Inside Papua New Guinea - ExxonMobil

Inside Papua New Guinea - ExxonMobil

Inside Papua New Guinea - ExxonMobil

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

An <strong>ExxonMobil</strong> publication<br />

<strong>Inside</strong> <strong>Papua</strong> <strong>New</strong> <strong>Guinea</strong><br />

<strong>ExxonMobil</strong>’s heritage of integrity<br />

Unlocking the subsalt<br />

PLUS<br />

Whale of a tale<br />

Singapore milestone<br />

A historic agreement<br />

1<br />

2011 – Number 2

1<br />

Connect with us<br />

Now you have more ways to stay connected for all<br />

the latest <strong>ExxonMobil</strong> news, views and discussions on<br />

today’s energy issues. From your computer. From your<br />

handheld. Wherever and whenever you want.<br />

World Wide Web<br />

exxonmobil.com<br />

<strong>ExxonMobil</strong> Perspectives Blog<br />

exxonmobilperspectives.com<br />

<strong>ExxonMobil</strong> Channel YouTube<br />

youtube.com/exxonmobil<br />

<strong>ExxonMobil</strong> on Twitter<br />

twitter.com/exxonmobil<br />

twitter.com/kenpcohen<br />

<strong>ExxonMobil</strong> Fuel Finder App<br />

For PCs and handhelds

In this issue<br />

<strong>Inside</strong> <strong>Papua</strong><br />

<strong>New</strong> <strong>Guinea</strong><br />

Companies progress<br />

huge gas project<br />

23 9 5<br />

17<br />

Rex W. Tillerson<br />

Chairman and CEO<br />

Mark W. Albers<br />

Senior Vice President<br />

Michael J. Dolan<br />

Senior Vice President<br />

Donald D. Humphreys<br />

Senior Vice President<br />

Andrew P. Swiger<br />

Senior Vice President<br />

Kenneth P. Cohen<br />

Vice President-Public and Government Affairs<br />

David S. Rosenthal<br />

Vice President-Investor Relations and Secretary<br />

Bob Davis<br />

Editor<br />

Pat Gabriel<br />

GCG<br />

Art Director<br />

Len Shelton<br />

Photography Coordinator<br />

Cynthia Solomon<br />

Production and Distribution Coordinator<br />

Please address all Lamp correspondence,<br />

including requests to reproduce any portion<br />

of the magazine, to the editor at Exxon Mobil<br />

Corporation, 5959 Las Colinas Blvd., Irving,<br />

TX 75039-2298.<br />

3<br />

Heritage of integrity<br />

Chairman, senior executives<br />

share their views<br />

5<br />

Secrets of the subsalt<br />

How technology is adding to<br />

U.S. energy supplies<br />

9<br />

Life-long learner<br />

The diverse career of<br />

scientist Jeff Beck<br />

Upfront<br />

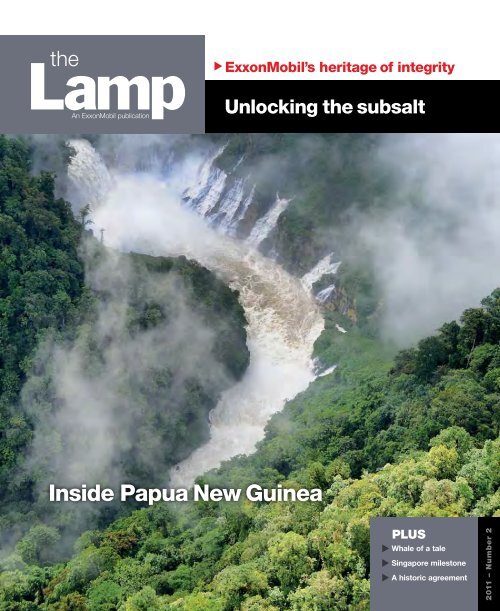

In the rugged mountains and<br />

jungles of <strong>Papua</strong> <strong>New</strong> <strong>Guinea</strong>,<br />

