Volume 10, Number 4, 2005 - American Biological Safety Association

Volume 10, Number 4, 2005 - American Biological Safety Association

Volume 10, Number 4, 2005 - American Biological Safety Association

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Volume</strong> <strong>10</strong>, <strong>Number</strong> 4, <strong>2005</strong>

213<br />

214<br />

216<br />

258<br />

Journal of the <strong>American</strong> <strong>Biological</strong> <strong>Safety</strong> <strong>Association</strong><br />

<strong>Volume</strong> <strong>10</strong>, <strong>Number</strong> 4, <strong>2005</strong><br />

Letter to the Editors<br />

President’s Page<br />

Articles<br />

Comparison of the Canadian Industrial Security Manual and the United States National<br />

Industrial Security Program Operating Manual<br />

Andrew Hammond .......................................................................................................................216<br />

The Infectious Dose of Francisella tularensis (Tularemia)<br />

Rachael M. Jones, Mark Nicas, Alan Hubbard, Matthew D. Sylvester, and Arthur Reingold .....227<br />

High-Dose Ultraviolet C Light Inactivates Spores of Bacillus Atrophaeus and Bacillus Anthracis<br />

Sterne on Nonreflective Surfaces<br />

Marie U. Owens, David R. Deal, Michael O. Shoemaker, Gregory B. Knudson,<br />

Janet E. Meszaros, and Jeffery L. Deal.....................................................................................240<br />

Autoclave Testing in a University Setting<br />

Richard N. Le, Amy L. Hicks, and Janice Dodge..........................................................................248<br />

Operating a BSL-4 Laboratory in a University Setting<br />

Tradeline Publications ..................................................................................................................253<br />

Special Features<br />

Use of Multiple SOP Styles to Increase Personnel Compliance and <strong>Safety</strong><br />

Within a BSL-2/BSL-3 Animal Facility<br />

Andrea Mitchell, Jeri Ellis, and Tim Ruddy..................................................................................258<br />

Book Review—Revenge of the Microbes by Abigail A. Salyers and Dixie D. Whitt<br />

Reviewed by George A. Pankey.....................................................................................................265<br />

Book Review—Biodefense: Principles and Pathogens Edited by Michael S. Bronze<br />

and Ronald A. Greenfield<br />

Reviewed by Michael P. Owen......................................................................................................266<br />

(continued on page 2<strong>10</strong>)

(continued from page 209)<br />

273<br />

2<strong>10</strong><br />

Ask the Experts—HEPA Filtered Supply Air for BSL-3 Laboratories?<br />

John H. Keene...............................................................................................................................268<br />

Biosafety Tips—Lymphocytic Choriomeningitis Virus—A Hazard in Rodent Animal Colonies<br />

Karen B. Byers ...............................................................................................................................270<br />

ABSA News<br />

<strong>2005</strong> ABSA Conference Photos.................................................................................................273<br />

<strong>2005</strong> ABSA Service Award Recipients......................................................................................274<br />

New ABSA Members for 2006 ...................................................................................................277<br />

<strong>2005</strong> ABSA Conference Sponsors.............................................................................................279<br />

Calendar of Events .......................................................................................................................280<br />

ABSA Journal Subscription Information ...................................................................................281<br />

ABSA Anthology Books Information and Order Form.............................................................282<br />

ABSA Chapters, Affiliates, and Affiliated Organizations........................................................283<br />

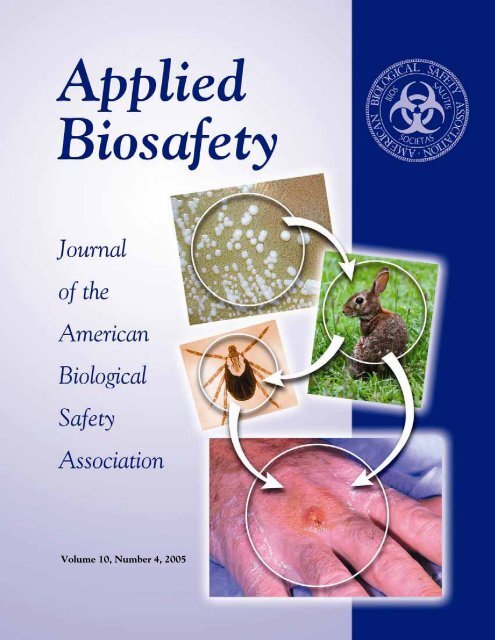

About the Cover<br />

Fransicella tularensis is the causative agent of tularemia. Exposure to F. tularensis has resulted in numerous<br />

laboratory acquired infections, some of which may have been due to aerosol exposures. Read more about<br />

infectious dose modeling on pages 227-239, “The Infectious Dose of Francisella tularensis (Tularemia)” by<br />

Rachael M. Jones, Mark Nicas, Alan Hubbard, Matthew D. Sylvester, and Arthur Reingold.<br />

One natural reservoir for this zoonotic disease is the rabbit. It can be transmitted to humans by handling<br />

infected blood or tissue, or consuming undercooked infected meat. The tick, an arthropod vector, can transmit<br />

the disease through its bite. The symptoms developed depend on the type of exposure route.<br />

Images from the CDC Public Health Image Library are: D. variabilis tick photo, taken by Andrew Brooks<br />

of CDC; Tularemia lesion on the dorsal skin of right hand photo, taken by Dr. Brachman of the CDC; and<br />

F. tularensis colony characteristics when grown on Chocolate, Martin Lewis or Thayer-Martin medium at<br />

48-72 hours, courtesy of Larry Stauffer, Oregon State Public Health Laboratory.

Applied Biosafety: Journal of the <strong>American</strong> <strong>Biological</strong> <strong>Safety</strong><br />

<strong>Association</strong> (ISSN 1535-6760) is published quarterly by the <strong>American</strong><br />

<strong>Biological</strong> <strong>Safety</strong> <strong>Association</strong> (ABSA). ABSA members receive the<br />

journal as a benefit of membership. An additional annual subscription<br />

for members is $60. Nonmembers and institutions/libraries may<br />

subscribe at the annual rates of $92 and $122 respectively. Single issue<br />

rates are as follows: members $18; nonmembers $28; and institutions/<br />

libraries $35.<br />

Authorization to Copy: No part of this publication may be<br />

reproduced, stored in a retrieval system, or transmitted in any form or<br />

by any means, electronic, electrostatic, magnetic tape, photocopying,<br />

recording, or otherwise, without permission in writing from the<br />

copyright holder.<br />

Change of Address: A change of address notice should be sent at<br />

least 6 weeks in advance to the ABSA National Office to ensure that<br />

all mailings, including the journal and newsletter, will reach you.<br />

ABSA is not responsible for misrouted mail as a result of insufficient<br />

notification of an address change. Undelivered copies resulting from<br />

an insufficient address change notification will not be replaced, but<br />

issues may be purchased at the single issue price as detailed above.<br />

ABSA National Office<br />

<strong>American</strong> <strong>Biological</strong> <strong>Safety</strong> <strong>Association</strong><br />

1202 Allanson Road<br />

Mundelein, IL 60060-3808, USA<br />

847-949-1517 / Fax 847-566-4580<br />

E-mail: absa@absa.org<br />

Web Site: www.absa.org<br />

Advertising Rates<br />

Rates 1x 2x 4x<br />

Outside back cover $800 $720 $680<br />

Inside front cover $600 $540 $5<strong>10</strong><br />

Inside back cover $600 $540 $5<strong>10</strong><br />

Full page $500 $450 $425<br />

1/2 page $300 $270 $255<br />

1/4 page $200 $180 $170<br />

Color rates: $350 for first color (after black) and $300 each additional color.<br />

