Acceptable Quality Level (AQL) - Ansell Healthcare Europe

Acceptable Quality Level (AQL) - Ansell Healthcare Europe

Acceptable Quality Level (AQL) - Ansell Healthcare Europe

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Acceptable</strong> <strong>Quality</strong> <strong>Level</strong><br />

(<strong>AQL</strong>)<br />

<strong>Acceptable</strong> <strong>Quality</strong> <strong>Level</strong> (<strong>AQL</strong>) is a statistical<br />

measure of the consistency or quality predictor of<br />

manufactured goods. It applies to all batch type<br />

production as a means of ensuring that the process<br />

average meets the standards determined. For<br />

medical products, it is critical that the products are<br />

manufactured to a very high standard at all times.<br />

Surgical and examination gloves are essential barrier<br />

protection items and neither you nor your patients<br />

want to receive a defective glove, however very rarely<br />

this may occur.<br />

What is a homogeneous<br />

batch?<br />

The term homogeneous batch refers to products<br />

that are made in groups and from the exact same<br />

parameters. Gloves, for example, would be from such<br />

a batch if the latex used, production settings and<br />

finishing processes are all exactly the same over that<br />

period. Any alteration at any stage of production is<br />

considered a new batch.<br />

Process average<br />

This term refers to the manufacturing process’<br />

average defect or reject rate. It is critical as an<br />

indicator of the manufacturing quality. To assess this<br />

a set number of gloves taken from the production<br />

line every two minutes are subjected to a full range of<br />

quality tests. The reject rate is the failure percentage<br />

of the product. Production processes are kept in tight<br />

tolerances with the use of control charts.<br />

Control charts<br />

These charts are like recipe cards and they outline all<br />

the parameters for the product being manufactured.<br />

In the case of <strong>Ansell</strong> gloves, for example, they would<br />

contain the latex and chemical mix for the dip, the<br />

production speed, oven temperatures, type of former<br />

to be used and every parameter including the post<br />

production processing. The tighter the parameters or<br />

tolerances in the control chart, the more consistent<br />

the quality of production will be. Every manufacturing<br />

step of an <strong>Ansell</strong> glove is documented and mapped<br />

for the production process to ensure our gloves are of<br />

the highest possible standards.<br />

<strong>AQL</strong> sampling<br />

The table on the reverse is an example of the<br />

arbitrary statistical system for <strong>AQL</strong> testing. You will<br />

see that inspection levels are set at ‘<strong>Level</strong> I’. This<br />

is the industry standard for medical grade quality<br />

inspection. Variance to another inspection level e.g.<br />

for machinery, would prescribe different tolerance<br />

levels. The variable parameters are:<br />

1. The lot/batch size.<br />

2. The inspection level – determined by<br />

AS/NZS4079:1997 and 4011:1997 at level I.<br />

3. <strong>AQL</strong> level determined.<br />

Depending on these points, the number of allowable<br />

failures per sample test will determine the arbitrary<br />

‘yes’ or ‘no’ for that batch to statistically pass the <strong>AQL</strong><br />

standard. Failure will mean that the manufacturer has<br />

to inspect every piece of the batch to remove defective<br />

products. This is time consuming and expensive.<br />

Therefore, it is better to build the quality assurance<br />

system into the production process rather than use<br />

inspection at a later stage to remove defects which<br />

occur through inexact production processes.

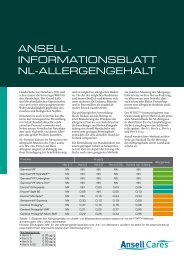

Curve number <strong>Ansell</strong> 2 3 World standard 5<br />

<strong>AQL</strong> 0.065 0.9 1.1 1.5 2.5<br />

Inspection level II II II II II<br />

Lot/batch size 10,000 10,000 10,000 10,000 10,000<br />

Sample size 200 200 200 200 200<br />

Acceptance number 0 3 5 7 10<br />

Curves for Sampling Plan<br />

Probability<br />

of<br />

Acceptance<br />

1.200000<br />

1.000000<br />

0.800000<br />

0.600000<br />

0.400000<br />

0.200000<br />

0.000000<br />

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5 6 6.5 7 7.5 8 8.5 9 9.5 10 10.5 11 11.5 12<br />

You can see in the graph that the lot (batch) size and<br />

inspection level are the same and only the <strong>AQL</strong> level<br />

varies. At an <strong>AQL</strong> of 2.5 the acceptable number of<br />

defects in the sample lot is 10. This falls to 7 allowable<br />

defects at an <strong>AQL</strong> of 1.5 (the world surgical glove<br />

standard). <strong>Ansell</strong>’s <strong>AQL</strong> level of 0.065 (before packaging)<br />

means that a single defect in the sample lot will result<br />

in an <strong>AQL</strong> failure, resulting in every glove in the<br />

production batch being inspected. As previously stated,<br />

this is time consuming and expensive. Setting an <strong>AQL</strong><br />

so low is only possible if the quality and consistency of<br />

production is very high and tightly controlled.<br />

An <strong>AQL</strong> test is an absolute test i.e. ‘yes’ it passes or<br />

‘no’ the batch cannot be released. However the <strong>AQL</strong><br />

test is a direct reflection on the manufacturing process<br />

quality and conformity. <strong>Ansell</strong>’s <strong>AQL</strong> level of 0.065<br />

Percent Defective<br />

<strong>AQL</strong> 0.065 INSP-II <strong>AQL</strong> 0.9 INSP-II <strong>AQL</strong> 1.1 INSP-II <strong>AQL</strong> 1.5 INSP-II <strong>AQL</strong> 2.5 INSP-II<br />

<strong>Ansell</strong> <strong>Healthcare</strong> <strong>Europe</strong> N.V.<br />

Riverside Business Park, Spey House, Boulevard International 55, B-1070 Brussels, Belgium<br />

Tel. +32 (0) 2 528 74 00 Fax +32 (0) 2 528 74 01 Fax Customer Service +32 (2) 528 74 03<br />

http://www.anselleurope.com E-mail info@eu.ansell.com<br />

(before packaging) ensures that you will consistently be<br />

assured of the highest quality barrier protection. There is<br />

however, as with everything a very rare occasion when a<br />

glove may be defective.<br />

What is the <strong>AQL</strong> level of the<br />

gloves you are using now?<br />

<strong>Ansell</strong>’s <strong>AQL</strong> standards:<br />

• Surgical gloves is 0.065 before packaging<br />

(World standard 1.5).<br />

• Examination gloves 1.5 (World standard 2.5).<br />

Be <strong>Ansell</strong> Sure.