<strong>ExxonMobil</strong> and its joint-venture<br />

partners are building a liquefied<br />

natural gas project that will<br />

provide energy to Asia Pacific,<br />

where energy demand is rising<br />

faster than anywhere in the world.<br />

The project is expected to<br />

produce more than 9 trillion cubic<br />

feet of natural gas during its<br />

30-year life. Three photographers<br />

traveled to the country to capture<br />

the amazing pictures in our cover<br />

story beginning on page 17.<br />

This summer, <strong>ExxonMobil</strong><br />

and Rosneft signed a strategic<br />

cooperation agreement<br />

for exploration, technology<br />

exchange and joint projects<br />

13<br />

A first for Nigeria<br />

Building local sources for<br />

energy companies<br />

15<br />

A historic agreement<br />

<strong>ExxonMobil</strong> and Rosneft team up<br />

in Russia and in the United States<br />

17<br />

<strong>New</strong> energy for Asia Pacific<br />

A huge project takes shape in<br />

<strong>Papua</strong> <strong>New</strong> <strong>Guinea</strong><br />

in Russia and in the United<br />

States. The historic pact includes<br />

searching for oil and gas in some<br />

of the most promising and least<br />

explored areas in the world. The<br />

article starts on page 15.<br />

Beginning on page 9 is the story<br />

of <strong>ExxonMobil</strong> scientist Jeff Beck.<br />

His career has included developing<br />

new chemical catalysts,<br />

improving refinery processes,<br />

directing research activities and<br />

negotiating a biofuels venture as<br />

well as managing our worldwide<br />

polyethylene business. With more<br />

than 60 patents to his name,<br />

Beck embodies how <strong>ExxonMobil</strong><br />

provides its employees with<br />

diverse career opportunities.<br />

<strong>ExxonMobil</strong>’s discovery of an<br />

23<br />

Can-do spirit in Singapore<br />

Keeping a competitive edge<br />

25<br />

Champions test skills<br />

Top drivers trade places<br />

at Mobil 1 event<br />

29<br />

Whale of a tale<br />

Marine research offshore<br />

Sakhalin and beyond<br />

estimated 700 million equivalent<br />

barrels of oil and gas in 7,000<br />

feet of water 250 miles southwest<br />

of <strong>New</strong> Orleans was not easy.<br />

Company geoscientists used<br />

cutting-edge technology to “see”<br />

what couldn’t be seen before.<br />

Read how it was done beginning<br />

on page 5.<br />

Plus, a first for Nigeria (page<br />

13) and a Mobil 1 event that<br />

tested the skills of two champion<br />

race car drivers (page 25).<br />

We hope you enjoy this issue<br />

of The Lamp.<br />

Bob Davis<br />

Editor<br />

31<br />

Legacy of innovation<br />

The many forms of butyl rubber<br />

33<br />

Panorama<br />

Business highlights<br />

from around the world<br />

2

<strong>ExxonMobil</strong>’s heritage of integrity<br />

Three perspectives, one conclusion:<br />

Ethical behavior matters<br />

For over a century, <strong>ExxonMobil</strong><br />

has managed its business with<br />

the conviction that the company’s<br />

most important assets are its<br />

people and their reputation for<br />

scrupulous conduct. Rex W.<br />

Tillerson, chairman and CEO, and<br />

Senior Vice Presidents Mike Dolan<br />

and Mark Albers share their views<br />

about the paramount importance<br />

of ethical behavior in achieving<br />

business success.<br />

Ethics and society<br />

In May, <strong>ExxonMobil</strong> Chairman<br />

and CEO Rex Tillerson told<br />

the 2011 graduating class of<br />

Worcester (Mass.) Polytechnic<br />

Institute that they would need<br />

more than vision, ingenuity and<br />

skills as they took their place in a<br />

rapidly changing world.<br />

3<br />

“Your contributions to society,”<br />

he said, “depend on a firm ethical<br />

foundation of personal and<br />

professional integrity.”<br />

Tillerson pointed to the damage<br />

caused in recent years by financial<br />

scandals and unethical behavior<br />

in business and government.<br />

“The damage strikes at the<br />

heart of a free society,” he said.<br />

“It undermines the trust in the<br />

overwhelming majority of businesses<br />

and entrepreneurs who<br />

live and compete by the rules.”<br />

Tillerson stressed that companies<br />

with a core value of integrity<br />

are also more competitive.<br />

“It makes us more responsible<br />

because it reminds us that our<br />

actions and decisions have implications<br />

for our families, communities<br />

and nation,” he said. “And<br />

Story by Bill Corporon Photography by Robert Seale<br />

it makes us more courageous<br />

because it allows us to stand<br />

firm with our principles – even<br />

if, at times, it means we must<br />

stand alone.”<br />

Integrity is as essential in the<br />

public arena as it is in the workplace,<br />

said Tillerson. Worldwide,<br />

people and their governments<br />

are debating policies that will<br />

govern the energy industry’s<br />

research and investments as well<br />

as the world’s economic health.<br />

“In these debates,” Tillerson<br />

said, “you stand between the<br />

public policymakers and the public<br />

itself. Your voice will be needed<br />

to separate scientific fact from<br />

science fiction and economic<br />

realities from wishful thinking.”<br />

Tillerson said that ethical leadership<br />

in a wide range of fields is<br />

essential to ensuring the integrity<br />

of the scientific process.<br />

“Whether it is in business operations,<br />

technical challenges or in<br />

ethical questions, integrity is a commitment<br />

to do the right things, the<br />

right way, every time – whether or<br />

not anyone is looking.”<br />

The enduring need<br />

for integrity<br />

Senior Vice President Mike Dolan,<br />

in delivering the Silas Lecture at<br />

Georgia Tech University, said that<br />

while the world has changed significantly<br />

over the decades, “the relationship<br />

between ethical leadership,<br />

a corporation’s culture and longterm<br />

engineering success has not.”<br />

As the energy industry strives<br />

to meet rising energy demand,<br />

oil and natural gas companies

must manage a multitude of<br />

risks – financial, technological,<br />

operational, geopolitical and environmental.<br />

For <strong>ExxonMobil</strong>, said<br />

Dolan, “sound engineering must<br />

take into account effective risk<br />

management, and the best way<br />

to ensure that is to build a corporate<br />

culture that supports ethical<br />

leadership.”<br />

Dolan said that <strong>ExxonMobil</strong>’s<br />

commitment to business principles<br />

is part of its business model.<br />

“Central to this commitment is<br />

the global use of our Operations<br />

Integrity Management System,”<br />

he said. “This provides a structured<br />

approach for assessing<br />

safety, security, health and environmental<br />

risks, establishing procedures<br />

for mitigating concerns,<br />

monitoring conformance with<br />

standards and reporting results<br />

to management.”<br />

<strong>ExxonMobil</strong>’s belief in ethical<br />

leadership is also demonstrated<br />

in its support for economic<br />

development and its commitment<br />

to human rights.<br />

“We understand that our longterm<br />

success is strengthened by<br />

economic and social progress,”<br />

Dolan said. “We believe that<br />

practicing ethical leadership is<br />

not only the right thing to do,<br />

but also the best thing to do to<br />

achieve long-term, sustainable<br />

business success.”<br />

Ethics in engineering<br />

Senior Vice President Mark<br />

Albers shared his perspective on<br />

ethics with the graduating class<br />

of Texas A&M University at Qatar<br />

earlier this year.<br />

“As scientists and engineers,<br />

we must face the reality that we<br />

shoulder many of modern society’s<br />

hopes and dreams,” he said.<br />

“Our work and our achievements<br />

make it possible for people the<br />

world over to lead safe, healthy,<br />

productive and meaningful lives.<br />

Because of the important role we<br />

play, we have a special responsibility<br />

to uphold the highest standards<br />

of integrity.”<br />

Albers cited three areas in<br />

which integrity is essential:<br />

“Operational integrity, which<br />

means doing things the right<br />

way. Technical integrity, which<br />

protects the research and development<br />

process, drives accountability<br />

and strengthens our focus<br />

on science-based solutions.<br />

Exxon Mobil Corporation headquarters, Irving, Texas.<br />

And personal integrity as a key<br />

element in building trust, which<br />

strengthens our ability to work as<br />

a team, makes it possible to build<br />

lasting partnerships and improves<br />

the effectiveness of our entire<br />

organization.”<br />

Albers encouraged students to<br />

seek out employers that set “high<br />

standards for personal conduct<br />

and reward ethical leadership.”<br />

“Identify mentors who exemplify<br />

proper behavior, and learn<br />

from them,” he said. “See how<br />

they deal with others. Study how<br />

they make decisions.”<br />

The world faces unlimited possibilities<br />

in what can be achieved<br />

in the years to come, Albers said,<br />

“if we act with integrity and focus<br />

on doing what is right versus<br />

what is easy.” the Lamp<br />

4

5<br />

Unlocking the secrets<br />

of the U.S. subsalt<br />

Story by Mike Long<br />

<strong>ExxonMobil</strong> geoscientists use advanced technology<br />

to find significant oil and gas resources in the Gulf<br />

of Mexico. Their work could prove highly beneficial<br />

in adding to future U.S. energy supplies.

