Exclusive U.S. Distributor - Apollo Design Technology

Exclusive U.S. Distributor - Apollo Design Technology

Exclusive U.S. Distributor - Apollo Design Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Exclusive</strong> U.S. <strong>Distributor</strong>

Table Of Contents<br />

Introduction ...................................................................................................... 2<br />

Product Description ........................................................................................ 2<br />

Safety Information and Symbols .................................................................... 2<br />

Security Advice ............................................................................................ 3<br />

Protection from Eye Injury ............................................................................ 3<br />

Protection from Electric Shock ..................................................................... 3<br />

Protection from Fire ...................................................................................... 4<br />

Protection from Injury and Damage .............................................................. 4<br />

Health Advice ................................................................................................... 5<br />

Functional Advice ............................................................................................ 5<br />

Environmental Advice .................................................................................... 5<br />

LED Lifetime Advice ........................................................................................ 5<br />

Unpacking ........................................................................................................ 5<br />

Getting started (IP65 Version only) ................................................................ 6<br />

Making Internal Connections ....................................................................... 6<br />

Indoor/Outdoor Conversion (Diagram) ......................................................... 8<br />

Internal Connections (Diagram) ................................................................... 9<br />

Getting started changing the lens panel (only if required) .........................10<br />

Lens panel change (Diagram) .....................................................................11<br />

Getting started (IP20 & IP65 Version) ............................................................12<br />

Choosing a Location ...................................................................................12<br />

Secure Mounting .........................................................................................12<br />

Making AC Power Connections ...................................................................13<br />

Making DMX Control Connections (Diagram) .............................................14<br />

Operation/User Interface (Diagram) ..............................................................14<br />

Operation Modes ............................................................................................15<br />

“ST” Static Color Mode ..............................................................................15<br />

“C” Color Mode ..........................................................................................15<br />

“SP” Switch / Strobe Mode.........................................................................16<br />

“FP” Fade Patterns Mode ...........................................................................17<br />

“SLA” DMX Slave Mode .............................................................................17<br />

“GDMX” General DMX Mode .....................................................................18<br />

“CBAL” Color Balance Mode .....................................................................19<br />

“EDIT” Edit Settings Mode ................................................................... 20-21<br />

Maintenance ................................................................................................... 21<br />

Technical Data ............................................................................................... 21<br />

Standards ....................................................................................................... 22<br />

Warranty ......................................................................................................... 22<br />

1

<strong>Exclusive</strong> U.S. <strong>Distributor</strong><br />

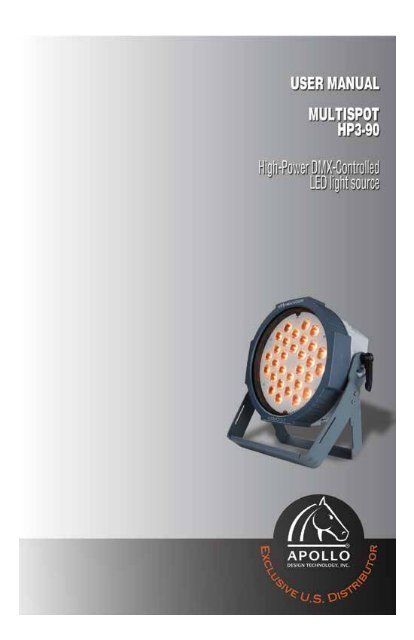

Introduction<br />

Dear customer,<br />

Congratulations on the purchase of the Multispot HP3-90 from <strong>Apollo</strong>. <strong>Apollo</strong> is the US<br />

exclusive distributor for Multiform, a leading global manufacturer of professional lighting<br />

equipment with decades of experience in design, production, and quality assurance.<br />

To meet your requirements, this unit has been designed and built to the highest standards<br />

to assure you have made a sound investment. To take full advantage of all possibilities<br />

and for your own safety and the safety of your environment, please read these operating<br />

instructions carefully before you start using the unit.<br />

Product Description<br />

The Multispot HP3-90 is a high-power DMX-controlled LED light source for both indoor<br />

and outdoor applications, ranging from architectural illumination to stage lighting. This<br />

fixture has been designed for flexibility and reliability, including various connection options<br />

and an advanced cooling system that allow for longer LED lifetime.<br />

Safety Informaton<br />

Read the safety precautions in this chapter before installing,<br />

powering up, operating or servicing this device. Failure to do<br />

so may void the product warranty, and releases the manufacturer<br />

and distributor from all product liability.<br />

Symbols used in this manual<br />

The following symbols are used to identify important safety information on the product<br />

