to get the file - ESI Group

to get the file - ESI Group

to get the file - ESI Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FROM THE VIRTUAL TRY-OUT SPACE<br />

TALK PAMNEWS<br />

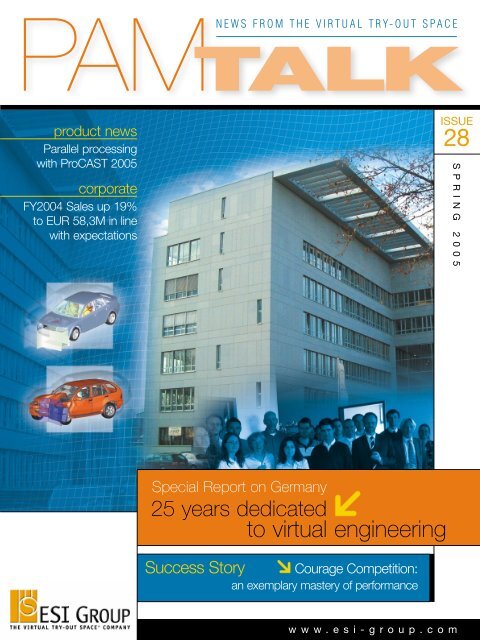

product news<br />

Parallel processing<br />

with ProCAST 2005<br />

corporate<br />

FY2004 Sales up 19%<br />

<strong>to</strong> EUR 58,3M in line<br />

with expectations<br />

Special Report on Germany<br />

25 years dedicated<br />

<strong>to</strong> virtual engineering<br />

Success S<strong>to</strong>ry Courage Competition:<br />

an exemplary mastery of performance<br />

ISSUE<br />

28<br />

www.esi-group.com<br />

SPRING 2005

IBM, <strong>the</strong> IBM logo, <strong>the</strong>“e”logo, eServer, <strong>the</strong> eServer logo, OpenPower and Power Architecture are trademarks or registered trademarks of International Business Machines Corporation in <strong>the</strong> United States and/or o<strong>the</strong>r countries.<br />

Linux is a trademark of Linus Torvalds in <strong>the</strong> United States, o<strong>the</strong>r countries, or both. O<strong>the</strong>r company, product and service names may be trademarks or service marks of o<strong>the</strong>rs. © 2004 IBM Corporation. All rights reserved.<br />

FEELTHE POWER OF LINUX.<br />

Introducing <strong>the</strong> IBM eServer OpenPower system. With this server,<br />

you can have it all. Power Architecture and <strong>the</strong> Linux®operating<br />

system. Outstanding reliability features and 64-bit computing.This<br />

is what you’ve been waiting for. A server specifically enhanced for<br />

Linux. It’s a purist’s dream. It’s instant entrée in<strong>to</strong> <strong>the</strong> Linux movement.<br />

And it’s an affordable way <strong>to</strong> adopt Power Architecture. Join <strong>the</strong><br />

movement at ibm.com /eserver/pumpup<br />

server

4<br />

7<br />

10<br />

12<br />

18<br />

19<br />

PAMTALK is issued quarterly<br />

by <strong>ESI</strong> <strong>Group</strong><br />

Executive Edi<strong>to</strong>r: Vincent Chaillou<br />

Edi<strong>to</strong>r-in-Chief: Danièle Burdin-Dumont<br />

Stéphanie Austin<br />

<strong>ESI</strong> <strong>Group</strong> Marketing<br />

PARC D’AFFAIRES SILIC<br />

99 RUE DES SOLETS - BP 80112<br />

94513 Rungis Cedex - FRANCE<br />

Tel: +33 (0) 1 41 73 58 00<br />

Fax: +33 (0) 1 46 87 72 02<br />

www.esi-group.com<br />

info@esi-group.com<br />

Design: Agence TETRAKTYS<br />

ISSN 1635-866X<br />

Impression : RIVET PRESSE EDITION - 24, rue Claude-Henri Gorceix<br />

87280 LIMOGES<br />

Dépôt légal : Avril 05<br />

contents<br />

SUCCESS STORY<br />

Courage Competition: an exemplary mastery of performance<br />

CORUS and <strong>ESI</strong> <strong>Group</strong> partnership<br />

PRODUCT NEWS<br />

Visual-Crash for PAM; <strong>the</strong> first brick of <strong>ESI</strong> <strong>Group</strong>’s new open<br />

integrated environment<br />

EASI-Process<br />

3 questions <strong>to</strong> Velayudham Ganesan, Business Development Manager<br />

SPECIAL REPORT<br />

25 years dedicated <strong>to</strong> virtual engineering<br />

PAM-STAMP 2G helps Kirchhoff Au<strong>to</strong>motive<br />

design car modules ‘right first time”<br />

CASTING<br />

Parallel processing with ProCAST 2005<br />

PAM-QUIKCAST 2005 speeds up casting process evaluation<br />

Solidification course 2005<br />

<strong>ESI</strong> <strong>Group</strong>’s casting solutions gain ground in South America<br />

EVENTS<br />

Official inauguration of <strong>ESI</strong> <strong>Group</strong>’s Software<br />

Product Development Center in Bangalore, India<br />

CORPORATE<br />

New sales activities and distribution of EASi-CRASH<br />

products in Germany by <strong>ESI</strong> GmbH<br />

FY2004 Sales up 19% <strong>to</strong> EUR 58,3M<br />

in line with expectations.<br />

What’s new at www.esi-group.com?<br />

All PAM and SYS products are trademarks of <strong>ESI</strong> <strong>Group</strong>. All o<strong>the</strong>r<br />

products, names and companies referenced are trademarks or<br />

registered trademarks of <strong>the</strong>ir respective owners. All text and images<br />

included in <strong>the</strong> articles are <strong>the</strong> copyright of <strong>the</strong> companies presenting<br />

<strong>the</strong>ir applications and simulations tasks.<br />

Pho<strong>to</strong> credits: Corus, Courage Competition, Dana S.H Foundiciones,<br />

Kirchhoff Au<strong>to</strong>motive, Montupet, Rims<strong>to</strong>ck, <strong>ESI</strong> <strong>Group</strong>.<br />

www.esi-group.com<br />

ISSUE<br />

28<br />

SPRING 2005<br />

e e<br />

Germany<br />

special projects<br />

As industry now embraces a new paradigm called<br />

Simulation-Based-Design, more favorable <strong>to</strong> innovation<br />

and overall more effective and less expensive than our<br />

traditional trial and error methodology, physical pro<strong>to</strong>types<br />

are now being progressively replaced, not only because<br />

<strong>the</strong>y are cost, time and energy consuming, but because<br />

<strong>the</strong>y cannot always be used, and in some situations, <strong>the</strong>y<br />

cannot even exist!<br />

The realistic account of <strong>the</strong> physics of materials and of <strong>the</strong><br />

fabrication processes which determine <strong>the</strong>m is a critical<br />

fac<strong>to</strong>r <strong>to</strong> ensuring <strong>the</strong> reliability of virtual simulation.<br />

A fine example of <strong>the</strong> extent of <strong>the</strong>se major changes is<br />

reflected in <strong>the</strong> activity our subsidiary in Germany, <strong>ESI</strong><br />

GmbH which celebrates <strong>the</strong> quarter century anniversary of<br />

its opening in 1979, moving from <strong>the</strong> inception of crash<br />

techniques with Volkswagen in <strong>the</strong> early eighties, <strong>to</strong> <strong>to</strong>day’s<br />

most advanced simulation technology such as FPM for<br />

OOP decision process for Airbag.<br />

di<strong>to</strong>rial<br />

More recently, <strong>the</strong> acquisition of VA, EASi, CFD and<br />

Casting technologies, has enabled our German team <strong>to</strong><br />

widen its skills and knowledge, through dedicated<br />

business units, like <strong>the</strong> new SPM team whose mission is <strong>to</strong><br />

serve <strong>the</strong> EASI cus<strong>to</strong>mer base and support <strong>the</strong> SPM/EASi<br />

Process solutions, and new technologies such as Casting<br />

for Virtual Manufacturing.<br />

Simulation-Based-Design is no longer a futuristic<br />

methodology for early adopters, but along with Virtual<br />

Manufacturing (VM), it is at <strong>the</strong> very core of our VTOS<br />

solutions, it means <strong>to</strong> predict product performance<br />

“as built” and not only “as designed” and this is <strong>the</strong><br />

perspective of our team in Germany for example <strong>to</strong> work<br />

with our cus<strong>to</strong>mers <strong>to</strong> reach new levels in productivity<br />

and innovation<br />

Vincent Chaillou<br />

President and Chief Operating Officer,<br />

Products<br />

edi<strong>to</strong>rial<br />

Operations, <strong>ESI</strong> <strong>Group</strong><br />

d i t o r i a l<br />

3

SUCCESS STORY PRODUCT NEWS SPECIAL REPORT CASTING EVENTS CORPORATE<br />

Courage C65 won 2004 LMES 1,000 kms championship with three vic<strong>to</strong>ries, category LMP2<br />