15% discount for agencies (orders must be supplied on agency letterhead).<br />

Mechanical Requirements Width Height<br />

Outside back cover (full bleed) 8-1/2” 11”<br />

Inside front cover (full bleed) 8-1/2” 11”<br />

Inside back cover (full bleed) 8-1/2” 11”<br />

Full page 7” <strong>10</strong>”<br />

1/2 page - horizontal 7” 4-7/8”<br />

1/2 page - vertical 3-3/8” <strong>10</strong>”<br />

1/4 page 3-7/8” 4-7/8”<br />

Trim size—8-1/2” x 11”<br />

Film—133 line screen, right reading, emulsion side down, color separated<br />

Submission Deadlines<br />

February 1 for Spring issue May 1 for Summer issue<br />

August 1 for Fall issue November 1 for Winter issue<br />

The publication of any advertisement by this journal is not an<br />

endorsement of the advertiser or of the products or services advertised.<br />

ABSA is not responsible for any claims made in any advertisement.<br />

ABSA Journal Editorial Board<br />

Co-Editors<br />

Barbara Johnson, Department of Defense, Arlington, VA<br />

Karen B. Byers, Dana Farber Cancer Institute, Boston, MA<br />

Associate Editor<br />

Elizabeth Gilman Duane, Wyeth, Cambridge, MA<br />

Lynn Harding, Biosafety Consultant, Chattanooga, TN<br />

Assistant Editors<br />

Richard Fink, Wyeth BioPharma, Andover, MA<br />

John H. Keene, Biohaztec Associates, Inc., Midlothian, VA<br />

Thomas A. Kost, GlaxoSmithKline, Research Triangle Park, NC<br />

Ed Krisiunas, WNWN International, Burlington, CT<br />

International Editors<br />

Allan Bennett, European <strong>Biological</strong> <strong>Safety</strong> <strong>Association</strong> (EBSA),<br />

United Kingdom<br />

Maureen Best, International Biosafety Working Group (IBWG),<br />

Canada<br />

Otto Doblhoff-Dier, European <strong>Biological</strong> <strong>Safety</strong> <strong>Association</strong> (EBSA),<br />

Austria<br />

Betty Kupskay, ABSA Canada, Canada<br />

Ai Ee Ling, Asia Pacific Biosafety <strong>Association</strong> (APBA), Singapore<br />

Leila Oda, Associação Nacional de Biossegurança (ANBio), Brazil<br />

Production Editor<br />

Karen D. Savage<br />

Editorial Board<br />

Matthew J. Bankowski, ViroMed (LabCorp), Minnetonka, MN<br />

Franklin R. Champlin, Mississippi State University, Mississippi<br />

State, MS<br />

Mary L. Cipriano, Abbott Laboratories, Abbott Park, IL<br />

Robert P. Ellis, Colorado State University, Fort Collins, CO<br />

Glenn A. Funk, Lawrence Livermore National Laboratory,<br />

Livermore, CA<br />

Raymond W. Hackney, Jr., University of North Carolina, Chapel<br />

Hill, NC<br />

Philip Hagan, Georgetown University, Washington, DC<br />

Robert J. Hawley, Midwest Research Institute, Frederick, MD<br />

Richard Henkel, Centers for Disease Control and Prevention,<br />

Atlanta, GA<br />

Debra L. Hunt, Duke University, Durham, NC<br />

Peter C. Iwen, University of Nebraska Medical Center, Omaha, NE<br />

John H. Keene, Biohaztec Associates, Inc., Midlothian, VA<br />

Paul Michael Kivistik, University of Nevada, Reno, NV<br />

Joseph P. Kozlovac, USDA-ARS, Beltsville, MD<br />

Jens H. Kuhn, Harvard Medical School, Southborough, MA<br />

Margy S. Lambert, University of Wisconsin, Madison, WI<br />

R. Thomas Leonard, University of Virginia, Charlottesville, VA<br />

Paul J. Meechan, Merck Research Laboratories, West Point, PA<br />

Mark Nicas, University of California, Berkeley, CA<br />

Beryl J. Packer, Iowa State University, Ames, IA<br />

Tim Ravita, Constella Health Sciences, Atlanta, GA<br />

Richard Rebar, GlaxoSmithKline R&D, King of Prussia, PA<br />

Jonathan Y. Richmond, Jonathan Richmond & Associates, Inc.,<br />

Southport, NC<br />

Deanna S. Robbins, Department of Veterans Affairs, Baltimore, MD<br />

Richard J. Shaughnessy, University of Tulsa, Tulsa, OK<br />

Allan Showler, USDA-ARS, Weslaco, TX<br />

Cecil R. Smith, Ohio State University, Columbus, OH<br />

Gerard J. Spahn, The Salk Institute, La Jolla, CA<br />

Donald Vesley, University of Minnesota, Minneapolis, MN<br />

Catherine L. Wilhelmsen, United States Army Medical Research<br />

Institute of Infectious Diseases (USAMRIID), Fort Detrick, MD<br />

Linda B. Wolfe, Whitehead Institute for Biomedical Research,<br />

Cambridge, MA<br />

Jeffrey D. Wolt, Iowa State University, Ames, IA<br />

Alan G. Woodard, International Environmental Health Alliance,<br />

Gansevoort, NY

Vision<br />

212<br />

ABSA, the leader in the profession of biological safety.<br />

Mission Statement<br />

The <strong>American</strong> <strong>Biological</strong> <strong>Safety</strong> <strong>Association</strong> is dedicated to expanding biological safety awareness to<br />

prevent adverse occupational and environmental impact from biohazards.<br />

Goals<br />

• Expand professional and public awareness of biological safety through effective communication.<br />

• Participate in the development of biological safety and biosecurity standards, guidelines, and<br />

regulations.<br />

• Develop ABSA as the recognized resource for professional and scientific expertise in biological<br />

safety and biosecurity.<br />

• Advance biological safety as a scientific discipline through education, research, and professional<br />

development.<br />

ABSA Officers<br />

President<br />

Glenn A. Funk, Lawrence Livermore National Laboratory, Livermore, CA<br />

President-Elect<br />

Robert J. Hawley, Midwest Research Institute, Frederick, MD<br />

Secretary<br />

Rosamond Rutledge-Burns, National Institute Standards & Technology, Gaithersburg, MD<br />

Treasurer<br />

Leslie Delpin, University of Connecticut, Storrs, CT<br />

Past-President<br />

Elizabeth Gilman Duane, Wyeth, Cambridge, MA<br />

Council Members<br />

Robert P. Ellis, Colorado State University, Fort Collins, CO<br />

Joseph P. Kozlovac, USDA Agricultural Research Service, Beltsville, MD<br />

Patricia Olinger, Pharmacia Corporation, Kalamazoo, MI<br />

Chris Thompson, Greenfield, IN<br />

Executive Director<br />

Edward J. Stygar, Jr.

Letter to the Editors<br />

James J. Coogan<br />

Siemens Building Technologies, Buffalo Grove, Illinois<br />

Let me commend Allan Bennett et al. on valuable<br />

piece of research and an illuminating article<br />

entitled “Development of Particle Tracer Techniques<br />

to Measure the Effectiveness of High Containment<br />

Laboratories” in Applied Biosafety (<strong>Volume</strong> <strong>10</strong>, <strong>Number</strong><br />

