

NOTICE: The data and information presented herein are based upon tests, research and reports which are considered by us to be reliable and believed<br />

to be accurate. The data and information are presented without warranty, guarantee or liability on our part, and are presented to the customer for his<br />

own consideration, investigation and verification. If user requires independent information on ingredients in this or any other material, we recommend<br />

contact with Canadian Centre for Occupational Health and Safety (CCOHS) in Hamilton, Ontario (905 572-4400)

Product Name: MSDS No.: Date: Oct 15, 2010<br />

Product Name:<br />

Product Use:<br />

Chemical Name:<br />

Praxair Material Safety Data Sheet<br />

1. Chemical Product and Company Identification<br />

Trade Name:<br />

Synonym:<br />

Chemical Formula: Chemical Family:<br />

Telephone:<br />

Emergencies:<br />

Supplier<br />

/Manufacture:<br />

Phone:<br />

Fax:<br />

*Call emergency numbers 24 hours a day only for spills, leaks, fire, exposure, or accidents involving this<br />

product. For routine information, contact your supplier or Praxair sales representative.<br />

DANGER!<br />

ROUTES OF EXPOSURE:<br />

THRESHOLD LIMIT VALUE:<br />

INHALATION:<br />

2. Hazards Identification<br />

Emergency Overview<br />

Flammable gas under pressure. Can form explosive mixtures with air. Fusible plugs in top,<br />

bottom, or valve melt at 98 - 104 C. Do not discharge at pressures above 103 kPa. May cause<br />

dizziness and drowsiness. Self-contained breathing apparatus may be required by rescue<br />

workers. At normal temperature and pressure, commercial acetylene is a colourless gas with<br />

a distinctive garlic-like odour.<br />

EFFECTS OF A SINGLE (ACUTE) OVEREXPOSURE:<br />

SKIN CONTACT:<br />

SKIN ABSORPTION:<br />

SWALLOWING:<br />

EYE CONTACT:<br />

Copyright © 2005, Praxair Canada Inc. Page 1 of 9

EFFECTS OF REPEATED (CHRONIC) OVEREXPOSURE:<br />

*NOTES TO PHYSICIAN:<br />

Acute:<br />

Chronic:<br />

OTHER EFFECTS OF OVEREXPOSURE:<br />

MEDICAL CONDITIONS AGGRAVATED BY OVEREXPOSURE:<br />

Oct 15, 2010<br />

SIGNIFICANT LABORATORY DATA WITH POSSIBLE RELEVANCE TO HUMAN HEALTH HAZARD EVALUATION:<br />

CARCINOGENICITY:<br />

3. Composition and Information on Ingredients<br />

COMPONENTS CAS<br />

NUMBER<br />

INHALATION:<br />

SKIN CONTACT:<br />

SWALLOWING:<br />

EYE CONTACT:<br />

NOTES TO PHYSICIAN:<br />

4. First Aid Measures<br />

CONCENTRATION<br />

% by Mole<br />

Copyright © 2005, Praxair Canada Inc. Page 2 of 9

Oct 15, 2010<br />

Aspired acetone may cause severe lung damage. If a large quantity of material has been swallowed, stomach contents<br />

should be evacuated quickly in a manner which avoids aspiration. Otherwise, treatment should be directed at the control<br />

of symptoms and the clinical condition. No specific antidote is known.<br />

EXTINGUISHING MEDIA:<br />

PRODUCTS OF COMBUSTION:<br />

PROTECTION OF FIREFIGHTERS:<br />

DANGER!<br />

SPECIFIC PHYSICAL AND CHEMICAL HAZARDS:<br />

5. Fire Fighting Measures<br />

FLAMMABLE : IF YES, UNDER WHAT CONDITIONS?<br />

SENSITIVITY TO IMPACT:<br />

SENSITIVITY TO STATIC DISCHARGE:<br />

PROTECTIVE EQUIPMENT AND PRECAUTIONS FOR FIREFIGHTERS:<br />

FLAMMABLE LIMITS IN AIR, % by volume:<br />

FLASH POINT:<br />

AUTOIGNITION TEMPERATURE:<br />

LOWER: UPPER:<br />

6. Accidental Release Measures<br />

STEPS TO BE TAKEN IF MATERIAL IS RELEASED OR SPILLED:<br />

Personal Precautions:<br />

Copyright © 2005, Praxair Canada Inc. Page 3 of 9

DANGER! Flammable, high-pressure gas.<br />

Environmental Precautions:<br />

PRECAUTIONS TO BE TAKEN IN HANDLING:<br />

PRECAUTIONS TO BE TAKEN IN STORAGE:<br />

7. Handling and Storage<br />

OTHER HAZARDOUS CONDITIONS OF HANDLING, STORAGE, AND USE:<br />

Flammable high-pressure gas.<br />

Oct 15, 2010<br />

May form explosive mixtures with air. Gas can cause rapid<br />

suffocation due to oxygen deficiency.<br />

Prevent reverse flow. Reverse flow into cylinder may cause rupture. Use a check valve or<br />

other protective device in any line or piping from the cylinder. When returning cylinder to supplier, be sure valve is<br />

closed, then install valve outlet plug tightly. Never work on a pressurized system. If there is a leak, close the cylinder<br />

valve. Vent the system down in a safe and environmentally sound manner in compliance with all federal, provincial, and<br />

local laws; then repair the leak. Never place a compressed gas cylinder where it may become part of an electrical<br />

