Porous-structure grinding wheels - Mole Abrasivi Ermoli

Porous-structure grinding wheels - Mole Abrasivi Ermoli

Porous-structure grinding wheels - Mole Abrasivi Ermoli

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

MOLE ABRASIVI ERMOLI S.R.L.<br />

Sede ed uffici: Via Cairoli, 4 - 21046 - Malnate (VA)<br />

Tel. 0332-425114 - Fax 0332-426742 - info@ermoli.it - www.ermoli.it<br />

Stabilimento: Via Cairoli, 14 - 21046 Malnate (VA)<br />

Tel 0332-426088<br />

Codice Fiscale e Partita IVA IT 00210280129 - Registro Imprese VA 2386 - R.E.A. Varese 5558<br />

POROUS-STRUCTURE GRINDING WHEELS<br />

Reduce surface contact area between <strong>grinding</strong> wheel and workpiece, thus reducing<br />

friction, shear stress and overheating<br />

Improve circulation of coolant fluid inside wheel, thus reducing <strong>grinding</strong> burn on<br />

workpieces<br />

Allow <strong>grinding</strong> of materials that clog <strong>grinding</strong> wheel surface such as aluminium, rubber,<br />

plastic, common cast irons or cork<br />

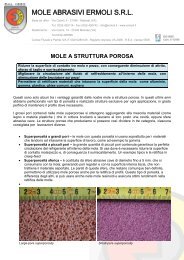

These are just some of the advantages of our porous-<strong>structure</strong> <strong>grinding</strong> <strong>wheels</strong>. Over the last few years<br />

we have perfected various types of porosity and have produced exclusive <strong>structure</strong>s for every<br />

application, which are even able to maintain the profile where necessary.<br />

The large pores contained in super-porous <strong>grinding</strong> <strong>wheels</strong> are obtained by adding materials such as<br />

wood or plastic materials to the mix which burn during firing and leave in their place a cavity, or in other<br />

words concave abrasive spheres. The porous <strong>structure</strong> that we produce can therefore be divided into<br />

three categories, each one recommended for different machining processes:<br />

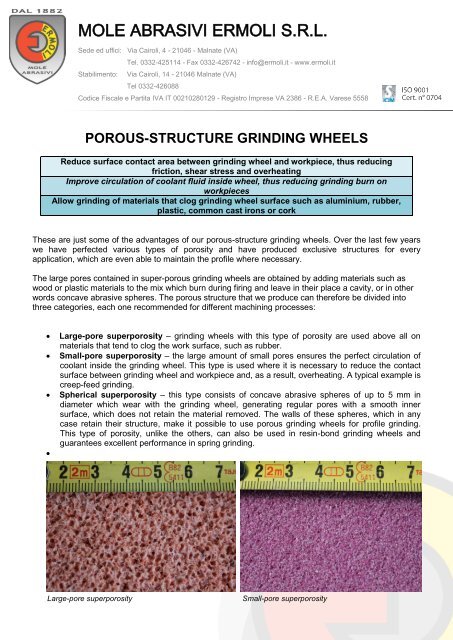

Large-pore superporosity – <strong>grinding</strong> <strong>wheels</strong> with this type of porosity are used above all on<br />

materials that tend to clog the work surface, such as rubber.<br />

Small-pore superporosity – the large amount of small pores ensures the perfect circulation of<br />

coolant inside the <strong>grinding</strong> wheel. This type is used where it is necessary to reduce the contact<br />

surface between <strong>grinding</strong> wheel and workpiece and, as a result, overheating. A typical example is<br />

creep-feed <strong>grinding</strong>.<br />

Spherical superporosity – this type consists of concave abrasive spheres of up to 5 mm in<br />

diameter which wear with the <strong>grinding</strong> wheel, generating regular pores with a smooth inner<br />

surface, which does not retain the material removed. The walls of these spheres, which in any<br />

case retain their <strong>structure</strong>, make it possible to use porous <strong>grinding</strong> <strong>wheels</strong> for profile <strong>grinding</strong>.<br />

This type of porosity, unlike the others, can also be used in resin-bond <strong>grinding</strong> <strong>wheels</strong> and<br />

guarantees excellent performance in spring <strong>grinding</strong>.<br />

<br />

Large-pore superporosity Small-pore superporosity

MOLE ABRASIVI ERMOLI S.R.L.<br />

Sede ed uffici: Via Cairoli, 4 - 21046 - Malnate (VA)<br />

Tel. 0332-425114 - Fax 0332-426742 - info@ermoli.it - www.ermoli.it<br />

Stabilimento: Via Cairoli, 14 - 21046 Malnate (VA)<br />

Tel 0332-426088<br />

Codice Fiscale e Partita IVA IT 00210280129 - Registro Imprese VA 2386 - R.E.A. Varese 5558<br />

Spherical superporosity Resin - Cubitron