3, <strong>2005</strong>). The facts and observations presented<br />

support some common engineering assumptions and<br />

challenge others. Both results are valuable.<br />

Definition of Laboratory Protection Factor and<br />

the test methods described advance our ability to<br />

discuss effective pressurization. The result that containment<br />

correlates more closely to infiltrating air<br />

flow than to pressure difference is intriguing. I expect<br />

it surprises many engineers as much as it does<br />

me.<br />

The explanation offered is that the air flowing<br />

inward through the door catches contaminants and<br />

prevents their escape while the door is open and a<br />

person walks through it. The authors themselves<br />

seem to find it unlikely that such low air velocity<br />

captures contaminants. (The air velocity reported<br />

through the open door is 0.14 m s-1 and lower:<br />

much less than the velocity of the swinging door or<br />

the walking person.)<br />

Perhaps it is appropriate to propose another explanation<br />

for the results. Consider the effect that the<br />

Editorial Note<br />

Letters to the Editors (approximately 400 words)<br />

discuss information published in Applied Biosafety in<br />

the past nine months or discuss topic areas of general<br />

interest in the biosafety profession. Letters can<br />

Applied Biosafety, <strong>10</strong>(4) p. 213 © ABSA <strong>2005</strong><br />

infiltrating air flow has on contaminant concentrations<br />

while the door is closed before and after entry<br />

or exit. Just inside the door, contaminated air is continuously<br />

replaced by the clean infiltrating air. This<br />

lowers the concentration near the door. When entry<br />

or exit occurs, certainly some air leaves the room,<br />

but this air is cleaner than it would be with a lower<br />

infiltrating air flow rate, so less contaminant leaves<br />

the room. After the entry or exit is complete and the<br />

door is closed, some quantity of contaminant lingers<br />

outside the room. A portion of it is picked up by the<br />

particle counters, but presumably, some of it is<br />

drawn back into the room by the on-going infiltration.<br />

In short, the supposition is that infiltrating air<br />

flow has a continuous cleaning effect near the door,<br />

and that this on-going effect (rather than several seconds<br />

of infiltration at very low velocity during entry<br />

or exit) increases the Laboratory Protection Factor.<br />

Do the authors have more information that will<br />

help us choose one mechanism or the other to explain<br />

the results? In some cases, the question is<br />

moot. Containment is the issue and the mechanism<br />

may be unimportant, but there are ventilation systems<br />

where the distinction is crucial.<br />

be submitted electronically to Karen D. Savage,<br />

Production Editor, at ksavage@covad.net or by mail<br />

to ABSA National Office, Applied Biosafety, 1202<br />

Allanson Road, Mundelein, IL 60060. Letters published<br />

in part or whole are subject to editing for clarity<br />

and special formatting.<br />

213

I suspect every new organization president wrestles<br />

with questions like “What do I want to achieve<br />

during my presidency?” and “Where do I want to<br />

lead the organization during the next year?” These<br />

are weighty issues that focus on the best interests of<br />

the membership in general and the institution in<br />

particular. They’re made especially challenging by<br />

the outstanding leadership and successes provided<br />

by recent past presidents. I have, appropriately, a<br />

very high standard to uphold.<br />

With 1,500 members representing 30 different<br />

countries and 16 Affiliates and affiliated organizations,<br />

ABSA is no longer a small club of friends. We<br />

are gaining the mass to be noticed, to be listened to,<br />

to be asked for advice and help, and to make a difference<br />

in the realms of science we impact. It would<br />

be easy for me to suggest that we grow the organization<br />

because as we grow larger, we grow stronger and<br />

we have a louder voice. There is truth in this, and<br />

growing ABSA is a worthy goal that we should pursue.<br />

However, at this point, I believe it is also important<br />

to “grow our profession”—to bring more highly<br />

qualified scientists into our ranks, to strengthen our<br />

knowledge base, and to provide additional ABSA<br />

members who will enrich our organization. I believe<br />

there are many scientists and health and safety professionals<br />

who are unaware of the challenges and<br />

rewards of biosafety as a career, or of the need for<br />

highly skilled biosafety professionals in the scientific<br />

community.<br />

To keep our profession attractive to others and<br />

respected within the scientific community, we must<br />

maintain, strengthen, and continue to demonstrate<br />

the high professional standards to which we adhere<br />

every day. Each of us must set the Gold Standard for<br />

professionalism, for technical competency, for cus-<br />

214<br />

President’s Page<br />

Glenn A. Funk<br />

Gualala, California<br />

Applied Biosafety, <strong>10</strong>(4) pp. 214-215 © ABSA <strong>2005</strong><br />

tomer service, and for flexibility and adaptability to<br />

meet the varied and often unanticipated needs of<br />

our customers. We must not simply continue to be<br />

the best of the best; we must continually get better at<br />

what we do. As “Neutron Jack” Welch, ex-CEO of<br />

General Electric, used to say, “You can’t just talk the<br />

talk; you’ve also got to walk the walk.”<br />

One of the things we do best in ABSA is share<br />

our knowledge through networking, seminars, training<br />

sessions, and professional courses. ABSA is your<br />

organization, and I urge you to use the opportunities<br />

it offers to improve your skills as a biosafety professional.<br />

Meanwhile, your ABSA Council and I will<br />

continue to make ABSA better for you. The management<br />

consultants who helped us restructure our<br />

business model also helped us identify important<br />

areas for Task Force study; we held off implementing<br />

these during the first year in order to focus on the<br />

business infrastructure. This year we’ll put Task<br />

Forces to work defining the parameters of the biosafety<br />

profession, enhancing the value and benefits<br />

of professional Registration and Certification, and<br />

determining the feasibility and usefulness of an<br />

ABSA Emergency Response capability to provide<br />

assistance during national and international emergencies<br />

that involve biosafety. If you have an interest<br />

in serving on one of these Task Forces, please let me<br />

know (gafunk@absa.org).<br />

One other effort soon to be underway is a renewed<br />

push to catalog the ABSA Historical Collection<br />

and transfer it to safe archival storage. Once<br />

that’s done, we can look at ways to make it accessible<br />

to members through, for example, displays at meetings<br />

and articles in this Journal. Ultimately, I’d like<br />

to see at least parts of the collection available online.<br />

In future columns I’ll discuss other ideas for

moving ABSA forward. As always, I greatly appreciate<br />

your volunteer efforts to help make ABSA what<br />

it is. We wouldn’t be here today if it weren’t for the<br />

active and positive participation of our many talented<br />

members. As President, my door is open to<br />

Corrections and Clarifications<br />

G. A. Funk<br />

you. Please send me e-mails with your ideas and suggestions.<br />

We’ll talk about them, I’ll take the great<br />

ideas to Council, and together we’ll continue to<br />

make ABSA better and stronger.<br />

Special Features, Ask the Experts: “USDA BSL-3 Facility Requirements: What’s the<br />

Concern?” authorship attribution in the Table of Contents is incorrect (<strong>Volume</strong> <strong>10</strong>, <strong>Number</strong><br />

3, page 133). It should be: John H. Keene.<br />

EPA Pesticide Program Update from EPA’s Office of Pesticide Programs<br />

<strong>10</strong>/11/05: EPA Approves New Non-Chemical Control for Corn Rootworm<br />

www.epa.gov/pesticides<br />

After an intensive, multi-year scientific analysis, EPA has approved applications submitted by Mycogen<br />

Seeds (c/o Dow AgroSciences, LLC) and Pioneer Hi-Bred International, Inc. for the use of a new corn<br />

plant-incorporated protectant (PIP) designed to control corn rootworm. Corn rootworm is a widespread<br />

and destructive insect pest responsible for the single largest use of conventional insecticides in the United<br />

States. The new product is the second PIP to offer protection against corn rootworm and is expected to<br />

result in a further reduction of chemical insecticide use by growers.<br />

The new corn plant-incorporated protectant, Event DAS-59122-7 Corn, produces its own insecticide<br />

within the corn plant derived from Bacillus thuringiensis (Bt), a naturally occurring soil bacterium. The Bt<br />

proteins used in this product, called Cry34Ab1 and Cry35Ab1 (Cry 34/35), control corn rootworm.<br />

To reduce the likelihood of corn rootworm developing resistance to Bt, EPA is requiring Mycogen and<br />