circuit.<br />

RECOMMENDED PUBLICATIONS:<br />

NFPA 55: Standard for the Storage,<br />

Use, and Handling of Compressed and Liquefied Gases in Portable Cylinders<br />

Guidelines for Handling Gas Cylinders and Containers<br />

Copyright © 2005, Praxair Canada Inc. Page 4 of 9

VENTILATION/ENGINEERING CONTROLS:<br />

PERSONAL PROTECTION:<br />

LOCAL EXHAUST:<br />

MECHANICAL (General):<br />

8. Exposure Controls/Personal Protection<br />

INGREDIENTS CAS NUMBER LD50 LC50<br />

THRESHOLD LIMIT VALUE:<br />

SPECIAL:<br />

OTHER:<br />

RESPIRATORY PROTECTION:<br />

SKIN PROTECTION:<br />

EYE PROTECTION:<br />

OTHER PROTECTIVE EQUIPMENT:<br />

(Species &<br />

Routes)<br />

IMMEDIATELY DANGEROUS TO LIFE AND HEALTH (IDLH):<br />

(Rat, 4<br />

hrs.)<br />

Exposure Limits<br />

Oct 15, 2010<br />

Copyright © 2005, Praxair Canada Inc. Page 5 of 9

PHYSICAL STATE:<br />

BOILING POINT<br />

SPECIFIC<br />

GRAVITY:<br />

SPECIFIC<br />

GRAVITY:<br />

APPEARANCE & ODOUR:<br />

9. Physical and Chemical Properties<br />

FREEZING POINT:<br />

VAPOUR<br />

PRESSURE<br />

SOLUBILITY IN<br />

WATER,<br />

EVAPORATION<br />

RATE<br />

VAPOUR DENSITY: % VOLATILES BY<br />

VOLUME:<br />

STABILITY:<br />

CONDITIONS OF CHEMICAL INSTABILITY:<br />

INCOMPATIBILITY (materials to avoid):<br />

HAZARDOUS DECOMPOSITION PRODUCTS:<br />

HAZARDOUS POLYMERIZATION:<br />

CONDITIONS TO AVOID:<br />

CONDITIONS OF REACTIVITY:<br />

ACUTE DOSE EFFECTS:<br />

STUDY RESULTS:<br />

10. Stability and Reactivity<br />

11. Toxicological Information<br />

12. Ecological Information<br />

pH:<br />

MOLECULAR WEIGHT:<br />

COEFFICIENT OF<br />

WATER/OIL<br />

DISTRIBUTION:<br />

ODOUR THRESHOLD:<br />

Oct 15, 2010<br />

Copyright © 2005, Praxair Canada Inc. Page 6 of 9

WASTE DISPOSAL METHOD:<br />

TDG/IMO SHIPPING NAME:<br />

13. Disposal Considerations<br />

14. Transport Information<br />

HAZARD CLASS: IDENTIFICATION #:<br />

SHIPPING LABEL(s):<br />

PLACARD (When Required):<br />

SPECIAL SHIPPING INFORMATION:<br />

WHMIS (Canada):<br />

International Regulations:<br />

EINECS:<br />

DSCL (EEC):<br />

International Lists:<br />

15. Regulatory Information<br />

PRODUCT RQ:<br />

Oct 15, 2010<br />

The following selected regulatory requirements may apply to this product. Not all such requirements are identified. Users of this<br />

product are solely responsible for compliance with all applicable federal, provincial, and local regulations. This product has been<br />

classified in accordance with the hazard criteria of the CPR and the MSDS contains all the information required by the CPR.<br />

MIXTURES:<br />

HAZARD RATING SYSTEM:<br />

HMIS RATINGS:<br />

2<br />

4<br />

2<br />

16. Other Information<br />

Copyright © 2005, Praxair Canada Inc. Page 7 of 9

STANDARD VALVE CONNECTIONS FOR U.S. AND CANADA:<br />

THREADED:<br />

PIN-INDEXED YOKE:<br />

ULTRA-HIGH-INTEGRITY<br />

CONNECTION:<br />

PREPARATION INFORMATION:<br />

DATE:<br />

DEPARTMENT:<br />

TELEPHONE:<br />

DO NOT USE ADAPTERS.<br />

Oct 15, 2010<br />

Safety and Environmental Services<br />

905-803-1600<br />

Praxair Flowing Airstream<br />

Oct 15, 2010<br />

Copyright © 2005, Praxair Canada Inc. Page 8 of 9

Copyright © 2005, Praxair Canada Inc.<br />

Oct 15, 2010<br />

Page 9 of 9

No Change April 18, 2011

No Change as of May 2011

SAFETY DATA SHEET<br />

-1-<br />

SDS NO. 7-E<br />

DATE REVISED: 07/14/2010<br />

This Safety Data Sheet complies with European Commission Directive 91/155/EEC, ISO 11014-1 and ANSI Z400.1<br />

1. PRODUCT AND COMPANY IDENTIFICATION<br />

Product Name: ALL-STATE JET FLUX P/N: 69080170, 69080171, 69080172<br />

Application: Brazing Flux<br />

Classification: None<br />

Supplier: THE ESAB GROUP, INC., 801 Wilson Avenue, Hanover, PA 17331<br />

Telephone No.: 1-717-637-8911, 1-800-933-7070<br />

Emergency No.: 1-717-637-8911 and 1-800-424-9300 (CHEMTREC)<br />

Web site: www.esabna.com<br />

2. HAZARDS IDENTIFICATION<br />

Emergency Overview: A clear, colorless flammable liquid with an organic odor. Can irritate the skin and eyes. Toxic if swallowed;<br />

may also cause blindness. Vapors are harmful if inhaled.<br />

Can irritate the skin and eyes Toxic if swallowed and may cause blindness due to the methyl alcohol content. Vapor can cause<br />

respiratory irritation and may cause headaches, nausea, and depression of the central nervous system resulting in drowsiness or<br />

the loss of consciousness.<br />

Persons with a pacemaker should not go near brazing operations until they have consulted their doctor and obtained information<br />

from the manufacturer of the device.<br />

When this product is used in a brazing process, the most important hazards are heat, radiation, electric shock and brazing fumes.<br />

Heat: Spatter and melting metal can cause burn injuries and start fires.<br />

Radiation: Arc rays can severely damage eyes or skin.<br />

Electricity: Electric shock can kill.<br />

Fumes: Overexposure to brazing fumes may result in symptoms like metal fume fever, dizziness, nausea, dryness or<br />

irritation of the nose, throat or eyes. Chronic overexposure to brazing fumes may affect pulmonary function.<br />