PAM-CRASH validation<br />

of <strong>the</strong> C60 frontal crash<br />

(<strong>to</strong>tal mass: 1,000 kg,<br />

initial speed: 14 m/s,<br />

difference between<br />

experiments and<br />

simulation: less<br />

than 5%)<br />

Alain de Rouvray<br />

congratulating<br />

Nicolas Perrin and<br />

Yves Courage<br />

Time is a drastic<br />

constraint for racing car<br />

builders who only have six<br />

months <strong>to</strong> produce a new<br />

model compared <strong>to</strong><br />

three years for standard<br />

vehicles. In addition,<br />

development cycles are<br />

punctuated by<br />

championships, which<br />

reduces available time<br />

and a race car is made<br />

up of 3,000 different<br />

parts often modified<br />

over a season. All this<br />

combined with<br />

compliance <strong>to</strong> severe regulations and<br />

extreme safety criteria, give an<br />

overview of how designing winning<br />

cars is a real challenge!<br />

The challenge<br />

of endurance racing<br />

To provide <strong>the</strong> highest levels of<br />

performance and technical reliability<br />

Courage Competition has <strong>to</strong><br />

concentrate its efforts on:<br />

■ minimizing time dedicated <strong>to</strong><br />

feasibility studies and tests on <strong>the</strong><br />

racing tracks,<br />

■ mastering all available<br />

CAD/CAM/CAE technologies<br />

adopted by <strong>the</strong> major racing teams,<br />

■ quickly evaluating <strong>the</strong> most<br />

profitable solutions applicable <strong>to</strong><br />

small series (pro<strong>to</strong>types<br />

manufacturing),<br />

■ deciding quickly on <strong>the</strong> right design<br />

in less than six months,<br />

■ taking in<strong>to</strong> account mechanical parts<br />

in-service lifetime and fatigue.<br />

Finally, new regulations in favor of<br />

engine power limitation impose<br />

Courage Competition <strong>to</strong> perform<br />

several design modifications of <strong>the</strong><br />

external shapes and <strong>the</strong> undertray until<br />

reaching <strong>the</strong> expected structural<br />

weight reduction. Consequently,<br />

Courage is making extensive use of<br />

composite materials and is relying<br />

more and more on virtual simulation.<br />

Courage<br />

Competition:<br />

an exemplary<br />

mastery of<br />

performance<br />

In <strong>the</strong> rush for ever-enhanced<br />

reliability and performance<br />

PAM-CRASH and SYSPLY help <strong>the</strong><br />

French racing team optimize design<br />

and safety while reducing lead-times<br />

Teaming for competitiveness<br />

Courage Competition has a permanent<br />

strategic objective <strong>to</strong> control <strong>the</strong><br />

car's development from initial design<br />

<strong>to</strong> production. The company<br />

manufactures half of <strong>the</strong> composite<br />

body parts in its Le Mans workshops.<br />

In this respect, <strong>the</strong> independent French<br />

car manufacturer has deployed <strong>the</strong><br />

most promising technologies <strong>to</strong> carry<br />

out development tasks while being<br />

ready <strong>to</strong> face new championship<br />

challenges.<br />

A few years ago, Courage Competition<br />

initiated <strong>the</strong> CATIA V5 CAD/CAM<br />

solution in partnership with HP. After<br />

implementing this solution, Courage<br />

Competition is now focusing on both<br />

crash-tests and composite material<br />

structure design. The company intends<br />

<strong>to</strong> reduce <strong>the</strong> number of expensive<br />

physical pro<strong>to</strong>type trials by using <strong>ESI</strong><br />

<strong>Group</strong>’s simulation solutions: PAM-<br />

CRASH for virtual crash test and<br />

SYSPLY for composite design<br />

simulation. In 2003, again in<br />

collaboration with HP, <strong>the</strong> first phase<br />

‘<br />

Up <strong>to</strong> now we have successfully validated with<br />

PAM-CRASH <strong>the</strong> results of a frontal crash on <strong>the</strong>‘<br />

car’s survival body as well as o<strong>the</strong>r homologating<br />

crash tests on composite materials structures ‘‘<br />

success s<strong>to</strong>ry<br />

4 www.esi-group.com<br />

Yves Courage, President and founder, Courage Competition

SUCCESS STORY PRODUCT NEWS SPECIAL REPORT CASTING EVENTS CORPORATE<br />

consisted of validating technical<br />

parameters by accurately reproducing<br />

real, measured data.<br />

“Up <strong>to</strong> now we have successfully<br />

validated with PAM-CRASH <strong>the</strong> results<br />

of a frontal crash on <strong>the</strong> survival body<br />

as well as o<strong>the</strong>r homologating crash<br />

tests on composite materials<br />

structures,” says Yves Courage.<br />

“Ano<strong>the</strong>r significant result concerns <strong>the</strong><br />

design of <strong>the</strong> C65 flat bot<strong>to</strong>m; using<br />

SYSPLY we achieved a composite<br />

materials structure 25% lighter and<br />

almost two times stiffer than <strong>the</strong><br />

previous one. The virtual simulation of<br />

crash-tests and composite part design<br />

are now fully integrated within <strong>the</strong><br />

development process of any new<br />

family of cars, in order <strong>to</strong> reduce <strong>the</strong><br />

number of pro<strong>to</strong>types by one third”<br />

adds <strong>the</strong> President and founder.<br />

SYSPLY analysis<br />

of <strong>the</strong> Courage C65 cockpit<br />

The Courage C65 body has undergone<br />

several endurance racing<br />

homologating tests as specified by<br />

ACO (Au<strong>to</strong>mobile Club de l’Ouest), <strong>the</strong><br />

leading au<strong>to</strong>mobile club in France,<br />

crea<strong>to</strong>r and organizer of <strong>the</strong> Le Mans<br />

24-hour race. The tests consist in<br />

complying <strong>to</strong> a series of criteria with a<br />

minimal weight. “The frontal crash and<br />

<strong>the</strong> analysis of loads and pressures on<br />

<strong>the</strong> roll bar have shown good<br />

agreement with experimental<br />

measurements,” explains Nicolas<br />

www.esi-group.com<br />

Perrin, race engineer, responsible for<br />

Research & Development and FEM<br />

Analysis, Courage Competition.<br />

“SYSPLY allows <strong>to</strong> identify quickly <strong>the</strong><br />

areas where gains of weight or stiffness<br />

can be achieved and this is of decisive<br />

importance for <strong>the</strong> design of <strong>the</strong> future<br />

chassis,” states N. Perrin.<br />

SYSPLY also helps <strong>to</strong> determine <strong>the</strong><br />

shape, <strong>the</strong> alignment and <strong>the</strong> placing of<br />

carbon fabric which covers over 80%<br />

of a Courage model, mainly <strong>the</strong> body,<br />

<strong>the</strong> chassis, <strong>the</strong> aerofoil or <strong>the</strong><br />

undertray. A direct link with CAD<br />

enables several geometries <strong>to</strong> be<br />

imported from Catia for fur<strong>the</strong>r design<br />

analyses using SYSPLY. During <strong>the</strong><br />

designing sequence SYSPLY assists<br />

<strong>the</strong> user in choosing <strong>the</strong> necessary<br />

number of layers, <strong>the</strong> alignment of<br />

fibers and <strong>the</strong> draping sequences. All<br />

this implies considerable time and<br />

costs savings.<br />

“Future work will be directed <strong>to</strong>wards<br />

simulation of lateral crash <strong>to</strong> ensure an<br />

increased protection of <strong>the</strong> driver,<br />

among o<strong>the</strong>r analyses, such as fracture<br />

and fatigue”, concludes Yves Courage.<br />

In 2004, Courage Competition was <strong>the</strong><br />

first and only competi<strong>to</strong>r <strong>to</strong> launch <strong>the</strong>ir<br />

C65 racing cars, meeting new<br />

regulation and security rules of LMP2<br />

pro<strong>to</strong>type category. The team is still<br />

looking <strong>to</strong> expand its technological<br />

leadership and innovation capacity<br />

through virtual simulation.<br />

The results obtained are quite significant<br />

Without SYSPLY With SYSPLY<br />

and allow Courage Competition <strong>to</strong><br />

consider a broadest cus<strong>to</strong>mer base in<br />

Europe and in <strong>the</strong> USA with <strong>the</strong> rapid<br />

acceptance of its commercial product in<br />

<strong>the</strong> LMP2 category and <strong>to</strong> enter again in<br />

<strong>the</strong> <strong>to</strong>p endurance category, <strong>the</strong> LMP1<br />

pro<strong>to</strong>type, finally realizing <strong>the</strong> ultimate<br />

founder’s dream: win <strong>the</strong> Le Mans 24hour<br />

race!<br />

‘<br />

Using SYSPLY<br />

for <strong>the</strong> design of <strong>the</strong><br />

C65 flat bot<strong>to</strong>m, we<br />

achieved a structure ‘<br />

25% lighter and almost<br />

‘‘<br />

two times stiffer<br />

Yves Courage, President and founder,<br />

Courage Competition<br />

SYSPLY analysis of <strong>the</strong> C65 cockpit for<br />

<strong>the</strong> homologating test. Model with<br />

41801 elements <strong>to</strong> study displacements,<br />

materials orientation, loads and pressure<br />

on <strong>the</strong> roll bar.<br />

SYSPLY optimization of <strong>the</strong> C65 flat bot<strong>to</strong>m<br />

