Adhesives and Tapes

Adhesives and Tapes

Adhesives and Tapes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4<br />

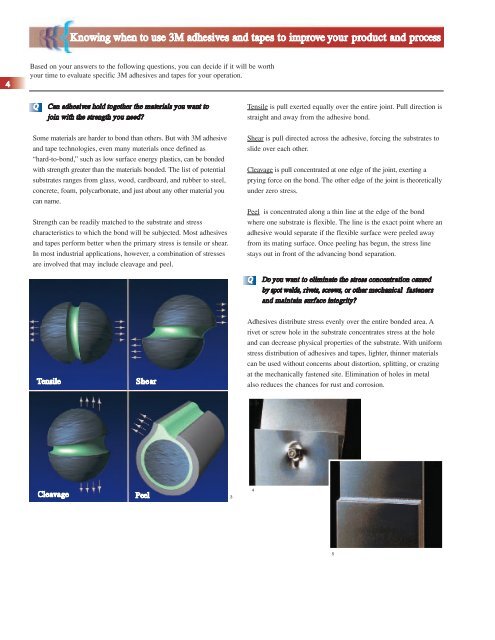

Tensile Shear<br />

Cleavage<br />

Knowing when to use 3M adhesives <strong>and</strong> tapes to improve your product <strong>and</strong> process<br />

Based on your answers to the following questions, you can decide if it will be worth<br />

your time to evaluate specific 3M adhesives <strong>and</strong> tapes for your operation.<br />

QQ CCaann aaddhheessiivveess hhoolldd ttooggeetthheerr tthhee mmaatteerriiaallss yyoouu wwaanntt ttoo<br />

jjooiinn wwiitthh tthhee ssttrreennggtthh yyoouu nneeeedd??<br />

Some materials are harder to bond than others. But with 3M adhesive<br />

<strong>and</strong> tape technologies, even many materials once defined as<br />

“hard-to-bond,” such as low surface energy plastics, can be bonded<br />

with strength greater than the materials bonded. The list of potential<br />

substrates ranges from glass, wood, cardboard, <strong>and</strong> rubber to steel,<br />

concrete, foam, polycarbonate, <strong>and</strong> just about any other material you<br />

can name.<br />

Strength can be readily matched to the substrate <strong>and</strong> stress<br />

characteristics to which the bond will be subjected. Most adhesives<br />

<strong>and</strong> tapes perform better when the primary stress is tensile or shear.<br />

In most industrial applications, however, a combination of stresses<br />

are involved that may include cleavage <strong>and</strong> peel.<br />

Peel<br />

3<br />

Tensile is pull exerted equally over the entire joint. Pull direction is<br />

straight <strong>and</strong> away from the adhesive bond.<br />

Shear is pull directed across the adhesive, forcing the substrates to<br />

slide over each other.<br />

Cleavage is pull concentrated at one edge of the joint, exerting a<br />

prying force on the bond. The other edge of the joint is theoretically<br />

under zero stress.<br />

Peel is concentrated along a thin line at the edge of the bond<br />

where one substrate is flexible. The line is the exact point where an<br />

adhesive would separate if the flexible surface were peeled away<br />

from its mating surface. Once peeling has begun, the stress line<br />

stays out in front of the advancing bond separation.<br />

QQ DDoo yyoouu wwaanntt ttoo eelliimmiinnaattee tthhee ssttrreessss ccoonncceennttrraattiioonn ccaauusseedd<br />

bbyy ssppoott wweellddss,, rriivveettss,, ssccrreewwss,, oorr ootthheerr mmeecchhaanniiccaall ffaasstteenneerrss<br />

aanndd mmaaiinnttaaiinn ssuurrffaaccee iinntteeggrriittyy??<br />

<strong>Adhesives</strong> distribute stress evenly over the entire bonded area. A<br />

rivet or screw hole in the substrate concentrates stress at the hole<br />

<strong>and</strong> can decrease physical properties of the substrate. With uniform<br />

stress distribution of adhesives <strong>and</strong> tapes, lighter, thinner materials<br />

can be used without concerns about distortion, splitting, or crazing<br />

at the mechanically fastened site. Elimination of holes in metal<br />

also reduces the chances for rust <strong>and</strong> corrosion.<br />

4<br />

5