Prolonged inhalation of nickel and chromium compounds above safe exposure limits can cause cancer.<br />

Overexposure to manganese and manganese compounds above safe exposure limits can cause irreversible<br />

damage to the central nervous system, including the brain, symptoms of which may include slurred speech,<br />

lethargy, tremor, muscular weakness, psychological disturbances and spastic gait.<br />

Flame<br />

Processing:<br />

When used with combustible gas equipment (e.g., oxy-acetylene torch), read the use and safety information for<br />

that equipment.<br />

3. COMPOSITION/INFORMATION ON INGREDIENTS<br />

This product is a liquid.<br />

Ingredients Weight % CAS# EINECS# Hazard<br />

classification (1)<br />

IARC (2) NTP (3) OSHA<br />

List (4)<br />

Acetone 25 67-64-1 200-662-2 F; R11, Xi; R36<br />

R66, R67<br />

-- -- --<br />

Methyl Alcohol 20 67-56-1 200-659-6 F; R11<br />

T; R23/24/25-<br />

39/23/24/25<br />

-- -- --<br />

Trimethylborate 55 121-43-7 204-468-9 R10, Xn; R21 -- -- --<br />

(1)<br />

Hazard Classification according to European Council Directive 67/548/EEC, for R-phrases, see Section 16.<br />

(2)<br />

Evaluation according to the International Agency for Research on Cancer.<br />

1 – Human Carcinogen 2B – Possibly carcinogenic to humans<br />

(3)<br />

Classification according to the 11th Report on Carcinogens, published by the US National Toxicology Program.<br />

K – Known Carcinogen S – Suspect Carcinogen<br />

(4)<br />

Carcinogen listing according to OSHA, Occupational Safety & Health Administration (USA).

Product Identity: ALL-STATE JET FLUX P/N: 69080170, 69080171, 69080172<br />

-2-<br />

SDS NO. 7-E<br />

DATE REVISED: 07/14/2010<br />

4. FIRST AID MEASURES<br />

Inhalation: If breathing has stopped, perform artificial respiration and obtain medical assistance immediately! If breathing is<br />

difficult, provide fresh air and call physician.<br />

Eye contact: To liquid or mist, flush with water for at least fifteen minutes. For radiation burns due to arc flash, see physician. To<br />

remove dusts or fumes flush with water for at least fifteen minutes. If irritation persists, obtain medical assistance.<br />

Skin contact: Immediately remove liquid from skin and wash with mild soap and water. Launder contaminated clothing before<br />

reusing. For skin burns from arc radiation, promptly flush with cold water. Get medical attention for burns or irritations<br />

that persist. To remove dust or particles wash with mild soap and water.<br />

Electric shock: Disconnect and turn off the power. Use a nonconductive material to pull victim away from contact with live parts or<br />

wires. If not breathing, begin artificial respiration, preferably mouth-to-mouth. If no detectable pulse, begin Cardio<br />

Pulmonary Resuscitation (CPR). Immediately call a physician.<br />

Ingestion: Call a physician or poison control center immediately. Do not induce vomiting unless directed to do so by a physician.<br />

General: Move to fresh air and call for medical aid.<br />

5. FIRE FIGHTING MEASURES<br />

Use CO2, dry chemical, water spray or alcohol foam. Water stream may spread the burning liquid. Vapors may travel to a source of<br />

ignition and flash back. Firefighters should wear full protective equipment and self-contained breathing apparatus. Keep product<br />

containers exposed to heat or fire cool with water stream to prevent rupture from internal pressure.<br />

6. ACCIDENTAL RELEASE MEASURES<br />

Extinguish all sources of ignition within 35 feet (11m) of spill or vapor release. Provide adequate ventilation. If spill is of significant or<br />

unknown quantity, use self-contained breathing apparatus during clean up. Always wear proper protective clothing to prevent skin or<br />

eye contact. Released product which has evaporated forms smooth, slippery surface on floors, posing an accident risk. Absorb small<br />

spills with sand or fuller’s earth, and place in appropriate waste container. Large spills should be diluted and pumped into approved<br />

containers for disposal in accordance with all local, state, and federal laws and regulations.<br />

Personal precautions: refer to Section 8.<br />

Environmental precautions: refer to Section 13.<br />

7. HANDLING AND STORAGE<br />

Handling:<br />

Avoid contact with skin, eyes and clothing. Do not swallow or breathe vapors produced by use of product. Wash hands after using.<br />

Some individuals can develop an allergic reaction to certain materials. Retain all warning and identity labels.<br />

Storage:<br />

Store in cool, dry, well-ventilated place suitable for flammable liquids. Keep away from strong oxidizers and from sources of ignition<br />

including sparks, static electricity or open flames.<br />

8. EXPOSURE CONTROL/PERSONAL PROTECTION<br />

Avoid exposure to brazing fumes, radiation, spatter, electric shock, heated materials and dust.<br />

Engineering measures: (Brazing operations)<br />

Ensure sufficient ventilation, local exhaust, or both, to keep brazing fumes and gases from breathing zone and general area. Keep<br />

working place and protective clothing clean and dry. Train welders to avoid contact with live electrical parts and insulate conductive<br />

parts. Check condition of protective clothing and equipment on a regular basis.<br />

Personal protective equipment: (Brazing operations)<br />

Use respirator or air supplied respirator when brazing in a confined space, or where local exhaust or ventilation is not sufficient to keep<br />

exposure values within safe limits. Use special care when brazing painted or coated steels since hazardous substances from the<br />

coating may be emitted. Wear hand, head, eyes, ear and body protection like welders gloves, helmet or face shield with filter lens,<br />

safety boots, apron, arm and shoulder protection. Keep protective clothing clean and dry.<br />

Use industrial hygiene monitoring equipment to ensure that exposure does not exceed applicable national exposure limits. The<br />

following limits can be used as guidance. When used with brazing products, refer to the brazing product SDS, Section 10, for<br />

information on brazing fumes.