About Courage Competition<br />

Technical data<br />

Courage C65<br />

■ Configuration: two seater with<br />

open roof, central rear engine,<br />

propulsion<br />

■ Chassis: carbon fiber,<br />

honeycomb aluminum<br />

■ Body: carbon, kevlar,<br />

honeycomb with aeronautical<br />

fixations<br />

■ Suspension: double<br />

wishbones, dynamic springshock<br />

absorber<br />

■ Engine: AER 4 cyl., 2.0 L<br />

Turbo, 2.5 BAR<br />

■ Power: around 530hp, max<br />

speed at 7500 rpm<br />

■ Transmission: Hewland<br />

Courage TLS 6 speed<br />

sequential gearbox<br />

■ Wheels: BBS 18’’ rims<br />

■ Brakes: Brembo caliper,<br />

carbon discs and pads<br />

■ Tank capacity: 90 Liters<br />

■ Weight without driver: 750 Kg<br />

■ As founder, Yves Courage's first entry in<strong>to</strong> Le Mans dates back <strong>to</strong><br />

1977. But Courage Competition made its debut in endurance<br />

racing at <strong>the</strong> 24 Hours in 1982.<br />

■ For more than 20 years Courage pro<strong>to</strong>types have been competing<br />

with <strong>the</strong> biggest names in international car racing always obtaining<br />

excellent scores at <strong>the</strong> final ranking.<br />

success s<strong>to</strong>ry 5

SUCCESS STORY PRODUCT NEWS SPECIAL REPORT CASTING EVENTS CORPORATE<br />

CORUS and <strong>ESI</strong> <strong>Group</strong> partnership<br />

Integration of <strong>the</strong> Corus-Vegter model in<strong>to</strong> PAM-STAMP 2G software<br />

improves reliability and cost benefits<br />

About Corus<br />

Real-life product<br />

pressed without<br />

complications<br />

Corus, Europe’s third largest<br />

steel manufacturer, is<br />

achieving recognition in <strong>the</strong><br />

au<strong>to</strong>motive industry as an<br />

“intelligent supplier of<br />

material”. Corus provides<br />

innovative solutions <strong>to</strong><br />

construction, au<strong>to</strong>motive,<br />

packaging, mechanical<br />

engineering and o<strong>the</strong>r<br />

markets worldwide.<br />

Corus’ expertise is drawn<br />

from an intimate knowledge<br />

of contemporary vehicle<br />

performance requirements,<br />

manufacturing-feasible ideas,<br />

and material properties.<br />

Corus, <strong>the</strong> international<br />

metal’s producer, and <strong>ESI</strong><br />

<strong>Group</strong> have announced <strong>the</strong><br />

integration of <strong>the</strong> Corus-<br />

Vegter model, a new advanced material<br />

simulation model, in<strong>to</strong> <strong>the</strong> PAM-STAMP<br />

2G software package. Through Corus<br />

and <strong>ESI</strong> <strong>Group</strong> expertise, au<strong>to</strong>motive<br />

Conventional material model<br />

predicts fracture incorrectly<br />

PAM-STAMP 2G<br />

simulation with Corus<br />

material model predicts<br />

feasible production<br />

designers and engineers will be able <strong>to</strong><br />

significantly improve accuracy of<br />

formability analysis predictions and<br />

press stamping evaluations.<br />

Formability analysis <strong>to</strong>ols are currently<br />

used <strong>to</strong> predict material behavior <strong>to</strong><br />

simulate what happens when sheet<br />

material is stamped in<strong>to</strong> a threedimensional<br />

part, such as a body panel.<br />

However, as carmakers increasingly<br />

use advanced high strength steels and<br />

aluminum alloys, existing material<br />

simulation <strong>to</strong>ols – largely based on data<br />

from mild strength steels and featuring<br />

relatively simple models- are becoming<br />

more and more inadequate for <strong>the</strong> latest<br />

simulation requirements, especially<br />

panel quality and <strong>to</strong>lerance control.<br />

Corus has developed <strong>the</strong> Corus-Vegter<br />

model, which consists of an improved<br />

yield locus description and an improved<br />

strain hardening description. It<br />

incorporates Corus’ advanced<br />

understanding of sheet metal behavior<br />

during deformation. This development<br />

is a response <strong>to</strong> <strong>the</strong> need from <strong>the</strong><br />

global au<strong>to</strong>motive industry for a model<br />

that can accurately predict <strong>the</strong> behavior<br />

of more modern and widely used<br />

materials.<br />

Easy <strong>to</strong> use, <strong>the</strong> Vegter model features<br />

<strong>the</strong> latest data, including high strength<br />

steels and aluminum. Not only does it<br />

improve <strong>the</strong> performance of stamping<br />

operations but it also provides a<br />

powerful <strong>to</strong>ol <strong>to</strong> help manufacturers<br />

speed up <strong>the</strong> proving process, <strong>the</strong>refore<br />

reducing <strong>the</strong> costs of new product<br />

development. The ability <strong>to</strong> more<br />

accurately predict behavior will also<br />

lead <strong>to</strong> improved part reliability on new<br />

vehicle models.<br />

“New material grades present constant<br />

challenges <strong>to</strong> improve final part quality<br />

assessment and <strong>to</strong>lerance control.<br />

Through <strong>the</strong> cooperation with Corus,<br />

<strong>ESI</strong> <strong>Group</strong> has developed within PAM-<br />

STAMP 2G state-of-<strong>the</strong>-art material<br />

technology modeling <strong>to</strong> meet <strong>the</strong><br />

demand for high quality material<br />

models”, said Dr Fouad El Khaldi,<br />

Product Operations Manager, <strong>ESI</strong><br />

<strong>Group</strong>.<br />

Validation using <strong>the</strong> Renault<br />

Modus inner read door<br />

Validated on standard test pieces as<br />

well as on an actual au<strong>to</strong>motive<br />

component, <strong>the</strong> model allows<br />

engineers and designers <strong>to</strong> predict yield<br />

behavior more accurately under<br />

complex stress states.<br />

To demonstrate <strong>the</strong> increased accuracy<br />

of <strong>the</strong> Corus-Vegter material model<br />

compared <strong>to</strong> standard models, Renault<br />

and Corus chose <strong>the</strong> rear inner door of<br />

<strong>the</strong> Renault Modus as a test case. The<br />

strains resulting from <strong>the</strong> first draw were<br />

measured using <strong>the</strong> PHAST<br />

measurement system. To build <strong>the</strong><br />

simulation, Corus used a laser scanner<br />

on-site at Renault <strong>to</strong> obtain <strong>the</strong> actual<br />

geometry of <strong>the</strong> <strong>to</strong>ols used by Renault.<br />

The simulation was performed with<br />

three material models: <strong>the</strong> standard<br />

Hill’48 model, <strong>the</strong> Hill’90 model and <strong>the</strong><br />

Corus-Vegter model.<br />

The Corus-Vegter model correctly<br />

predicts <strong>the</strong> risk of rupture of <strong>the</strong> most<br />

critical area of <strong>the</strong> part.<br />

The thinning, strain distribution and<br />

blank edge movement (draw-in) as<br />

predicted by <strong>the</strong> Corus-Vegter model<br />

were closer <strong>to</strong> reality than <strong>the</strong><br />

predictions obtained from <strong>the</strong> Hill’48<br />

and Hill’90 model.<br />

Ano<strong>the</strong>r advantage of this model is <strong>the</strong><br />

very little extra CPU time which is<br />

needed for this increase in accuracy.<br />

“The validation of <strong>the</strong> Corus-Vegter<br />

model in PAM-STAMP 2G on an<br />

industrial part shows how collaboration<br />

between Car Manufacturer, Steel<br />

Manufacturer and Software Supplier<br />

can contribute <strong>to</strong> <strong>the</strong> continuous<br />

improvement of <strong>the</strong> quality of simulation<br />

results” said Mr. M. El Mouatassim,<br />

CAE and stamping feasibility team<br />

leader and BIW engineering, Renault.<br />

To conclude, we can say that <strong>the</strong> Vegter<br />

model is a good example of how Corus,<br />

in partnership with <strong>ESI</strong> <strong>Group</strong>, provides<br />

<strong>the</strong> engineering <strong>to</strong>ols that enable<br />

au<strong>to</strong>motive cus<strong>to</strong>mers <strong>to</strong> design more<br />

confidently and <strong>to</strong> optimize processes<br />

in advance of expensive pro<strong>to</strong>type or<br />

<strong>to</strong>oling build.<br />

success s<strong>to</strong>ry<br />

6 www.esi-group.com

SUCCESS STORY PRODUCT NEWS SPECIAL REPORT CASTING EVENTS CORPORATE<br />

Visual-Crash for PAM,<br />

<strong>the</strong> first brick of <strong>ESI</strong> <strong>Group</strong>'s<br />

new open integrated<br />

environment<br />

<strong>ESI</strong> <strong>Group</strong> integrates EASI’s renowned technology<br />

in<strong>to</strong> its state-of-<strong>the</strong>-art solvers<br />

Visual-Crash for PAM<br />

(VCP) marks a decisive step<br />

<strong>to</strong>wards <strong>ESI</strong> <strong>Group</strong>'s new<br />

open integrated environment,<br />

now available for PAM-CRASH solution.<br />

<strong>ESI</strong> <strong>Group</strong> leverages <strong>the</strong> acquisition of<br />

