sorbitol, Parteck™ SI - EMD Chemicals

sorbitol, Parteck™ SI - EMD Chemicals

sorbitol, Parteck™ SI - EMD Chemicals

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

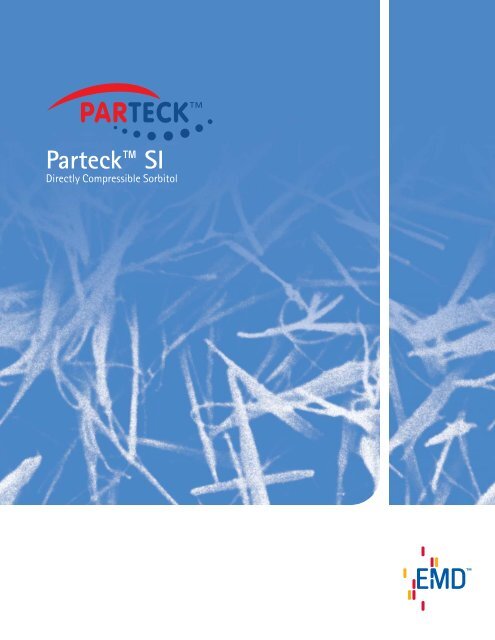

PARTECK <br />

Parteck <strong>SI</strong><br />

Directly Compressible Sorbitol

Parteck <strong>SI</strong><br />

Directly Compressible<br />

Sorbitol<br />

Main applications<br />

Superior direct compression characteristics,<br />

excellent mouthfeel, pleasant taste, good flow and<br />

high solubility make Parteck <strong>SI</strong> the excipient of<br />

choice for sugar free chewables, effervescent<br />

tablets and lozenges. Parteck <strong>SI</strong> is particularly<br />

suitable for formulations where low dose active<br />

preparations are required. This includes sublingual<br />

and buccal tablets where mouthfeel is important.<br />

In addition, the unique ability of Parteck <strong>SI</strong><br />

particles to form stable ordered mixtures has been<br />

widely studied and applied extensively in the area<br />

of reconstitution syrups and suspensions.

General Characteristics<br />

of Sorbitol<br />

· Non cariogenic<br />

· Chemically stable<br />

· Pleasant tasting<br />

· High solubility<br />

Method: 99% test material and 1%<br />

magnesium stearate were mixed<br />

and compressed on an Korsch EK0<br />

DMS (rpm:54, punch: flat, facetted,<br />

11mm; tablet weight 500mg).<br />

Parteck <strong>SI</strong> is spray-dried <strong>sorbitol</strong>,<br />

cryst. <strong>sorbitol</strong> A is commercially<br />

available as crystalline <strong>sorbitol</strong>.<br />

Tablet Hardness [N]<br />

Parteck <strong>SI</strong><br />

· Unique, functional Sorbitol particles<br />

· Excellent compressibility<br />

· High adsorption capacity<br />

· High dilution potential<br />

· Low hygroscopicity of Parteck <strong>SI</strong> tablets<br />

· Free flowing<br />

· Variety of types available<br />

Parteck brand of products are manufactured by Merck KGaA,<br />

Darmstadt, Germany under the Functional Particle Engineering<br />

concept, which allows the design and control of particle size distribution,<br />

modification of the physical properties of particles and the<br />

processing of excipients together.<br />

Parteck <strong>SI</strong>, a superior, directly compressible Sorbitol (<strong>SI</strong>=Sorbitol<br />

Instant), is offered in a variety of particle size distributions and qualities<br />

designed to meet requirements of the pharmaceutical industry.<br />

Parteck <strong>SI</strong>: A Unique Particle Structure<br />

The particle structure of Parteck <strong>SI</strong> consists of very loosely packed,<br />

randomly orientated, interwoven filamentary crystals. These needle-like<br />

crystals, unique to Parteck <strong>SI</strong>, give rise to its distinctive physical<br />

properties. As a truly directly compressible material, Parteck <strong>SI</strong> offers<br />

a number of benefits to the pharmaceutical formulator.<br />

Parteck <strong>SI</strong> Compression profile<br />

450<br />

400<br />

350<br />

300<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

Parteck <strong>SI</strong> 400<br />

Parteck <strong>SI</strong> 150<br />

cryst. <strong>sorbitol</strong> A<br />

0 5 10 15 20 25 30 35<br />

Compression Force [kN]<br />

Excellent compressibility<br />

For lozenges and chewable tablets the high compressibility of diluent is<br />

of the utmost importance. When compared to standard, commercially<br />

available crystalline <strong>sorbitol</strong>, Parteck <strong>SI</strong> exhibits superior compression<br />

properties. This excellent compressibility profile reduces the stress on<br />

tabletting machines and other processing tools by operating at lower<br />

pressures for a given tablet hardness.