and in this manual:<br />

WARNING! Read manual before installation, operation or servicing.<br />

WARNING! Safety hazard. Risk of injury or death.<br />

WARNING! Hazardous voltage. Risk of severe or fatal electric shock.<br />

WARNING! Shock hazard. Equipment must be properly grounded.<br />

WARNING! Hot surface. Risk of skin burn or skin irritation.<br />

2

WARNING! Fire hazard.<br />

WARNING! LED light emission. Risk of eye injury.<br />

Security Advice Before Use<br />

General advice:<br />

1. Read this manual completely before using the product.<br />

2. Keep this manual in your records for future reference.<br />

3. Follow all instructions printed in this manual, otherwise<br />

warranty may become void.<br />

4. Follow all printed safety advice on the device.<br />

5. Carry this product with care. Dropping or heavy vibration may<br />

damage this product mechanically and/or electrically.<br />

6. The manufacturer and distributor take no responsibility for injury<br />

or damage caused by not following the safety precautions and<br />

instructions printed within this manual and on the device.<br />

Protection From Eye Injury<br />

1. Warning: Depending on the configuration of the device, this device<br />

reaches the limits of IEC/EN62471 Group 2 and may extend into<br />

Group 3.<br />

2. To avoid eye injury, do not look into the beam from a distance<br />

of less than 28’ (8.5m) from the front surface of the fixture without<br />

protective eyewear such as shade-5 welding goggles. At greater<br />

distances, light output is harmless to the naked eye provided that<br />

the eye’s natural aversion response is normal.<br />

3. Do not view the beam directly with optical instruments such as<br />

magnifiers, telescopes, binoculars or similar optical instruments<br />

that may concentrate the light output.<br />

4. Ensure that during setup and DMX programming, no persons are<br />

within 28’ (8.5m) of the device’s front surface to avoid accidental<br />

exposure to the light beam.<br />

Protection From Electric Shock:<br />

1. Only connect this unit to a mains socket outlet with protective earth<br />

connection, ground-fault (earth-fault) and overload protection.<br />

2. When removing the AC power cord from an AC power outlet, grip<br />

the plug. Never pull on the cable only. To disconnect the unit from<br />

AC power, remove the AC power cord from the AC power outlet.<br />

Do not disconnect the unit from AC power using the locking power<br />

connector. The locking power connector does not have a breaking<br />

capacity, i.e. the locking power connector should not be connected<br />

or disconnected under load or when live.<br />

3

<strong>Exclusive</strong> U.S. <strong>Distributor</strong><br />

3. Disconnect the unit from AC power before cleaning.<br />

Use a smooth and dry cloth only for cleaning.<br />

4. Do not submerge unit in liquid.<br />

5. If unit is not converted to comply with IP65 rating, do not expose<br />

this unit to any dripping or splashing liquids, and do not place<br />

objects filled with liquids, such as vases, on the unit. Do not operate<br />

this unit near open water or in high humidity.<br />

6. Choose the position of the AC cord according to the lowest risk of<br />

damage by foot traffic or rolling equipment.<br />

7. Do not open the unit for service. There are no user-serviceable<br />

parts inside. Warranty will be void in any case of unauthorized<br />

service by the user or other unauthorized persons.<br />

Protection From Fire:<br />

1. Take care to not place the unit near sources of heat (e.g. powerful<br />

amplifiers, fog machines).<br />

2. Allow at least 6” (15cm) between this unit and other devices or walls<br />

to allow for proper cooling.<br />

3. Take care to allow sufficient air convection in the unit’s environment<br />

to avoid overheating. Make sure air convection slots are not<br />

blocked. Do not operate this unit in environmental temperatures<br />

exceeding 105°F (40°C).<br />

4. Be sure unit is kept at least 30” (76cm) away from any flammable<br />

materials.<br />

5. Do not attach gel or diffusion directly to the LEDs or the front of<br />

the unit.<br />

6. To avoid overloading power, check the total maximum power of your<br />

AC wall outlet if you are using powerCON jumpers to daisy chain<br />

units together.<br />

7. When using powerCON jumpers to daisy chain units using the<br />

locking power outlet, do not connect more than 12 units together.<br />

Protection From Injury and Damage:<br />

1. Never use any accessories or modifications not authorized by the<br />

manufacturer of this unit.<br />

2. Choose a location for operation where the unit is protected from<br />

vibration and where a fixed mounting position is provided. In case of<br />

overhead-mounting, follow applicable rigging rules and regulations<br />

for rigging safety, including the use of an approved safety cable.<br />

3. The surface of the device may get hot during operation. Do not<br />

touch heat sink areas of the device during operation. Allow 30<br />

minutes of cool-down time after powering off before touching.<br />

4. If fluids have spilled into the unit when configured to IP20,<br />

immediately disconnect power to the unit and return the unit to<br />

<strong>Apollo</strong> for service.<br />

5. This unit has no user serviceable parts. If service is needed, return<br />

unit to <strong>Apollo</strong> for service.<br />

4

Health advice<br />

This unit produces and absorbs electromagnetic radiation. The strength of radiation<br />

and the sensitivity for disturbing interference conforms to CE and FCC requirements.<br />

A corresponding sign is printed on the backside of the unit. Any change or modification<br />

may affect the behavior of the unit concerning electromagnetic radiation, and may cause<br />

non-conformity to CE requirements. The manufacturer takes no responsibility in this case.<br />

Functional advice<br />

This unit is immune to the presence of electromagnetic disturbances – both conducted<br />

and radiated - up to a certain level. Under peak conditions, the unit is classified to show<br />

a “class C” performance criteria and may encounter temporary degradation or loss of<br />

function. In such a case, disconnect the unit AC power from the unit and reconnect it<br />

again to recover.<br />

Environmental advice<br />

This unit is built to conform to the ROHS standards and the WEEE<br />

directive 2002/96/EC of the European Parliament and of the Council<br />

of the European Union. Under these regulations, the product shall<br />

not be discarded into regular garbage at the end of its life, but shall be returned<br />

to authorized recycling stations. It is highly recommended that North American users<br />

follow environmentally safe disposal/recycling practices.<br />

LED Lifetime advice<br />

LED lifetime is determined by the gradually declining brightness of an LED over time<br />

where, the point of 50% brightness reduction marks the defined end of its lifetime. The<br />

driving factor of this effect is the heat that the chip inside the LED is exposed to. While an<br />

LED may reach 100,000 hours under ideal circumstances,<br />

the real-world lifetime may only be 30,000 to 50,000 hours. This may be less if the LED is<br />

exposed to excessive heat, which can be caused by continuously running all LEDs inside<br />

this device at full power and/or operating the unit in high environmental temperatures. If<br />

improving the lifetime of the LED is a concern, keeping the operating temperature lower<br />

is advised. This may include forced air external cooling and/or the reduction of overall<br />

intensity.<br />

Unpacking<br />

Please check that the box contains the following items:<br />

Main parts: 1 Multispot HP3-90 LED main unit<br />

1 operation manual<br />

Accessory parts: 2 M6 security lugs<br />

1 power cable (IP20 unit only)<br />

If any part is missing, please contact your dealer immediately for replacement.<br />

5

<strong>Exclusive</strong> U.S. <strong>Distributor</strong><br />

Getting started: IP65 version only<br />

Making Internal Connections<br />

Your Multiform HP fixture is available in several IP-65 versions. Please take note of the<br />

following precautions and instructions to ensure that it is done properly to avoid personal<br />

injury and/or damage to the unit.<br />

Reliability risk: Disassembling and reassembling the unit in an<br />

inappropriate manner may defeat the IP65 rating and may void the<br />

warranty if water intrudes into the unit. It is essential to follow the<br />

instructions to maintain the IP65 rating of the fixture and its product<br />

warranty.<br />

Safety risk: Be sure that the unit is disconnected from AC power<br />

before proceeding. This procedure requires opening the unit and<br />

exposure to AC electrical parts. If the internal wiring is improperly done<br />

or not completed, the safety of the whole installation where this unit is<br />

used may be endangered and a risk of fire is possible. Therefore, this<br />

procedure should only be carried out by qualified technicians with<br />

relevant experience in safe work methods for electrical equipment<br />

service and maintenance. DO NOT attempt if you do not have the<br />

applicable experience. <strong>Apollo</strong> does not assume any liability for life and<br />

assets if such unqualified attempt is made.<br />

Before opening the unit, please make sure that:<br />

• This procedure is only being carried out by a qualified technician with relevant<br />

experience in safe work methods for electrical equipment service and maintenance.<br />