EASI by integrating <strong>the</strong> company's<br />

renowned technology in<strong>to</strong> its virtual<br />

engineering solution, known as <strong>the</strong><br />

Virtual Try-Out Space. This strategy<br />

paves <strong>the</strong> way <strong>to</strong> a unique open<br />

environment where competitive<br />

simulation software can be coupled<br />

with <strong>ESI</strong> <strong>Group</strong>'s state-of-<strong>the</strong>-art<br />

solvers. First delivered for PAM-CRASH<br />

users, this open environment allows<br />

<strong>the</strong>m <strong>to</strong> address any crash and safety<br />

related simulations as it effectively<br />

replaces <strong>the</strong> most competitive<br />

environment solutions.<br />

VCP combines PAM-CRASH former<br />

environment solution with EASi's<br />

technology. The embedded data model<br />

offers a very versatile environment<br />

where new applications and interfaces<br />

with tier solutions are easily<br />

implemented.<br />

“Visual-Crash for PAM allows PAM-<br />

CRASH users <strong>to</strong> focus and rely on high<br />

quality digital models, from start <strong>to</strong><br />

finish. As reliable simulation<br />

methodologies are emerging for multidisciplinary<br />

simulation, robust<br />

simulation-based design processes are<br />

now available, embedding proprietary<br />

Availability<br />

www.esi-group.com<br />

'know-how' and 'best practice' “said<br />

Vincent Chaillou, President and COO,<br />

Product Operations, <strong>ESI</strong> <strong>Group</strong>.<br />

From data input <strong>to</strong> visualization, VCP<br />

seamless environment provides PAM-<br />

CRASH users with fast iteration and<br />

rapid model revision process. The<br />

environment offers a quick model<br />

browsing, advanced meshing<br />

capabilities and rapid graphical<br />

assembly of system models. VCP<br />

allows graphical creation, modification<br />

and deletion of contacts, materials,<br />

constraint control cards and all crash<br />

entities.<br />

Visual-process associated <strong>to</strong> VCP<br />

brings a compelling advantage <strong>to</strong> PAM-<br />

CRASH users helping au<strong>to</strong>mate<br />

cumbersome and repetitive tasks, and<br />

easy coupling with third parties’<br />

applications. Using VCP's multiwindow,<br />

multi-models, multiapplication<br />

environment with visual<br />

verification, PAM-CRASH users easily<br />

address <strong>the</strong> coupling of finite element<br />

and rigid-body models, a requisite in<br />

safety simulation.<br />

Leveraging this state-of-<strong>the</strong>-art<br />

environment, a visualization and<br />

plotting solution helps analyze PAM-<br />

CRASH result data within a uniform<br />

interface. The viewer performs<br />

au<strong>to</strong>mated task and generates<br />

cus<strong>to</strong>mized reports <strong>the</strong>refore increasing<br />

engineer productivity.<br />

Visual-Crash for PAM Environment is available on PC platforms (Windows 2000, XP<br />

Professional), UNIX workstations (HP-UX, SunOS, SGI, IBM) and Linux-hardware<br />

vendors supported platforms.<br />

Porting open Virtual Try-Out<br />

Space on Microsoft 64-Bit<br />

Windows<br />

<strong>ESI</strong> <strong>Group</strong> demonstrated at EuroPAM’04 <strong>the</strong> powerful capabilities of its<br />

Open Virtual Try-Out Space Solution (VTOS), a proven engineering<br />

simulation environment, on Microsoft's new 64-bit Windows operating<br />

system. PAM-CRASH is <strong>the</strong> first crash simulation solution on <strong>the</strong> market<br />

<strong>to</strong> be ported <strong>to</strong> 64-bit Windows 64, before <strong>the</strong> future release of o<strong>the</strong>r<br />

major CAE software from <strong>ESI</strong> <strong>Group</strong>.<br />

The Open VTOS pro<strong>to</strong>type demonstration at EuroPAM 2004 includes<br />

several pre-ported product components such as PAM-CRASH solvers in<br />

SMP and DMP modes, as well as <strong>the</strong> new graphical framework for both<br />

Windows 64-bit Itanium Processor Family (IPF) and 64-bit Extended<br />

Systems (Intel Xeon with Extended Memory 64-bit technology).<br />

“<strong>ESI</strong> <strong>Group</strong> believes that Windows 64-bit will become one of <strong>the</strong> major<br />

operating systems for CAE applications as it delivers a highly competitive<br />

price/performance ratio within a consistent global simulation chain,” says<br />

Vincent Chaillou, President and COO, Product Operations, <strong>ESI</strong> <strong>Group</strong>.<br />

Microsoft's 64-bit operating system offers a cost-effective approach <strong>to</strong><br />

running typical CAE applications, which usually require large memory<br />

resources, in excess of 2-Gbytes. The new 64-bit systems running<br />

Windows XP professional x64 Edition allow, through a dual 32/64-bit<br />

offer, for mass market applications and continuous PLM engineering.<br />

Microsoft plans <strong>to</strong> introduce Windows XP professional x64 Edition and<br />

Windows Server 2003 x64 during <strong>the</strong> first half of 2005. Both operating<br />