An <strong>ExxonMobil</strong> exploration effort<br />

more than a decade in the making<br />

yielded oil and natural-gas<br />

discoveries that together represent<br />

one of the largest finds<br />

in the Gulf of Mexico since the<br />

late 1990s. It also strengthened<br />

hope that the Gulf still has major<br />

potential to supply future U.S.<br />

energy needs.<br />

The combined resources from<br />

two major oil fields and a gas field<br />

discovered 250 miles southwest<br />

of <strong>New</strong> Orleans total more than<br />

700 million oil-equivalent barrels<br />

on <strong>ExxonMobil</strong>-interest leases.<br />

Development of the<br />

<strong>ExxonMobil</strong>-operated Hadrian<br />

North oil field and Hadrian South<br />

gas field in about 7,000 feet<br />

of water will set a deepwater<br />

record for <strong>ExxonMobil</strong>.<br />

Initial production from the<br />

Lucius oil field and Hadrian<br />

South is expected in 2014.<br />

The Lucius reservoirs, which<br />

extend into adjoining blocks operated<br />

by Anadarko Petroleum<br />

Corp., are planned to be developed<br />

under a unitization agreement<br />

between <strong>ExxonMobil</strong>,<br />

Anadarko, Plains Exploration &<br />

Production Company, Apache<br />

Deepwater LLC, Petrobras<br />

America Inc. and Eni Petroleum<br />

US LLC. Gas production from<br />

Hadrian South is planned to be<br />

transported by pipeline to the<br />

Lucius production facility under<br />

a separate production-handling<br />

agreement. Both agreements will<br />

help speed production startup<br />

and lower costs.<br />

As development moves forward,<br />

the discovery of the Hadrian<br />

fields is primarily a story of how<br />

<strong>ExxonMobil</strong> geoscientists working<br />

at the leading edges of exploration<br />

technology were able to “see”<br />

what couldn’t be seen before.<br />

The subsalt puzzle<br />

The discoveries are in the Gulf’s<br />

ultra-deepwater subsalt play – an<br />

area extending west to east some<br />

250 miles and located about 270<br />

miles off the Texas and Louisiana<br />

shores in water 5,000 to 10,000<br />

feet deep. Below the seafloor,<br />

and extending across much of<br />

the play, are sections of salt up to<br />

10,000 feet thick.<br />

Some 170 million years ago,<br />

this salt was initially deposited<br />

as a near-continuous layer.<br />

Over millions of years, sediments<br />

deposited onto the salt<br />

forced it into a variety of shapes,<br />

some near-vertical and others<br />

more lateral. The natural forces<br />

pinched off some areas, creating<br />

salt canopies that now overlie<br />

thick sedimentary sections.<br />

Drilling in shallower waters in<br />

the 1980s and 1990s revealed<br />

the presence of potential hydro-<br />

Texas<br />

<strong>ExxonMobil</strong> Exploration’s<br />

(from left) Ricardo Livieres,<br />

John Emerick and Nick Way<br />

were part of the Hadrianarea<br />

exploration team.<br />

While more than 50,000 wells<br />

have been drilled in the Gulf<br />

of Mexico, the amount of<br />

undrilled acreage in the subsalt<br />

trend is substantial.<br />

Louisiana<br />

Subsalt trend Wells drilled<br />

Gulf of Mexico<br />

6

carbon-bearing reservoirs below<br />

these displaced salt features.<br />

However, the imaging technology<br />

allowing geoscientists to plan<br />

exploration wells to determine the<br />

commercial potential of subsalt<br />

prospects was still in very early<br />

development.<br />

A faint bump<br />

That didn’t stop <strong>ExxonMobil</strong><br />

seismic interpreter Flip Koch from<br />

putting pencil to paper to analyze<br />

newly acquired seismic data prior<br />

to a 1999 Gulf lease sale.<br />

Koch detected a structure<br />

beneath the subsalt that<br />

appeared as a faint “bump” on<br />

several seismic lines in an unexplored<br />

area that possibly others<br />

had not detected. As it turned<br />

out, <strong>ExxonMobil</strong> was the only<br />

7<br />

company to bid on the Keathley<br />

Canyon blocks that would eventually<br />

yield hundreds of millions of<br />

barrels of oil.<br />

Ricardo Livieres played a key<br />

role on the technical team that<br />

followed up Koch’s work to confirm<br />

that the Hadrian blocks represented<br />

a “good neighborhood”<br />

for oil and gas exploration.<br />

“We learned that a strong system<br />

was present for generating<br />

hydrocarbons, a number of reservoirs<br />

were available to explore<br />

and that the structure covered a<br />

large area,” says Livieres. “But you<br />

never know for sure until you drill.”<br />

Hadrian-1, drilled in 2004-<br />

2005 to a total depth of 27,973<br />

feet, proved dry in the deep<br />

objective. However, hydrocarbon-bearing<br />

reservoirs were<br />

Adrian Foster (left), Stephen Welch (center) and Dennis Brock<br />

review how to apply learnings from the Hadrian-area discoveries<br />

to future exploration and development in the subsalt trend.<br />

found in the shallower formations<br />

at about 20,000 feet.<br />

“After that first well, we knew<br />

we had hydrocarbons present,<br />

so we focused our technical<br />

work to understand where they<br />

went and where we should drill<br />

next,” says Nick Way, exploration<br />

project manager.<br />

Where’s the salt?<br />

Expanding on some basic geotechnical<br />

observations, Livieres<br />

began projecting out the small<br />

oil accumulations detected in<br />

Hadrian-1. The company also<br />

stepped up seismic-processing<br />

efforts to better understand the<br />

geometry of the overlying salt.<br />

“If you can figure out where<br />

the salt is, you have a much<br />

better chance of developing a<br />

clearer image of what’s below<br />

it,” says John Emerick, exploration<br />

supervisor. “Trouble is, salt<br />

significantly distorts seismic<br />

reflections. It can require a year<br />

or more of processing and interpreting<br />

the data to obtain an<br />

improved image.”<br />

Dennis Brock, current exploration<br />

team lead, adds that the<br />

image distortion caused by the<br />

subsalt is like viewing a pencil in<br />

a glass of water.<br />

“The bottom looks bent, but<br />

you know the pencil extends<br />

straight down through the water.<br />

When we attempt interpretations<br />

around the salt, what we see<br />

is that bent image. Things are<br />

not where they should be, plus<br />

they’re fuzzy.”<br />

Good news came in 2008,

when the team’s analysis led to<br />

the drilling of Hadrian-2 and the<br />

discovery of gas and heavy oil.<br />

That work also paved the way<br />

for drilling Hadrian-3 in 2009, a<br />

well that discovered thick reservoirs<br />

filled mostly with oil.<br />

On the cutting edge<br />

As plans progressed for drilling<br />

Hadrian-5, advances in threedimensional<br />

seismic surveys had<br />

vastly increased the volume of<br />

data available for seismic interpreters.<br />

The explorers took these<br />

data and used new high-speed<br />

computers and proprietary seismic-processing<br />

tools to generate<br />

a much-improved image of the<br />

deep, subsalt geology.<br />

“We were applying cuttingedge<br />

technology that had never<br />

been fully vetted in the subsalt,”<br />

says interpreter Stephen Welch.<br />

“We were pushing the limits of<br />

how fast you could apply these<br />

interpretation techniques. But it<br />

led to images that were superior<br />

to anything we could have seen<br />

just three years before.”<br />

Overcoming<br />

moratorium delays<br />

Only two days before<br />

<strong>ExxonMobil</strong> was to begin<br />

drilling Hadrian-5, the then-<br />

U.S. Minerals Management<br />

Service (MMS), now known as<br />

the Bureau of Ocean Energy<br />

Management, Regulation and<br />

Enforcement (BOEMRE), suspended<br />

Gulf operations following<br />

the BP Macondo incident.<br />

Late in 2010, with the drilling<br />

moratorium lifted and <strong>ExxonMobil</strong><br />

required to secure new drilling<br />

permits, the company assembled<br />

a cross-functional team from<br />

Exploration, Drilling, Land,<br />

Regulatory, Law, and Public &<br />

Government Affairs to work with<br />

BOEMRE to get the well reapproved.<br />

The team’s effectiveness<br />

paid off, and Hadrian-5 was the<br />

first new-drill well that BOEMRE<br />

approved after it lifted the moratorium<br />

in March 2011. Only four<br />

days after the permit was issued,<br />

drilling began. Three months<br />

later, the well confirmed a major<br />

oil accumulation that would form<br />

part of the Lucius field.<br />

Continuing Gulf focus<br />

With the Hadrian-area discoveries<br />

moving into development,<br />

exploration activity will continue<br />

in the Gulf of Mexico.<br />

“Our Gulf exploration team<br />

will continue looking at prospects<br />

along the subsalt trend,”<br />

says Adrian Foster, exploration<br />

manager. “We hold a substantial<br />

acreage position, and we intend<br />

to maintain a very active exploration<br />

program in the Gulf.”<br />

From an energy-security<br />

standpoint, Foster notes that the<br />

Gulf also offers an attractive location<br />

to bring reliable and needed<br />