Pioneer to ensure that buffer zones within the planted acreage be planted with corn that is not protected<br />

from corn rootworm to serve as a “refuge.” The insect populations in the refuges will help prevent<br />

resistance development when they cross-breed with insects in the Bt fields. This resistance management<br />

strategy was developed as a condition of the registration, and EPA will require routine monitoring and<br />

documentation that these measures are followed.<br />

The reduction in chemical pesticide use will benefit the environment directly and can mean less<br />

chemical exposure to people who apply pesticides to corn. The availability of multiple corn rootwormprotected<br />

corn products will also increase grower choice and price competition, resulting in lower seed<br />

prices for consumers and higher adoption rates. The product provides yet another way to combat corn<br />

rootworm, as well as indirect benefits such as energy savings resulting from reduced chemical insecticide<br />

use. As with similar products, EPA has approved Cry 34/35 for time-limited use, which will be subject to<br />

reevaluation in five years. For more information on EPA’s regulation of biopesticide products, see<br />

www/epa.gov/pesticides/biopesticides/.<br />

215

Abstract<br />

Because of the potential for use as a bioterrorism<br />

agent or bioweapon, many governments have imposed<br />

strict regulations regarding the possession, use, and<br />

transfer of “select” biological agents. Consequently,<br />

much of the information surrounding the possession and<br />

use of these agents is potentially classified, and those<br />

contractors and their employees who require access to<br />

this information must receive Facility (contractor) and<br />

Personnel (employees) clearances. Both Canada and<br />

the United States (U.S.) have produced industrial security<br />

manuals—the Industrial Security Manual (ISM)<br />

(Canadian and International Industrial Security Directorate,<br />

2004) and the National Industrial Security<br />

Program Operating Manual (NISPOM) (Defense<br />

Technical Information Center, 1995)—for use by<br />

cleared government contractors. These documents set<br />

forth the requirements, restrictions, and other safeguards<br />

that are necessary to prevent unauthorized disclosure<br />

of classified information and assets provided to<br />

or produced by private government contractors. This<br />

article compares and contrasts the requirements set<br />

forth in the ISM and the NISPOM. The results of this<br />

comparison present a valuable security management<br />

tool for private organizations that wish to engage in<br />

classified work for the Canadian, U.S., or both governments.<br />

216<br />

Article<br />

Introduction<br />

Applied Biosafety, <strong>10</strong>(4) pp. 216-226 © ABSA <strong>2005</strong><br />