• The unit is disconnected from any AC source.<br />

• The unit is completely dry, and has cooled down for at least 30 minutes after last<br />

operation. The unit should be at room temperature.<br />

• The location chosen to perform the work does not have more than 40% relative<br />

humidity and the temperature during the work does not exceed 105°F (40°C).<br />

This is important to avoid condensation inside of the unit if operated at lower<br />

temperatures.<br />

• The proper tools are used to disassemble and reassemble the unit to avoid any<br />

damage to the screws. A 4mm hex driver, a #2 Phillips screwdriver, and a 3/32” flat<br />

head screwdriver are required.<br />

• Tools with built-in torque measurement or other torque measurement devices are<br />

recommended to ensure that screws are fastened with the right amount of torque<br />

during reassembly.<br />

Permanent installations:<br />

For permanent installations, fixtures are shipped with IP-65 cable plates with water<br />

resistant cable glands. Cables are not included. Please take note of the following.<br />

6

To ensure the IP65 rating of the fixture is maintained, the proper<br />

size cable must be used.<br />

• Rubber AC cable of at least 3x16AWG, with outer diameter of not less than .236”<br />

(6mm), and not more than .354” (9mm).<br />

• DMX signal cable, 2x22AWG twisted pair with shield, with outer diameter of not<br />

less than .236” (6mm), and not more than .354” (9mm).<br />

Reliability risk: Using cable material of unsuitable outer diameter or<br />

with insufficient flexibility of its outer jacket may defeat the IP65 rating<br />

of the fixture and may void any warranty.<br />

NOTE: If opting to not install cable in all 4 PG9 glands, it is necessary to install the<br />

rubber plugs in place of cable to maintain the IP65 rating. 3 pieces are provided for<br />

this purpose.<br />

Please follow the below step-by-step instructions to properly install the necessary<br />

cables.<br />

1. Place the unit on its front. Remove the 6 socket head caps screws<br />

that hold the rear cover of the power supply compartment. Set the<br />

screws aside, do not lose them.<br />

2. The PSU PCB and MCU PCB are attached to the rear cover. Carefully<br />

lift the cover straight up from the main unit.<br />

3. Gently turn the cover around. You will see two sets of wires in a white<br />

sleeve coming through a hole in the main body. Carefully unplug just<br />

these wires from the PSU PCB and MCU PCB. The cover and<br />

attached electronics should now be loose.<br />

4. Insert your cables through the PG9 glands mounted to the cover.<br />

Do not tighten the gland cover nuts yet so the cable can still<br />

slide through the glands. Pull enough cable through to allow<br />

preparation of the cable ends.<br />

5. AC cable preparation and installation:<br />

a. Remove 1 1/2” (38mm) of the outer jacket.<br />

b. Strip each wire 3/8” (9.5mm).<br />

c. Insert the AC leads into the screw terminal block on the PSU<br />

PCB. If connecting an output cable, insert both wires of each<br />

cable into the terminal block.<br />

d. Carefully tighten screws taking care to not over tighten as this<br />

could cause damage to the terminal block and PSU PCB.<br />

6. DMX cable preparation and installation:<br />

a. Remove 1 1/2” (38mm) of the outer jacket<br />

b. Strip each wire 3/16” (4.75mm)<br />

c. Insert the wires into the screw terminal blocks on the MCU<br />

PCB. It is recommended to cover the shield wire with a piece<br />

of 1 1/4” (6.35mm) long 1/8” (3.2mm) heat shrink to protect<br />

from creating shorts on the MCU PCB.<br />

d. Carefully tighten screws taking care to not over tighten as this<br />

could cause damage to the terminal block and MCU PCB.<br />

7

<strong>Exclusive</strong> U.S. <strong>Distributor</strong><br />

7. Pull the cables from the outside of the rear cover until the remaining<br />

internal length is minimized without putting strain on the cables or their<br />

connections to the terminal blocks.<br />

8. Tighten the cover nuts of the PG9 glands. Be sure the rubber gland<br />

seal adapts properly and tightly to the cable’s outer perimeter to<br />

maintain the IP65 rating.<br />

9. At this point, carefully inspect the rubber seal on the main unit to<br />

ensure that it is properly seated in the grove of the outer edge of<br />

the rear compartment.<br />

10. Carefully reconnect the wires unplugged in step 3 to the proper locations<br />

on the PSU PCB and MCU PCB. Take care to properly line up the<br />

connectors before attempting to plug them in to avoid damage to<br />

the connectors.<br />

11. Gently turn the cover so the electronics are facing down. Carefully<br />

lower the cover straight down into the main unit. Check to ensure that<br />

the rubber seal is still properly seated, and then carefully place the<br />

cover down on the main unit. NOTE: It is extremely important the<br />

rubber seal is properly seated in the groove of the outer edge of the<br />

rear compartment to maintain the IP65 rating.<br />

12. Carefully replace the 6 socket head cap screws into the proper holes<br />

on the main unit. Tighten them to 5.3 in-lbs (0.6 N-m) ~ 6.2 in-lbs<br />

(0.7 N-m) torque.<br />

Indoor/Outdoor Conversion<br />

A. Detach Rear Cover<br />

B. Connect Cable Wires C. Re-attach Rear Cover<br />

8

Internal Connections (View from PCB Side)<br />

1<br />

2<br />

3<br />

5<br />

4<br />

[AC-In/Out] L (Red Lead)<br />

[AC-In/Out] N (Black Lead)<br />

[AC-In/Out] GND (YG Lead)<br />

[DMX-Out] GND (Black Lead)<br />

[DMX-Out] - DATA (Green Lead)<br />

[DMX-Out] + DATA (Red Lead)<br />

DANGER! Safety hazard. Risk of<br />

severe injury or death.<br />

WARNING! Hazardous voltage.<br />

Risk of lethal or severe electric shock.<br />

9<br />

[MCU-PCB Supply] + DC (Red Lead)<br />

[MCU-PCB Supply] - DC (Black Lead)<br />

[LED-PCB Supply] + DC (Red Lead)<br />

[LED-PCB Supply] GND (Black Lead)<br />

[DMX-In] + DATA (Red Lead)<br />

[DMX-In] - DATA (Green Lead)<br />

[DMX-In] GND (Black Lead)<br />

[Supply] + DC (Red Lead)<br />

[Supply] - DC (Black Lead)<br />

NOTE: Any internal work on this unit<br />

shall only be carried out by qualified<br />

technicians who are familiar with safe<br />

repair techniques. Disconnect AC<br />

before opening the unit.<br />

Semi-Permanent and Temporary Installations<br />

For semi-permanent and temporary installations, fixtures will be shipped with 3’ long<br />

power in/out and 3’ long DMX in/out cables. Power cable connectors are not includes.<br />