Product Identity: ALL-STATE JET FLUX P/N: 69080170, 69080171, 69080172<br />

-3-<br />

SDS NO. 7-E<br />

DATE REVISED: 07/14/2010<br />

Substance CAS# ACGIH TLV (1) mg/m 3 OSHA PEL (2) mg/m 3<br />

Acetone 67-64-1 1188, 1782 (STEL)<br />

[500 ppm , 750 ppm (STEL)]<br />

Methyl Alcohol 67-56-1 262, 382 (STEL)<br />

[200 ppm, 250 ppm (STEL)]<br />

2400<br />

[1000 ppm]<br />

260<br />

[200 ppm]<br />

Trimethylborate 121-43-7 None None<br />

(1)<br />

Threshold Limit Values according to American Conference of Governmental Hygienists, 2010<br />

(2)<br />

Permissible Exposure Limits according to the Occupational Safety & Health Administration (USA)<br />

Unless noted, all values are for 8 hour time weighted averages (TWA).<br />

9. PHYSICAL AND CHEMICAL PROPERTIES<br />

Appearance: Colorless liquid with organic odor.<br />

Specific Gravity: 0.855 (H2O = 1)<br />

Boiling Point: 58°C/137°F<br />

Freezing Point: -26°C/-32°F<br />

Vapor Pressure: 161 mm Hg<br />

Vapor Density: 1.6<br />

Evaporation Rate: 16 (vs. butyl acetate = 1)<br />

Solubility in Water: Decomposes at 10%.<br />

Flash Point: -7.7°C/18°F<br />

Upper/Lower Flame Limit: 36.5%/6.0%<br />

Auto-ignition Temperature: Not determined.<br />

10. STABILITY AND REACTIVITY<br />

General: This product is intended for normal brazing purposes.<br />

Stability: This product is stable under normal conditions.<br />

Reactivity: Contact with strong oxidizers may cause a violent reaction.<br />

When this product is used in a brazing process, hazardous decomposition products would include those from the volatilization,<br />

reaction or oxidation of the brazing consumable and of the materials from the base metal and coating.<br />

Refer to applicable national exposure limits for fume compounds, including those exposure limits for compounds found in Section 8 of<br />

this SDS and of the brazing consumable SDS. A significant amount of the chromium in the fumes can be hexavalent chromium, which<br />

has a very low exposure limit in some countries. Manganese and nickel also have low exposure limits that may be easily exceeded.<br />

Reasonably expected gaseous products would include carbon oxides, nitrogen oxides, boron oxides and ozone. Air contaminants<br />

around the brazing area can be affected by the brazing process and influence the composition and quantity of fumes and gases<br />

produced.<br />

11. TOXICOLOGICAL INFORMATION<br />

Inhalation of brazing fumes and gases can be dangerous to your health. Classification of brazing fumes is difficult because of varying<br />

base materials, coatings, air contamination and processes. The International Agency for Research on Cancer has classified welding<br />

fumes as possibly carcinogenic to humans (Group 2B).<br />

Acute toxicity: Acetone: LD50, oral, rat: 9,750 mg/kg; dermal, rabbit: 20,000 mg/kg; LC50 Rat : 50,100 mg/m 3 (8hr)<br />

Methanol: LD50, oral, rat: 5,628 mg/kg dermal, rabbit: 20 ml/kg; LC50: inhalation, rat: 64,000 ppm (4hr) Affects optic<br />

nerve. Irritant.<br />

Trimethylborate: LD50 oral, rat: 6,140 mg/kg; dermal, rabbit: 1,981 mg/kg.<br />

Overexposure to brazing fumes may result in symptoms like metal fume fever, dizziness, nausea, dryness or<br />

irritation of the nose, throat or eyes.

Product Identity: ALL-STATE JET FLUX P/N: 69080170, 69080171, 69080172<br />

-4-<br />

SDS NO. 7-E<br />

DATE REVISED: 07/14/2010<br />

Chronic toxicity: None anticipated from flux.<br />

Overexposure to brazing fumes may affect pulmonary function. Prolonged inhalation of nickel and chromium<br />

compounds above safe exposure limits can cause cancer. Overexposure to manganese and manganese<br />

compounds above safe exposure limits can cause irreversible damage to the central nervous system, including the<br />

brain, symptoms of which may include slurred speech, lethargy, tremor, muscular weakness, psychological<br />

disturbances and spastic gait.<br />

12. ECOLOGICAL INFORMATION<br />

Brazing consumables and materials could degrade/weather into components originating from the consumables or from the materials<br />

used in the brazing process. Avoid exposure to conditions that could lead to accumulation in soils or groundwater.<br />

13. DISPOSAL CONSIDERATIONS<br />

Discard any product, residue, disposable container or liner in an environmentally acceptable manner, in full compliance with federal<br />

and local regulations. Use recycling procedures if available.<br />

USA RCRA: Unused product is considered an ignitable hazardous waste if discarded, RCRA ID D001.<br />

Prevent waste from contaminating surrounding environment.<br />

Residues from brazing consumables and processes could degrade and accumulate in soils and groundwater.<br />

14. TRANSPORT INFORMATION<br />

US DOT: Class: Flammable liquid Shipping Name: Flammable liquid n.o.s. (acetone, methanol)<br />

ID Number: UN1993<br />

Packing group: II<br />

Canada TDG: Class: Flammable liquid Shipping Name: FLAMMABLE LIQUID n.o.s. (acetone, methanol)<br />

ID Number: UN1993<br />

Packing group: II<br />

15. REGULATORY INFORMATION<br />

Read and understand the manufacturer's instructions, your employer's safety practices and the health and safety instructions on the<br />

label. Observe any federal and local regulations. Take precautions when brazing and protect yourself and others.<br />