Comparison of the Canadian Industrial Security<br />

Manual and the United States National<br />

Industrial Security Program Operating Manual<br />

Andrew Hammond<br />

Constella Health Sciences, Atlanta, Georgia<br />

As a result of the October 2001 anthrax letter<br />

attacks, both the United States and Canada enacted<br />

new laws imposing additional restrictions on certain<br />

hazardous biological agents and toxins. The U.S.<br />

enacted the Public Health Security and Bioterrorism<br />

Preparedness and Response Act of 2002 (Public Law<br />

<strong>10</strong>7-188) (U.S. Government Printing Office, 2002)<br />

and Canada passed the Public <strong>Safety</strong> Act, 2002<br />

(Parliament of Canada, 2002). Because of the potential<br />

for “select” biological agents and toxins being<br />

used as bioterrorism agents or in a bioweapons program,<br />

both Acts impose strict regulations regarding<br />

their possession, use, and transfer. Consequently,<br />

much of the information surrounding the possession<br />

and use of these agents is potentially classified (or<br />

confidential), and those organizations and their employees<br />

who require access to this information must<br />

receive Facility (organization) and Personnel<br />

(employee) clearances. Both Canada and the U.S.<br />

have produced industrial security manuals—Industrial<br />

Security Manual (ISM) (Canadian and International<br />

Industrial Security Directorate, 2004) and the National<br />

Industrial Security Program Operating Manual<br />

(NISPOM) (Defense Technical Information Center,<br />

1995)—for use by cleared government contractors.<br />

These documents set forth the requirements, restrictions,<br />

and other safeguards that are necessary to prevent<br />

unauthorized disclosure of classified information<br />

(and assets) provided to or produced by private

government contractors and to control the authorized<br />

disclosure of classified information (and assets)<br />

released by the governments to their contractors.<br />

United States—National Industrial<br />

Security Program Operating Manual<br />

Security Classifications<br />

An original classification decision at any level<br />

can be made only by a U.S. Government official<br />

who has been delegated this authority in writing.<br />

Contractors may make derivative classification decisions<br />

based on the guidance provided by the Contract<br />

Security Classification Specification that is issued<br />

with each classified contract. Derivative classification<br />

is the act of classifying a specific item of information<br />

or material on the basis of an original classification<br />

decision already made by an authorized<br />

original classification authority. The source of authority<br />

for derivative classification ordinarily consists<br />

of a previously classified document or a classification<br />

guide issued by an original classification authority.<br />

Top Secret<br />

Top secret information or material is that information<br />

or material whose unauthorized disclosure<br />

could be reasonably expected to cause exceptionally<br />

grave damage to the national security that the original<br />

classification authority is able to identify or describe.<br />

Examples include armed hostilities against the<br />

United States or its allies, disruption of foreign relations<br />

vitally affecting the national security, and the<br />

disclosure of scientific or technological developments<br />

vital to national security.<br />

Secret<br />

Secret information or material is that information<br />

or material whose unauthorized disclosure<br />

could be reasonably expected to cause serious damage<br />

to the national security that the original classification<br />

authority is able to identify or describe. Examples<br />

of serious damage include significant impairment<br />

of a program or policy directly related to the<br />

national security and compromise of significant scientific<br />

or technological developments relating to national<br />

security.<br />

A. Hammond<br />

Confidential<br />

Confidential information or material is that information<br />

or material whose unauthorized disclosure<br />

could be reasonably expected to cause damage to<br />

the national security that the original classification<br />

authority is able to identify or describe. Examples<br />

include documents relating to clearance or assignment<br />

of personnel who will have knowledge of, or<br />

access to, classified information or materials or details<br />

pertaining to features of routes and schedules of<br />

shipments of confidential materials.<br />

Facility Security<br />

Facility Clearances<br />

A facility security clearance (FCL) is an administrative<br />

determination that a facility is eligible for access<br />

to classified information at the same or lower<br />

classification category as the clearance being granted.<br />

Contractors are eligible for custody of classified material,<br />

if they have an FCL and storage capability approved<br />

by the Cognizant Security Agency (CSA).<br />

A procuring activity of the Government or<br />

cleared contractor may request a facility clearance for<br />

a contractor or prospective contractor/<br />

subcontractor when a definite, classified procurement<br />

need has been established. Also, the contractor<br />

must be organized and existing under the laws of any<br />

of the 50 states, the District of Columbia, or Puerto<br />

Rico, and be located in the U.S. and its territorial<br />

areas or possessions.<br />

Meetings<br />

Classified disclosure at a meeting (e.g., conference,<br />

seminar, symposium, exhibit, convention,<br />

training course, or other such gathering) which<br />

serves a government purpose and at which adequate<br />

security measures have been provided in advance<br />

may be conducted by a cleared contractor provided<br />

the meeting is authorized by a Government Agency<br />

that has agreed to assume security jurisdiction. The<br />

Government Agency must approve security arrangements,<br />

announcements, attendees, and the location<br />

of the meeting. (Classified meetings shall be held<br />

only at a Federal Government installation or a<br />

cleared contractor facility where adequate physical<br />

security and procedural controls have been ap-<br />

217

proved.) Contractors wishing to conduct classified<br />

meetings shall submit their requests to the Government<br />

Agency having principal interest in the subject<br />

matter of each meeting.<br />

Personnel Security<br />

Security Officers<br />

The Facility Security Officer (FSO) shall be a<br />

U.S. citizen employee appointed by the contractor<br />

who is cleared as part of the facility clearance. The<br />

FSO will supervise and direct security measures necessary<br />

for implementing the NISPOM and related<br />

Federal requirements for classified information.<br />

The senior management official and the FSO<br />

must always be cleared to the level of the Facility<br />

Clearance (FCL). Other officials, as determined by<br />

the CSA, must be granted a Personnel Clearance<br />

(PCL) or be excluded from classified access.<br />

Personnel Clearances<br />

An industrial personnel security clearance is an<br />

administrative determination that an industrial employee<br />

is eligible for access to classified information.<br />

This determination is based on investigation and<br />

review of available personal data and a finding that<br />

access is clearly consistent with national interests.<br />

An individual may be processed for a personnel<br />

security clearance only when employed by a cleared<br />

contractor in a job requiring access to classified information.<br />

As an exception, a candidate for employment<br />

may be processed for a PCL provided a written<br />

commitment for employment that prescribes a fixed<br />

date for employment within the ensuing 180 days<br />

has been made by the contractor, and the candidate<br />

has accepted the employment offer in writing.<br />

Under rare circumstances, a non-U.S. citizen<br />

may be issued a Limited Access Authorization for<br />

access to classified information. Specific criteria and<br />

limitations are provided in the NISPOM.<br />

Contractors have no authority to grant, deny, or<br />

revoke personnel clearances for their employees.<br />

This authority is reserved by the U.S. Government.<br />

Subcontracting<br />

Before a prime contractor may release, disclose<br />

classified information to a subcontractor, or cause<br />

218<br />

Comparison of the Canadian Manual and the U.S. Manual<br />

classified information to be generated by a subcontractor,<br />

he or she must determine the security requirements<br />

of the subcontract and determine clearance<br />

status of prospective subcontractors. The prime<br />

contractor shall verify the clearance status and safeguarding<br />

capability of the subcontractor from the<br />

CSA. If a prospective subcontractor does not have<br />

the appropriate FCL or safeguarding capability, the<br />

prime contractor shall request the CSA of the subcontractor<br />

to initiate the necessary action.<br />

The prime contractor shall ensure that a Contract<br />

Security Classification Specification is incorporated<br />

in each classified subcontract. The contractor<br />

shall also review the security requirements during<br />

the different stages of the subcontract and provide<br />

the subcontractor with applicable changes in these<br />

security requirements. Upon completion of the subcontract,<br />

the subcontractor may retain classified material<br />

received or generated under the subcontract<br />

for a 2-year period, provided the prime contractor or<br />

GCA does not advise to the contrary.<br />

Education, Training, and Briefings<br />

Contractors shall provide all cleared employees<br />

with security training and briefings commensurate<br />

with their involvement with classified information.<br />

Contractors shall also be responsible for ensuring<br />

that the FSO, and others performing security duties,<br />

complete security training deemed appropriate by<br />

the CSA. (Training, if required, should be completed<br />

within 1 year of appointment to the position<br />

of FSO.) The contractor is responsible for providing<br />

all cleared employees with some form of security<br />

education and training at least annually.<br />

The SF 312 is an agreement between the United<br />

States and an individual who is cleared for access to<br />

classified information. An employee issued an initial<br />

PCL must execute an SF 312 prior to being granted<br />

access to classified information. The employee must<br />

also receive an initial security briefing that includes a<br />

Threat Awareness Briefing, a Defensive Security<br />

Briefing, an overview of the security classification<br />

system, employee reporting obligations and requirements,<br />

and security procedures and duties applicable<br />

to the employee’s job.<br />

Contractors shall debrief cleared employees at<br />

the time of termination (discharge, resignation, or

etirement); when an employee’s PCL is terminated,<br />