DMX connectors are included and will be either IP-20 or IP-65 compatible depending<br />

on which cable package is ordered.<br />

Note on Internal Condensation<br />

Under some extreme conditions of heating and cooling condensation can form on<br />

the inside of front lens and menu display. This is normal. Condensation will evaporate<br />

when the fixture is powered on and heats up. The internal components of the HP<br />

fixture are coated to protect against moisture.<br />

5<br />

4<br />

3<br />

1<br />

2

<strong>Exclusive</strong> U.S. <strong>Distributor</strong><br />

Getting started: changing the lens panel (only if required)<br />

Your Multiform HP3-90 has been factory-fitted with a 25° lens panel. A 60° lens panel is<br />

available as an option. If you wish to exchange the lens panel to achieve a 60° dispersion<br />

angle, please contact your dealer to order the 60° lens panel. Please take note of the<br />

following precautions and instructions below to ensure the lens panel exchange is done<br />

properly to avoid damage to the unit.<br />

Reliability risk: Disassembling and reassembling the unit in an inappropriate<br />

manner may defeat the IP65 rating and may void the warranty if water intrudes<br />

into the unit. It is essential to follow the instructions to maintain the IP65 rating of<br />

the fixture and its product warranty.<br />

Before you start to exchange the lens panel, please make sure that:<br />

• All cables are disconnected from unit.<br />

• The unit is completely dry, and has cooled down for at least 30 minutes after last<br />

operation. The unit should be at room temperature.<br />

• The location chosen to exchange the lens panel does not have more than 40% relative<br />

humidity and the temperature during the exchange does not exceed 105°F (40°C). This<br />

is important to avoid condensation inside of the unit if operated at lower temperatures.<br />

• The proper tools are used to exchange the lens panel to avoid any damage to the unit<br />

and screws. A 4mm hex driver and a #2 Phillips screwdriver are required.<br />

• Tools with built-in torque measurement or other torque measurement devices are<br />

recommended to ensure that screws are fastened with the right amount of torque<br />

during reassembly.<br />

Please follow the below step-by-step instructions to properly exchange<br />

the lens panel.<br />

1) Place the unit on its facedown on its front frame. Remove the 8 socket head cap<br />

screws that hold the front frame to the main fixture body (Illustration step A). Set<br />

the screws aside, do not lose them.<br />

2) Carefully take hold of the main fixture body and front frame and turn the unit over<br />

onto its back. It is possible that the glass seal around the front glass could stick<br />

to the front frame and unexpectedly break loose, potentially damaging the glass.<br />

Carefully lift off the front frame while holding down the front glass to be sure the<br />

glass seal does not stick to the front frame.<br />

3) Carefully lift off the front glass including the glass seal (Illustration step B). Do not<br />

remove the glass seal from around the glass.<br />

4) Remove the 5 lens panel screws holding the lens panel in place. Set the screws<br />

aside, do not lose them.<br />

5) It is possible to damage the LEDs if the lens panel is not removed properly.<br />

Carefully remove the lens panel by gripping it by the two finger grip points and<br />

lifting it straight up off of the unit.<br />

10

6) Once again, it is possible to damage the LEDs if the lens panel is not placed<br />

properly. The LEDs can be easily damaged by coming into contact with the<br />

lenses. Carefully place the lens panel by gripping it by the two finger grip<br />

points and gently lower it straight down onto the unit. Do not apply pressure<br />

to the lens panel. If the lens is not properly aligned, carefully lift it back up and<br />

check alignment before carefully lowering it back down.<br />

7) Carefully replace the 5 lens panel screws. Tighten them to 4.4 in-lbs<br />

(0.50 N-m) ~ 4.8 in-lbs (0.55 N-m) torque.<br />

8) Be sure that the glass seal is installed properly around the front glass and<br />

carefully place the front glass into position on the unit.<br />

9) Check to be sure that the glass seal is properly seated down and inside of<br />

the 8 tabs around the edge of the unit. If this is not done properly, the unit<br />

may not meet IP65 rating.<br />

10) Carefully lower the front frame down onto the main unit with the screw holes<br />

aligned. Avoid any position change of the front glass with seal and the<br />

main seal.<br />

11) Carefully take hold of the main fixture body and the front frame and turn<br />

the unit over onto the front frame.<br />

12) Carefully replace the 8 socket head cap screws which secure the front frame<br />

to the main fixture body. Tighten them to 26.5 in-lbs (3.0 N-m) ~ 29.2 in-lbs<br />

(3.3 N-m) torque.<br />

11

<strong>Exclusive</strong> U.S. <strong>Distributor</strong><br />

Getting Started: IP20 and IP65 Versions<br />

Choosing A Location<br />

Risk of fire: The Multispot HP3-90 has been designed to operate at<br />

environmental temperatures up to 105°F (40°C). For proper<br />

operation, the unit must be operated with unobstructed air convection<br />

to its outside metal case.<br />

Do not:<br />

• Operate the Multispot HP3-90 in environments with more than 105°F (40°C)<br />

environmental temperature.<br />

• Operate the Multispot HP3-90 in any closed space, unless forced air convection<br />

is provided.<br />

• Operate less than 30” (76cm) away from any flammable materials.<br />

Secure Mounting<br />

The Multispot HP3-90 can be mounted in various ways:<br />

Floor standing operation<br />

• Turn the bracket to the lower side of the unit and fold out the second bracket.<br />