WARNING: Brazing fumes and gases are hazardous to your health and may damage lungs and other organs. Use adequate<br />

ventilation.<br />

ELECTRIC SHOCK can kill.<br />

ARC RAYS and SPARKS can injure eyes and burn skin.<br />

Wear correct hand, head, eye and body protection.<br />

Canada: WHMIS classification: B2, D1B, D2A, D2B<br />

Canadian Environmental Protection Act (CEPA): All constituents of this product are on the Domestic Substance List (DSL).<br />

USA: Under the OSHA Hazard Communication Standard, this product is considered hazardous.<br />

This product contains or produces a chemical known to the state of California to cause cancer and birth defects (or other<br />

reproductive harm). (California Health & Safety Code § 25249.5 et seq.)<br />

United States EPA Toxic Substance Control Act: All constituents of this product are on the TSCA inventory list or are<br />

excluded from listing.<br />

CERCLA/SARA Title III<br />

Reportable Quantities (RQs) and/or Threshold Planning Quantities (TPQs):<br />

Ingredient name RQ (lb) TPQ (lb)<br />

Acetone 5000 None<br />

Methanol 5000 None<br />

Trimethylborate None None<br />

Spills or releases resulting in the loss of any ingredient at or above its RQ require immediate notification to the National<br />

Response Center and to your Local Emergency Planning Committee.

Product Identity: ALL-STATE JET FLUX P/N: 69080170, 69080171, 69080172<br />

-5-<br />

SDS NO. 7-E<br />

DATE REVISED: 07/14/2010<br />

Section 311 Hazard Class<br />

As shipped: Immediate, Fire hazard In use: Immediate, Fire hazard<br />

EPCRA/SARA Title III 313 Toxic Chemicals<br />

The following metallic components are listed as SARA 313 “Toxic Chemicals” and potential subject to annual SARA 313<br />

reporting. See Section 3 for weight percent.<br />

Ingredient name Disclosure threshold<br />

Methanol 1.0% de minimis concentration<br />

16. OTHER INFORMATION<br />

This Safety Data Sheet has been revised due to modifications to several paragraphs and/or new format. This SDS supersedes 7-D.<br />

Refer to ESAB “Welding and Cutting - Risks and Measures”, F52-529 “Precautions and Safe Practices for Electric Welding and<br />

Cutting” and F2035 “Precautions and Safe Practices for Gas Welding, Cutting and Heating” available from ESAB, and to:<br />

USA: Contact ESAB at www.esabna.com or 1-800-ESAB-123 if you have questions about this SDS.<br />

American National Standard Z49.1 “Safety in Welding and Cutting”, ANSI/AWS F1.5 “Methods for Sampling and Analyzing<br />

Gases from Welding and Allied Processes”, ANSI/AWS F1.1 “Method for Sampling Airborne Particles Generated by<br />

Welding and Allied Processes”, AWSF3.2M/F3.2 “Ventilation Guide for Weld Fume”, American Welding Society, 550 North<br />

Le Jeune Road, Miami, Florida, 33135. Safety and Health Fact Sheets available from AWS at www.aws.org.<br />

OSHA Publication 2206 (29 C.F.R. 1910), U.S. Government Printing Office, Superintendent of Documents, P.O. Box<br />

371954, Pittsburgh, PA 15250-7954.<br />

American Conference of Governmental Hygienists (ACGIH), Threshold Limit Values and Biological Exposure Indices, 6500<br />

Glenway Ave., Cincinnati, Ohio 45211, USA.<br />

NFPA 51B “Standard for Fire Prevention During Welding, Cutting and Other Hot Work” published by the National Fire<br />

Protection Association, 1 Batterymarch Park, Quincy, MA 02169.<br />

UK: WMA Publication 236 and 237, “Hazards from Welding Fume”, “The arc welder at work, some general aspects of health<br />

and safety”.<br />

Germany: Unfallverhütungsvorschrift BGV D1, “Schweißen, Schneiden und verwandte Verfahren”.<br />

Canada: CSA Standard CAN/CSA-W117.2-01 “Safety in Welding, Cutting and Allied Processes”.<br />

This product has been classified according to the hazard criteria of the CPR and the SDS contains all the information<br />

required by the CPR.<br />

R-phrases: R10 – Flammable.<br />

R11 – Highly flammable.<br />

R21 – Harmful in contact with skin.<br />

R36 – Irritating to eyes.<br />

R66 – Repeated exposure may cause skin dryness or cracking.<br />

R67 – Vapours may cause drowsiness and dizziness.<br />

R23/24/25 – Toxic by inhalation, in contact with skin and if swallowed.<br />

R39/23/24/25 – Toxic: danger of vary serious irreversible effects through inhalation, in contact with skin and if<br />

swallowed.<br />

ESAB requests the users of this product to study this Safety Data Sheet (S.D.S.) and become aware of product hazards and safety<br />

information. To promote safe use of this product a user should:<br />

- notify its employees, agents and contractors of the information on this S.D.S and any product hazards/safety information.<br />

- furnish this same information to each of its customers for this product.<br />

- request such customers to notify employees and customers for the same product hazards and safety information.<br />

The information herein is given in good faith and based on technical data that ESAB believes to be reliable. Since the conditions of<br />

use are outside our control, we assume no liability in connection with any use of this information and no warranty, expressed or implied<br />

is given. Contact ESAB for more information.