suspended, or revoked, and upon termination of the<br />

FCL.<br />

Visits<br />

The contractor must determine that the visit is<br />

necessary and that the purpose of the visit cannot be<br />

achieved without access to, or disclosure of, classified<br />

information. All classified visits require advance<br />

notification to, and approval of, the organization<br />

being visited. In urgent cases, visit information may<br />

be furnished by telephone provided that it is followed<br />

up in writing. The contractor shall issue a<br />

Visit Authorization Letter (VAL) to the organization<br />

being visited that shall include the following:<br />

• Contractor’s name, address, and telephone number,<br />

assigned CAGE Code, and certification of the<br />

level of the FCL<br />

• Name, date, place of birth, and citizenship of the<br />

employee intending to visit<br />

• Certification of the proposed visitor’s PCL and<br />

any special access authorizations required for the<br />

visit<br />

• Name of person(s) to be visited<br />

• Purpose and sufficient justification for the visit<br />

to allow for a determination of the necessity of the<br />

visit<br />

• Date or period during which the VAL is to be<br />

valid<br />

Contractors shall maintain a record of all visitors<br />

to their facility who have been approved for access<br />

to classified information.<br />

Document Security<br />

General Marketing<br />

All classified material shall be marked on the<br />

face of the document to show the name and address<br />

of the facility responsible for its preparation and the<br />

date of preparation. The highest level of classified<br />

information contained in a document is its overall<br />

marking. The overall marking shall be conspicuously<br />

marked or stamped at the top and bottom on the<br />

outside of the front cover, on the title page, on the<br />

first page, and on the outside of the back cover. Interior<br />

pages of classified documents shall be marked at<br />

A. Hammond<br />

the top and bottom with the highest classification of<br />

the information appearing thereon or marked UN-<br />

CLASSIFIED if all the information on the page is<br />

UNCLASSIFIED. The major components of complex<br />

documents are likely to be used separately.<br />

Therefore, each major component shall be marked<br />

as a separate document. Also, each section, part,<br />

paragraph, or similar portion of a classified document<br />

shall be marked to show the highest level of its<br />

classification, or that the portion is unclassified. Unclassified<br />

subjects and titles shall be selected for classified<br />

documents, if possible. If a classified subject or<br />

title must be used, it shall be marked with the appropriate<br />

symbol—(TS), (S), or (C)—placed immediately<br />

following and to the right of the item.<br />

All classified information shall be marked to<br />

reflect the source of the classification and declassification<br />

instructions. This required information shall<br />

be placed on the cover, first page, title page, or in<br />

another prominent position.<br />

General Storage<br />

Cognizant security officials shall work to meet<br />

appropriate security needs according to the intent of<br />

the NISPOM and at an acceptable cost.<br />

TOP SECRET material shall be stored in a<br />

GSA-approved security container, an approved vault,<br />

or an approved Closed Area. Supplemental protection<br />

is required.<br />

SECRET material shall be stored in the same<br />

manner as TOP SECRET material without supplemental<br />

protection.<br />

CONFIDENTIAL material shall be stored in the<br />

same manner as TOP SECRET or SECRET material<br />

except that no supplemental protection is required.<br />

Reproduction<br />

Contractors shall establish a reproduction control<br />

system to ensure that reproduction of classified<br />

material is held to the minimum consistent with<br />

contractual and operational requirements. Classified<br />

reproduction shall be accomplished by authorized<br />

employees knowledgeable about the procedures for<br />

classified reproduction. The use of technology that<br />

prevents, discourages, or detects the unauthorized<br />

reproduction of classified documents is encouraged.<br />

219

All reproductions of classified material shall be<br />

conspicuously marked with the same classification<br />

markings as the material being reproduced.<br />

Domestic Transmission Standards<br />

(Outside of Facility)<br />

Top Secret<br />

• Written authorization of the Government Contracting<br />

Activity (GCA)<br />

• Sealed, opaque inner and outer covers with the<br />

inner cover being a wrapper or envelope plainly<br />

marked with the assigned classification and addresses<br />

of both sender and addressee<br />

• A receipt that identifies the sender, the addressee,<br />

and the document shall be attached to or<br />

enclosed in the inner cover<br />

• Via:<br />

a. Defense Courier Service (DCS), if authorized<br />

by GCA<br />

b. A designated courier or escort cleared for<br />

access to TOP SECRET information<br />

c. By electrical means over CSA-approved secured<br />

communications security circuits provided<br />

such transmission conforms with the<br />

NISPOM, the telecommunications security<br />

provisions of the contract, or is authorized<br />

by the GCA<br />

Secret<br />

• Sealed, opaque inner and outer covers with the<br />

inner cover being a wrapper or envelope plainly<br />

marked with the assigned classification and addresses<br />

of both sender and addressee<br />

• A receipt that identifies the sender, the addressee,<br />

and the document shall be attached to or<br />

enclosed in the inner cover<br />

• Via:<br />

a. TOP SECRET methods<br />

b. USPS Express or Registered mail<br />

c. A cleared “Commercial Carrier”<br />

d. A cleared commercial messenger service engaged<br />

in the intracity/local area delivery<br />

(same day delivery only) of classified material<br />

e. A commercial delivery company approved by<br />

the CSA<br />

f. Other methods as directed, in writing, by<br />

the GCA<br />

220<br />

Comparison of the Canadian Manual and the U.S. Manual<br />

Confidential<br />

• Packaged by SECRECT material methods except<br />

that a receipt is required only if the sender deems it<br />

necessary<br />

• Via:<br />

a. SECRET methods<br />

b. USPS Certified mail<br />

International Transmission Standards<br />

Top Secret<br />

• Domestic requirements<br />

• Via:<br />

a. Defense Courier Service<br />

b. Department of State Courier System<br />

c. Courier service authorized by GCA<br />

Secret and Confidential<br />

• Domestic requirements<br />

• Via:<br />

a. Registered mail through U.S. Army, Navy,<br />

or Air Force postal facilities<br />

b. Appropriately cleared contractor employee<br />

c. U.S. civil service employee or military person<br />

designated by the GCA<br />

d. U.S. and Canadian registered mail with registered<br />

mail receipt to and from Canada and<br />

via a U.S. or Canadian government activity<br />

e. As authorized by the GCA<br />

Destruction<br />

Contractors shall destroy classified material in<br />

their possession as soon as possible after it has<br />

served the purpose for which it was intended.<br />

Classified material may be destroyed by burning,<br />

shredding, pulping, melting, mutilation, chemical<br />

decomposition, or pulverizing. Pulpers, pulverizers,<br />

or shedders may be used only for the destruction of<br />

paper products. Residue shall be inspected during<br />

each destruction to ensure that classified information<br />

cannot be reconstructed. Crosscut shredders<br />

shall be designed to produce residue particle size not<br />

exceeding 1/32 inch in width by 1/2 inch in length.<br />

Public destruction facilities may be used only<br />

with the approval of the CSA, and classified material<br />

removed from a cleared facility for destruction shall<br />

be destroyed on the same day it is removed.<br />

Destruction shall be performed only by appropri-

ately cleared employees of the contractor. For destruction<br />

of TOP SECRET material, two persons are<br />

required. For destruction of SECRET and CONFI-<br />

DENTIAL material, one person is required.<br />

Destruction records that indicate the date of<br />

destruction, identify the material destroyed, and are<br />

signed by the individuals designated to destroy and<br />

witness the destruction are required for TOP SE-<br />

CRET material.<br />

Information System Security<br />

Information systems (IS) that are used to capture,<br />

create, store, process, or distribute classified<br />

information must be properly managed to protect<br />

against unauthorized disclosure of classified information<br />

and loss of data integrity, and to ensure the<br />

availability of the data and system.<br />

Protection requires a balanced approach including<br />

IS security features to include. but not limited<br />

to, administrative, operational, physical, computer,<br />

communications, and personnel controls. Protective<br />

measures commensurate with the classification of<br />

the information, the threat, and the operational requirements<br />

associated with the environment of the<br />

IS are required.<br />

The requirements outlined in the NISPOM apply<br />

to all information systems processing classified<br />

information. Additional requirements for high-risk<br />

systems and data are covered in the NISPOM Supplement.<br />

The CSA is the Designated Accrediting/<br />

Approving Authority (DAA) responsible for accrediting<br />

information systems used to process classified<br />

information in industry. A formal certification and<br />

accreditation (C&A) occurs after the protection<br />

measures have been implemented and any required<br />

IS protection documentation has been approved.<br />

Certification validates that the protection measures<br />

described in the System Security Plan (SSP) have<br />

been implemented on the system and that the protection<br />

measures are functioning properly. Accreditation<br />

is the approval by the CSA for the system to<br />

process classified information.<br />

A. Hammond<br />

Canada—Industrial Security Manual<br />

Security Classifications<br />

The originator of the information and assets<br />

determines the classification level.<br />

Top Secret<br />

TOP SECRET refers to information and assets<br />

related to the national interest that may qualify for<br />

an exemption or exclusion under the Access to Information<br />

Act or Privacy Act and that the compromise<br />

of which would reasonably be expected to cause<br />

exceptionally grave injury to the national interest.<br />

Secret<br />

SECRET refers to information and assets related<br />

to the national interest that may qualify for an exemption<br />

or exclusion under the Access to Information<br />

Act or Privacy Act and that the compromise of<br />

which would reasonably be expected to cause serious<br />

injury to the national interest.<br />

Confidential<br />

CONFIDENTIAL refers to information and<br />

assets related to the national interest that may qualify<br />