• Place the unit in a secure position.<br />

• Make sure to comply with the cooling requirements of the unit.<br />

Hanging/Rigging, ceiling-mounted Operation<br />

Risk of injury: Overhead mounting requires extensive experience,<br />

including, among others, calculating working load limits, good<br />

knowledge of the installation material being used, and periodic<br />

safety inspection of all installation material and the unit.<br />

If you lack such qualifications, do not attempt the installation<br />

yourself. Improper installation can result in injury. Be sure to<br />

complete all rigging and installation procedures before applying<br />

power to the unit.<br />

• Leave the inner and outer bracket folded.<br />

• The unit should be installed out of reach of people and outside areas where<br />

persons may walk by or be seated.<br />

• Make sure the installation area can hold a minimum point load of 10<br />

times the unit’s weight.<br />

• In fixed installations, attach the unit with self-locking screws/nuts to the<br />

mounting point.<br />

• When mounting the unit to truss, be sure to secure an appropriately rated<br />

clamp to the hanging yoke through the center hole of the hanging yoke.<br />

• Attach the supplied M6 safety lugs to the rear side threaded insert points.<br />

Secure the installation with an appropriate safety cable fixed to an individual<br />

separate mounting point. Be sure to only use the designated rigging point for<br />

the safety cable.<br />

12

• Always use a certified safety cable that can hold 12 times the weight of<br />

the unit when installing the unit. This secondary safety attachment should<br />

be installed in a way that no part of the unit can drop more than 8” (20cm)<br />

if the main attachment fails.<br />

• Never stand directly below the device when mounting, removing, or servicing<br />

the fixture.<br />

• The installation should be inspected every year by a skilled person to ensure safety.<br />

• Be sure to comply with the cooling requirements of the unit.<br />

Making AC Power Connections<br />

Risk of fire / Safety risk<br />

• The Multispot HP3-90 requires an AC power source with sufficient<br />

power and correct grounding to ensure safe operation. The AC power<br />

source must be equipped with a circuit breaker. Make sure to only use<br />

compliant AC supply lines.<br />

• The Multispot HP3-90 has an AC outlet that is designed to carry<br />

loads of no more than 10A. Make sure that all connected units in a<br />

chain fed by the first unit do not exceed a maximum of 10A current<br />

consumption.<br />

• When using powerCON jumpers to daisy chain units using the locking<br />

power outlet, do not connect more than 12 units together.<br />

• Do not disconnect the unit from AC power using the locking power<br />

connector. The locking power connector does not have a breaking<br />

capacity, i.e. the locking power connector should not be connected<br />

or disconnected under load or when live.<br />

To connect the unit to AC power, first plug the cable into the unit. Align the tabs on the<br />

locking power input connector (blue) with the slots in the locking power inlet (blue) and<br />

insert connector until it stops, then rotate the connector clockwise until the silver tab<br />

clicks into place and locks the connector in. If using powerCON jumpers to daisy chain<br />

power across multiple units using the locking power outlet, connect all units, up to 12,<br />

together before connecting the first unit to AC power. Align the tabs on the locking power<br />

output connector (grey) with the slots in the locking power outlet (grey) and insert connector<br />

until it stops, then rotate the connector counterclockwise until the silver tab clicks<br />

into place and locks the connector in. Once all units are connected together, the first unit<br />

may be connected to AC power.<br />

To remove the power cables from the units, first disconnect the first unit from AC power.<br />

Grasp the locking power input connector (blue), slide the silver tab back, and rotate the<br />

connector counterclockwise until it stops, then pull the connector straight out of the<br />

locking power inlet. Grasp the locking power output connector (grey), slide the silver tab<br />

back, and rotate the connector clockwise until it stops, then pull the connector straight<br />

out of the locking power outlet.<br />

13

<strong>Exclusive</strong> U.S. <strong>Distributor</strong><br />

NOTE: The locking power connector does not have a breaking capacity, i.e. the locking<br />

power connector should not be connected or disconnected under load or when live.<br />

Making DMX Control Connections<br />

Connect the Multispot HP3-90 to a suitable DMX controller where needed, and<br />

interconnect several units by means of their DMX In/Outputs as required. The last unit<br />

shall be fitted with a proper 120 Ohm termination resistor-equipped DMX-plug as shown<br />

in below drawing. Please make sure that all used DMX cables comply with below<br />

standard:<br />

Operation<br />

User interface<br />

User Interface Overview:<br />

1 MODE selection Button<br />

2 LEFT ARROW Button<br />

3 RIGHT ARROW Button<br />

4 – Button<br />

5 + Button<br />

6 DISPLAY: Sound-to-Light Indicator<br />

7 DISPLAY: 4-Digit Message Display Area<br />

8 DISPLAY: + Indicator<br />

9 DISPLAY: - Indicator<br />

14<br />

Termination<br />

10 DISPLAY: ARROW Indicators<br />

11 DISPLAY: DMX Signal<br />

Presence Indicator<br />

12 Microphone cover membrane<br />

13 DMX Input<br />

14 DMX Output<br />

15 AC Power Input<br />

16 AC Power Output<br />

17 M6 safety lug mounting thread<br />

18 M10 nut insert point

Operation Modes<br />

The Multispot HP3-90 has several operating modes to allow for local preset<br />

control and remote operation.<br />

“ST” Static Color Mode<br />

Press the MODE button (1) until the first two digits on the display shows “ST”. Choose<br />

a color, “ST 0” – “ST25”, by pressing the left/right buttons (2 or 3), see table below. The<br />

+/- buttons (4 or 5) change the dimming level, “L 0” – “L100”. Pressing the +/- buttons (4<br />

or 5) once shows the current dimming level. The dimming level can then be changed by<br />

using the +/- buttons (4 or 5). Holding the +/- buttons (4 or 5) for longer than 1 second<br />

accelerates the change rate of the displayed value to 3 times normal speed. The display<br />

will automatically return to show “ST##” after 5 seconds, and the dimming level will<br />

remain as set.<br />

# Color # Color<br />

ST 0 All Off ST13 Flesh<br />

ST 1 Red ST14 Light Blue Green<br />

ST 2 Green ST15 Light Green<br />

ST 3 Blue ST16 Light Purple<br />

ST 4 Yellow ST17 Light Lavender<br />

ST 5 Pink ST18 Light Blue<br />

ST 6 Turquoise ST19 White 1 (cool)<br />

ST 7 Lime ST20 White 2<br />

ST 8 Orange ST21 White 3<br />

ST 9 Marine ST22 White 4<br />

ST10 Blue Green ST23 White 5 (warm)<br />

ST11 Lavender ST24 Light Orange<br />

ST12 Hot Pink ST25 Dark Orange<br />

NOTE: This mode is automatically disabled when an external DMX signal is present.<br />