A Subsidiary of The ESAB Group, Inc.<br />

SAFETY DATA SHEET<br />

Revised: March 25, 2009 Supersedes: October 10, 2008<br />

Product Name: ALUMINUM WELDING WIRE AND METALLIZING WIRE<br />

Emergency Phone: 1-717-637-8911 or 1-800-424-9300<br />

1. CHEMICAL PRODUCT AND COMPANY IDENTIFICATION<br />

AlcoTec Wire Corporation<br />

2750 Aero Park Drive Traverse City, MI 49686-9263 USA Phone (231) 941-4111<br />

Sales and Marketing Fax (231) 941-9154 Administrative and Quality Control Fax (231) 941-1040<br />

alcotec@alcotec.com E-mail www.alcotec.com Web site<br />

SDS NO. 7994-G<br />

Chemical Formula: Mixture.<br />

Other Designations: AlcoTec ALMIGWELD (Aluminum spooled electrode)<br />

AlcoTec ALTIGWELD (Aluminum straight length welding rod)<br />

Aluminum Metallizing Wire (coils and spools)<br />

AlumaArc (Aluminum spooled electrode and straight length welding rod)<br />

Manufacturer: AlcoTec Wire Corporation, 2750 Aero Park Drive, Traverse City, MI 49686-9263 USA<br />

Product Use: Welding, Filler Metal, Metallizing, Brazing<br />

2. HAZARDS INFORMATION<br />

EMERGENCY OVERVIEW<br />

Solid, silvery, odorless. Non-flammable as supplied. Small chips, fine turnings, and dust from processing may<br />

ignite readily.<br />

Explosion/fire hazards may be present when (See Sections 5, 7 and 10 for additional information):<br />

Dust or fines are dispersed in the air.<br />

Fines or dust are in contact with other metal<br />

oxides (e.g., rust).<br />

Chips, fines, or dust are in contact with water.<br />

Molten aluminum is in contact with<br />

water/moisture or other metal oxides.<br />

Dust or fume from welding can cause eye, skin, or upper respiratory tract irritation; metal fume fever; lung<br />

diseases, neurological effects and other systemic effects.<br />

Potential Health Effects<br />

EYES: Fume can cause irritation. Ultraviolet radiation from welding can cause flash burns.<br />

SKIN: Can cause irritation. Ultraviolet radiation from welding can cause flash burns.<br />

INHALATION: Can cause respiratory tract irritation, metal fume fever, and other health effects listed below:<br />

Cancer hazard<br />

Aluminum is welded in a protective, inert atmosphere such as argon or helium using the MIG or TIG process.<br />

Welding processes generate welding fumes and an intense ultraviolet radiation that results in the formation of<br />

ozone, and oxides of nitrogen. Ultraviolet radiation from welding can also cause flash burns to the eyes and skin.<br />

The International Agency for Research on Cancer has classified welding fumes as possibly carcinogenic to<br />

humans (Group 2B).<br />

Exposure to low levels of ozone can cause irritation of the eyes, nose, and throat. Inhalation can cause chest<br />

tightness, headache, shortness of breath, cough, wheeze, nausea, and narrowing of airways. Symptoms<br />

disappear when removed from exposure.<br />

Exposure to high levels of ozone may cause acute respiratory distress with shortness of breath, pulmonary<br />

changes, hemorrhage, and pulmonary edema (fluid in the lungs). Symptoms of pulmonary edema may be<br />

delayed for one or more hours. Exposure of test animals and human tissue to high concentrations has shown<br />

chromosomal changes, reproductive effects, blood changes, and death from lung congestion.<br />

Oxides of nitrogen can cause irritation of the eyes, skin (when moist), and respiratory tract. Exposure to high<br />

levels of nitrogen oxides can cause delayed pulmonary edema (fluid in the lungs) which may be fatal. Nitric<br />

oxide can cause formation of methemoglobin, which decreases the blood’s ability to carry oxygen. Chronic<br />

overexposure can cause pulmonary fibrosis (scarring of the lungs).<br />

Overexposure to Aluminum dust/fines and fumes can cause reduced lung function and may be associated with<br />

neurological effects.

SAFETY DATA SHEET SDS NO. 7994-G<br />

Revised: March 25, 2009 Supersedes: October 10, 2008 Page 2 of 9<br />

Product Name: ALUMINUM WELDING WIRE AND METALLIZING WIRE<br />

Overexposure to magnesium oxide fumes can cause respiratory tract irritation and fever, chills, shortness of<br />

breath, and malaise (metal fume fever). Temporary symptoms can include fever, chills, nausea, vomiting, and<br />

muscular pain.<br />

Chronic exposure to inert dusts of silicon can cause increased airway resistance and contributes to chronic<br />

bronchitis. Intratracheal administration of silicon in rabbits produced significant pulmonary lesions.<br />

Exposure to zinc oxide fumes subsequent to burning, welding, and molten metal work can result in fever,<br />

chills, shortness of breath, and malaise (metal fume fever), and upper respiratory tract irritation. Temporary<br />

symptoms can include fever, chills, nausea, vomiting, and muscular pain. Exposure to dust or fines presents a<br />

low health risk by inhalation.<br />

Overexposure to manganese and manganese compounds above safe exposure limits can cause irreversible<br />

damage to the central nervous system, including the brain, symptoms of which may include slurred speech,<br />

lethargy, tremor, muscular weakness, psychological disturbances and spastic gait.<br />

Hexavalent chromium (Chrome VI) can cause asthma, kidney damage, primary irritant dermatitis, sensitization<br />

dermatitis, skin ulceration, and pulmonary edema (fluid in the lungs). Chronic inhalation or overexposure has<br />

been associated with lung, nasal, and gastrointestinal cancer. Hexavalent chromium is listed as carcinogenic<br />

to humans by IARC (Group 1)*. Chromium and some of its compounds are listed as carcinogenic by the NTP.<br />

Hexavalent chromium compounds may be generated during welding operations, with alloys containing<br />

chromium. A SIGNIFICANT AMOUNT OF THE CHROMIUM IN THE FUMES CAN BE HEXAVALENT<br />

CHROMIUM, WHICH HAS A VERY LOW EXPOSURE LIMIT, 0.005 mg/m 3 (5µg/m 3 ).<br />

The potential for overexposure to copper fume may exist when welding, flame cutting, etc. Overexposure to<br />

copper dust/mists can cause irritation of the eyes, skin, and upper respiratory tract. Chronic overexposure may<br />

result in blood disorders (anemia), and skin and hair discolorations. Overexposure to copper fume can result in<br />

respiratory tract irritation, nausea, and fever, chills, shortness of breath and malaise (metal fume fever).<br />