energy supplies to U.S. markets.<br />

“The Gulf will continue to<br />

deliver large discoveries, and we<br />

look forward to continued success<br />

there.” the Lamp<br />

Upside down in the subsalt<br />

Drilling Manager Mark Moyer has experienced just about<br />

every kind of downhole environment possible in managing<br />

engineering and operations for <strong>ExxonMobil</strong> wells<br />

around the world.<br />

Few have proved as complex as the Gulf’s ultra-deepwater<br />

subsalt play, says Moyer.<br />

“Rock formations are normally older the deeper you<br />

drill. With salt movement, however, things can get turned<br />

upside down. For instance, in one well, we encountered<br />

an unusually thick section of older rock above salt and<br />

then found younger rock below it.<br />

“Generally, the older the rock, the harder the rock. Our<br />

drilling slowed to about 3 to 5 feet an hour through this<br />

thick older section versus an average of 50 feet an hour<br />

in the rest of the well.”<br />

Very hard rock can also cause vibrations in the drill string,<br />

which is filled with expensive electronic equipment to measure<br />

downhole conditions and rock properties, he says.<br />

“To avoid equipment damage, we applied the latest<br />

model of <strong>ExxonMobil</strong>’s vibration-analysis software.<br />

An <strong>ExxonMobil</strong> Upstream Research scientist was also<br />

onboard the rig to make adjustments as needed to provide<br />

the smoothest drilling possible.<br />

“Despite the subsalt’s complexity and unpredictability,<br />

we handled the challenges effectively and reduced both<br />

drilling time and costs without compromising safety. Plus,<br />

<strong>ExxonMobil</strong> made a significant discovery. What could be<br />

better than that?”<br />

<strong>ExxonMobil</strong> contracted<br />

the leading-edge Maersk<br />

Developer semi-submersible<br />

to drill the Hadrian-5 well.<br />

8

Life-long learner discovers<br />

wealth of opportunities<br />

Neil Armstrong’s walk<br />

on the moon made a big<br />

impression on Beck.<br />

9 Story by Tracy Torma Photography by Janice Rubin<br />

Photo Corbis Corporation<br />

Jeff Beck has been interested in<br />

science his entire life. The spark<br />

began when he experienced the<br />

futuristic exhibits in the Hall of<br />

Science pavilion built for the 1964<br />

World’s Fair in his neighborhood<br />

of Flushing, Queens, <strong>New</strong> York.<br />

“It was way beyond its time,<br />

and featured new products and<br />

new possibilities for the way<br />

we could live in the future,” he<br />

remembers.<br />

His interest was fueled when<br />

he witnessed the first moon<br />

landing on TV in 1969. His high<br />

<strong>ExxonMobil</strong> scientist Jeff Beck says his interest<br />

in science at an early age led to a life-long quest<br />

for learning. Today, the corporation’s most recent<br />

inductee into the National Academy of Engineering,<br />

and holder of more than 60 patents, is still identifying<br />

new things to contribute to the company’s success.<br />

school yearbook’s prediction<br />

that he would earn a Ph.D. in<br />

chemistry came true in 1989<br />

when he graduated from the<br />

University of Pennsylvania with a<br />

doctorate in inorganic chemistry.<br />

At the time, the oil and gas<br />

industry was rebounding from a<br />

downturn, and Beck found an<br />

opportunity at Mobil to fulfill his<br />

dream of becoming a researcher.<br />

His new job was at the company’s<br />

state-of-the-art laboratory<br />

in Princeton, <strong>New</strong> Jersey.<br />

What began as a narrowly<br />

focused role in research broadened<br />

into a multifaceted career<br />

that provided Beck with opportunities<br />

to use his scientific background<br />

to help the company<br />

address complex energy needs.<br />

The early days<br />

As a young research chemist at<br />

Mobil, Beck recalls: “Free thinking<br />

led to new ideas, and we’d<br />

go into the lab and try them out.”<br />

He became involved in two<br />

significant discoveries, not only<br />

for Mobil and the energy indus-

Much of Jeff Beck’s career has been spent researching<br />

and developing complex catalysts (like the one shown in<br />

the rendering above) that improve chemical processes.<br />

try, but also for the advancement<br />

of basic science. In the<br />

early 1990s, he was a key member<br />

of a team that discovered a<br />

technology patented by Mobil<br />

that opened up a whole new<br />

field of molecular chemistry.<br />

In the mid-1990s, he and his<br />

team created the PxMax and<br />

XyMax catalysts for selective<br />

production of paraxylene, a key<br />

building block in the production<br />

of polyester fiber. Both technologies<br />

are now commercialized in<br />

33 <strong>ExxonMobil</strong> facilities and other<br />

licensee locations operating or<br />

under construction worldwide.<br />

His work to scale up the paraxylene<br />

catalysts for commercial<br />

applications exposed Beck to<br />

the scope of the industry and<br />

the opportunities <strong>ExxonMobil</strong><br />

afforded beyond simply research.<br />

“It made me realize how<br />

robust scientific ideas have to be<br />

in order for them to be commercialized,”<br />

he says.<br />

Above: Jeff Beck’s passion<br />

for science began when he<br />

attended the 1964 World’s Fair<br />

in <strong>New</strong> York and visited many<br />

of the exposition’s futuristic<br />

exhibits. At right, Beck’s<br />

picture from his high school<br />

yearbook, where he stated his<br />

goal was “to go to college and<br />

attain a Ph.D. in chemistry.”<br />

Photo Corbis Corporation<br />

10

The 1964 World’s Fair in <strong>New</strong> York is<br />

best remembered as a showcase of<br />

mid-20th-century American culture<br />

and technology. Fifty-one million<br />

people visited it during its two-year<br />

run, touring major exhibits by IBM,<br />

DuPont and Westinghouse.<br />

Cooperative learning<br />

In 1996, Beck led a team in the<br />

development of new petrochemical<br />

technologies at Mobil laboratories<br />

in Paulsboro, <strong>New</strong> Jersey.<br />

“I learned how catalysts are<br />

applied in refining and petrochemical<br />

processes, and how<br />

engineers design equipment to<br />

optimize their effects,” he says.<br />

“We brought together scientific<br />

and engineering perspectives. It<br />

became clear how scientists work<br />

to create better routes to impor-<br />

11<br />

“ Throughout my career, I learned from<br />

colleagues who are the best in the business<br />

– and that has made all the difference.”<br />

tant molecules or make new ones<br />

the world has never seen before.<br />

Engineers look at a piece of science<br />

and technology and make it<br />

work on a practical basis.”<br />

Shortly thereafter, Beck transferred<br />

to Mobil’s Engineering<br />

Department, where he got his<br />

first direct exposure to refining<br />

processes and operations.<br />

When Exxon and Mobil<br />

merged in 1999, he became<br />

director of the Catalyst<br />

Technology Laboratory for the<br />

Photo Corbis Corporation<br />

Jeff Beck on the caliber of <strong>ExxonMobil</strong> people<br />

Long legacy<br />

Jeff Beck is <strong>ExxonMobil</strong>’s most recent inductee<br />

into the National Academy of Engineering (NAE),<br />

one of the highest professional distinctions<br />

accorded an engineer.<br />

Founded in 1964, the NAE is a private, independent,<br />

nonprofit institution that provides engineering<br />

leadership for U.S. research. Its mission is to<br />

promote the technological welfare of the nation by<br />

tapping into the expertise and insights of eminent<br />

members of the engineering community. In addition<br />

to its role as advisor to the federal government,<br />

the NAE also conducts independent studies<br />

to examine important topics in engineering and<br />

technology.<br />

The rigorous selection process seeks to identify<br />

individuals who have distinguished themselves<br />

as business and academic managers, as technical<br />

experts, as university faculty and as leaders in<br />

government and private engineering organizations.<br />

new <strong>ExxonMobil</strong> Research and<br />

Engineering Company in Clinton,<br />

<strong>New</strong> Jersey. There, he studied<br />

ways to utilize the catalyst technologies<br />

of the two companies<br />

to address <strong>ExxonMobil</strong> refining<br />

and petrochemical products’<br />

manufacturing needs. Soon after,<br />

Beck would find himself doing<br />

something entirely different when<br />

he was asked to serve as technical<br />

manager for the company’s<br />

refinery in Baytown, Texas.<br />

Responsible for daily techni-<br />

cal support of all processes at<br />

the biggest refinery in the United<br />

States, he learned a new side of<br />

the business and gained greater<br />

insight into why <strong>ExxonMobil</strong> provides<br />

its employees with a broad<br />

range of career experiences.<br />

“If you’re going to manage<br />

large groups of people, you<br />

need to understand how different<br />

individuals think and solve<br />

problems,” he says.