for an exemption or exclusion under the Access<br />

to Information Act or Privacy Act and that the compromise<br />

of which would reasonably be expected to<br />

cause injury to the national interest.<br />

Protected “C”<br />

PROTECTED “C” refers to information and<br />

assets related to other than the national interest that<br />

may qualify for an exemption or exclusion under the<br />

Access to Information Act or Privacy Act that could<br />

reasonably be presumed to cause extremely serious injury,<br />

such as loss of life, if compromised.<br />

Protected “B”<br />

PROTECTED “B” refers to information and<br />

assets related to other than the national interest that<br />

may qualify for an exemption or exclusion under the<br />

Access to Information Act or Privacy Act that could<br />

reasonably be expected to cause serious injury if compromised.<br />

221

Protected “A”<br />

PROTECTED “A” refers to information and<br />

assets related to other than the national interest that<br />

may qualify for an exemption or exclusion under the<br />

Access to Information Act or Privacy Act that could<br />

reasonably be presumed to cause injury if compromised.<br />

Facility Security<br />

Facility Clearances<br />

A Facility Security Clearance is an administrative<br />

determination that an organization is eligible, from a<br />

security viewpoint, for access to CLASSIFIED and<br />

PROTECTED information and assets of the same<br />

or lower classification level as the clearance being<br />

granted.<br />

There are three types of Facility Security Clearances<br />

each of which may be authorized at the classification<br />

level of CONFIDENTIAL, SECRET, or TOP<br />

SECRET:<br />

1. Personnel Assigned (PA). This is the most basic<br />

type of Facility Security Clearance which involves<br />

security screening of the organization’s Key Senior<br />

Officials and employees. There is NO requirement<br />

to evaluate the physical security status of the organization’s<br />

facilities. The organization is not authorized<br />

to possess or store CLASSIFIED information and<br />

assets.<br />

2. Document Safeguarding Capability (D.Sc.). In addition<br />

to the security screening of the organization’s<br />

Key Senior Officials and employees, the physical security<br />

of the organization’s facilities is assessed to<br />

ensure safeguarding requirements are met. The organization<br />

is authorized to possess and store CLAS-<br />

SIFIED information and assets.<br />

3. Production (PROD). This includes all of the elements<br />

of a Document Safeguarding Facility Security<br />

Clearance. In addition, the security of the manufacturing,<br />

repairing, modifying, or otherwise working<br />

on CLASSIFIED components or items is assessed to<br />

ensure government security requirements are met.<br />

A Designated Organization Screening (at the PRO-<br />

TECTED level) is an administrative determination<br />

that an organization is eligible, from a security viewpoint,<br />

for access to PROTECTED information and<br />

assets of the same or lower level as the clearance be-<br />

222<br />

Comparison of the Canadian Manual and the U.S. Manual<br />

ing granted. The three types of Designated Organization<br />

Screening are equivalent to the three types of<br />

Facility Security Clearances except they pertain only<br />

to PROTECTED information and assets. Each of<br />

the three types may be authorized at one of the following<br />

levels: PROTECTED “A,” PROTECTED<br />

“B,” or PROTECTED “C.”<br />

An organization is eligible to obtain an organization<br />

security screening/clearance only if it is sponsored<br />

by an authorized sponsor in support of an existing<br />

or impending contract or bid solicitation<br />

which calls for access to CLASSI-<br />

FIED/PROTECTED information, assets, and/or<br />

certain restricted work sites.<br />

Meetings<br />

(No provisions are established within the Canadian<br />

Industrial Security Manual.)<br />

Personnel Security<br />

Security Officers<br />

All organizations that require a Designated Organization<br />

Screening or a Facility Security Clearance<br />

shall appoint a Company Security Officer. The Company<br />

Security Officer shall be appointed by the<br />

Chief Executive Officer (CEO) or the designated Key<br />

Senior Official (KSO) of the organization. The CSO<br />

must be a Canadian citizen employee, report to a<br />

designated KSO, and be security screened or cleared<br />

to the Reliability Status level or Facility Security<br />

Clearance level of the facility. The appointment of<br />

the Company Security Officer must be approved by<br />

the Canadian and International Industrial Security<br />

Directorate (CIISD).<br />

When a facility-cleared Canadian parent organization<br />

owns one or more cleared subsidiaries in Canada,<br />

a Corporate Company Security Officer (CCSO)<br />

should be appointed to oversee government industrial<br />

security matters for the entire corporation.<br />

Personnel Clearances<br />

Personnel Security Screening must be carried<br />

out according to the highest sensitivity level of information<br />

and assets that will be accessed during the

contracting process and/or required for access to<br />

restricted work sites. Access to PROTECTED information,<br />

assets, and restricted work sites requires that<br />

an individual has Reliability Status, and access to<br />

CLASSIFIED information, assets, and/or restricted<br />

work sites requires a Security Clearance at the appropriate<br />

level of sensitivity.<br />

Only individuals employed or under a contract<br />

to commence employment within 60 days by a private<br />

sector organization on a contract/subcontract<br />

requiring access to CLASSIFIED/PROTECTED<br />

information, assets, and/or certain restricted work<br />

sites may be security screened. Non-Canadian citizens<br />

may be security cleared with access limitations.<br />

The limitations include denying access to CLASSI-<br />

FIED/PROTECTED information and assets which<br />

are not of Canadian origin, do not come from the<br />

country of which the person is a citizen, or are not<br />

releasable to his/her nation of origin.<br />

Contractors have no authority to deny or revoke<br />

Personnel Security Clearances for employees. This<br />

authority is reserved by the Canadian Government.<br />

The contractor may suspend the access of an individual,<br />

while notifying CIISD of the circumstances.<br />

Subcontracting<br />

Contractors shall subcontract work only to companies<br />

holding a current Designated Organization<br />

Screening or a Facility Security Clearance of the type<br />

and at the level appropriate to the work to be performed<br />

under the subcontract. CIISD approval of<br />

the subcontractor must be obtained before award of<br />

the subcontract and the Designated Organization<br />

Screening or Facility Security Clearance for the proposed<br />

subcontractor(s) must be verified by CIISD<br />

before issue of bid solicitation documents. Contractors<br />

shall not assign a subcontract to organizations<br />

located outside of Canada without the prior written<br />

approval of CIISD and the Public Works and Government<br />

Services Canada (PWGSC) contracting authority.<br />

The prime contractor shall ensure the security<br />

safeguarding of work placed with subcontractors.<br />

Education, Training, and Briefings<br />

A major objective of the Company Security<br />

Officer in conducting a Security Education Program<br />

A. Hammond<br />

involves working closely with management, from the<br />

top down, to ensure proper company security. Managers<br />

and supervisors at all levels are responsible not<br />

only for their own personal security measures, but<br />

also for ensuring that proper security procedures are<br />

followed by all employees in the organization. An<br />

initial security briefing, reinforced by an ongoing Security<br />

Education and Awareness Program, is essential<br />

to the maintenance of an effective security program.<br />

Upon receiving a Personnel Security Clearance<br />

an employee acknowledges his or her responsibilities<br />

by reading and signing the Security Screening Certificate<br />

and Briefing Form, TBS/SCT 330-47 Rev.<br />

2002/06. A briefing from the Company Security<br />

Officer, which details the individual’s specific responsibilities<br />

and duties relative to security in the<br />

facility, must be presented. (New employees, even<br />

though not yet security-screened and therefore prohibited<br />

from access to CLASSIFIED information<br />

and assets, should be given a security briefing appropriate<br />

to their duties.)<br />

Visits<br />

A Visit Clearance Request (VCR) (submitted to<br />

CIISD via a Request for Visit form) is required<br />

when a security-cleared individual must visit a government/commercial<br />

organization in Canada or<br />

abroad, for the purpose of having access to CLASSI-<br />

FIED information and assets or where access to the<br />

installation is restricted in the interest of national<br />

security. Visitors must not proceed with CLASSI-<br />

FIED visits without prior visit clearance authorization<br />

from CIISD. The host organization shall deny<br />

access to CLASSIFIED information and assets or<br />

access to certain restricted work sites until the visitors’<br />

Personnel Security Clearance level and their<br />

need-to-know have been verified and confirmed by<br />

the CIISD through official visit protocol.<br />

Submission of a VCR initiates verification by<br />

CIISD that confirms:<br />

• The organization requesting the visit has an Facility<br />

Security Clearance to the required level<br />

• Each of the proposed visitors has a valid Personnel<br />

Security Clearance to the required level<br />

• Foreign disclosure limitations are identified and<br />

strictly observed<br />

Visit Clearance Request is approved when the<br />

223

equesting organization is notified by CIISD. Visitors<br />

must not proceed on CLASSIFIED visits without<br />

prior visit clearance authorization.<br />

Visit Clearance Request (VCR) requires strict<br />

lead-times imposed by the authorities of foreign nations.<br />

Every effort must be made to ensure that leadtimes<br />

are observed, as failure to do so will likely result<br />

in rejection of the RFV.<br />

Organizations shall maintain a record of all individuals<br />

who visit the facility for the purpose of having<br />

access to CLASSIFIED information. This record<br />

shall be separate from the record of unclassified visits.<br />

Document Security<br />

General Marketing<br />

All documents shall be marked on the outside of<br />

both the front and back covers with the highest level<br />

of classification and loose documents shall be<br />

marked on every sheet. Security markings should<br />

include the applicable classification/protection and<br />

the date or event at which declassification or downgrading<br />

is to occur. All covering or transmittal letters<br />

or forms or circulation slips must be marked to show<br />

the highest level of classification or protection of the<br />