Nickel dust and fume can cause skin sensitization, allergic contact dermatitis, and conjunctivitis. Chronic<br />

inhalation of high levels of nickel can cause irritation of airways and lungs, lung fibrosis (scarring of the lungs),<br />

nasal septum perforation, nasal sinusitis, respiratory sensitization and asthma. Nickel compounds have been<br />

associated with cancer of lungs, larynx, and paranasal sinuses in humans. Nickel compounds are listed on the<br />

NTP and are listed as carcinogenic to humans by IARC (Group 1)*. Nickel metal is possibly carcinogenic to<br />

humans as defined by IARC (Group 2B)*.<br />

Beryllium can cause irritant dermatitis, allergic contact dermatitis, and skin granulomas. Inhalation of excessive<br />

levels of beryllium can result in acute pneumonitis (inflammation of the lung tissues).<br />

Beryllium can cause lung sensitization in susceptible individuals. Chronic inhalation of dust and fumes by<br />

these sensitized individuals can result in a serious, progressive disease called Chronic Beryllium Disease<br />

(CBD). This disease, often misdiagnosed as sarcoidosis, is an allergic condition in which the lung tissues<br />

become inflamed. This inflammation, sometimes accompanied with fibrosis (lung scarring), restricts the uptake<br />

of oxygen into the blood stream. CBD can, over time, be fatal.<br />

Inhalation of beryllium has produced lung tumors in animals. Beryllium is listed on the NTP and is known to be<br />

carcinogenic to humans by IARC (Group 1)*. (See Section 8)<br />

Lead inorganic dust and fume is listed as a possibly carcinogenic to humans by IARC Group 2B*.<br />

Overexposure to lead dust or fume can cause weakness of extremities (peripheral neuropathy), stomach<br />

disturbances, harm to the kidneys, liver, central nervous system, blood and blood forming tissues, and<br />

reproductive organs. Overexposure to lead has been associated with human reproductive effects (e.g.<br />

reduced fertility and damage to the fetus of exposed pregnant women). Lead is a cumulative toxic metal by<br />

inhalation or ingestion.<br />

Warning: This product contains or produces a chemical known to the State of California to cause cancer and<br />

birth defects (or other reproductive harm). (California Health & safety Code 25249.5 et seq.)<br />

Medical conditions aggravated by exposure to the product:<br />

Chronic lung disease, skin rashes, and asthma.<br />

*IARC CLASSIFICATIONS:<br />

Group 1: The agent is carcinogenic to humans.<br />

There is sufficient evidence that a casual relationship existed between exposure to the agent and<br />

human cancer.

SAFETY DATA SHEET SDS NO. 7994-G<br />

Revised: March 25, 2009 Supersedes: October 10, 2008 Page 3 of 9<br />

Product Name: ALUMINUM WELDING WIRE AND METALLIZING WIRE<br />

Group 2B: The agent is possibly carcinogenic to humans.<br />

Generally includes agents for which there is limited evidence in humans in the absence of<br />

sufficient evidence in experimental animals.<br />

3. COMPOSITION INFORMATION ON INGREDIENTS<br />

Alloy Ingredients: (% by weight shown as a maximum or a range, except for Aluminum, which is a minimum % by weight)<br />

Alloy Si Fe Cu Mn Mg Cr Ni Zn Ti<br />

Others<br />

Each 1<br />

Others<br />

Total<br />

Al<br />

1100 0.95 = Si + Fe 0.05-0.20 0.05 ---- ---- ---- 0.10 ---- 0.05 0.15 99.00<br />

1350 0.10 0.40 0.05 0.01 ---- 0.01 ---- 0.05 ---- 0.03 3 0.10 99.50<br />

1188 0.06 0.06 0.005 0.01 0.01 ---- ---- 0.03 0.01 0.01 4 ---- 99.88<br />

1199 0.006 0.006 0.006 0.002 0.006 ---- ---- 0.006 0.002 0.002 7 ---- 99.99<br />

2319 0.20 0.30 5.8-6.8 0.20-0.40 0.02 ---- ---- 0.10 0.10-0.20 0.05 5 0.15 Rmnd 2<br />

4043 4.5-6.0 0.8 0.30 0.05 0.05 ---- ---- 0.10 0.20 0.05 0.15 Rmnd 2<br />

4047 (718) 11.0-13.0 0.8 0.30 0.15 0.10 ---- ---- 0.20 ---- 0.05 0.15 Rmnd 2<br />

4145 (716) 9.3-10.7 0.8 3.3-4.7 0.15 0.15 0.15 ---- 0.20 ---- 0.05 0.15 Rmnd 2<br />

4643 3.6-4.6 0.8 0.10 0.05 0.10-0.30 ---- ---- 0.10 0.15 0.05 0.15 Rmnd 2<br />

5183 0.40 0.40 0.10 0.50-1.0 4.3-5.2 0.05-0.25 ---- 0.25 0.15 0.05 0.15 Rmnd 2<br />

5356 0.25 0.40 0.10 0.05-0.20 4.5-5.5 0.05-0.20 ---- 0.10 0.06-0.20 0.05 0.15 Rmnd 2<br />

5554 0.25 0.40 0.10 0.50-1.0 2.4-3.0 0.05-0.20 ---- 0.25 0.05-0.20 0.05 0.15 Rmnd 2<br />

5556 0.25 0.40 0.10 0.50-1.0 4.7-5.5 0.05-0.20 ---- 0.25 0.05-0.20 0.05 0.15 Rmnd 2<br />

5654 0.45 = Si + Fe 0.05 0.01 3.1-3.9 0.15-0.35 ---- 0.20 0.05-0.15 0.05 0.15 Rmnd 2<br />

206.0 0.10 0.15 4.2-5.0 0.20-0.50 0.15-0.35 ---- 0.05 0.10 0.15-0.30 0.05 6 0.15 Rmnd 2<br />