“C” Color Picker Mode<br />

Press the MODE button (1) until the first digit on the display shows “C”. There are 226<br />

color steps. Choose a color, “C 0” – “C225”, by pressing the left/right buttons (2 or 3).<br />

The +/- buttons (4 or 5) change the dimming level, “L 0” – “L100”. Pressing the +/- buttons<br />

(4 or 5) once shows the current dimming level. The dimming level can then be<br />

changed by using the +/- buttons (4 or 5). Holding the +/- buttons (4 or 5) for longer than<br />

1 second accelerates the change rate of the displayed value to 3 times normal speed.<br />

The display will automatically return to show “C###” after 5 seconds, and the dimming<br />

level will remain as set.<br />

NOTE: This mode is automatically disabled when an external DMX signal is present.<br />

15

<strong>Exclusive</strong> U.S. <strong>Distributor</strong><br />

“SP” Switch / Strobe Patterns Mode<br />

In this mode you will only find hard switching and strobe patterns. Press the MODE<br />

button (1) until the first two digits on the display shows “SP”. Choose a pattern, “SP 0” –<br />

“SP12”, by pressing the left/right buttons (2 or 3), see table below.<br />

# Pattern # Pattern<br />

SP 0 Red - Green SP 7 Red - Green - Blue<br />

SP 1 Green - Blue SP 8 Red - Yellow - Green - Turquoise - Blue - Hot Pink<br />

SP 2 Red - Blue SP 9 Strobe Red<br />

SP 3 Red - Yellow SP10 Strobe Green<br />

SP 4 Hot Pink - Lime SP11 Strobe Blue<br />

SP 5 Pink - Blue SP12 Strobe White<br />

SP 6 Turquoise - Pink<br />

The +/- buttons (4 or 5) change the color speed or activate the Sound-to-Light function,<br />

“SL 0” – “SL25”, “S2L” . Pressing the +/- buttons (4 or 5) once shows the current setting.<br />

The setting can then be changed by using the +/- buttons (4 or 5), see table below. The<br />

display will automatically return to show “SP##” after 5 seconds, and the speed setting<br />

will remain as set.<br />

Setting Speed Setting Speed<br />

S2L Sound-to-Light SL13 1 step per second<br />

SL 1 1 step per 240 seconds SL14 1.5 steps per second<br />

SL 2 1 step per 120 seconds SL15 2 steps per second<br />

SL 3 1 step per 90 seconds SL16 2.5 steps per second<br />

SL 4 1 step per 60 seconds SL17 3 steps per second<br />

SL 5 1 step per 30 seconds SL18 4 steps per second<br />

SL 6 1 step per 20 seconds SL19 5 steps per second<br />

SL 7 1 step per 10 seconds SL20 6 steps per second<br />

SL 8 1 step per 5 seconds SL21 7 steps per second<br />

SL 9 1 step per 3 seconds SL22 8 steps per second<br />

SL10 1 step per 2 seconds SL23 9 steps per second<br />

SL11 1 step per 1.6 seconds SL24 10 steps per second<br />

SL12 1 step per 1.2 seconds SL25 11 steps per second<br />

Please note that above speed levels are only applicable to patterns “SP 0” – “SP 8”.<br />

When using patterns “SP 9” – “SP12”, “S2L “ indicates Sound-to-Strobe and “SL 1” –<br />

“SL25” are strobe speed ranging from 1Hz to 18Hz.<br />

When Sound-to-Light or Sound-to-Strobe, “S2L “, is selected, the “S” indicator (6) will be<br />

illuminated. The built-in microphone will be active.<br />

NOTE: This mode is automatically disabled when an external DMX signal is<br />

present.<br />

16

“FP” Fade Patterns Mode<br />

In this mode you will only find soft fade patterns. Press the MODE button (1) until the<br />

first two digits on the display shows “FP”. Choose a pattern, “FP 0” – “FP 7”, by pressing<br />

the left/right buttons (2 or 3), see table below.<br />

# Pattern # Pattern<br />

FP 0 Red - Green FP 4 Hot Pink - Lime<br />

FP 1 Green - Blue FP 5 Pink - Blue<br />

FP 2 Blue - Red FP 6 Turquoise - Pink<br />

FP 3 Red - Yellow FP 7 Red - Green - Blue (All Colors)<br />

The +/- buttons (4 or 5) change the color fade speed, “SL 0” – “SL25”. Pressing the<br />

+/- buttons (4 or 5) once shows the current setting. The setting can then be changed<br />

by using the +/- buttons (4 or 5), see table below. The display will automatically return<br />

to show “FP##” after 5 seconds, and the speed setting will remain as set.<br />

Setting Speed Setting Speed<br />

SL 0 1 loop per 960 seconds SL13 1 loop per 3 seconds<br />

SL 1 1 loop per 480 seconds SL14 1 loop per 2 seconds<br />

SL 2 1 loop per 360 seconds SL15 1 loop per 1.5 seconds<br />

SL 3 1 loop per 240 seconds SL16 1 loop per 1.25 seconds<br />

SL 4 1 loop per 120 seconds SL17 1 loop per 1 second<br />

SL 5 1 loop per 80 seconds SL18 1.2 loops per second<br />

SL 6 1 loop per 40 seconds SL19 1.4 loops per second<br />

SL 7 1 loop per 20 seconds SL20 1.6 loops per second<br />

SL 8 1 loop per 12 seconds SL21 1.9 loops per second<br />

SL 9 1 loop per 10 seconds SL22 2.2 loops per second<br />

SL10 1 loop per 8 seconds SL23 2.5 loops per second<br />

SL11 1 loop per 6 seconds SL24 2.8 loops per second<br />

SL12 1 loop per 4 seconds SL25 3.2 loops per second<br />

NOTE: This mode is automatically disabled when an external DMX signal is present.<br />

“SLA” DMX Slave Mode<br />

The Slave mode offers 4 independent groups of slaves. Press the MODE button (1) until<br />

the first three digits on the display shows “SLA”. The +/- buttons (4 or 5) change the slave<br />

group, “SLA1” – “SLA4”. The first unit will then control any connected units. Each slave<br />

group will be in the same preset and speed as the master, but the timing of the preset<br />

will be offset from the previous slave group. To have all units operating together, set all<br />

units to slave group 1.<br />

17

DMX<br />

channel<br />

1<br />

<strong>Exclusive</strong> U.S. <strong>Distributor</strong><br />

“GDMX” General DMX Mode<br />

Press the MODE button (1) until the display shows “GDMX”. When the unit is receiving a<br />

