Specification of Road Work upto Grouting Level - Ahmedabad ...

Specification of Road Work upto Grouting Level - Ahmedabad ...

Specification of Road Work upto Grouting Level - Ahmedabad ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

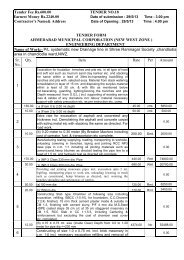

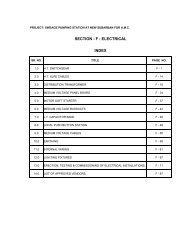

AHMEDABAD MUNICIPAL CORPORATION - ENGINEERING DEPARTMENT<br />

SPECIFICATIONS OF ROAD WORK UP TO GROUTING LEVEL<br />

This section gives detail specifications for mainly used materials, for other materials refer Building<br />

<strong>Specification</strong>s.<br />

For materials relevant IS code shall apply.<br />

TECHNICAL SPECIFICATIONS<br />

Item No.01 : Box cutting the road surface in all sorts <strong>of</strong> soil, murrum to proper lope & camber<br />

for making a base for road work including removing the excavated stuff & depositing on the<br />

road side as directed up to 50.00 mt. Lead.<br />

Any soil which generally yields to the application <strong>of</strong> pickaxes and shovels, spades, rakes or any<br />

such ordinary excavating implement or organic soil, gravel, silt, sand turf loam, clay, peat etc. falls<br />

under this category. For materials and workmanship for earthwork and excavation, relevant<br />

specification IS: 3764 & IS 1200 (Part I) shall be followed.<br />

To protect persons from injury and to avoid damage to property, adequate barricades, construction<br />

signs, red lanterns and guards as required shall be placed and maintained during the progress <strong>of</strong> the<br />

construction work and until it is safe for the traffic to use the roadways. The relevant Indian standards<br />

and the rules and regulations <strong>of</strong> local authorities in regards to safety provisions shall be observed.<br />

The depth <strong>of</strong> the excavation shall be as required. The site shall be cleared and all obstructions, loose<br />

stones, materials and rubbish <strong>of</strong> all kind, bush; wood and all type trees shall be removed, as directed.<br />

The materials so obtained shall be the property <strong>of</strong> AMC and shall be conveyed and stacked as<br />

directed, within 50-m. lead. The roots <strong>of</strong> the trees coming in the sides <strong>of</strong> the trenches shall be cut and<br />

coated with hot Bitumen.<br />

All types <strong>of</strong> trees, woods etc. which requires prior permission <strong>of</strong> Govt./ Forest Authority / Municipal<br />

Commissioner, before cutting shall be cut after obtaining such permission from them. The rate <strong>of</strong> site<br />

clearance is deemed to be included in the rate <strong>of</strong> earthwork.<br />

The excavation shall be carried out in true line and level and having width and depth, as shown in the<br />

drawings or as directed. The Contractor shall do the necessary shoring and strutting or shall provide<br />

necessary slopes to a safe angle or steps, as required or directed, at his own cost. No extra payment<br />

shall be made for such precautionary measures, taken. The bottom <strong>of</strong> the excavated area shall be<br />

leveled both longitudinally and transversely, as directed, by removing excess soil and watering, as<br />

required. No earth filling will be allowed for bringing it to level, if by mistake or any other reason,<br />

excavation is made deeper or wider than shown on the drawings or as directed. The extra depth or<br />

width shall be made up with sand filling, as specified for the bottom level <strong>of</strong> the subsequent finishing<br />

at the cost <strong>of</strong> the Contractor or as directed by Engineer-In-Charge.<br />

The Contractor shall at his own expense and without extra charge make provision <strong>of</strong> supporting all<br />

utility services, lighting the excavated areas, separating and stacking serviceable materials neatly,<br />

shoring, timbering, strutting, bailing out water either sub-soil or rainwater, including pumping at any<br />

stage <strong>of</strong> the work. Excavated areas shall be kept free <strong>of</strong> water while masonry or concrete or relevant<br />

base works are in progress and till the Engineer-in-charge considers it necessary. Contractor shall<br />

have to take levels before and after excavation. Contractor shall have to provide level and<br />

leveling staff and shall take levels with his own engineers in presence <strong>of</strong> AMC staff.<br />