C355.0 (4009) 4.5-5.5 0.20 1.0-1.5 0.10 0.40-0.6 ---- ---- 0.10 0.20 0.05 0.15 Rmnd 2<br />

A356.0 (4008, 4010) 6.5-7.5 0.20 0.20 0.10 0.25-0.45 ---- ---- 0.10 0.20 0.05 0.15 Rmnd 2<br />

357.0 6.5-7.5 0.15 0.05 0.03 0.45-0.6 ---- ---- 0.05 0.20 0.05 0.15 Rmnd 2<br />

Notes:<br />

1<br />

Beryllium shall not exceed 0.0003 percent.<br />

2<br />

Rmnd = remainder.<br />

3<br />

1350 may contain Gallium, 0.03% (max.), Boron 0.05% (max.), and Vanadium plus Titanium, 0.02% (max.).<br />

4<br />

1188 may contain Gallium, 0.03% (max.), and Vanadium, 0.05% (max.).<br />

5<br />

2319 contains Vanadium, 0.05-0.15% and Zirconium, 0.10-0.25%.<br />

6<br />

206.0 may contain Tin, 0.05% (max.).<br />

7<br />

1199 may contain 0.005% each (max.) of Gallium and Vanadium.<br />

4. FIRST AID MEASURES<br />

EYES: Flush eyes with plenty of water or saline for at least 15 minutes. Consult a physician.<br />

SKIN: Wash thoroughly with soap and water. Consult a physician if irritation persists.<br />

INHALATION: Remove to fresh air. Check for clear airway, breathing, and presence of pulse. Provide CPR for<br />

persons without pulse or respirations. Consult a physician immediately.

SAFETY DATA SHEET SDS NO. 7994-G<br />

Revised: March 25, 2009 Supersedes: October 10, 2008 Page 4 of 9<br />

Product Name: ALUMINUM WELDING WIRE AND METALLIZING WIRE<br />

5. FIRE FIGHTING MEASURES<br />

FLAMMABLE PROPERTIES: Non-flammable as shipped. Small chips and dust from processing may ignite<br />

readily.<br />

FIRE/EXPLOSION: May be a potential hazard under the following conditions:<br />

Dusts or fines dispersed in the air can be explosive.<br />

Chips, fines and dust in contact with water can generate flammable/explosive hydrogen gas. These gases<br />

could present an explosion hazard in confined or poorly ventilated spaces.<br />

Fines and dust in contact with certain metal oxides (e.g., rust). A thermite reaction, with considerable heat<br />

generation, can be initiated by a weak ignition source.<br />

Molten aluminum in contact with water/moisture or other metal oxides (e.g., rust). Moisture entrapped by<br />

molten aluminum can be explosive. Contact of molten aluminum with other metal oxides can initiate a<br />

thermite reaction.<br />

EXTINGUISHING MEDIA: Use fire fighting methods and materials that are appropriate for surrounding fire. Use<br />

coarse water spray on chips or turnings. For fines, dust or molten aluminum, use<br />

Class D extinguishing agents.<br />

DO NOT USE: Halogenated extinguishing agents on small chips/fines. Do not use water in fighting fires around<br />

molten aluminum.<br />

FIRE FIGHTING INSTRUCTIONS: Fire fighters should wear NIOSH approved, positive pressure, self-contained<br />

breathing apparatus and full protective clothing when appropriate.<br />

6. ACCIDENTAL RELEASE MEASURES<br />

SMALL/LARGE SPILL: If molten: Contain the flow using dry sand or salt flux as a dam. Do not use shovels or<br />

hand tools to halt the flow of molten aluminum. Allow the spill to cool before remelting as scrap.<br />

7. HANDLING AND STORAGE<br />

Product should be kept dry. Avoid generating dust. Avoid contact with sharp edges or heated metal. Hot and cold<br />

aluminum are not visually different.<br />

REQUIREMENTS FOR PROCESSES WHICH GENERATE DUSTS OR FINES<br />

If processing of these products includes operations where dust or extremely fine particulate is generated,<br />

obtain and follow the safety procedures and equipment guides contained in Aluminum Association Bulletin F1<br />

and National Fire Protection Association (NFPA) brochures listed in Section 16. Use non-sparking handling<br />

equipment. Cover and reseal partially empty containers. Provide grounding and bonding where necessary to<br />

prevent accumulation of static charges during aluminum dust handling and transfer operations. (See<br />

Section15).<br />

Local ventilation and vacuum systems must be designed to handle explosive dusts. Dry vacuums and<br />

electrostatic precipitators must not be used. Dust collection systems must be dedicated to aluminum dust only<br />

and should be clearly labeled as such. Do not co-mingle fines of aluminum with fines of iron, iron oxide (rust)<br />

or other metal oxides.<br />

Do not allow chips, fines or dust to contact water, particularly in enclosed areas.<br />

Avoid all ignition sources. Good housekeeping practices must be maintained.<br />

REQUIREMENTS FOR REMELTING OF ALUMINUM SCRAP MATERIAL AND/OR INGOT<br />

Molten aluminum and water can be an explosive combination. The risk is greatest when there is sufficient<br />

molten aluminum to entrap or seal off the water. Water and other forms of contamination on or contained in<br />

aluminum scrap or remelt ingot are known to have caused explosions in melting operations. While the<br />

products may have minimal surface roughness and internal voids, there remains the possibility of moisture<br />

contamination or entrapment. If confined, even a few drops of water can lead to violent explosions.

SAFETY DATA SHEET SDS NO. 7994-G<br />

Revised: March 25, 2009 Supersedes: October 10, 2008 Page 5 of 9<br />

Product Name: ALUMINUM WELDING WIRE AND METALLIZING WIRE<br />

All tooling and containers which come in contact with molten aluminum must be preheated or specially coated<br />

and rust free. Molds and ladles must be preheated or oiled before casting. Any surfaces that may contact<br />

molten aluminum (i.e., concrete) should be specially coated.<br />