systems are currently available in beta versions.<br />

product news 7

8<br />

SUCCESS STORY SPECIAL REPORT PRODUCT NEWS CASTING<br />

EVENTS CORPORATE<br />

EASi-Process<br />

An unmatched software for creating,<br />

au<strong>to</strong>mating, and cus<strong>to</strong>mizing<br />

CAE processes in CAE model building<br />

and analysis.<br />

Today’s vehicle systems<br />

and subsystems are<br />

engineered using established<br />

CAE processes <strong>to</strong> optimize<br />

<strong>the</strong>ir design for Stiffness and<br />

durability, Noise and vibration, Crash<br />

worthiness and Occupant safety,<br />

Sealing etc. European or US Federal<br />

standards, such as FMVSS 201 (Head<br />

impact), 208 (Frontal Crash), are very<br />

frequently carried out in engineering<br />

simulations using various preprocessors<br />

and post-processors.<br />

These generally include creation of<br />

baseline CAD data, preparation of FE<br />

models, formulation of <strong>the</strong> analysis<br />

problem in <strong>the</strong> appropriate solver<br />

language, submission <strong>to</strong> solver<br />

program <strong>to</strong> obtain analysis solution,<br />

post-processing of <strong>the</strong> results and<br />

finally writing a report. Each of <strong>the</strong>se<br />

processes itself could comprise of<br />

complex sub-processes and may<br />

even include exchanging data<br />

between different solvers. The time<br />

consuming tasks, from simulation<br />

model preparation <strong>to</strong> report<br />

generation, can be carried out in an<br />

au<strong>to</strong>mated environment resulting in<br />

productivity and enterprise benefits.<br />

product news<br />

The key aspect of building an EASi-<br />

Process template is <strong>to</strong> first understand<br />

<strong>the</strong> CAE process itself. The process<br />

flow template must be derived from<br />

<strong>the</strong> experienced user’s best and<br />

standardized practice <strong>to</strong> distinguish all<br />

inputs and outputs and recognize <strong>the</strong><br />

function of each task including<br />

breaking up complex process tasks<br />

in<strong>to</strong> simpler sub-processes.<br />

EASi-Process is a software<br />

environment that enables au<strong>to</strong>mation<br />

of CAE process simulation. It is<br />

developed as a complete solution <strong>to</strong><br />

this problem and is <strong>the</strong> first integrated<br />

environment for creating, au<strong>to</strong>mating<br />

and standardizing CAE processes.<br />

EASi-CRASH DYNA is a premier pre<br />

and post-processor for LS-DYNA<br />

within which <strong>the</strong> EASi-Process can be<br />

integrated <strong>to</strong> select and run <strong>the</strong><br />

predefined templates of <strong>the</strong> CAE<br />

process. This can also be performed<br />

by EASi-CRASH MADYMO, EASi-<br />

CRASH RADIOSS as well as in <strong>the</strong><br />

NVH and durability domain.<br />

Buildtime Environment<br />

“Process Builder” is a graphical<br />

interface developed within <strong>the</strong> EASi-<br />

VISTA architecture and dedicated <strong>to</strong><br />

experienced cus<strong>to</strong>mers that desire <strong>to</strong><br />

develop and maintain by <strong>the</strong>mselves<br />

<strong>the</strong>ir libraries of process templates.<br />

“Process Builder” contains a set of<br />

software modules and object libraries<br />

for various CAE tasks, which <strong>the</strong> user<br />

can add <strong>to</strong>. Each task is represented<br />

by a process block. Each block is<br />

provided with a knowledge advisory<br />

that captures <strong>the</strong> expertise of<br />

experienced users. The desired report<br />

layout format is envisaged and<br />

implemented in <strong>the</strong> “Generate Report”<br />

task block.<br />

Runtime Application<br />

A user friendly and intuitive graphical<br />

interface (mainly called as EASi-<br />

Process) is used <strong>to</strong> execute <strong>the</strong><br />

process templates. It is dedicated <strong>to</strong><br />

CAE users that perform day <strong>to</strong> day<br />

tasks which have been au<strong>to</strong>mated<br />

through a process template.<br />

The process execu<strong>to</strong>r can be<br />

integrated within <strong>the</strong> EASi-CRASH<br />

DYNA environment for quick<br />

interaction and model setup.<br />

This process au<strong>to</strong>mation, based on<br />

EASi-Process, provides intuitive<br />

environment, ideal for new users and<br />

non-specialists. It allows <strong>to</strong> shorten<br />

time per design iteration and decrease<br />

expertise requirement <strong>to</strong> prepare<br />

models and process results,<br />

The landmark technology of EASi-<br />

Process integrated with EASi-CRASH<br />

DYNA allows analysis processes <strong>to</strong> be<br />

implemented with au<strong>to</strong>mation<br />

techniques in a company <strong>to</strong>wards<br />

enterprise wide standardization. It<br />

alleviates CAE engineers from<br />

drudgery involved in conducting<br />

repetitive processes and frees <strong>the</strong>m <strong>to</strong><br />

truly spend <strong>the</strong>ir time in value added<br />

engineering for product development.<br />

Accuracy and consistency of reports<br />

are assured and <strong>the</strong> immediate benefit<br />

realized is extreme productivity.<br />

www.esi-group.com

SUCCESS STORY SPECIAL REPORT PRODUCT NEWS CASTING<br />

EVENTS CORPORATE<br />

PAMTALK:<br />

Can you tell me about<br />

EASi-PROCESS ?<br />

Velayudham Ganesan: EASi-PROCESS<br />

is an advanced CAE environment <strong>to</strong><br />

capture and standardize <strong>the</strong> corporate<br />

best practices.<br />

This solution not only<br />

au<strong>to</strong>mates regula<strong>to</strong>ry<br />

test simulation<br />

procedures such as<br />

FMVSS, IIHS, ECE-R<br />

for crash and safety,<br />

but also structural<br />

assessment such as NVH<br />

and durability.<br />

Process templates are provided in<br />

EASi-CRASH environment or Visual<br />

Environment <strong>to</strong> accelerate model<br />

building and simulation tasks. Typical<br />

gains lead users <strong>to</strong> spend a few<br />

minutes in setting up a model when<br />

<strong>the</strong>y spend several days with<br />

traditional methods.<br />

The engineers <strong>get</strong> huge benefits in<br />

terms of productivity, standardization;<br />

can spend more time on engineering<br />

while modeling and simulation is done<br />

in a fast-methodology using EASi-<br />

PROCESS.<br />

www.esi-group.com<br />

3<br />

questions <strong>to</strong>...<br />

1 2<br />

Velayudham Ganesan,<br />

Business Development Manager<br />

North America and Asia<br />

PAMTALK:<br />

For which application<br />

is EASi-PROCESS<br />

<strong>the</strong> best solution?<br />

Velayudham Ganesan: Au<strong>to</strong>motive<br />

crash & safety analyses with LS-<br />

DYNA, PAM-CRASH, MADYMO,<br />

RADIOSS, NVH and durability<br />

analyses with NASTRAN are currently<br />

supported best in EASi-PROCESS.<br />

Pre-defined templates FMVSS201,<br />

581, 208, ECE-R21, EPVS-<br />

Body Static Analysis, are<br />

available <strong>to</strong> name a<br />

few.<br />

EASi-PROCESS for<br />

CAE au<strong>to</strong>mation is<br />

also suitable for<br />

certain simulation<br />

procedures in Aero<br />

industries.<br />

PAMTALK:<br />

What are <strong>the</strong> specific<br />

requirements of <strong>the</strong>se<br />

industries?<br />

Velayudham Ganesan: These<br />

industries need standardized<br />

processes <strong>to</strong> execute <strong>the</strong> CAE<br />

simulation and analysis for repetitive<br />

tasks with consistency, accuracy and<br />

productivity.<br />

Our au<strong>to</strong>mated procedure enables <strong>to</strong><br />

execute <strong>the</strong> standardized process<br />

resulting in an increase in<br />

productivity. Fur<strong>the</strong>rmore, models are<br />

insured <strong>to</strong> be built using corporate<br />

methodology while eliminating users’<br />

errors.<br />

New users and<br />

non-specialists<br />

long for an easy<br />

<strong>to</strong> use, intuitive<br />

environment,<br />

which needs<br />

less training<br />

effort.<br />

3<br />

Also, <strong>the</strong>re is a decrease in expertise<br />

requirements <strong>to</strong> prepare models and<br />

process results having standard<br />

procedures implemented in<br />

environment.<br />

This also enables corporate knowhow<br />

protection when subcontracting<br />

has <strong>to</strong> be performed.<br />

product news 9

SUCCESS STORY PRODUCT NEWS SPECIAL REPORT CASTING EVENTS CORPORATE<br />

Special report<br />

on Germany<br />

PAMTALK: <strong>ESI</strong> GmbH<br />

celebrated its 25th<br />

anniversary this year,<br />

what were <strong>the</strong> key steps<br />

and major achievements?<br />

Stefan Rudolph: <strong>ESI</strong> GmbH was<br />

founded in 1979 as <strong>the</strong> first <strong>ESI</strong><br />

subsidiary. Initially <strong>the</strong> office was<br />

established <strong>to</strong> undertake consultancy<br />

studies mainly for <strong>the</strong> nuclear power<br />

industry in Germany, as well as for <strong>the</strong><br />

civil and military fields. With <strong>the</strong> decline<br />

of <strong>the</strong> nuclear industry a great effort was<br />

made <strong>to</strong> enter <strong>the</strong> important German<br />

car market in <strong>the</strong> mid 1980's. In this<br />

purpose, we under<strong>to</strong>ok specific<br />

developments in both metal stamping<br />

and crash analysis fields in close<br />

collaboration with industrial partners.<br />

Consequently, from about 1985 <strong>ESI</strong><br />

GmbH played a major role in<br />

industrializing crashworthiness<br />

simulation and helping <strong>to</strong> establish new<br />

products and markets in Japan, <strong>the</strong><br />

USA and elsewhere.<br />

“25 years dedicated<br />

<strong>to</strong> virtual engineering”<br />

Interview with Stefan Rudolph<br />

Managing Direc<strong>to</strong>r, <strong>ESI</strong> GmbH<br />

<strong>ESI</strong> GmbH<br />

headquarters<br />

in Eschborn, near<br />

Frankfurt/Main<br />

PAMTALK: Is <strong>the</strong><br />

predominance of <strong>the</strong><br />

au<strong>to</strong>motive industry still<br />

influencing your current<br />

activities?<br />

Stefan Rudolph: <strong>ESI</strong> GmbH is largely<br />

focused on <strong>the</strong> au<strong>to</strong>motive industry but<br />

is also supporting its cus<strong>to</strong>mers in <strong>the</strong><br />

aerospace, chemistry, foundry, or heavy<br />

industries. We are partnering with<br />

research centers, Fraunhoffer Institutes<br />

and most of universities in Germany.<br />

Today <strong>the</strong> office is heavily involved in<br />

research work at both European and<br />

German levels. Most of this work<br />

concerns improved material failure<br />

modeling, welding, sheet metal and<br />

composites forming, composites failure<br />

analysis and dummy developments.<br />

Finally, <strong>ESI</strong> GmbH is actively developing<br />

specific new options in collaboration<br />

with <strong>ESI</strong> <strong>Group</strong>. For example, in<br />

addition <strong>to</strong> <strong>the</strong> joint work on <strong>the</strong> H-<br />