The following <strong>ExxonMobil</strong> employees<br />

have been inducted into the NAE:<br />

Jeff Beck – 2011, for discovery and<br />

commercialization of selective, environmentally<br />

beneficial catalytic routes to<br />

major petrochemicals, and for leadership<br />

in industrial engineering.<br />

Amos Avidan – 2009, for contributions<br />

to the understanding, scale-up<br />

and commercialization of fluid-bed reactors,<br />

liquefied natural gas facilities and<br />

gasification plants.<br />

Andrew Jackson – 2009, for contributions<br />

to tribology and research in<br />

elasto-hydrodynamic lubrication, fatigue,<br />

machine efficiency, automotive emissions<br />

and synthetic lubricants.<br />

Enrique Iglesia – 2008, for outstanding<br />

contributions to the understanding<br />

of catalyst structure-function<br />

relationships and the development of<br />

novel catalysts and for leadership in<br />

the field of catalysis.<br />

Shun Chong Fung – 2007, for the<br />

investigation of factors underlying the<br />

deactivation and reactivation of catalysts,<br />

and for the application of the findings<br />

in commercial practice.<br />

Charles Kresge – 2007, for contributions<br />

to the rational design and<br />

engineering of mesoporous inorganic<br />

materials.<br />

Steve Jaffe – 2006, for the development<br />

of computer models describing<br />

complex petroleum processing chemistry<br />

and kinetics, and for contributions to<br />

the optimization of refining operations.<br />

Dream job<br />

After two years in Texas, Beck<br />

landed his dream job back in<br />

<strong>New</strong> Jersey as manager of<br />

<strong>ExxonMobil</strong> Corporate Strategic<br />

Research, where he directed the<br />

technical efforts of more than<br />

250 scientists, engineers and<br />

technicians in all areas of petroleum<br />

and petrochemical science.<br />

“It was like running a science<br />

institute,” he says. “In addition to<br />

working with the chemical, refining<br />

and upstream groups, we<br />

Frederick Krambeck – 1999, for<br />

advancing the theory of complex reacting<br />

mixtures, and for applying chemical<br />

reaction engineering principles to the<br />

design of commercial processes.<br />

Lee Raymond – 1999, for keeping<br />

a major oil company at the forefront of<br />

exploration and production technology.<br />

James Katzer – 1998, for research<br />

on catalysis and reaction engineering,<br />

and for leadership in commercializing<br />

catalytic processes.<br />

Arnold Stancell – 1997, for petrochemcial<br />

research and development,<br />

and for management of oil and gas<br />

resources.<br />

Michael Ramage – 1996, for contributions<br />

to chemical reactor engineering,<br />

and for engineering leadership.<br />

Nai Chen – 1990, for discovery of<br />

commercially important shape-selective<br />

catalytic processes for producing premium<br />

fuels and lubricants.<br />

James Mathis – 1990, for outstanding<br />

research management in the<br />

petroleum industry, and for application<br />

of chemical technology to the public<br />

welfare.<br />

Richard Tucker – 1987, for fostering<br />

an atmosphere for integrating research<br />

and engineering with innovation, and<br />

for pioneering macro-engineering technologies<br />

in the petroleum and chemical<br />

areas.<br />

also worked with the corporation<br />

on alternative energy solutions.”<br />

While there, Beck led a team<br />

that negotiated <strong>ExxonMobil</strong>’s<br />

$600 million research collaboration<br />

with Synthetic Genomics,<br />

Inc. in algae-based biofuels, and<br />

managed several other efforts in<br />

alternative energy, and in carbon<br />

capture and storage.<br />

Opportunity came knocking<br />

again in 2010, when he<br />

was appointed global polyethylene<br />

marketing manager for<br />

John Wise – 1986, for inspiring technical<br />

contributions and leadership in the<br />

development and commercialization of<br />

important petroleum, petrochemical and<br />

synthetic fuels processes.<br />

Vern Weekman Jr. – 1985, for pioneering<br />

contributions in applying theory<br />

to practice, and for combining technological<br />

achievement with engineering<br />

education.<br />

Seymour Meisel – 1981, for integrating<br />

basic exploratory research and<br />

process-engineering developments<br />

leading to successful commercialization<br />

of important new technology.<br />

James Wei – 1978, for advancement<br />

of chemical engineering by mathematical<br />

analysis of complex reaction of such<br />

analysis to commercial processes.<br />

Lawrence Swabb – 1977, for<br />

leadership in synthetic fuels research,<br />

particularly in the development of the<br />

hydroforming process for hydrocarbon<br />

conversion.<br />

Paul Weisz – 1977, for contributions<br />

in pioneering the use of molecular<br />

sieves as cracking catalysts for petroleum<br />

hydrocarbons.<br />

John Sinfelt – 1975, for contributions<br />

in catalysis by metals and bi-functional<br />

catalysis, and especially for the concept<br />

of polymetallic-cluster catalysts.<br />

Harold Fisher – 1969, for advances<br />

in research, engineering and management<br />

in the petroleum industry.<br />

<strong>ExxonMobil</strong> Chemical Company<br />

in Houston. “This is perhaps<br />

the most different of my jobs,”<br />

he notes. “It involves customer<br />

relationships and understanding<br />

market dynamics for products.<br />

It’s pure business, but the business<br />

is based on technology,<br />

and I’m finding a way to use my<br />

technical expertise to enhance<br />

my impact in the job.”<br />

He advises new graduates<br />

just beginning careers in science<br />

and technology to be open to<br />

new opportunities.<br />

“Begin by being the best<br />

scientist or engineer you can<br />

be,” he says. “Then learn how<br />

the world has been changed by<br />

science and engineering. You<br />

may just find out that you want<br />

to learn more about that part of<br />

it as well. You may even end up<br />

just like a kid from Queens trying<br />

to solve the world’s toughest<br />

energy problems.” the Lamp<br />

12

When a pipeline contractor<br />

working for Mobil Producing<br />

Nigeria (MPN), an Exxon Mobil<br />

Corporation affiliate, installed<br />

2,000 tons of specialized pipelines<br />

in the Edop-Idoho field<br />

offshore Akwa Ibom State, it<br />

caused quite a stir within the<br />

country’s oil and natural gas<br />

industry – and with good reason.<br />

The 24-inch-diameter pipes,<br />

manufactured by SCC Mills<br />

Abuja and coated by Adamac<br />

Pipes Coating and Services<br />

Limited, represented the first time<br />

that the industry used made-in-<br />

Nigeria pipes in an offshore oil<br />

and gas installation here.<br />

Such a feat would have been<br />

unheard of as little as five years<br />

ago. But the Nigerian National<br />

Petroleum Corporation encouraged<br />

companies, whenever<br />

13<br />

First made-in-Nigeria pipe<br />

breaks new ground<br />

Story by Ozemoya Okordion<br />

Program encourages continuing investments<br />

in local engineering and fabrication yards.<br />

Mobil Producing Nigeria (MPN) Executive Vice Chairman Cyril Odu (left) and Ernest<br />

Nwapa, executive secretary of the Nigerian Content Development and Monitoring Board,<br />

discuss the progress that has been made in local content development in Nigeria by MPN.<br />

possible, to use pipelines manufactured<br />

in-country for local projects.<br />

At the time, SCC Mills only<br />

had experience making the kind<br />

of pipes needed to transport<br />

water, not oil and gas.<br />

“We worked extensively with<br />

SCC Mills and National Petroleum<br />

Investment Management Services<br />

(NAPIMS) for four years to<br />

develop new specifications for<br />

the pipes, so they would meet<br />

international standards for lowpressure<br />

and shallow-water applications,”<br />

says Cyril Odu, MPN<br />

executive vice chairman.<br />

Collaboration showcased<br />

The achievement, which industry<br />

experts consider remarkable<br />

given the limited local fabrication<br />

capability just a few years<br />

before, showcased a collabora-<br />

tive effort by MPN, NAPIMS,<br />

other Nigerian government<br />

agencies and service contractors.<br />

For example, MPN<br />

arranged for joint visits with<br />

SCC Mill employees to South<br />

Africa and South Korea to study<br />

mill facilities and materials procurement.<br />

They traveled to the<br />

United States to learn engineering<br />

standards. MPN retained<br />

experienced inspectors to train<br />

SCC workers in proper pipemilling<br />

procedures.<br />

Adamac Pipes established<br />

local sources for the iron ores<br />

needed for the coating services,<br />

while other companies, such<br />

as Saipem Nigeria Ltd, were<br />

brought in to handle marine<br />

operations for welding and laying<br />

the pipelines on the seabed.<br />

But the combined efforts led<br />

to contracts creating hundreds<br />

of direct and indirect jobs for<br />

Nigerians.<br />

“It culminates many years<br />

of hard work,” says Morrison<br />

Fiddi, group general manager<br />

of NAPIMS. “With this, oil and<br />

gas companies in Nigeria can<br />

procure quality pipes produced<br />

locally at significantly lower cost<br />

than if they were purchased<br />

from foreign suppliers.”<br />

Understandably, the Nigerian<br />

government is excited by the<br />

accomplishment, which could<br />

spur additional investments in<br />

local engineering and fabrication<br />

yards, creating even more jobs<br />

for local workers. In fact, officials<br />

estimate that three or four new<br />

mills and other manufacturing<br />

plants will be built around the<br />

country in the next four years.