DMX signal, the DMX indicator (11) will be illuminated.<br />

Setting the DMX Address<br />

The +/- buttons (4 or 5) change the DMX address, “ 1” – “ 512”. Pressing the +/- buttons<br />

(4 or 5) once shows the current DMX address. The DMX address can then be changed<br />

by using the +/- buttons (4 or 5). Holding the +/- buttons (4 or 5) for longer than 1 second<br />

accelerates the change rate of the displayed value to 3 times normal speed. The<br />

display will automatically return to show “GDMX” after 5 seconds, and the DMX address<br />

will remain as set. The DMX address remains the same regardless of the selected DMX<br />

control mode. However, the number of channels used may change depending on the<br />

selected DMX control mode.<br />

Selecting a DMX Control Mode<br />

Pressing the left/right buttons (2 or 3) once shows the current DMX control mode. The left/<br />

right buttons (2 or 3) can then be used to cycle through the following DMX control modes.<br />

- “3RAW” 3 Channels – 1=Red, 2=Green, 3=Blue<br />

- “3CCC” 4 Channels – 1=Red, 2=Green, 3=Blue, 4=Intensity/Strobe<br />

- – CH 4 values – 000-127=Intensity, 128-239=Strobe, 240-255=Full Intensity<br />

- “3CMS” 5 Channels – 1=Red, 2=Green, 3=Blue, 4=Intensity, 5=Strobe<br />

- “HSLS” 4 Channels – 1=Hue, 2=Saturation, 3=Lightness, 4=Strobe<br />

- “PRES” 4 Channels – Presets, see section below.<br />

When the DMX control mode is set to Presets, the DMX value of channel 3 determines<br />

which presets channel 1 controls. If the DMX value of channel 3 is 000-049, channel<br />

1 selects static colors, see table below. Channel 4 strobe speed is 015=slow (1Hz) to<br />

255=fast (18Hz).<br />

Value<br />

Range<br />

Function<br />

18<br />

DMX<br />

channel<br />

Value<br />

Range<br />

Function<br />

000-010 Red<br />

154-163 Light Purple<br />

011-020 Green 164-174 Light Lavender<br />

021-030 Blue 175-184 Light Blue<br />

031-040 Yellow 185-194 White 1 (cool)<br />

041-051<br />

052-061<br />

Pink<br />

Turquoise<br />

1<br />

195-204<br />

205-215<br />

White 2<br />

White 3<br />

062-071 Lime 216-225 White 4<br />

072-081 Orange 226-235 White 5 (warm)<br />

082-092 Marine 236-245 Light Orange<br />

093-102 Blue Green 246-255 Dark Orange<br />

103-112 Lavender 2 000-255 Intensity<br />

113-122 Hot Pink 3 000-049 Static Colors<br />

123-133<br />

134-143<br />

Flesh<br />

Light Blue Green<br />

4<br />

000-014<br />

015-255<br />

Strobe off<br />

Strobe on<br />

144-153 Light Green

If the DMX value of channel 3 is 050-255, channel 1 selects fade/switch colors, see<br />

table below. Channel 3 controls the fade/switch speed (050=slow/255=fast). Channel 4<br />

strobe speed is 015=slow (1Hz) to 255=fast (18Hz).<br />

DMX channel Value Range Function<br />

000-015 Fade Red - Green<br />

016-031 Fade Blue - Green<br />

032-047 Fade Blue - Red<br />

048-063 Fade Red - Lime<br />

064-079 Fade Hot Pink - Lime<br />

080-095 Fade Pink - Blue<br />

096-111 Fade Turquoise - Pink<br />

1<br />

112-127<br />

128-143<br />

Fade Red - Green - Blue (All Colors)<br />

Switch Red - Green<br />

144-159 Switch Green - Blue<br />

160-175 Switch Red - Blue<br />

176-191 Switch Red - Yellow<br />

192-207 Switch Hot Pink - Lime<br />

208-223 Switch Pink - Blue<br />

224-239 Switch Turquoise - Pink<br />

240-255 Switch Red - Green - Blue<br />

2 000-255 Intensity<br />

3 050-255 Fade/Switch Speed<br />

4<br />

000-014<br />

015-255<br />

Strobe off<br />

Strobe on<br />

“CBAL” Color Balance Mode<br />

In this mode you can define the unit’s color balance by setting a maximum brightness for<br />

each LED color, giving you the individual color balance you desire. Any changes made<br />

to the color balance will affect the unit in all modes. Press the MODE button (1) until the<br />

display shows “CBAL”. Once color balance mode is entered all the LEDs will turn on at<br />

their set value. Use the left/right buttons (2 or 3) to enter color balance mode and cycle<br />

though “R###”, “G###”, and “B###”. ### indicates values from 200 through 255. (Values<br />

below 200 are disabled to avoid overall output reduction of the fixture.) Pressing the +/buttons<br />

(4 or 5) will change the values. All changes are effective immediately.<br />

NOTE: To make sure that several fixtures used together do not exhibit different color<br />

behavior, all fixtures must be calibrated to the same color balance.<br />

19

<strong>Exclusive</strong> U.S. <strong>Distributor</strong><br />

“EDIT” Edit Settings Mode<br />

Press the MODE button (1) until the display shows “EDIT”. Pressing the left/right buttons<br />

(2 or 3) will cycle through the following options.<br />

“ADMX” Automatic DMX Addressing – Automatic DMX Addressing is used<br />

to quickly setup multiple Multiform HP3-90 units that are daisy chained with DMX<br />

cable. Two modes, Slave and DMX, are available. When in DMX mode, the first unit<br />

will determine the DMX mode and addresses of the units. The desired DMX mode and<br />

starting address needs to be set on the first unit prior to using this feature.<br />

Press the left/right buttons (2 or 3) until the display shows “ADMX”. Pressing the<br />

+/- buttons (4 or 5) once shows “ OFF”. Pressing the + button (4) will set the units to<br />

“GDMX” (General DMX mode) and start the auto addressing process. This process<br />

assumes that it is executed from the first device in a chain. It will set all the following<br />

devices’ settings to the same DMX mode as the first unit and assign DMX channels<br />

consecutively according to the chosen DMX mode. Pressing the - button (5) will set the<br />

units to DMX Slave Mode. The master unit will be assigned to slave group 1, and the<br />

following units will be assigned to consecutive groups up to “SLA4” then starting over at<br />