Model, BMW <strong>Group</strong> has recently<br />

ordered a “virtual seat comfort testing”<br />

joint study devoted <strong>to</strong> <strong>the</strong> assessment<br />

and adaptation <strong>to</strong> its requirements. Our<br />

research work in advanced composites<br />

and plastics processes has also<br />

opened new areas in food industry,<br />

consumer appliances, carpet<br />

<strong>the</strong>rmoforming, etc.<br />

PAMTALK: Could you<br />

tell us more about your<br />

projects for <strong>the</strong> coming<br />

years?<br />

Stefan Rudolph: In <strong>the</strong> current context<br />

of global economy, our cus<strong>to</strong>mers are<br />

under pressure <strong>to</strong> reduce costs and<br />

time-<strong>to</strong>-market, while increasing<br />

productivity. <strong>ESI</strong> GmbH has a vital role<br />

<strong>to</strong> play by offering reliable and fast<br />

solutions, able not only <strong>to</strong> fulfill<br />

regulations but <strong>to</strong> help improve<br />

performances, comfort, aeroacoustics,<br />

and enhance <strong>the</strong> product quality. We<br />

are thus promoting 2G and 3G solutions<br />

in response <strong>to</strong> manufacturers’ needs <strong>to</strong><br />

achieve synergies between <strong>the</strong> various<br />

types of tests involved in product<br />

design and manufacturing. Through<br />

multi-trade value chains such as PAM-<br />

CRASH / PAM-STAMP coupling or<br />

PAM-STAMP / SYSWELD chaining,<br />

German industry leaders will benefit<br />

from powerful, yet easy-<strong>to</strong>-use<br />

solutions enabling <strong>to</strong> solve even bigger<br />

problems. Simulation-Based.Design is<br />

<strong>the</strong> major challenge for <strong>the</strong> German<br />

industry <strong>to</strong>o!<br />

Starting from 1988 <strong>ESI</strong> GmbH was also<br />

actively involved in safety and restraint<br />

systems’ extensive testing and<br />

validation studies with German industry.<br />

We carried out <strong>the</strong> first dummy specific<br />

developments up <strong>to</strong> new EuroSID<br />

dummies appeared in <strong>the</strong> early nineties.<br />

We have also been working on a new,<br />

more detailed model, in collaboration<br />

with FAT (Forschungsvereinigung<br />

Au<strong>to</strong>mobiltechnik) working group, a<br />

consortium supported by <strong>the</strong> German<br />

car manufacturers.<br />

special report<br />

10 www.esi-group.com

SUCCESS STORY PRODUCT NEWS SPECIAL REPORT CASTING EVENTS CORPORATE<br />

PAM-STAMP 2G helps<br />

Kirchhoff Au<strong>to</strong>motive design<br />

car modules ‘right first time’<br />

Through PAM-STAMP 2G simulation of <strong>the</strong> entire stamping process,<br />

Kirchhoff Au<strong>to</strong>motive achieves its objectives for productivity and high quality.<br />

Because of ever shorter<br />

development times, Kirchhoff<br />

Au<strong>to</strong>motive has <strong>to</strong> do a solid<br />

planning of its production<br />

processes. For more than 100 years<br />

<strong>the</strong> company has been developing,<br />

manufacturing and supplying metal<br />

structures for <strong>the</strong> au<strong>to</strong>motive industry<br />

and has grown <strong>to</strong> an international<br />

supplier providing complete car<br />

modules. “For an exact implementation<br />

of <strong>to</strong>ol planning we rely on PAM-<br />

STAMP 2G and PAM-AUTOSTAMP's<br />

highly effective system <strong>to</strong> perform<br />

accurate deep drawing simulations,”<br />

says Mr. Raimund Teipel, simulations<br />

manager, Kirchhoff Au<strong>to</strong>motive.<br />

PAM-AUTOSTAMP deep<br />

drawing process assessment<br />

Kirchhoff Au<strong>to</strong>motive produces chassis<br />

and structural parts for cars and trucks<br />

as well as a wide variety of deep drawn<br />

pressed panels for cars. Deep drawing<br />

consists of stretching sheet metal<br />

blanks around a punch, which are<br />

drawn in<strong>to</strong> a die cavity <strong>to</strong> achieve <strong>the</strong><br />

desired final shape.<br />

Kirchhoff Au<strong>to</strong>motive makes extensive<br />

use of PAM-AUTOSTAMP, a 'physics<br />

based' software for <strong>the</strong> accurate<br />

prediction of deep drawing processes.<br />

PAM-AUTOSTAMP's ease-of-use<br />

simplifies <strong>the</strong> modeling process<br />

allowing <strong>the</strong> simulation of each stage,<br />

from <strong>the</strong> effects of gravity on <strong>the</strong> blank<br />

<strong>to</strong> trimming and flanging.<br />

Checking wrinkles at each stage of <strong>the</strong><br />

stamping process is very important <strong>to</strong><br />

ensure part quality and safety, which<br />

are major requirements from Kirchhoff.<br />

www.esi-group.com<br />

Using PAM-AUTOSTAMP Kirchhoff can<br />

thus evaluate and predict stresses,<br />

strains, fractures and geometrical<br />

imperfections that may occur during<br />

<strong>the</strong> deep drawing operation. The user<br />

is guided through <strong>the</strong> final validation of<br />

<strong>the</strong> forming process, <strong>to</strong>lerances and<br />

overall quality control, helping <strong>to</strong> avoid<br />

costly and time-consuming<br />

downstream problems.<br />

On-line decision-making<br />

on formability issues<br />

Kirchhoff takes advantage of PAM-<br />

AUTOSTAMP’s detailed results for<br />

validating formability issues and<br />

predicting subtle issues such as sliplines<br />

and cosmetic surface defects.<br />

Kirchoff also models drawbeads very<br />

accurately, even considering <strong>the</strong><br />

opening effect <strong>the</strong>y have on a<br />

blankholder, delivering better<br />

prediction of required press forces.<br />

PAM-STAMP 2G<br />

thinning and rupture<br />

risk prediction<br />

PAM-STAMP 2G contains<br />

a wide range of material<br />

models. These models<br />

are supported by a<br />

comprehensive material<br />

database, which includes many<br />

aluminum alloys and high strength<br />

steels, becoming increasingly common<br />

in au<strong>to</strong>motive component<br />

manufacturing.<br />

In this way, Kirchhoff Au<strong>to</strong>motive is<br />

able <strong>to</strong> design <strong>the</strong> 'right first time'<br />

<strong>to</strong>oling and <strong>to</strong> optimize <strong>the</strong> process.<br />

“Fur<strong>the</strong>rmore we use PAM-STAMP 2G<br />

in early development phases of a car<br />

from design <strong>to</strong> production of<br />

assemblies. This procedure generates<br />

significant cost and time reductions,”<br />

adds Mr. Raimund Teipel, simulations<br />

manager, Kirchhoff Au<strong>to</strong>motive.<br />

For <strong>the</strong> future, Kirchhoff Au<strong>to</strong>motive<br />

plans <strong>to</strong> expand its development<br />

department and <strong>to</strong> increase its<br />

structural analysis and crash simulation<br />

activities. The company is now<br />

considering <strong>the</strong> benefit of using PAM-<br />

CRASH in addition <strong>to</strong> PAM-STAMP <strong>to</strong><br />

have an easy way <strong>to</strong> map <strong>the</strong> results of<br />

production analysis <strong>to</strong> crash analysis.<br />

About Kirchhoff <strong>Group</strong><br />

Deep drawn metal<br />

structures meeting<br />

Kirchhoff’s quality<br />

and safety<br />

standards<br />

The Kirchhoff <strong>Group</strong> is a global player in <strong>the</strong> au<strong>to</strong>motive components industry<br />

and is also a producer of high performance <strong>to</strong>ols and waste management<br />

vehicles. The <strong>Group</strong>, established in 1785, is owned and managed by <strong>the</strong><br />

Kirchhoff family.<br />

With more than 2,000 employees and a turnover about 250 Million €<br />

Kirchhoff operates manufacturing facilities around <strong>the</strong> world - five in Germany<br />

and o<strong>the</strong>rs in Ireland, Hungary, Spain, Portugal, Poland, Mexico and Brazil. Its<br />

cus<strong>to</strong>mers include <strong>the</strong> major au<strong>to</strong>motive companies and it is an accredited<br />

Tier 1 supplier <strong>to</strong> Ford, GM, VW/Audi and Daimler Chrysler.<br />

special report<br />

11

12<br />

SUCCESS STORY PRODUCT NEWS SPECIAL REPORT CASTING<br />

EVENTS CORPORATE<br />

Parallel processing<br />

with ProCAST 2005<br />

The new version of <strong>the</strong> ProCAST solution features parallel<br />

processing in order <strong>to</strong> drastically reduce turn around times.<br />