When offshore pipelines needed to be replaced,<br />

Mobil Producing Nigeria used a local manufacturer –<br />

an industry first for a Nigerian oil and gas facility.<br />

“It holds huge economic significance<br />

for Nigeria,” says Ernest<br />

Nwapa, executive secretary of the<br />

Nigerian Content Development<br />

and Monitoring Board. “We<br />

expect it will attract companies<br />

and individuals to invest in pipe<br />

mills and threading plants, or<br />

upgrade fabrication yards and<br />

machine shops, and other critical<br />

facilities to build Nigerian capacity<br />

and limit the importing of pipes<br />

and other products.”<br />

Strict standards upheld<br />

Nwapa says that companies<br />

doing business in Nigeria could<br />

not purchase locally made products<br />

because they did not meet<br />

the necessary strict international<br />

certification standards. But that<br />

has now changed. He says that<br />

extensive tests on the pipes<br />

both locally and overseas confirmed<br />

that they meet or exceed<br />

required technical specifications.<br />

“Not only do we have pending<br />

orders for more than 60 miles of<br />

specialized pipelines that will be<br />

made here,” Nwapa says, “but<br />

we are using the model created<br />

by MPN to ensure that industry<br />

quality and safety standards are<br />

met, and to help other local firms<br />

in developing their pipe mills.<br />

“MPN initiated this effort even<br />

when there was no expectation<br />

to do so,” Nwapa notes. “This<br />

demonstrated a commitment to<br />

pursue a national aspiration, and<br />

MPN should be proud for pioneering<br />

this courageous move.<br />

“This will surely boost Nigerian<br />

content development, create<br />

more opportunities for training,<br />

and sustain the employment<br />

of Nigerians in the oil and gas<br />

industry,” he says. the Lamp<br />

14

15<br />

A historic agreement<br />

The strategic cooperation<br />

agreement signed in August by<br />

<strong>ExxonMobil</strong> and Rosneft involves<br />

planned joint exploration and<br />

development of oil and naturalgas<br />

resources in Russia, the<br />

United States and other countries<br />

as well as the sharing of technology<br />

and expertise.<br />

If successful, the program<br />

will involve investments of up<br />

to $3.2 billion for exploration of<br />

East Prinovozemelskiy Blocks<br />

1, 2 and 3 in the Kara Sea, and<br />

the Tuapse License Block in the<br />

Black Sea. These are among<br />

Story by Bob Davis<br />

the most promising and least<br />

explored offshore areas in the<br />

world, with high potential for liquids<br />

and gas.<br />

Rex W. Tillerson, chairman<br />

and CEO of Exxon Mobil<br />

Corporation, who attended the<br />

ceremony with Russian Prime<br />

Minister Vladimir Putin, said<br />

<strong>ExxonMobil</strong> will benefit Russian<br />

energy development by working<br />

closely with Rosneft.<br />

“This large-scale partnership<br />

represents a significant strategic<br />

step by both companies,”<br />

Tillerson said. “This agreement<br />

<strong>ExxonMobil</strong> and Rosneft ink broad<br />

program for exploration, technologysharing<br />

and joint international projects.<br />

takes our relationship to a new<br />

level and will create substantial<br />

value for both companies.”<br />

Signing the agreement<br />

on behalf of <strong>ExxonMobil</strong><br />

Development Company, President<br />

Neil Duffin said, “Today’s agreement<br />

with Rosneft builds on<br />

our 15-year successful relationship<br />

in the Sakhalin-1 project.<br />

Our technology, innovation and<br />

project-execution capabilities will<br />

complement Rosneft’s strengths<br />

and experience, especially in the<br />

area of understanding the future<br />

of Russian shelf development.”<br />

“We have a clear vision for<br />

Rosneft’s strategic direction –<br />

building world-class expertise in<br />

offshore business and enhancing<br />

oil recovery,” said Rosneft<br />

President Eduard Khudainatov,<br />

following the signing ceremony<br />

in Russia.<br />

“The partnership between<br />

Rosneft, with its unique resource<br />

base, and the largest and one of<br />

the most highly capitalized companies<br />

in the world reflects our<br />

commitment to increasing capitalization<br />

of our business through<br />

application of best-in-class tech-

nology, an innovative approach<br />

to business management, and<br />

enhancement of our staff potential,”<br />

Khudainatov said. “This<br />

venture comes as a result of<br />

many years of cooperation with<br />

<strong>ExxonMobil</strong>, and brings Rosneft<br />

into large-scale world-class projects,<br />

turning the company into a<br />

global energy leader.”<br />

Rosneft will have the opportunity<br />

to gain equity interest in a<br />

number of <strong>ExxonMobil</strong>’s exploration<br />

plays in North America,<br />

including deepwater Gulf of<br />

Mexico and tight-oil fields in<br />

Texas, plus additional opportunities<br />

in other countries. The<br />

More than 30 million acres<br />

of exploration potential<br />

The East Prinovozemelskiy License Blocks encompass 30<br />

million acres in water depths ranging from 165 feet to 500<br />

feet. The Tuapse Block in the Black Sea has the total area of<br />

2.8 million acres with water depths ranging from 3,300 feet<br />

to 6,500 feet. Rosneft equity interest in both joint ventures<br />

will be 66.7 percent, while <strong>ExxonMobil</strong> will hold 33.3 percent.<br />

In the course of the projects, the companies will use<br />

global best practices to develop state-of-the-art safety and<br />

environmental protection systems.<br />

companies have also agreed<br />

to conduct a joint study involving<br />

the development of tight-oil<br />

resources in Western Siberia.<br />

In addition, an Arctic Research<br />

and Design Center for Offshore<br />

Developments in St. Petersburg<br />

will be created. Staffed by<br />

<strong>ExxonMobil</strong> and Rosneft employees,<br />

the center will use proprietary<br />

<strong>ExxonMobil</strong> and Rosneft technologies,<br />

and will develop new<br />

technology to support the joint<br />

Arctic projects, including drilling,<br />

production and ice-class drilling<br />

platforms, and other projects.<br />

The agreement provides for<br />

constructive dialogue with the<br />

Russian Federation government<br />

concerning creation of a fiscal<br />

regime based on global best<br />

practices.<br />

Rosneft and <strong>ExxonMobil</strong> also<br />

will create a program of staff<br />

exchanges of technical and<br />

management employees that will<br />

help strengthen the relationships<br />

between the companies and<br />

provide valuable career-development<br />

opportunities. the Lamp<br />

Photo Corbis Corporation<br />

16

17<br />

<strong>New</strong> energy<br />

for the Asia-Pacific market<br />

Story by Thomas L. Torget Photography by John Krutop, Michael Kotlen and Bob Crogan<br />

<strong>ExxonMobil</strong> and its joint-venture partners are developing a<br />

major new liquefied natural gas project in <strong>Papua</strong> <strong>New</strong> <strong>Guinea</strong><br />

to help meet the region’s rapidly growing energy demand.<br />

Five Bell 412 helicopters stay busy transporting passengers and<br />

cargo, both on and offshore. The personnel helicopters can carry<br />

as many as nine passengers, and cargo helicopters can carry<br />

up to 1,500 pounds of construction supplies. These helicopters<br />

travel up to 160 miles an hour with a range of 460 miles.

Construction crews will<br />

install more than 500 miles<br />

of pipeline, both onshore<br />

and offshore. The main gas<br />

pipeline will travel from an<br />

elevation above 9,000 feet in<br />

the Highlands to sea level.<br />

Nowhere in the world is energy<br />

demand rising faster than in the<br />

Asia-Pacific region. Energy use there<br />

is expected to grow by two-thirds<br />

during the next 25 years, which is<br />

equivalent to adding the population<br />

of another Australia to the region<br />

every 18 months.<br />

To help meet this soaring<br />

demand, Exxon Mobil Corporation<br />

subsidiary Esso Highlands Limited<br />

is working with six joint-venture<br />

partners to develop a major liquefied<br />

natural gas (LNG) project in<br />

resource-rich <strong>Papua</strong> <strong>New</strong> <strong>Guinea</strong>.<br />

Known as PNG LNG, the project<br />

is a multiphase development that<br />

The Hides Gas Conditioning Plant is now under<br />

construction. From here, the natural gas will travel<br />

by pipeline to the LNG plant north of Port Moresby.<br />

will include gas production and<br />

processing facilities, onshore and<br />

offshore pipelines, and a liquefaction<br />

plant with a capacity of 6.6<br />

million tons a year of LNG. The gas<br />

will be sold to customers in China,<br />

Japan and Taiwan, with deliveries<br />

expected to begin in 2014. During<br />

its 30-year life, the venture should<br />

produce more than 9 trillion cubic<br />

feet of natural gas. Investment in the<br />

initial phase of the project, excluding<br />

the cost of building ships, is<br />

estimated at $15 billion. More than<br />

9,300 workers are now involved in<br />

construction of the facilities.<br />

18

19<br />

William Siriam climbs aboard his<br />

Caterpillar front-end loader to<br />

excavate material at the site of<br />

the LNG processing and storage<br />

facility. Designed to have a low<br />

environmental impact, the plant<br />

is being built northwest of Port<br />

Moresby on the Gulf of <strong>Papua</strong>.<br />

Project Execution Engineer Kelly<br />

Canning learns about butterfly<br />

harvesting from Highlands butterfly<br />

and orchid farmer Lawrence<br />

Kage. Kage is also chairman of the<br />

Lake Kutubu Wildlife Reserve, an<br />

organization that works with local<br />

villagers to support sustainable<br />

fishing practices.<br />

Spectacular Beaver Falls is along the Soroga River<br />

in the Southern Highlands of <strong>Papua</strong> <strong>New</strong> <strong>Guinea</strong>.<br />

Because of extremely rugged terrain in the area,<br />

most people only see the falls from an aircraft.

