VPS126 Vertical Panel Saw

VPS126 Vertical Panel Saw

VPS126 Vertical Panel Saw

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

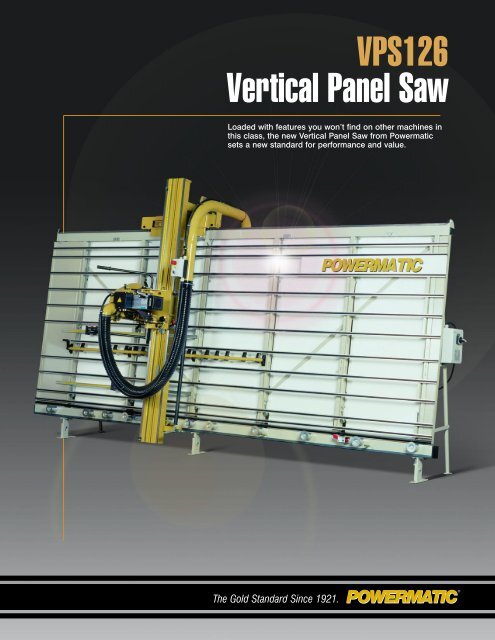

<strong>VPS126</strong><br />

<strong>Vertical</strong> <strong>Panel</strong> <strong>Saw</strong><br />

Loaded with features you won’t find on other machines in<br />

this class, the new <strong>Vertical</strong> <strong>Panel</strong> <strong>Saw</strong> from Powermatic<br />

sets a new standard for performance and value.<br />

The Gold Standard Since 1921.

The Gold Standard Since 1921.<br />

<strong>VPS126</strong> <strong>Vertical</strong> <strong>Panel</strong> <strong>Saw</strong><br />

This new panel saw has been<br />

designed with production in mind.<br />

The heavy steel frame is precision<br />

welded for rigidity. The “T” square<br />

beam is constructed of box-welded,<br />

precision ground hardened steel that<br />

travels on a series of seven specially<br />

designed bearings. Next, the massive<br />

carriage assembly travels vertically<br />

on the beam using a series of eleven<br />

precision bearings, all with four<br />

fixed locking points. All at the touch<br />

of a finger with unsurpassed ease<br />

and accuracy. ■ The auto-shifting<br />

grid frame provides full support<br />

to workpieces and automatically<br />

positions itself for blade clearance<br />

in the horizontal cutting mode. ■<br />

Power is supplied by a 4.8HP motor<br />

that can handle double panel cuts<br />

with ease. Large panels are fully<br />

supported by ball bearing rollers<br />

with a flip stop. ■ Production<br />

Cutting with Precision — the<br />

<strong>VPS126</strong> from Powermatic Delivers.<br />

FEATURE<br />

Heavy duty welded one piece<br />

steel frame<br />

Heavy duty ball bearing base<br />

rollers with auto stop<br />

Heavy welded T-square box type<br />

carriage assembly<br />

<strong>Saw</strong> assembly supported by<br />

eleven bearings for vertical travel<br />

Powerful 4.8HP motor with<br />

electric brake<br />

Automatic grid shifting frame<br />

<strong>Saw</strong> beam travels on seven<br />

ball bearings<br />

Integral dust exhaust fan<br />

on motor<br />

Repeat rip cutting device<br />

Mid fence with stop<br />

Automatic riving knife splitter<br />

Big 4.8HP motor with<br />

integral dust assist blower<br />

is fully shrouded and<br />

soundproofed. Includes<br />

electric brake, automatic<br />

riving knife splitter and<br />

pressure adjustable saw<br />

foot guard.<br />

BENEFIT<br />

Superior rigidity and accuracy<br />

Full support and easy movement<br />

of large work pieces<br />

Precise alignment for absolute accuracy<br />

Ease of use and precision cuts<br />

Plenty of power for production cutting<br />

and enhanced safety<br />

Fast set-up for all horizontal cutting<br />

operations<br />

Ease of use and precision cuts<br />

Aids in dust collection and maintains<br />

a clear work area<br />

Quick and accurate for multiple rips<br />

Most comfortable working position<br />

Supports work pieces on<br />

horizontal cuts and moves with<br />

pressure foot<br />

Accessory PN-6687016<br />

Scoring Block assembly.<br />

Uses dual knives and<br />

has quick adjustments<br />

for depth, width and<br />

pressure. Installs in<br />

minutes and provides<br />

excellent chip-free cuts.<br />

Flip down Mid-fence<br />

with panel stop. <strong>Vertical</strong><br />

cutting scale with flip<br />

stop. Stock Support Rollers<br />

with short panel support.<br />

All standard equipment.

<strong>VPS126</strong> <strong>Vertical</strong> <strong>Panel</strong> <strong>Saw</strong><br />

Model Number <strong>VPS126</strong><br />

Stock Number 1791286K<br />

Maximum Cutting Length 126" (3200mm)<br />

Maximum Cutting Height 75" (1900mm)<br />

Maximum Horizontal Cutting Height 67" (1700mm)<br />

Maximum Depth of Cut 21 /4" (60mm)<br />

Motor 4.8HP<br />

Voltage (Wired 230) 230/460 3PH<br />

Blade Diameter 10" (250mm)<br />

Blade Arbor 30mm<br />

Blade Speed 5300 rpm<br />

Readout Scales 5<br />

Recommended CFM 600<br />

Dust Connection Diameter 4" (100mm)<br />

Weight Gross/Net Lbs. 1870/1705 lbs<br />

Overall Dimensions 100" Hx 57" W x 170" L<br />

Includes: Auto Shifting Frame<br />

Heavy Duty Rollers with Auto Stop<br />

Motor Brake<br />

Integral Dust Collector<br />

Mid Fence with <strong>Panel</strong> Stop<br />

Repeat Horizontal Cutting Attachment<br />

Full Set of Service Tools<br />

4 Fixed <strong>Vertical</strong> Cutting Positions<br />

4 Adjustable Horizontal Cutting Stops<br />

<strong>Vertical</strong> Cut-Off Support<br />

Installation, Assembly and Part Manuals<br />

PN Accy. Low Level Stop 6819020<br />

PN Accy. Scoring Unit 6687016<br />

PN Accy. Blade 10" x 30 mm x 80T 6080156<br />

WMH TOOL GROUP<br />

Industrial Woodworking Machinery Division<br />

427 Sanford Road<br />

LaVergne, TN 37086<br />

The Gold Standard Since 1921.<br />

1-800-248-0144<br />

www.powermatic.com<br />

Part No. 91-608

Beam travels with 7 specially<br />

designed bearings on hardened<br />

and ground ways<br />

• Auto shifting grid<br />

frame for horizontal<br />

cutting<br />

• <strong>Saw</strong> carriage moves<br />

vertically on 11<br />

bearings and precision<br />

ground and hardened<br />

ways<br />

• Mid-fence with stop,<br />

vertical cutting scale<br />

with flip stop, repeat<br />

horizontal cutting<br />

device with flip out<br />

bearing<br />

Big 4.8HP motor and shrouded<br />

dust extraction system<br />

Heavy duty stock<br />

support rollers and<br />

auto panel stop