Cutting costs and<br />

reducing time <strong>to</strong> market are<br />

two of <strong>the</strong> most pressing<br />

issues in <strong>the</strong> foundry<br />

industry <strong>to</strong>day. Casting process<br />

simulation helps achieve <strong>the</strong>se goals<br />

and is now widely used throughout <strong>the</strong><br />

industry for process design, improved<br />

yield and better casting quality. While<br />

simplified solutions can be efficiently<br />

used <strong>to</strong> quickly evaluate mold filling and<br />

solidification, <strong>the</strong> accurate prediction of<br />

complex flows and metallurgical<br />

phenomena still requires significant<br />

computation times. To tackle this issue<br />

and drastically reduce turn around<br />

times without any loss of accuracy and<br />

functionality, parallel processing was<br />

introduced in <strong>the</strong> ProCAST 2005<br />

release.<br />

DMP vs. SMP<br />

Different technologies are currently<br />

available for parallel processing.<br />

Symmetric Multi Processing (often<br />

referred <strong>to</strong> as Shared Memory Parallel<br />

casting<br />

processing) is one of <strong>the</strong>m. With SMP,<br />

specific programming directives are<br />

added in <strong>the</strong> software <strong>to</strong> allow<br />

computations <strong>to</strong> be distributed on<br />

several processors, all processors<br />

sharing <strong>the</strong> same memory addresses.<br />

SMP technology is only available on<br />

specific hardware platforms and limited<br />

in terms of <strong>the</strong> maximum number of<br />

processors. In practice, it does not<br />

provide significant speed ups beyond 8<br />

processors.<br />

Distributed Memory Parallel (DMP)<br />

processing is an alternative in which<br />

each processor accesses its own<br />

memory. A Message Passing Interface<br />

(MPI) is however required <strong>to</strong> distribute<br />

and share data between <strong>the</strong> different<br />

processors. With DMP, it is possible <strong>to</strong><br />

design parallel applications that scale<br />

<strong>to</strong> a greater number of processors at<br />

<strong>the</strong> expense of substantial<br />

programming efforts. Because of its<br />

versatility and potential for very high<br />

performance, <strong>the</strong> DMP technology was<br />

implemented in <strong>the</strong> ProCAST solvers.<br />

Schematic representation<br />

of <strong>the</strong> Distributed<br />

Memory Parallel<br />

processing principle<br />

Example of domain partitioning<br />

for a 8 processors <strong>the</strong>rmal simulation<br />

Model courtesy<br />

of Rims<strong>to</strong>ck<br />

Domain decomposition<br />

To distribute <strong>the</strong> work on <strong>the</strong> different<br />

processors, <strong>the</strong> Finite Element mesh<br />

needs <strong>to</strong> be partitioned in as many<br />

sub-domains as <strong>the</strong>re are processors.<br />

This functionality is au<strong>to</strong>matically<br />

activated in ProCAST and called<br />

domain decomposition. To be<br />

efficient, <strong>the</strong> decomposition needs <strong>to</strong><br />

provide a balanced repartition of <strong>the</strong><br />

workload (load balancing) and a<br />

minimal interface between <strong>the</strong><br />

different partitions so as <strong>to</strong> minimize<br />

<strong>the</strong> necessary exchange of data<br />

between <strong>the</strong> different processors.<br />

www.esi-group.com

SUCCESS STORY PRODUCT NEWS SPECIAL REPORT CASTING EVENTS CORPORATE<br />

Inter-operability<br />

and repeatability<br />

Full inter-operability is provided with<br />

ProCAST 2005: computations can be<br />

restarted on a different number of<br />

processors than what was initially<br />

used. The repeatability (ability <strong>to</strong><br />

reproduce identical results<br />

irrespective of <strong>the</strong> number of<br />

processors) has also been carefully<br />

checked. It should however be noted<br />

that, because floating point operations<br />

are performed in a different order<br />

depending on <strong>the</strong> number of<br />

processors, <strong>the</strong> accumulation of<br />

rounding off errors can lead <strong>to</strong> small<br />

result discrepancies.<br />

Scalability<br />

The performance of <strong>the</strong> parallel solver<br />

depends not only on <strong>the</strong> size of <strong>the</strong><br />

model and type of application but is<br />

also very much dependent on <strong>the</strong><br />

hardware configuration. In particular,<br />

significant differences have been<br />

noted between Gigabit E<strong>the</strong>rnet and<br />

Myrinet interconnect.<br />

Scalability results reported here were<br />

obtained on a Linux cluster with<br />

Gigabit E<strong>the</strong>rnet interconnect and<br />

show that speed-ups ranging from 5<br />

<strong>to</strong> 6 can be obtained for both filling<br />

and solidification on 8 processors<br />

platforms. Much better scalability has<br />

been recently obtained with Myrinet<br />

interconnect for up <strong>to</strong> 16 processors.<br />

Continuous efforts are being devoted<br />

<strong>to</strong> <strong>the</strong> fine tuning of <strong>the</strong> software <strong>to</strong><br />

improve <strong>the</strong> scalability and<br />

performance.<br />

Future outlook<br />

and product roadmap<br />

The ProCAST 2005 parallel version<br />

currently includes <strong>the</strong> main software<br />

functionalities <strong>to</strong> simulate mold filling<br />

and solidification with radiation. O<strong>the</strong>r<br />

specific software features such as lost<br />

foam, non-New<strong>to</strong>nian flows and<br />

www.esi-group.com<br />

advanced solidification modules<br />

including micro-porosity and CAFE<br />

modules are however not available for<br />

parallel processing at this stage.<br />

The stress solver is currently being<br />

finalized and will be released later<br />

during 2005 <strong>to</strong> allow for parallel fully<br />

coupled <strong>the</strong>rmo-mechanical<br />

simulations.<br />

ProCAST 2005 DMP – Scalability for filling simulation<br />

Speed up fac<strong>to</strong>r relative <strong>to</strong> a single processor run<br />

ProCAST 2005 DMP – Scalability for a <strong>the</strong>rmal only simulation<br />

Speed up fac<strong>to</strong>r relative <strong>to</strong> a single processor run<br />