“SLA1”, i.e. Unit 2 = “SLA2”, unit 3 = “SLA3”, unit 4 = “SLA4”, unit 5 = “SLA1”, and so on.<br />

NOTE: For this to execute properly, the first unit must not be connected to DMX and all<br />

units need to be in one of the following operating modes when the process is initiated –<br />

DMX Slave Mode, General DMX Mode, Color Balance Mode, or Edit Settings Mode.<br />

“ALOK” Auto Lock – Press the left/right buttons (2 or 3) until the display shows<br />

“ALOK”. Press the +/- buttons (4 or 5) to alternate between “ ON” or “ OFF”. When turned<br />

on, the unit will lock itself after 1 minute with no button presses. To unlock a locked unit,<br />

press the left (2) and right (3) buttons simultaneously.<br />

“ADIS” Auto Display Off – Press the left/right buttons (2 or 3) until the display<br />

shows “ADIS”. Press the +/- buttons (4 or 5) to alternate between “ ON” or “ OFF”. When<br />

turned on, the display backlight will turn off after 1 minute with no button presses.<br />

Pressing any button will turn the display backlight on again. The display elements<br />

themselves remain active at all times. When turned off, the display backlight stays lit.<br />

“TEMP” Temperature Display – Press the left/right buttons (2 or 3) until the display<br />

shows “TEMP”. Press the +/- buttons (4 or 5) to alternate between “ ON” or “ OFF”.<br />

When turned on, the display will show the current operating temperature in °C after 1<br />

minute with no button presses. Pressing any button will return the display to normal<br />

operation.<br />

20

“RSET” Reset – Press the left/right buttons (2 or 3) until the display shows “RSET”.<br />

Press the +/- buttons (4 or 5) to change the display to “YES+”. Pressing the + button (4)<br />

will perform a factory reset. This returns all the settings and calibration to the defaults.<br />

This does not include the operation hours.<br />

“HOUR” Operation Hours – Press the left/right buttons (2 or 3) until the display<br />

shows “HOUR”. Press the +/- buttons (4 or 5) to show the number of hours of operation.<br />

The unit can only display the hours up to 9999.<br />

“VERS” Software Version – Press the left/right buttons (2 or 3) until the display<br />

shows “VERS”. Press the +/- buttons (4 or 5) to show the software version.<br />

Maintenance<br />

This device does not need regular maintenance. It the unit fails to operate, return the<br />

unit to <strong>Apollo</strong> for service. There are no user serviceable parts inside. The glass front<br />

may be cleaned using a glass cleaner.<br />

Technical Data Multispot HP3-90<br />

Output 3550 lm<br />

LEDs, Total 30 RGB<br />

LEDs, Red 30<br />

LEDs, Green 30<br />

LEDs, Blue 30<br />

Optics Secondary, 25 degrees<br />

DMX Channels 3-5<br />

IP Rating 20 (as-is)/65 (with conversion kit)<br />

Mains Input AC90-250V~ 50/60Hz<br />

Power supply type Auto-switching<br />

Power consumption 95W<br />

Fuse internal (see service manual)<br />

DMX connections 5 pin XLR (Male / Female)<br />

Modulation Type Pulse Density Modulation (PDM)<br />

Control protocol DMX 512 (1990)<br />

Dimensions (with straight bracket)<br />

HxWxD<br />

21<br />

13” (33cm) x 12.8” (32.5cm) x 6.2”<br />

(15.75cm)<br />

Weight 14.8 lbs (6.7kg)

<strong>Exclusive</strong> U.S. <strong>Distributor</strong><br />

Standards<br />

This product complies with the following standards:<br />

EU electrical safety . . . . . . . . . . . . . . EN60598-1:2008, EN60598-2-1:1989<br />

EU general safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . EN60598-2-17<br />

EU photobiological safety . .. . .. . .. . .. . .. . .. . .. . EN 62471:2008<br />

EU EMC. . . . . . . . . . . EN55015: 2006 + A1:2007, EN61547:1995 + A1:2000<br />

EU Harmonics . . . . . . . . . . . . . . . . . . . . . . . . . . . . EN61000-3-2:2006<br />

EU Flicker . .. . .. . .. . .. . .. . .. . .. . .. . .. . ..EN61000-3-3:2008<br />

US safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .UL60065<br />

US EMC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .FCC Part 15<br />

This product meets both the EMC Directive 2004/108/EC and the Low Voltage<br />

Directive 2006/95/EC.<br />

Warranty<br />

Items are covered for defects in materials and workmanship for one year, including repair<br />

parts and repair labor on defective item, from date of <strong>Apollo</strong> invoice. The warranty covers<br />

freight for 30 days after initial purchase. <strong>Apollo</strong> does not cover any other loss resulting<br />

from product failure.<br />

Products being returned for warranty repair must display the original serial number sticker.<br />

Removal of the serial number sticker voids the product’s limited warranty.<br />

• Despite the care taken for the compilation of this book, <strong>Apollo</strong> <strong>Design</strong> <strong>Technology</strong>, Inc.,<br />

cannot be held responsible for any damages resulting from errors that may appear in<br />

this book. All efforts have been made to provide the most accurate, up-to-date<br />

instructions and illustrations possible.<br />

• Need assistance? Call <strong>Apollo</strong> at 800-288-4626 for details.<br />

Keep this information handy if requiring technical assistance.<br />

Serial Number<br />

Date Purchased<br />

Purchased From<br />

22

6-03-2012<br />

Other Quality Products<br />

From <strong>Apollo</strong><br />

• Stainless Steel Gobos<br />

• Glass Gobos<br />

• PrintScenic Plastic and Glass<br />

Gobos<br />

• Gel<br />

• Right Arm®<br />

• Smart Color® PRO Scrollers<br />

• Smart Move® Rotators<br />

• Smart Move® Vertical<br />

• Smart Power Power Supplies<br />

• EZ Iris DMX<br />

• Tape<br />

• Dichroics<br />

• Pattern Holders<br />

• Cable<br />

• Tuff-Stuff C-Clamps<br />

4130 Fourier Dr., Fort Wayne, IN 46818 USA<br />

Voice: +1.260.497.9191<br />

Fax: +1.260.497.9192<br />

International: (00)+1.260.497.9191<br />

www.apollodesign.net