Measurement shall be given by level results.<br />

Disposal <strong>of</strong> the Excavated Stuff:<br />

The excavated stuff <strong>of</strong> the selected type shall be used in backfilling the excavated areas wherever<br />

required in layers, including ramming and watering, ensuring proper compaction etc. complete up to<br />

lead <strong>of</strong> 50mt. The Contractor shall remove the balance <strong>of</strong> the excavated quantity from the site <strong>of</strong><br />

work, to a place, as directed by engineer in charge. The lead is the shortest practical route and not<br />

necessarily the route actually taken. The decision <strong>of</strong> Engineer-In-charge shall be final in this regard.<br />

The measurement <strong>of</strong> excavation <strong>of</strong> excavated area shall be made according to the sections shown on<br />

the drawing or as per sections given by the Engineer-in-charge. The rate shall include for clearing the<br />

site, surface dressing, and making layout for road.<br />

The rate shall be for a unit <strong>of</strong> one Cubic meter.<br />

Item No. 02: Conveyance charge for surplus excavated earth, lime, murrum, building rubbish,<br />

manure, garbage, sludge, excavated rock, fly ash, aggregates <strong>of</strong> any kind including spreading &<br />

leveling etc. complete. (iii) Lead up to 3 Km.<br />

All the surplus earth/excavated material etc. shall be carried away immediately from the site <strong>of</strong> work<br />

to a place within distance specified in the relevant item or as directed and ordered by the Engineer, so<br />

as not to cause any inconvenience to the public traffic. If the instructions are not complied within 7

days from the date <strong>of</strong> order to cart the surplus materials and clear the site, the said work shall be<br />

carried out by the Municipal Corporation at the risk and cost <strong>of</strong> the contractor and no claim or dispute<br />

shall be entertained in this respect.<br />

The rate <strong>of</strong> carting including carting <strong>of</strong> brick bats, metal, rubble vegetable and garbage, if necessary to<br />

clear the road surface.<br />

Carting <strong>of</strong> payment shall be given as per excavation without any bulkage.<br />

The rate shall be for a unit <strong>of</strong> one cubic meter.<br />

Item No.03 : Supplying <strong>of</strong> graded hand broken stone aggregate <strong>of</strong> 90 to 127 mm size at site<br />

(Spouls)<br />

The stone for rubble soling to be supplied by the contractor and shall be <strong>of</strong> good quality and size 90<br />

mm to 127 mm. The stone shall be quarried and shall be sound, angular, durable and free form flaws<br />

and decay and shall be approved by the Engineer in charge. The material shall conform to standard<br />

tests as required by AMC.<br />

The stone shall be stacked on neat and uniform ground at roadsides, stack shall be <strong>of</strong> the regular/<br />

geometric shape, and stack shall be measured in volume. The material shall be stacked in such a way<br />

that there shall be minimum voids. The rate includes quarrying blasting, hand breaking collection<br />

transporting, to the site and stacking in measurable stacks at site. Inferior quality <strong>of</strong> material brought<br />

on site shall be immediately removed from the site without any extra cost. The rubble or spouls shall<br />

be spread after measurements are recorded and orders are obtained from the Engineer in charge.<br />

Mode <strong>of</strong> Payment<br />

The rate shall be paid on cubic meter basis.<br />

Item No.04 : Labour charges for spreading the spouls 127 mm thickness Layer earth filling<br />

correcting the grade and camber comp. with watering, rolling, including preparing the surface<br />

by brushing for removing all loose or dirt etc. completed.<br />

The item relates to labour work <strong>of</strong> soling. The spouls stacked at any lead from the filling area should<br />

be used good earth obtained from outside only after Engineer in charge approved. The spouls shall be<br />

sorted out from stacks. Extra earth, debris, shall be removed and the spouls shall be placed in position<br />

over the earth level formed to give a suitable soling formation by packing voids, no hollow space is<br />

left. The soling shall be filled up with the same material <strong>of</strong> finer size, interlock the small cavities<br />

between the soling and the whole soiling shall be made a compact, solid and continues level which<br />

shall not be disturbed while rolling. The entire surface shall be well watered and rolled with a heavy<br />

roller weight not less than 8 ton capacity as directed by engineer in charge. The gaps formed shall be<br />

packed again by the same process. Spouls shall be laid on herringbone bond to required grade and<br />

camber. Contractor shall provide required number <strong>of</strong> labour at time <strong>of</strong> rolling to rectify undulation<br />

and depression without any extra payment. The contractor shall have to prepare the surface true in<br />

accordance to camber & gradient <strong>of</strong> the road. If any extra depth <strong>of</strong> soling is required in the process<br />

that will not be paid for separately.<br />

The measurement will be on square meter basis <strong>of</strong> the actual area <strong>of</strong> soling surface prepared.<br />