To support local education,<br />

PNG LNG has provided supplies<br />

to more than 22,500 students<br />

like Jacinta, shown with her<br />

younger brother Eric.<br />

Upstream North Land and<br />

Community Affairs Manager<br />

David Ekins (left) and<br />

Upstream Area Construction<br />

Manager Jim Smith confer<br />

during a visit to Nogoli Camp<br />

in the Southern Highlands.<br />

20

21<br />

Project has seven participants<br />

Participating interests in PNG LNG<br />

include Esso Highlands Limited as operator<br />

(33.2%), Oil Search Limited (29%),<br />

National Petroleum Company PNG (PNG<br />

Government, 16.6%), Santos Limited<br />

(13.5%), JX Nippon Oil and Gas Exploration<br />

(4.7%), Mineral Resources Development<br />

Company (PNG landowners, 2.8%) and<br />

Petromin PNG Holdings Limited (0.2%).<br />

Juha production facility<br />

250 mcfd<br />

Illustration by Pat Gabriel<br />

Jascintha RuMark, a civil<br />

quality inspector, says that<br />

<strong>ExxonMobil</strong>’s safety and<br />

environmental culture has<br />

been instilled into the lives<br />

of everyone on the project.<br />

Rich gas line<br />

Liquids line<br />

Hides gasconditioning<br />

plant<br />

960 mcfd<br />

Angore<br />

wellheads<br />

Liquids line to Kutubu<br />

Gas line to LNG plant

Kutubu<br />

oil facility<br />

(existing)<br />

Australia<br />

The project’s newly constructed Mubi<br />

River bridge provides access from the<br />

lowlands in the south to the Highlands<br />

in the north. The 435-foot bridge, near<br />

Beaver Falls, is the longest of its type<br />

in <strong>Papua</strong> <strong>New</strong> <strong>Guinea</strong>.<br />

•Wewak<br />

Kopi<br />

•<br />

Oil export<br />

platform<br />

(existing)<br />

Subsea gas<br />

line<br />

250 miles<br />

<strong>Papua</strong> <strong>New</strong> <strong>Guinea</strong><br />

•Lae<br />

LNG plant<br />

•<br />

Port Moresby<br />

National Workforce Development<br />

Manager Patti McNulty (center)<br />

is shown with the first group of<br />

operations and maintenance<br />

technicians to complete initial<br />

training before the group heads<br />

to Nova Scotia, Canada, for a<br />

year of advanced skills training.<br />

Initial LNG supplies to Asia<br />

PNG LNG will supply four major customers in<br />

Asia through long-term sales, including: CPC<br />

Corporation, Taiwan; Osaka Gas Company<br />

Limited; The Tokyo Electric Power Company<br />

Inc.; and Unipec Asia Company Limited, a<br />

subsidiary of China Petroleum and Chemical<br />

Corporation (Sinopec). the Lamp<br />

To learn more<br />

pnglng.com<br />

22

Millennium, a sculpture commissioned<br />

for the grand opening of the Singapore<br />

Chemical Plant in 2002, embodies<br />

Singapore’s can-do spirit.<br />

23<br />

Story by Mike Long<br />

A can-do spirit<br />

thrives in Singapore<br />

<strong>ExxonMobil</strong>’s Singapore Chemical Plant celebrates<br />

10 years of progress – and the best is yet to come.<br />

The Singapore Chemical Plant (foreground) and Singapore Refinery<br />

form <strong>ExxonMobil</strong>’s largest integrated manufacturing complex in Asia.<br />

