High Bonding Acrylic Foam Tape - Eyes-e-tools

High Bonding Acrylic Foam Tape - Eyes-e-tools

High Bonding Acrylic Foam Tape - Eyes-e-tools

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

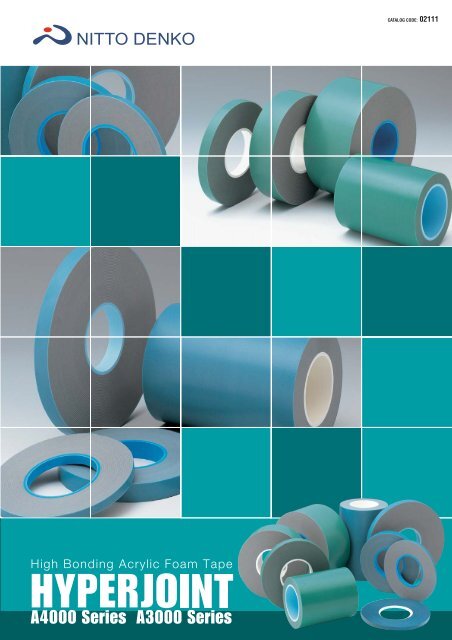

<strong>High</strong> <strong>Bonding</strong> <strong>Acrylic</strong> <strong>Foam</strong> <strong>Tape</strong><br />

CATALOG CODE: 02111

HYPERJOINT —<strong>High</strong> <strong>Bonding</strong> <strong>Acrylic</strong> <strong>Foam</strong> <strong>Tape</strong>—<br />

■ A4000 Series (Hi Soft Type)<br />

Product<br />

<strong>Tape</strong><br />

Thickness<br />

Minimum<br />

Width<br />

Standard<br />

Length<br />

Release Liner<br />

Core Sample<br />

[mm] [mm] [m] Material Print Color<br />

A4002 0.2 3 50<br />

A4004 0.4 3 50<br />

A4006 0.6 3 50<br />

A4008 0.8 3 50<br />

A4012 1.2 3 50<br />

A4016 1.6 3 50<br />

Polyolefin<br />

Film<br />

Polyolefin<br />

Film<br />

Polyolefin<br />

Film<br />

Polyolefin<br />

Film<br />

Polyolefin<br />

Film<br />

Polyolefin<br />

Film<br />

*Other widths and lengths are also available. Please contact our sales representative for details.<br />

■ A3000 Series (Soft Type)<br />

Blue White<br />

Blue Light Blue<br />

Blue Marine Blue<br />

Blue White<br />

Blue Marine Blue<br />

Blue Marine Blue<br />

Product<br />

<strong>Tape</strong><br />

Thickness<br />

Minimum<br />

Width<br />

Standard<br />

Length<br />

Release Liner<br />

Core Sample<br />

[mm] [mm] [m]<br />

Material Print Color<br />

A3004 0.4 3 50<br />

A3008 0.8 3 50<br />

A3012 1.2 3 50<br />

Polyolefin<br />

Film<br />

Polyolefin<br />

Film<br />

Polyolefin<br />

Film<br />

*Other widths and lengths are also available. Please contact our sales representative for details.<br />

Green Light Blue<br />

Green White<br />

Green Marine Blue

■ <strong>Tape</strong> Structure<br />

■ Peel Strength ■ Shear Strength<br />

Peel Strength [N/25mm]<br />

Adhesion Area Ratio [%]<br />

60<br />

50<br />

40<br />

30<br />

20<br />

10<br />

100<br />

90<br />

80<br />

70<br />

60<br />

50<br />

The A4000 series follows ragged or distorted surfaces with its highly<br />

conformable foam backing and can obtain the maximum adhesion area.<br />

5kg<br />

0<br />

Substrate/painted board: Clear acrylic-coated board<br />

(Acid rain resistant paint, waterborne base coat)<br />

■ Conformability ■ Deformability<br />

Testing Method<br />

25µm<br />

<strong>Foam</strong> tape<br />

20 20 PET <strong>Acrylic</strong> plate<br />

50µm<br />

Distance<br />

Initial 24 hrs. later<br />

A4004 A4008 A4012 A3004 A3008 A3012<br />

A4012 A3012<br />

100µm<br />

Bottom face Adhesion area<br />

Adhesion area ratio =<br />

Adhesion area / <strong>Tape</strong> area x 100<br />

<strong>Acrylic</strong> Adhesive<br />

<strong>Acrylic</strong> <strong>Foam</strong><br />

<strong>Acrylic</strong> Adhesive<br />

Release Liner (Polyolefin Film)<br />

Shear Strength [MPa]<br />

1.4<br />

1.2<br />

1.0<br />

0.8<br />

0.6<br />

0.4<br />

0.2<br />

0<br />

Substrate/painted board (same as on the left) x chrome board<br />

(chrome-plated board for emblem)<br />

Deformation Ratio [%]<br />

A4004 A4008 A4012 A3004 A3008 A3012<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

The A3000 series shows the smallest amount of deformation when<br />

external force is applied. Excellent shear adhesion strength.<br />

Stainless steel<br />

<strong>Foam</strong> tape<br />

10 x 10mm 12N/cm 2<br />

A4012 A3012<br />

Initial 24 hrs. later<br />

B<br />

A<br />

Deformation ratio =<br />

B/A x 100

■ Applications<br />

Center pillar garnish<br />

Over fender<br />

Side molding decoration<br />

Weatherstrip<br />

Scuff plate<br />

Side molding<br />

Mudguard<br />

Roof rail<br />

Sunroof drain<br />

• Strong adhesion to HYPERJOINT polyester release liner and easy peeling<br />

• Tab tape uses strong film material, is easy to grip and contributes to work<br />

efficiency<br />

• Standard size: 0.12mm ✕ 220mm ✕ 100m<br />

Door weatherstrip<br />

Manufactured by: LORD Far East Inc.<br />

Emblem<br />

Bumper decoration<br />

■ Tab <strong>Tape</strong>: T-200 (for picking up release liner) ■ Recommended Primers for HYPERJOINT A Series<br />

Reverse-side Treatment<br />

Polyester Film<br />

Rubber Adhesive<br />

Manufactured by: Nitto Lifetec Corporation<br />

Product No. Substrate Type<br />

RC-1017 (Standard Type)<br />

RC-1017UV (Blacklight Test Type)<br />

RC-1023<br />

RC-1028 (Detoluenated Type)<br />

AP-134<br />

✽ If you have any questions about tab tape specifications or primer, please contact our sales representatives.<br />

■ <strong>Tape</strong> Laminating Procedures<br />

Alcohol<br />

TPO, PP, etc<br />

TPO, PP, etc<br />

PVC, PBT, etc<br />

TPO, PP, etc<br />

Glass, etc<br />

1. Surface preparation 2. Apply tape to surface 3. Apply pressure to the finished joint<br />

Completely wipe off any dust from the substrate<br />

surface. If any oil or wax is attached to the substrate<br />

surface, completely remove it using alcohol<br />

or solvent.<br />

Affix the Hyperjoint tape and then perform<br />

pressure bonding using a rubber roller or the<br />

like placed on the peel-apart liner in such<br />

a manner that the bonded adhesive is free of<br />

air bubbles.Then remove the peel-apart liner.<br />

Position the material and apply equal pressure<br />

to the entire adhesive area using a press, rubber<br />

roller or the like. (Criterion for pressure bonding:<br />

Roll pressure 20~50 N/25 mm)