Item No.05 : Supply <strong>of</strong> graded machine cut black trap stone aggregate <strong>of</strong> Sevaliya/Timba or<br />

equivalent quality. Metal <strong>of</strong> size 25 mm to 40 mm.<br />

The Aggregates shall consist <strong>of</strong> Black trap machine crushed stone only, obtained from quarries<br />

situated in Sevaliya /Timba or equivalent. It shall remain visibly black on immersion in water. They<br />

shall be clean, strong, durable <strong>of</strong> fairly cubical shape and free from disintegrated pieces, organic or<br />

other deleterious matters and adherent coating. They shall be free from elongated and flaky piece also.<br />

The size <strong>of</strong> the aggregate shall be as per standard required by AMC .<br />

For stacking relevant <strong>Specification</strong> <strong>of</strong> Item No. A-3 shall be apply.<br />

The rate shall be paid on cubic meter basis.<br />

Item No.06 : Labour work for spreading the metal in total 100mm th. in two uniform layers<br />

each <strong>of</strong> 50 mm thick, including providing and applying bitumen for semi grouting 1.5 kg/sq.mt.<br />

for each layer (in both layer) & providing and spreading the key black trap aggregate <strong>of</strong><br />

Sevaliya/Timba or equivalent quality on top (second) layer at the rate <strong>of</strong> 0.013 cmt per sq.mt. <strong>of</strong><br />

size 18 mm passing & 9.5 mm retained. Rolling with 10 T.roller etc. complete as directed.<br />

The metal shall be screened <strong>of</strong> any rubbish, dust or grass. Then metal shall be laid uniformly in two<br />

layers <strong>of</strong> 50 mm each, to the required grade and camber as directed by the Engineer in charge. Laying<br />

<strong>of</strong> metal shall be started after the consolidating soling layers prepared perfectly to the proper line level<br />

and camber. Where camber <strong>of</strong> soling is found doubtful it shall be corrected prior to spreading metal.<br />

Metal filled in the basket shall be spread evenly in required number <strong>of</strong> layers as directed. Metal shall<br />

be spread in proper grade and camber if required using camber boards, so as to ensure the corrected

surface. The surface shall be checked at every 15 mts. by means <strong>of</strong> template and string for correctness<br />

<strong>of</strong> the camber. The consolidation <strong>of</strong> metal shall be done by the contractor with a minimum 8 to 10 T<br />

roller. The contractor shall provide required number <strong>of</strong> labors at the time <strong>of</strong> rolling to rectify the<br />

undulation that might have occurred during rolling. To carryout grouting <strong>of</strong> the above said 50 mm<br />

thick metalling coat the contractor shall bring all the required equipment and materials as directed.<br />

Bitumen <strong>of</strong> 80/100 grade penetration <strong>of</strong> approved quality heated to a temperature <strong>of</strong> about 150 C. and<br />

shall be applied hot by means <strong>of</strong> a sprayer uniformly over the surface at the rate <strong>of</strong> 1.5 kg./sq. mt. up<br />

to the satisfaction <strong>of</strong> Engineer in charge. Immediately following the application <strong>of</strong> bitumen and while<br />

it is still hot second layer <strong>of</strong> metal shall be spread in proper thickness and again application <strong>of</strong><br />

bitumen at the rate <strong>of</strong> 1.5 kg./sq. mt. as above for second layer shall be done. Key aggregate <strong>of</strong> as<br />

specified in below table and <strong>of</strong> approved quality shall be evenly spread out at rate <strong>of</strong> 0.013 cum. per<br />

sq. mt. After spreading the chipping the whole area shall be rolled over thoroughly with a 8 T to 10 T.<br />

roller It is important that the rolling should be done while the bitumen is still s<strong>of</strong>t and it should be<br />

continued until the road sets and there is no settlement under the roller.<br />

During the period between the initial compaction <strong>of</strong> coarse aggregate and compaction<br />

<strong>of</strong> the surface course shall be protected form all traffic other than essential to its construction, till the<br />

final compaction level is attained. All above operation shall be carried by the contractor using his<br />

equipments and material including fuel or wood required for burning etc. and as directed up to the<br />

entire satisfaction <strong>of</strong> Engineer in charge . Vehicles tube tire burning shall not be allowed.<br />

As shown in the TABLE-500-7<br />

I.S. Sieve (mm) Per cent by weight passing the sieve<br />

Key Aggregate<br />

53<br />

26.5<br />

22.4 100<br />

13.2 40-75<br />

5.6 0-20<br />

2.8 0-5