Effect of the operating pressure<br />

of an Alpine air jet sieve on the<br />

content of Ampicillin trihydrate<br />

left in the mixture after sieving a<br />

standard 20% mixture of either<br />

Parteck <strong>SI</strong> or standard crystalline<br />

<strong>sorbitol</strong>.<br />

Method: 25-75% cryst. ascorbic,<br />

1% magnesium stearate and 24-<br />

74% test material were mixed<br />

and compressed on an Korsch<br />

EK0 DMS single punch tablet<br />

press (punch: flat, facetted,<br />

11mm; tablet weight 500mg).<br />

Parteck <strong>SI</strong> is spray-dried<br />

<strong>sorbitol</strong>, cryst. <strong>sorbitol</strong> A is<br />

commercially available as<br />

crystalline <strong>sorbitol</strong>.<br />

drug content after sieving [%] Ampicillin mixture with Parteck <strong>SI</strong><br />

7,5<br />

5<br />

2,5<br />

0<br />

0<br />

20 40 60<br />

80<br />

100<br />

pressure of air jet sieve [mm H2O] High adsorption capacity<br />

Parteck <strong>SI</strong> has the outstanding ability to form ordered mixtures with other solid<br />

substances. The unique, rough, porous surface area available for adsorption of<br />

Parteck <strong>SI</strong> (~ 1m 2 /g), allows the active to become entrapped within the filamentous<br />

matrix. The high potential for Parteck <strong>SI</strong>’s electrostatic attraction improves<br />

the overall stability of the resultant adsorbate. This phenomenon helps to increase<br />

the homogeneity of powder blends, to avoid dust development during manufacturing<br />

and to achieve a high level of content uniformity. Parteck <strong>SI</strong> can also be used<br />

as an excellent diluent for low dose preparations. The adsorption capacity and<br />

stability of resultant mixtures were tested when mixtures of Ampicillin trihydrate<br />

(20%) with Parteck <strong>SI</strong> or crystalline <strong>sorbitol</strong> (80%) were sieved using air jet sieve<br />

(pressure 100mm H 2 O). The sieved Ampicillin mixture with Parteck <strong>SI</strong> contained<br />

over 6% Ampicillin, whereas the concentration of the active in the crystalline<br />

<strong>sorbitol</strong> was below 1% reconstitution syrups and suspensions.<br />

High dilution potential<br />

Parteck <strong>SI</strong>’s open internal structure and high capacity to form ordered mixtures<br />

assures the highest quality (hardness) tablet even with actives that have little or no<br />

compressibility of their own. This feature is illustrated in the chart below showing<br />

tablet hardness with Parteck <strong>SI</strong> when it is compressed in combination with<br />

increasing amounts of ascorbic acid.<br />

250<br />

200<br />

150<br />

100<br />

50<br />

0<br />

25<br />

Asorbic acid concentration [%]<br />

Parteck <strong>SI</strong> 400<br />

Parteck <strong>SI</strong> 150<br />

cryst. <strong>sorbitol</strong> A<br />

50 75<br />

Tablet Hardness [N] Vitamin C tablets made with Parteck <strong>SI</strong><br />

Parteck <strong>SI</strong> 400<br />

cryst. <strong>sorbitol</strong> A

Method: tablet diameter 11mm,<br />

weight 360mg. Tablets were<br />

stored at room temperature at<br />

65% relative humidity for 1, 2 and<br />

4 weeks. Initial moisture content<br />

of Parteck <strong>SI</strong> and cryst. <strong>sorbitol</strong><br />

0.5%.<br />

Low hygroscopicity of Parteck <strong>SI</strong> tablets<br />

Crystalline Sorbitol is known to be slightly hygroscopic which increases the<br />

likelihood of potential problems with the production and the stability of tablets.<br />

