VULCAIN 2 : Thrust Chamber - EADS

VULCAIN 2 : Thrust Chamber - EADS

VULCAIN 2 : Thrust Chamber - EADS

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The cylindrical section of the<br />

combustion chamber has been<br />

elongated by a factor of almost<br />

three to provide for complete<br />

gasification and burning of the<br />

increased amount of liquid<br />

oxygen. To protect the copper<br />

alloy liner against oxygen<br />

degradation effects, such as<br />

blanching, wall film cooling has<br />

been employed from the injector<br />

face plate down to the nozzle<br />

throat section.<br />

The overall dump cooled nozzle<br />

extension used on Vulcain 1 has<br />

been replaced by a completely<br />

new nozzle design that provides<br />

for dump coolant injection at an<br />

area ratio of 29.2 and turbine gas<br />

injection at an area ratio of 32. This<br />

new nozzle design enables Vulcain<br />

2 to deliver a specific impulse of<br />

429 sec.<br />

The coaxial injector elements<br />

cause the LOX and LH2 propellants<br />

to be mixed together. LOX is<br />

injected at the centre of the<br />

injection elements, around which<br />

the LH2 is injected. These<br />

propellants are mainly atomised<br />

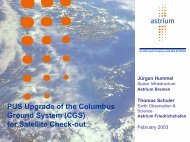

Propellants<br />

Specific impulse vacuum<br />

<strong>Thrust</strong> vacuum<br />

Propellant mass flow rate at thrust chamber inlet<br />

- LH2<br />

-LOX<br />

- Turbine exhaust gas (injected in Nozzle)<br />

<strong>Thrust</strong> chamber inlet conditions<br />

- LH2 Pressure<br />

- LH2 Temperature<br />

- LOX Pressure<br />

- LOX Temperature<br />

Mixture ratio (TC)<br />

Combustion chamber pressure<br />

Nozzle area ratio<br />

Nozzle exit diameter<br />

Overall engine length<br />

<strong>Thrust</strong> chamber mass<br />

and mixed by shear forces<br />

generated by the velocity<br />

differences between LOX and<br />

LH2. Although the injector<br />

design is complex, it does assure<br />

consistent and reliable<br />

combustion efficiencies close to<br />

99 %, which are reached during<br />

the remaining process in the<br />

combustion chamber.<br />

In the combustion chamber, the<br />

mixed propellants are burned and<br />

accelerated up to sonic<br />

conditions. The combustion<br />

temperatures in the chamber<br />

reach almost 3250 °C at<br />

pressures greater than 100 bar.<br />

Combustion temperature control<br />

is achieved by a flow of LH2 in the<br />

cooling channels within the<br />

combustion chamber wall. This<br />

thin copper alloy wall, just 1.5 mm<br />

thick separates the combustion<br />

temperatures from the - 239 to -<br />

150 °C LH2 cooling flow.<br />

The final acceleration of hot<br />

gases, up to supersonic<br />

velocities, is achieved by gas<br />

expansion in the nozzle.<br />

LOX/LH2<br />

429 s<br />

1359 kN<br />

<strong>VULCAIN</strong>2:<strong>Thrust</strong> <strong>Chamber</strong><br />

40.4 kg/s<br />

272.6 kg/s<br />

10.1 kg/s<br />

182.1 bar<br />

36.0 K<br />

153.9 bar<br />

96.7 K<br />

6.74<br />

117.3 bar<br />

58.2<br />

2.09 m<br />

3.44 m<br />

909 kg<br />

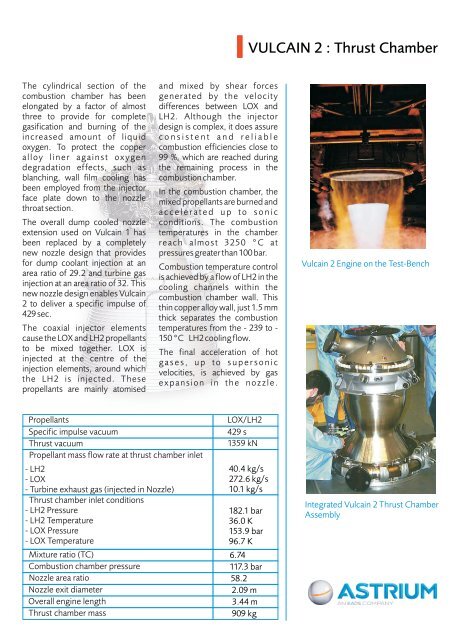

Vulcain 2 Engine on the Test-Bench<br />

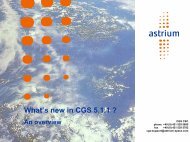

Integrated Vulcain 2 <strong>Thrust</strong> <strong>Chamber</strong><br />

Assembly