Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

Automotive spark-ignited direct-injection gasoline engines

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

450<br />

F. Zhao et al. / Progress in Energy and Combustion Science 25 (1999) 437–562<br />

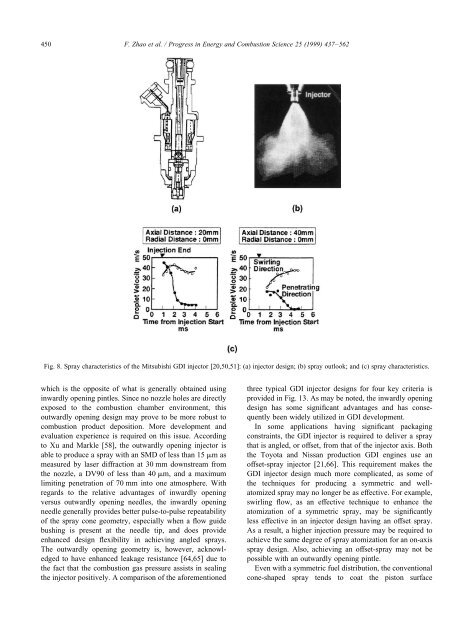

Fig. 8. Spray characteristics of the Mitsubishi GDI injector [20,50,51]: (a) injector design; (b) spray outlook; and (c) spray characteristics.<br />

which is the opposite of what is generally obtained using<br />

inwardly opening pintles. Since no nozzle holes are <strong>direct</strong>ly<br />

exposed to the combustion chamber environment, this<br />

outwardly opening design may prove to be more robust to<br />

combustion product deposition. More development and<br />

evaluation experience is required on this issue. According<br />

to Xu and Markle [58], the outwardly opening injector is<br />

able to produce a spray with an SMD of less than 15 mm as<br />

measured by laser diffraction at 30 mm downstream from<br />

the nozzle, a DV90 of less than 40 mm, and a maximum<br />

limiting penetration of 70 mm into one atmosphere. With<br />

regards to the relative advantages of inwardly opening<br />

versus outwardly opening needles, the inwardly opening<br />

needle generally provides better pulse-to-pulse repeatability<br />

of the spray cone geometry, especially when a flow guide<br />

bushing is present at the needle tip, and does provide<br />

enhanced design flexibility in achieving angled sprays.<br />

The outwardly opening geometry is, however, acknowledged<br />

to have enhanced leakage resistance [64,65] due to<br />

the fact that the combustion gas pressure assists in sealing<br />

the injector positively. A comparison of the aforementioned<br />

three typical GDI injector designs for four key criteria is<br />

provided in Fig. 13. As may be noted, the inwardly opening<br />

design has some significant advantages and has consequently<br />

been widely utilized in GDI development.<br />

In some applications having significant packaging<br />

constraints, the GDI injector is required to deliver a spray<br />

that is angled, or offset, from that of the injector axis. Both<br />

the Toyota and Nissan production GDI <strong>engines</strong> use an<br />

offset-spray injector [21,66]. This requirement makes the<br />

GDI injector design much more complicated, as some of<br />

the techniques for producing a symmetric and wellatomized<br />

spray may no longer be as effective. For example,<br />

swirling flow, as an effective technique to enhance the<br />

atomization of a symmetric spray, may be significantly<br />

less effective in an injector design having an offset spray.<br />

As a result, a higher <strong>injection</strong> pressure may be required to<br />

achieve the same degree of spray atomization for an on-axis<br />

spray design. Also, achieving an offset-spray may not be<br />

possible with an outwardly opening pintle.<br />

Even with a symmetric fuel distribution, the conventional<br />

cone-shaped spray tends to coat the piston surface