attachments.<br />

For TOP SECRET information, mark the classification<br />

in the upper right corner of each document<br />

page and show the total number of pages on each<br />

page of the document.<br />

For SECRET information, mark the classification<br />

in the upper right corner of each document<br />

page.<br />

For CONFIDENTIAL information, mark the<br />

classification in the upper right corner of the face of<br />

the document.<br />

For PROTECTED information, mark the word<br />

“PROTECTED” in the upper right corner of the<br />

face of the document and, where required, with the<br />

letter “A,” “B,” or “C” to indicate the level of protection.<br />

General Storage<br />

PROTECTED B and PROTECTED C information<br />

and assets and all CLASSIFIED information<br />

must be stored in an approved security container.<br />

224<br />

Comparison of the Canadian Manual and the U.S. Manual<br />

PROTECTED A information and assets shall be<br />

stored in a locked container.<br />

CLASSIFIED or PROTECTED information<br />

and assets may be stored on open shelving in a secure<br />

room, only after inspection and approval by<br />

CIISD and only to the level approved by CIISD.<br />

Also, CLASSIFIED and PROTECTED information<br />

and assets shall not be stored in the same container<br />

as negotiable or attractive assets.<br />

Reproduction<br />

Reproduction of CLASSIFIED information<br />

shall be done only with the authorization of the<br />

Company Security Officer or an authorized Alternate<br />

Company Security Officer. Reproductions must<br />

be marked, registered, and accounted for in the<br />

same manner as for the originals. Reproductions of<br />

PROTECTED information must be marked in the<br />

same manner as the originals. TOP SECRET and<br />

PROTECTED C information shall NEVER be reproduced<br />

without written authorization from<br />

CIISD.<br />

Domestic Transmission Standards<br />

(Outside of Facility)<br />

Top Secret<br />

• Documents must be double enveloped (gum<br />

sealed, heavy duty) and sealed with government approved<br />

security tape.<br />

• A self-addressed receipt is enclosed in the inner<br />

envelope or wrapping and the inner envelope or<br />

wrapping is closed with an approved security tape.<br />

• Inner envelope or wrapping must bear the security<br />

marking and the recipient’s address.<br />

• Shipment must be recorded prior to leaving a<br />

Security Zone and the recipient must be notified in<br />

advance of shipment.<br />

• Documents are sent via a securitycleared/reliability-checked<br />

individual employed by<br />

the dispatching/receiving Facility Security Cleared<br />

Canadian organization.<br />

Secret, Confidential, and Protected “C”<br />

• Documents must be double enveloped (gum<br />

sealed, heavy duty) and sealed with government approved<br />

security tape.<br />

• A self-addressed receipt is enclosed in the inner

envelope or wrapping and the inner envelope or<br />

wrapping is closed with an approved security tape.<br />

• Inner envelope or wrapping must bear the security<br />

marking and the recipient’s address.<br />

• Via:<br />

a. Priority courier<br />

b. Registered mail<br />

c. A security-cleared/reliability-checked individual<br />

employed by the dispatching/receiving<br />

Facility Security Cleared Canadian organization<br />

Protected “A” and “B”<br />

• Single, gum-sealed, heavy duty envelope<br />

• Via:<br />

a. First class mail<br />

b. An individual employed with the organization<br />

c. Classified/Protected “C” methods<br />

International Transmission Standards<br />

Top Secret, Secret, Confidential, and Protected “C”<br />

• Double enveloped (gum sealed, heavy duty) and<br />

sealed with government approved security tape<br />

• Via CIISD<br />

Protected “B”<br />

• Single, gum sealed, heavy-duty envelope<br />

• Via CIISD<br />

Protected “A”<br />

• Single, gum sealed, heavy-duty envelope<br />

• Via first class mail, priority courier, or registered<br />

mail<br />

Destruction<br />

Unless otherwise specified, TOP SECRET, and<br />

PROTECTED “C” information and assets must be<br />

returned to CIISD for disposal.<br />

Unless otherwise specified, SECRET, CONFI-<br />

DENTIAL, and PROTECTED “A” and “B” information<br />

and assets of Canadian origin may be destroyed<br />

by the organization with the approval of<br />

CIISD.<br />

CLASSIFIED and PROTECTED information<br />

and assets which have been authorized for destruction<br />

must be disposed of in accordance with the<br />

following:<br />

A. Hammond<br />

• It must be destroyed only by approved destruction<br />

equipment, or at a facility authorized by CIISD.<br />

• Information awaiting destruction or in transit to<br />

destruction must be safeguarded in the manner prescribed<br />

for the most highly CLASSIFIED and PRO-<br />

TECTED information asset involved.<br />

• CLASSIFIED and PROTECTED information/assets<br />

awaiting destruction must be kept separate<br />

from other information/assets awaiting destruction.<br />

• An employee with a proper security clearance or<br />

with Reliability Status, as applicable, must be present<br />

to monitor the destruction of CLASSIFIED and<br />

PROTECTED information, respectively.<br />

• Surplus copies and waste that could reveal<br />

CLASSIFIED and PROTECTED information must<br />

be protected to the appropriate level and should be<br />

promptly destroyed.<br />

Information System Security<br />

The ISM establishes operational standards in<br />

Canadian industry for the safeguarding of Government<br />

information electronically processed, stored, or<br />

transmitted. This also applies to the safeguarding of<br />

technology assets. The administrative, organizational,<br />

physical, and personnel security standards as<br />

documented in the ISM also apply to the information<br />

technology environment.<br />

The Government Security Policy requires that<br />

the degree of safeguarding provided by industry be<br />

commensurate with the level of the information and<br />

assets and the associated threats and risks. The contracting<br />

authority is responsible for ensuring that the<br />

requirements of the Government Security Policy are<br />

met and that the security standards are applied by<br />

the private sector contractor. The security standards<br />

contained in the Government Security Policy, Information<br />

Technology Standards, are the minimum<br />

standards for security in the private sector. Assessments,<br />

advice, and guidance regarding these standards<br />

are available from the Canadian and International<br />

Industrial Services Directorate (CIISD) of<br />

Public Works and Government Services Canada<br />

(PWGSC).<br />

The prime contractor’s Information Technology<br />

Facility(s) must be approved by CIISD prior to processing<br />

government information.

Conclusions<br />

“It’s important to be responsible here and to be particularly<br />

careful after 9/11 that we’re not giving our<br />

enemies information or materials that would make<br />

their job easier.” (Chui, 2003)<br />

John H. Marburger III,<br />

Director, Office of Science & Technology Policy<br />

(and science adviser to President George W. Bush)<br />

To no surprise, the anthrax letter attacks of<br />

2001 led directly to national policy changes since<br />

they specifically targeted both lawmakers and media<br />

personnel at their workplaces. To better protect<br />

their citizens, the United States and Canadian governments<br />

established controls not only over the possession<br />

and use of hazardous biological agents, but<br />

also over the information pertaining to their possession<br />

and use. Legislation is now in place that forbids<br />

the disclosure of information that may identify<br />

which biological agents are possessed, who possesses<br />

that agent(s) and where, and any safeguard and security<br />

measures used to protect unauthorized access to<br />

the agent(s). Because of the genuine threat of bioterrorism,<br />

biodefense research has become a vital and<br />

necessary component of an overall national security<br />

program. The United States alone has committed<br />

billions of dollars towards biodefense research and<br />

development. To protect biodefense information<br />

and assets, organizations working on projects<br />

deemed to be “classified” (for the sake of national<br />

security) must follow precise requirements, restrictions,<br />

and safeguards established by their federal government.<br />

For Canada and the United States, these<br />

requirements are conveyed in the Canadian Industrial<br />

Security Manual (ISM) and the U.S. National Industrial<br />

Security Program Operating Manual (NISPOM). These<br />

manuals provide guidance in implementing a uni-<br />

226<br />

Comparison of the Canadian Manual and the U.S. Manual<br />

form and cost-effective security system, thus allowing<br />

an organization to focus mainly on research rather<br />

than the burden of developing and implementing<br />

security procedures. Without these standards and<br />

consistent security policies and practices the potential<br />

for compromise leading to a serious national<br />

security threat is enormous.<br />

References<br />

Canadian and International Industrial Security Directorate.<br />

(2004). Industrial security manual. Available<br />

at www.ciisd.gc.ca/ism/text/preface-e.asp. Accessed<br />

online 2004.<br />

Chui, G. (2003). Security concerns imperil research:<br />

Restrictions shackle scientists, some say. The Mercury<br />

News, March 3, 2003. Available at www.<br />

mercurynews.com/mld/mercurynews/news/<br />

5303757.htm?1c. Accessed online 2004.<br />

Defense Technical Information Center. (2004). National<br />

industrial security program operating manual<br />

(DoD 5220.22-M). Available at www.dtic.mil/whs/<br />

directives/corres/html/522022m.htm. Accessed<br />

online 2004.<br />

Parliament of Canada. (2004). Public <strong>Safety</strong> Act,<br />

2002. Available at www.parl.gc.ca/37/3/parlbus/<br />

chambus/house/bills/summaries/c7-e.pdf. Accessed<br />

online 2004.<br />

U.S. Government Printing Office. (2004). Public<br />

Health Security and Bioterrorism Preparedness and Response<br />

Act of 2002. Available at frwebgate.access.gpo.<br />

gov/cgi-bin/getdoc.cgi?dbname=<strong>10</strong>7_cong_public_<br />

laws&docid=f:publ188.<strong>10</strong>7.pdf. Accessed online<br />

2004.

Article<br />

The Infectious Dose of Francisella<br />

tularensis (Tularemia)<br />

Abstract<br />

Quantitatively estimating an individual’s risk of<br />

infection by an airborne pathogen requires knowledge<br />

of the expected dose and the pathogen’s infectious<br />

dose. Based on our review of the published literature on<br />

tularemia, we conclude that the infectious dose of Francisella<br />

tularensis varies among individuals, but that a<br />

substantial proportion of the population can be infected<br />

by a single bacillus. We also conclude that infection can<br />

be initiated by inhaling bacilli carried on respirable particles<br />

(diameters less than <strong>10</strong> µm) or nonrespirable particles<br />