At the January 2002 grand opening<br />

of the <strong>ExxonMobil</strong> Singapore<br />

Chemical Plant (SCP), then-Singapore<br />

Deputy Prime Minister Lee<br />

Hsien Loong dedicated a sculpture<br />

commissioned for the event.<br />

Titled Millennium, the life-sized<br />

statue, representing a “tapestry of<br />

humanity,” was crafted by a visually<br />

impaired artist to embody the<br />

can-do spirit of Singapore.<br />

That same spirit also marks<br />

the continued operational excellence<br />

and growth of SCP.<br />

From the initial $2 billion<br />

grassroots investment to construct<br />

the facility, to the ongoing<br />

upgrades that provide even<br />

greater advantages for chemical<br />

and refining integration, the complex<br />

represents <strong>ExxonMobil</strong>’s<br />

largest single investment in the<br />

Asia-Pacific region.<br />

Encompassing some 200<br />

acres on Jurong Island, most<br />

of which was reclaimed from<br />

the sea, the SCP site is fully<br />

integrated with the 605,000-barrel-a-day<br />

Singapore Refinery.<br />

Together they form <strong>ExxonMobil</strong>’s<br />

largest integrated manufacturing<br />

complex in Asia.<br />

A global player<br />

SCP plays a key role in supporting<br />

the company’s manufacturing<br />

and supply network globally<br />

as well as regionally.<br />

It features a world-scale<br />

steam cracker that uses<br />

<strong>ExxonMobil</strong> technology to process<br />

hydrocarbon feedstock<br />

from the Singapore Refinery and<br />

other Asia-Pacific sources to<br />

produce 1.5 million tons of basic<br />

chemicals a year. These include<br />

ethylene, propylene and butylenes<br />

for use in making plastics<br />

and other products. In addition,<br />

byproducts from the steam<br />

cracker are sent to cogeneration<br />

units to generate steam and<br />

electricity for powering the entire<br />

refining and chemical complex.<br />

SCP serves more than 15<br />

major markets with a variety of<br />

products, including:<br />

Polypropylene, used to make<br />

automotive trim parts, appliances<br />

and other consumer<br />

products<br />

Polyethylene, used in numerous<br />

products such as flexible<br />

food packaging, milk bottles<br />

and storage containers<br />

Oxo-alcohols, converted into<br />

plasticizers that enhance the<br />

quality of finished products<br />

including cable insulation, floor<br />

tiles, caulking and gloves<br />

Industry and<br />

community honors<br />

The complex has received<br />

numerous awards for excellence<br />

in safety and environmental performance.<br />

These include honors<br />

from the Singapore Chemistry<br />

Industry Council for employee<br />

health and safety, community<br />

awareness and emergency<br />

response, pollution prevention,

process safety, product stewardship<br />

and distribution.<br />

Active in the community, SCP<br />

has supported a number of<br />

educational initiatives. It was also<br />

instrumental in the startup of the<br />

Neighborhood Environmental<br />

Safety and Health Network, which<br />

promotes best-practice sharing<br />

in safety, health and environment<br />

among its industrial neighbors.<br />

Size to double<br />

In 2007, <strong>ExxonMobil</strong> began construction<br />

of a second world-scale<br />

steam cracker and associated<br />

derivative units to be fully inte-<br />

grated with SCP and the refinery.<br />

The project includes construction<br />

of new polyethylene,<br />

polypropylene and specialty<br />

elastomers plants, an aromaticsextraction<br />

unit and expansion of<br />

oxo-alcohol production.<br />

Upon startup of the cracker<br />

in the second half of 2012, the<br />

expansion will have doubled<br />

SCP’s size to make the integrated<br />

refining and petrochemical<br />

complex <strong>ExxonMobil</strong>’s largest<br />

in the world. The complex will<br />

also become a showcase for the<br />

<strong>ExxonMobil</strong> model of refinery and<br />

chemical integration, combining<br />

This 15-story steam-cracking furnace weighing the equivalent<br />

of five jumbo airliners is one of seven that are part of a project<br />

to double the size of the Singapore Chemical Plant.<br />

the company’s strengths in feedstock<br />

flexibility, operating excellence<br />

and production efficiency.<br />

SCP Manager Derk Jan<br />

Hartgerink recalls attending a<br />

meeting in the early 1990s when<br />

the idea of an integrated chemical<br />

plant was first discussed.<br />

“We put together a preliminary<br />

blueprint, mainly just a concept,”<br />

says Hartgerink, who was serving<br />

as feedstock coordinator<br />

for a planning group that at the<br />

time was called Exxon Chemical<br />

Major Ventures Asia Pacific. “The<br />

plans were reworked over several<br />

years as new manufacturing and<br />

processing technologies became<br />

available. To have seen SCP grow<br />

from the idea stage to become<br />

one of the world’s<br />

largest sources<br />

of petrochemical<br />

products has<br />

To learn more<br />

exxonmobil.com/<br />

chemical<br />

been a remarkable experience.<br />

“Now, as we celebrate SCP’s<br />

10th anniversary, we are about<br />

to complete a major expansion<br />

that should make our 20th anniversary<br />

twice as exciting. I look<br />

forward to that celebration with<br />

much anticipation.” the Lamp<br />

24

25<br />

Champion race<br />

drivers swap cars<br />

to showcase Mobil 1 lubricants<br />

NASCAR’s Tony Stewart and Formula 1’s<br />

Lewis Hamilton trade rides at legendary<br />

Watkins Glen International.<br />

Story by Thomas L. Torget<br />

Imagine football quarterback<br />

Peyton Manning firing fastballs<br />

from the pitcher’s mound at<br />

Yankee Stadium. Or baseball’s<br />

Derek Jeter calling signals as quarterback<br />

of the Dallas Cowboys.<br />

Two famous race car drivers<br />

did something almost as amazing<br />

earlier this year, when they traded<br />

cars and took turns speeding<br />

around Watkins Glen International<br />

raceway in <strong>New</strong> York.<br />

Tony Stewart earns his living<br />

driving stock cars in the United<br />

States in races sanctioned by the<br />

National Association for Stock<br />

Car Auto Racing (NASCAR).<br />

Lewis Hamilton drives Formula 1<br />

race cars in Grand Prix events,<br />

sanctioned by the Federation<br />

Internationale de l’Automobile<br />

(FIA) and held around the world.<br />

Both drivers are recognized<br />

worldwide as being among auto<br />

racing’s best.<br />

NASCAR and Formula 1 cars<br />

have a number of differences<br />

between them. NASCAR vehicles<br />

are heavier and more powerful.<br />

Formula 1 cars are much smaller<br />

and more aerodynamic. The skills<br />

required for success in each category<br />

differ significantly, and driving<br />

an unfamiliar car at racetrack<br />

speeds presents a real challenge,<br />

even to experienced drivers.<br />

“Mobil 1 has supported championship<br />

racing for more than 30<br />

years,” says Rebecca Aldred,<br />

global brand manager for Mobil 1<br />

synthetic motor oil. “To showcase<br />

that support, we brought these<br />

two champions together so they<br />

could drive each other’s cars on a<br />

challenging course. Because both<br />

cars use Mobil 1, it was a perfect<br />

way to demonstrate the product’s<br />

superior performance under the<br />

extreme conditions of racing.”<br />

Trading places<br />

Before a crowd of race fans and<br />

motorsports journalists from<br />

around the world, Hamilton took<br />

laps in Stewart’s No. 14 Mobil 1/<br />

Office Depot Chevrolet Impala,<br />

while Stewart took the course in<br />

the Vodafone McLaren Mercedes<br />

MP4-23.<br />

“I’d always wondered what

Mobil motor oils are made for the way you drive<br />

<strong>ExxonMobil</strong> is the industry leader in the manufacture<br />

and marketing of synthetic motor oils, from premium-conventional<br />

to advanced-synthetic. Mobil’s<br />

family of motor oils is designed for new as well as<br />

high-mileage vehicles in everyday and extremedriving<br />

conditions. From NASCAR to Formula 1,<br />

American Le Mans to Porsche SuperCup, winning<br />

motorsports teams trust Mobil 1 technology<br />

to deliver the performance and engine protection<br />

needed to meet the grueling demands of the track.<br />

Mobil 1 is recommended by more car builders<br />

than any other brand of synthetic motor oil<br />

Mobil 1 Extended Performance delivers guaranteed<br />

protection of critical engine parts for up to<br />

15,000 miles between oil changes*<br />

Opposite page: David Coulthard,<br />

former Formula 1 racing driver and<br />

winner of 13 Grand Prix events, introduces<br />

Mobil 1 drivers Tony Stewart<br />

and Lewis Hamilton at Watkins Glen<br />

International raceway in <strong>New</strong> York.<br />

Above: Tony Stewart (left) and Lewis<br />

Hamilton get ready to swap cars and<br />

demonstrate their racing skills.<br />

Mobil 1 Advanced Fuel Economy helps improve<br />

fuel economy by up to 2 percent** while providing<br />

outstanding engine protection<br />

Mobil 1 High Mileage is designed specifically for<br />

vehicles with more than 75,000 miles, and contains<br />

additional seal conditioner to help prevent leaks<br />

In addition to producing the best-performing motor<br />

oils for cars, trucks and motorcycles, we also offer<br />

other Mobil 1 products to help keep your vehicles in<br />

top condition. These include automatic transmission<br />

fluids, gear lubricants, synthetic grease and oil filters.<br />

*Please follow the recommendations in your owner’s manual while your car is under warranty.<br />

For more information about the Mobil 1 Extended Performance Guarantee, see www.mobiloil.<br />

com/USA-English/MotorOil/Oils/Mobil_1_Extended_Performance_Warranty.aspx.<br />

** Comparison based upon 2 percent potential fuel economy improvement obtained by switching<br />

from higher viscosity oils to a 0W-20 or 0W-30 grade. Actual savings are dependent upon vehicle/engine<br />

type, outside temperature, driving conditions and your current engine oil’s viscosity.<br />

26

27<br />

Not your family automobiles<br />

At a glance, NASCAR vehicles resemble family sedans. But,<br />

close inspection reveals a car quite different from what’s in your<br />

garage. Every detail of these race cars is engineered for maximum<br />

speed, performance and safety. A typical Sprint Cup Series<br />

car weighs about 3,400 pounds, is powered by an 850-horsepower<br />

engine that produces 530 foot-pounds of torque, and<br />

achieves speeds exceeding 200 miles an hour.<br />

Formula 1 cars feature highly engineered fiber-composite bodies,<br />

open wheels and aerofoil wings front and rear. The wings<br />

create downward force that helps control the vehicle, particularly<br />

around curves. These cars are relatively lightweight (slightly over<br />

1,411 pounds) and have engines that produce over 760 horsepower<br />

revving to 18,000 rpm. Race speeds exceed 240 mph.<br />

it would be like behind the<br />

wheel of a NASCAR stock car,<br />

because it’s completely different<br />

from a Formula 1 car,” says<br />

Hamilton, a native of Stevenage,<br />

England. “Thanks to Mobil 1, I<br />

not only got the chance to drive<br />

the car of Tony Stewart, but<br />

he got to drive my Vodafone<br />

McLaren Mercedes Formula 1<br />

car, too. That was one of the<br />

coolest experiences of my life.”<br />

Hamilton joined the Vodafone<br />

McLaren Mercedes racing team<br />

in 2007 at age 21. At the end<br />

of only his second season in<br />

the sport, he was named FIA<br />

Formula 1 World Champion. He<br />

has now competed in 78 Grand<br />

Prix races, winning 16 times,<br />

most recently at the German<br />

Grand Prix on July 24.<br />

Tony Stewart, who has won<br />

39 Sprint Cup races and two<br />

Sprint Cup championships, says<br />

he’s always been intrigued by<br />

the open-wheel cars used in<br />

Formula 1 racing.<br />

“Feeling the power behind the<br />

Vodafone McLaren Mercedes<br />

was amazing, and being able to<br />

drive it in front of a crowd of avid<br />

race fans at a track like Watkins<br />

Glen made it even more spe

cial,” says Stewart, whose openwheel<br />

experience came in the<br />

IZOD IndyCar Series where he<br />

won the championship in 1997,<br />

along with running Sprint Cars in<br />

the World of Outlaws and Sprint,<br />

Midget and Silver Crown cars in<br />

United States Auto Club racing.<br />

Huge global campaign<br />

“The Mobil 1 car swap allowed<br />

<strong>ExxonMobil</strong> to take advantage<br />

of the tremendous fan interest<br />

in two of Mobil 1’s premier drivers,”<br />

says Debra Emory, global<br />

marketing communications<br />

manager, <strong>ExxonMobil</strong> Lubricants<br />

& Specialties. “Our worldwide<br />

promotion drew more than 100<br />

journalists and photographers<br />

from eight countries to the event<br />

and generated media coverage<br />

in 35 countries.<br />

“In addition, fans and motorsports<br />

reporters posted on<br />

YouTube some 100 videos<br />

about the car swap, which have<br />

been viewed more than 400,000<br />

times. Our car swap tab on the<br />

Mobil 1 Facebook page has<br />

been visited more than 15,000<br />

times. And some 400 messages<br />

from fans and reporters via<br />

Twitter have reached in excess<br />

of 500,000 people.”<br />

Emory estimates that more<br />

than a half-billion consumers<br />

heard about the Mobil 1 car<br />

swap based on the 546 million<br />

media impressions (individuals<br />

who read the story) generated<br />