However, in tablets made with Parteck <strong>SI</strong> a hard and smooth film is formed on<br />

the surface of the tablet after compression. This reduces the ability of moisture to<br />

penetrate into the core. Parteck <strong>SI</strong> tablets stored at 65% relative humidity and<br />

room temperature for four weeks, showed a weight increase of only 0.8%<br />

compared with 1.3% for the tablets containing crystalline <strong>sorbitol</strong>.<br />

Water uptake of Parteck <strong>SI</strong> tablets<br />

The choice is yours<br />

Parteck <strong>SI</strong> 400 is recommended for most applications. However, there are<br />

additional specialized Parteck <strong>SI</strong> products available as well. More detailed<br />

information on type and particle size is available upon request.<br />

Most Parteck <strong>SI</strong> qualities comply with the Sorbitol monographs of Ph Eur,<br />

BP and NF<br />

Product # Product Size<br />

1.03140.1000 Parteck <strong>SI</strong> 400, Sorbitol Instant, Ph Eur, BP, NF, E420 1kg<br />

1.03140.9028 Parteck <strong>SI</strong> 400, Sorbitol Instant, Ph Eur, BP, NF, E420 25kg<br />

1.03557.1000 Parteck <strong>SI</strong> 500, Sorbitol Instant Granular, NF, FCC 1kg<br />

1.03557.9028 Parteck <strong>SI</strong> 500, Sorbitol Instant Granular, NF, FCC 25kg<br />

1.03583.9028 Parteck <strong>SI</strong> 150, Sorbitol Powder, Ph Eur, BP, NF, E420 25kg<br />

1.07703.1000 Parteck <strong>SI</strong> 400, Sorbitol Instant, Ph Eur, BP, NF, micro tested 1kg<br />

1.07703.9028 Parteck <strong>SI</strong> 400, Sorbitol Instant, Ph Eur, BP, NF, micro tested 25kg<br />

1.11597.1000 Parteck <strong>SI</strong> 400LEX, Sorbitol Instant Low Endotoxin, Ph Eur, BP, NF 1kg<br />

1.11597.9028 Parteck <strong>SI</strong> 400LEX, Sorbitol Instant Low Endotoxin, Ph Eur, BP, NF 25kg

<strong>EMD</strong> <strong>Chemicals</strong>’ products are warranted to<br />

meet the specifications set forth on their<br />

label only. Any change or modification of<br />

an <strong>EMD</strong> <strong>Chemicals</strong>’ product or its<br />

prescribed procedure for use may adversely<br />

affect its stated specification and therefore<br />

<strong>EMD</strong> <strong>Chemicals</strong> shall not be liable in the<br />

event of any such change or modification.<br />

All <strong>EMD</strong> <strong>Chemicals</strong>’ products are sold on<br />

the condition that they be used and<br />

disposed of only within the scope of<br />

currently recognized critical standards<br />

related to human health and the physical<br />

environment. Price and specifications are<br />

subject to change without notice. We<br />

reserve the right to discontinue items<br />

without prior notice.<br />

EXCEPT FOR THE WARRANTY STATED<br />

ABOVE, <strong>EMD</strong> CHEMICALS MAKES NO<br />

OTHER WARRANTY OF ANY KIND WITH<br />

REGARD TO ITS PRODUCTS WHETHER<br />

EXPRESS, ARI<strong>SI</strong>NG BY OPERATION OF<br />

LAW, OR IMPLIED BY COURSE OF<br />

DEALING, USAGE OF TRADE OR<br />

OTHERWISE, INCLUDING WITHOUT<br />

LIMITATION THE IMPLIED WARRANTIES<br />

OF MERCHANTABILITY AND FITNESS<br />

FOR A PARTICULAR PURPOSE. <strong>EMD</strong><br />

CHEMICALS SHALL NOT IN ANY<br />

CIRCUMSTANCE BE LIABLE FOR ANY<br />

SPECIAL, INDIRECT, INCIDENTAL OR<br />

CONSEQUENTIAL DAMAGES.<br />

LT 331018 REV08/03<br />

<strong>EMD</strong> <strong>Chemicals</strong> Inc.<br />

480 South Democrat Road<br />

Gibbstown, NJ 08027<br />

Phone 800-222-0342<br />

856-423-6300<br />

Fax 856-423-4389<br />

www.emdchemicals.com