Model courtesy of Rims<strong>to</strong>ck<br />

AVAILABILITY<br />

The ProCAST 2005 parallel version is<br />

currently available on Linux clusters<br />

(Redhat 7.3 and Entreprise server),<br />

as well as UNIX multi-processor<br />

platforms from IBM and SGI.<br />

casting 13

14<br />

SUCCESS STORY PRODUCT NEWS SPECIAL REPORT CASTING<br />

EVENTS CORPORATE<br />

PAM-QUIKCAST 2005 speeds up<br />

casting process evaluation<br />

PAM-CAST has evolved<br />

<strong>to</strong> a new solution for casting<br />

process evaluation. PAM-<br />

QUIKCAST 2005, <strong>the</strong> new<br />

Finite Difference casting software<br />

package features dramatic reductions<br />

in volume meshing and overall<br />

processing times.<br />

With an intuitive user interface, an<br />

enhanced mesh genera<strong>to</strong>r, and<br />

improved filling and solidification<br />

solvers PAM-QUIKCAST 2005 allows<br />

for shorter process evaluation and fast<br />

iterations between different mold<br />

designs.<br />

New mesh genera<strong>to</strong>r<br />

performance<br />

A key fac<strong>to</strong>r <strong>to</strong> obtain accurate results<br />

with Finite Difference solvers is <strong>the</strong><br />

application of local volume and<br />

surface correction fac<strong>to</strong>rs. These<br />

correction fac<strong>to</strong>rs are necessary in<br />

order <strong>to</strong> compute exact volumes but<br />

also <strong>to</strong> apply proper heat transfer and<br />

boundary conditions on <strong>the</strong> external<br />

surfaces of <strong>the</strong> different volumes<br />

describing <strong>the</strong> casting process. The<br />

computation of surface correction<br />

fac<strong>to</strong>rs is by far <strong>the</strong> most time<br />

consuming part. To reduce meshing<br />

times, a new and efficient algorithm<br />

was implemented <strong>to</strong> calculate surface<br />

casting<br />

AVAILABILITY<br />

PAM-QUIKCAST<br />

2005 is available<br />

on Windows 2000<br />

and XP platforms,<br />

as well as UNIX<br />

workstations from<br />

HP-Compaq, IBM,<br />

SGI and Sun.<br />

From PAM-CAST <strong>to</strong> PAM-QUIKCAST,<br />

a new and rebuilt version providing a<br />

significant reduction of turn around times<br />

Low pressure die casting simulation of a cylinder head.<br />

Courtesy: Montupet<br />

Meshing CPU time<br />

CPU time for 5 <strong>the</strong>rmal cycles<br />

Mold filling<br />

Final solidification<br />

corrections. While providing <strong>the</strong> same<br />

level of accuracy as before, meshing<br />

times are now reduced <strong>to</strong> just a few<br />

minutes for even <strong>the</strong> most complex<br />

geometries.<br />

Improved CPU times<br />

The filling and solidification solvers<br />

were also improved in order <strong>to</strong> shorten<br />

simulation times. A proper tuning of<br />

internal solver parameters and<br />

specific software optimizations on<br />

Windows platforms result in a overall<br />

time reduction of a fac<strong>to</strong>r 2. This<br />

improvement is particularly visible on<br />

mold cycling and solidification<br />

simulations.<br />

The above table illustrates<br />

performances, as compared <strong>to</strong> <strong>the</strong><br />

previous PAM-CAST release, of <strong>the</strong><br />

new solvers on a large low pressure<br />

die casting application. CPU times<br />

indicated here were obtained on a<br />

standard Windows platform.<br />

New product features<br />

A specific new option has been added<br />

<strong>to</strong> import not only geometry or grid<br />

PAM-CAST<br />

74 mns<br />

21 h 18 mns<br />

9 h 25 mns<br />

4 h 51 mns<br />

PAM-QUIKCAST<br />

5 mns<br />

7 h 59 mns<br />

6 h 52 mns<br />

2 h 07 mns<br />

information but also process<br />

conditions from a previous model.<br />

This new feature can be used <strong>to</strong><br />

quickly re-define all process<br />

parameters from one model <strong>to</strong> <strong>the</strong><br />

o<strong>the</strong>r irrespective of any geometry<br />

modifications.<br />

The <strong>the</strong>rmal interpolation menu has<br />

also been improved <strong>to</strong> allow for<br />

various types of temperature<br />

interpolations. In particular, end of<br />

filling temperatures interpolation <strong>to</strong> a<br />

ProCAST Finite Element model is<br />

possible <strong>to</strong> complement <strong>the</strong> standard<br />

filling and solidification calculation<br />

with a <strong>the</strong>rmo-mechanical analysis.<br />

Two new parameters have been<br />

added <strong>to</strong> <strong>the</strong> definition of <strong>the</strong> third<br />

stage pressure effect: a solid fraction<br />

cut-off value and <strong>the</strong> time at which <strong>the</strong><br />

pressure is released. The “third stage”<br />

pressure effect only affects macroporosity<br />

calculations and can be used<br />

<strong>to</strong> account for additional material<br />

feeding during solidification in high<br />

pressure die casting as well as low<br />

pressure die casting applications. The<br />

solid fraction cut-off value can be<br />

used <strong>to</strong> define <strong>the</strong> extend of <strong>the</strong> liquid<br />

network and tuned <strong>to</strong> account for<br />

various pressure levels.<br />

www.esi-group.com

SUCCESS STORY PRODUCT NEWS SPECIAL REPORT CASTING<br />

EVENTS CORPORATE<br />

The time at which <strong>the</strong> pressure is<br />

released is particularly useful for low<br />

pressure die casting processes. When<br />

<strong>the</strong> calculation reaches this time, all<br />

<strong>the</strong> metal connected <strong>to</strong> <strong>the</strong> inlet<br />

through a liquid network is removed<br />

from <strong>the</strong> calculation as illustrated in<br />

<strong>the</strong> opposite example of a wheel low<br />

pressure die casting.<br />

Based on a structured Finite Volume<br />

technology, PAM-QUIKCAST simulates<br />

PAM-QUIKCAST 2005 offers numerous<br />

new pre-processing functionalities<br />

including:<br />

■ Shortcuts <strong>to</strong> mesh quality checks,<br />

■ Simplified mesh editing <strong>to</strong>ols,<br />

■ Undo option for manual merging<br />

operations,<br />

■ New volume domain selection filter,<br />

■ Au<strong>to</strong>matic Finite Difference grid<br />

creation,<br />

■ Study versions management <strong>to</strong>ols<br />

(add, change, delete options),<br />

■ Information on surface areas,<br />

volumes and weights,<br />

■ Possibility <strong>to</strong> define and execute<br />

several calculations in a batch<br />

process.<br />

Les Diablerets, Switzerland - May 22-27, 2005<br />

For <strong>the</strong> fourteenth consecutive<br />

year, Calcom <strong>ESI</strong>, <strong>the</strong> <strong>ESI</strong><br />

<strong>Group</strong> casting business unit,<br />

is organizing a solidification course<br />

in collaboration with <strong>the</strong> Swiss<br />

Federal Institute of Technology of<br />

Lausanne (EPFL). During one<br />

week, courses and exercises will<br />

be presented by renowned<br />

lecturers from Swiss, French,<br />

Austrian and <strong>the</strong> US universities.<br />

Dedicated <strong>to</strong> metallurgists and<br />

foundry engineers, this course is<br />

orientated <strong>to</strong>wards <strong>the</strong> application<br />

of solidification <strong>the</strong>ories <strong>to</strong><br />

industrial casting processes. The<br />

macroscopic aspects of <strong>the</strong><br />

processes (transfer phenomena)<br />

www.esi-group.com<br />

a wide range of processes<br />

such as gravity die casting,<br />

low and high pressure die<br />

casting including semisolid<br />

materials. The new<br />

version completes <strong>ESI</strong><br />

<strong>Group</strong>'s casting portfolio<br />

which includes ProCAST,<br />

and CALCOSOFT, for fast<br />

and efficient modeling of<br />

continuous casting<br />

processes.<br />

New pre-processing features New post-processing features<br />

PAM-QUIKCAST 2005 offers numerous<br />

new post-processing functionalities<br />

including:<br />

■ Graphics display of distance<br />

information,<br />

■ Possibility <strong>to</strong> refer <strong>to</strong> a color scale,<br />

■ New sectioning algorithm without<br />

“stair” effect,<br />

■ Curve display of averaged quantities<br />

for multiple element selections,<br />

■ Result <strong>file</strong>s management <strong>to</strong>ols<br />

(extraction, concatenation of postprocessing<br />

<strong>file</strong>s),<br />

■ New raster <strong>file</strong> output in jpeg format,<br />

■ Solidification output frequency<br />

defined as a function of solidification<br />

rate,<br />

■ Possibility <strong>to</strong> switch from one study<br />

version <strong>to</strong> <strong>the</strong> o<strong>the</strong>r without reloading<br />

<strong>the</strong> model.<br />

Solidification course 2005<br />

are addressed <strong>to</strong><strong>get</strong>her with <strong>the</strong><br />

formation of microstructures and<br />

defects (microscopic phenomena).<br />

Connection between macroscopic<br />

and microscopic aspects, such as<br />

<strong>the</strong> prediction of microstructures<br />

and defects as a function of<br />

process parameters, will also<br />

be emphasized. Exercises,<br />

discussions, films and computer<br />

demonstrations are organized in<br />

order <strong>to</strong> apply, practice and<br />

visualize <strong>the</strong> contents of <strong>the</strong><br />

lectures. Due <strong>to</strong> <strong>the</strong> limited number<br />

of participants (maximum 40),<br />

interaction between <strong>the</strong><br />

participants and <strong>the</strong> seven<br />

lecturers will allow an optimum<br />

transfer of knowledge.<br />

Liquid fraction before releasing<br />

<strong>the</strong> pressure<br />

Central section of a wheel<br />

Finally, private or group<br />

discussions can take place during<br />

social hours and evenings in order<br />

<strong>to</strong> treat more specific problems<br />

which <strong>the</strong> participants may<br />

encounter.<br />

Since its first edition in 1992, <strong>the</strong><br />

course has ga<strong>the</strong>red 417<br />

Liquid fraction just after releasing<br />

<strong>the</strong> pressure<br />

PAM-QUIKCAST 2005 user interface<br />

Solidification course, annual event held in <strong>the</strong> heart of <strong>the</strong> Swiss Alps<br />

participants coming from 161<br />

companies distributed in 25<br />

countries representing all 5<br />

continents.<br />

Registration form, full program<br />

and fur<strong>the</strong>r details are available<br />

on www.calcom.ch<br />

casting<br />

15

16<br />

SUCCESS STORY PRODUCT NEWS SPECIAL REPORT CASTING<br />

EVENTS CORPORATE<br />

<strong>ESI</strong> <strong>Group</strong>’s casting<br />

solutions gain ground<br />

in South America<br />

Four new cus<strong>to</strong>mers choose <strong>ESI</strong> <strong>Group</strong>’s<br />

casting simulation software<br />

Teksid do Brazil grey<br />

and nodular iron<br />

castings for <strong>the</strong><br />

au<strong>to</strong>motive industry<br />

casting<br />

Four established<br />

industries and institutes have<br />

recently shown <strong>the</strong>ir<br />

confidence in <strong>ESI</strong> <strong>Group</strong> <strong>to</strong><br />

meet <strong>the</strong>ir casting simulation needs.<br />

The company is present through one<br />

regional technical support office and<br />

three agents located respectively in<br />

Brazil, Argentina and Venezuela. Based<br />

in Sao Paolo, <strong>ESI</strong> <strong>Group</strong> South America<br />

has started <strong>to</strong> market <strong>the</strong> casting<br />

simulation software range across major<br />

South American countries in January<br />

2003.<br />