Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

536<br />

Many new mixture-preparation and combustion-control<br />

strategies for <strong>direct</strong>-<strong>gasoline</strong>-<strong>injection</strong>, four-stroke, <strong>spark</strong>ignition<br />

<strong>engines</strong> have been proposed and developed since<br />

1990 by automotive companies, fuel system manufacturers<br />

and research institutions. Currently, five automotive companies<br />

have already put this engine technology into production<br />

in both the Japanese and European markets. These types of<br />

<strong>engines</strong> are classified as third-generation GDI <strong>engines</strong> [50].<br />

Based on the information available in the literature, the key<br />

features of these specific GDI <strong>engines</strong> that have been developed<br />

during this recent time period are briefly summarized<br />

in Table 2 and the details of some of these combustion<br />

systems are given below.<br />

6.2. Mitsubishi combustion system<br />

F. Zhao et al. / Progress in Energy and Combustion Science 25 (1999) 437–562<br />

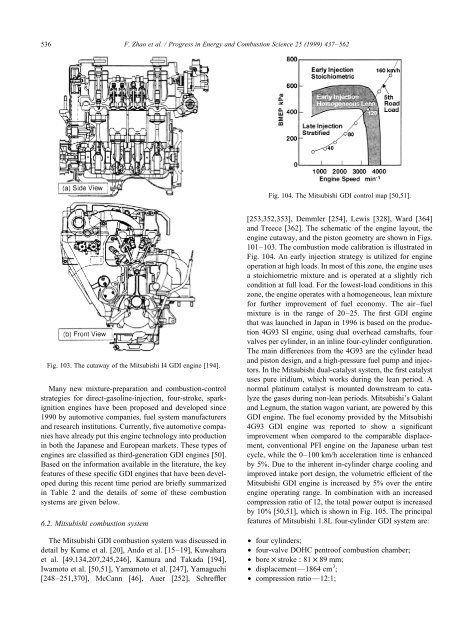

Fig. 103. The cutaway of the Mitsubishi I4 GDI engine [194].<br />

The Mitsubishi GDI combustion system was discussed in<br />

detail by Kume et al. [20], Ando et al. [15–19], Kuwahara<br />

et al. [49,134,207,245,246], Kamura and Takada [194],<br />

Iwamoto et al. [50,51], Yamamoto et al. [247], Yamaguchi<br />

[248–251,370], McCann [46], Auer [252], Schreffler<br />

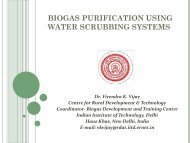

Fig. 104. The Mitsubishi GDI control map [50,51].<br />

[253,352,353], Demmler [254], Lewis [328], Ward [364]<br />

and Treece [362]. The schematic of the engine layout, the<br />

engine cutaway, and the piston geometry are shown in Figs.<br />

101–103. The combustion mode calibration is illustrated in<br />

Fig. 104. An early <strong>injection</strong> strategy is utilized for engine<br />

operation at high loads. In most of this zone, the engine uses<br />

a stoichiometric mixture and is operated at a slightly rich<br />

condition at full load. For the lowest-load conditions in this<br />

zone, the engine operates with a homogeneous, lean mixture<br />

for further improvement of fuel economy. The air–fuel<br />

mixture is in the range of 20–25. The first GDI engine<br />

that was launched in Japan in 1996 is based on the production<br />

4G93 SI engine, using dual overhead camshafts, four<br />

valves per cylinder, in an inline four-cylinder configuration.<br />

The main differences from the 4G93 are the cylinder head<br />

and piston design, and a high-pressure fuel pump and injectors.<br />

In the Mitsubishi dual-catalyst system, the first catalyst<br />

uses pure iridium, which works during the lean period. A<br />

normal platinum catalyst is mounted downstream to catalyze<br />

the gases during non-lean periods. Mitsubishi’s Galant<br />

and Legnum, the station wagon variant, are powered by this<br />

GDI engine. The fuel economy provided by the Mitsubishi<br />

4G93 GDI engine was reported to show a significant<br />

improvement when compared to the comparable displacement,<br />

conventional PFI engine on the Japanese urban test<br />

cycle, while the 0–100 km/h acceleration time is enhanced<br />

by 5%. Due to the inherent in-cylinder charge cooling and<br />

improved intake port design, the volumetric efficient of the<br />

Mitsubishi GDI engine is increased by 5% over the entire<br />

engine operating range. In combination with an increased<br />

compression ratio of 12, the total power output is increased<br />

by 10% [50,51], which is shown in Fig. 105. The principal<br />

features of Mitsubishi 1.8L four-cylinder GDI system are:<br />

• four cylinders;<br />

• four-valve DOHC pentroof combustion chamber;<br />

• bore × stroke : 81 × 89 mm;<br />

• displacement—1864 cm 3 ;<br />

• compression ratio—12:1;