SI Series Container Carrier Manual - Stellar Industries, Inc.

SI Series Container Carrier Manual - Stellar Industries, Inc.

SI Series Container Carrier Manual - Stellar Industries, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Subject to Change without Notification.<br />

© 2009 <strong>Stellar</strong> <strong>Industries</strong>, <strong>Inc</strong>.<br />

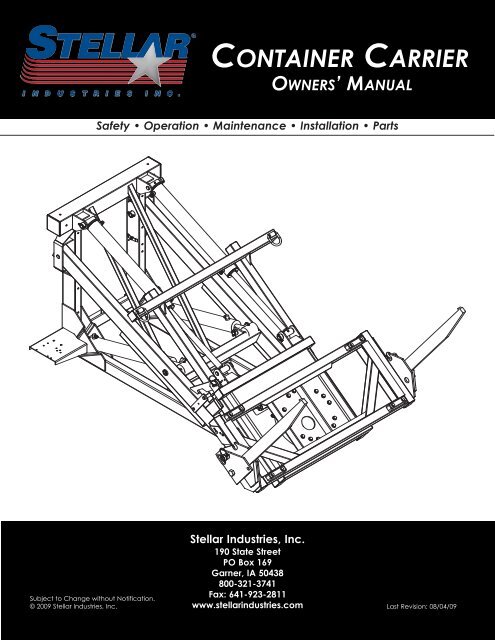

CONTAINER CARRIER<br />

OWNERS’ MANUAL<br />

Safety • Operation • Maintenance • Installation • Parts<br />

<strong>Stellar</strong> <strong>Industries</strong>, <strong>Inc</strong>.<br />

190 State Street<br />

PO Box 169<br />

Garner, IA 50438<br />

800-321-3741<br />

Fax: 641-923-2811<br />

www.stellarindustries.com Last Revision: 08/04/09

B <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

<strong>Container</strong> <strong>Carrier</strong> <strong>Manual</strong> Revisions<br />

Date of Revision Section Revised<br />

Description of Revision

Table of Contents<br />

Table of Contents i<br />

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii<br />

Chapter 1 - Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1<br />

Chapter 2 - Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3<br />

Lifting a Front Load <strong>Container</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4<br />

Placing a Front Load <strong>Container</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5<br />

Lifting a Rear Load <strong>Container</strong>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6<br />

Placing a Rear Load <strong>Container</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7<br />

Lifting a Large Rear Load <strong>Container</strong> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8<br />

Operation of Rotator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Trunnion Bar Stops. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9<br />

Chapter 3 - Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

Periodic Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

Daily Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

Monthly Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

General Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11<br />

Choice Lubricants for DX Bearings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12<br />

Chapter 4 - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13<br />

Basic Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14<br />

Truck Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14<br />

Bumper Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

Truck Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15<br />

<strong>Container</strong> <strong>Carrier</strong> Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16<br />

Hoist-Up Light Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17<br />

Oil Tank, Valve and Hose Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18<br />

Oil Tank, Valve and Hose Installation Continued.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19<br />

Cable Control Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20<br />

Cable Control Installation Continued.... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21<br />

Air Control Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22<br />

Air Controls - PN 47144 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23<br />

3-Section Air Controls - PN 46152 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24<br />

Decal Placement Kit - PN 46288. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25<br />

Hydraulic System Start-Up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26<br />

Hose Kit - PN 49534 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26<br />

Hydraulic Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27<br />

Electrical Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28<br />

Base Assembly - PN 45029 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29<br />

Chapter 5 - Assembly Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29<br />

Lift Frame Assembly - PN 45033. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30<br />

Fork Frame Assembly (Rotator) - PN 47487 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31<br />

Fork Frame Assembly (Non Rotator) - PN 45066 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32<br />

Reservoir Assembly (Cable Controls) - PN 46285 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33<br />

Reservoir Assembly (Air Controls) - PN 46074 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34<br />

Bumper Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35<br />

Warranty Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

ii <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

AN OVERVIEW TO OWNER, OPERATOR AND SERVICE PERSONNEL ABOUT SAFETY<br />

As the owner or employer, it is your responsibility to instruct the operator in the safe operation<br />

of this equipment and to provide the operator with properly maintained equipment.<br />

FAILURE TO READ THIS MANUAL BY ANYONE WHO WILL OPERATE, SERVICE, OR WORK<br />

AROUND THIS CONTAINER CARRIER IS A MISUSE OF THE EQUIPMENT. DEATH OR SERIOUS<br />

INJURY WILL RESULT FROM IMPROPER USE OR MAINTENANCE OF THIS MACHINE.<br />

Occupational safety is a prime concern of <strong>Stellar</strong> <strong>Industries</strong> in the design and production<br />

of this container carrier. Our goal in writing this manual was the safety of the operator and<br />

others who work around this equipment.<br />

It is your responsibility to know the specific requirements, governmental regulations, precautions<br />

and work hazards that exist in the operation and maintenance of this container<br />

carrier. You shall make these available and known to all personnel working with and<br />

around the equipment, so that all of you will take the necessary and required safety precautions.<br />

FAILURE TO HEED THESE INSTRUCTIONS CAN RESULT IN SERIOUS INJURY OR DEATH.<br />

It is also your responsibility to operate and maintain your container carrier with caution,<br />

skill, and good judgment. Following the recognized safety procedures will help you avoid<br />

accidents. Modification to any part of his container carrier can create a safety hazard<br />

and therefore shall not be made without the manufacturer’s written approval. Use only<br />

factory approved accessories, options, and parts on this equipment. The rebuilding or<br />

remounting of this equipment requires the mounting procedures and retesting to be in<br />

accordance with factory instructions. Safety covers and devices must remain installed<br />

and maintained in proper working condition. Safety decals must be maintained, be<br />

completely legible, and be properly located. If safety covers, devices, or decals are missing,<br />

they must be replaced with the proper designated <strong>Stellar</strong> part.<br />

Be capable, careful, and concerned! Make safety your everyday business!<br />

Attention!<br />

According to Federal Law (49 cfr part 571),<br />

each final-stage manufacturer shall complete<br />

the vehicle in such a manner that it<br />

conforms to the standards in effect on the<br />

date of manufacture of the incomplete<br />

vehicle, the date of final completion, or a<br />

date between those two dates. This requirement<br />

shall, however, be superseded by any<br />

conflicting provisions of a standard that<br />

applies by its terms to vehicles manufactured<br />

in two or more stages.<br />

Therefore, the installer of <strong>Stellar</strong> container<br />

carriers is considered one of the manufactur-<br />

ers of the vehicle. As such a manufacturer,<br />

the installer is responsible for compliance<br />

with all applicable federal and state regulations.<br />

They are required to certify that the<br />

vehicle is in compliance with the Federal<br />

Motor Vehicle Safety Standards and other<br />

regulations issued under the National Traffic<br />

and Motor Vehicle Safety Act.<br />

Please reference the Code of Federal<br />

Regulations, title 49 - Transportation, Volume<br />

5 (400-999), for further information, or visit<br />

www.gpoaccess.gov/nara/index.html for<br />

the full text of Code of Federal Regulations.

Introduction<br />

<strong>Stellar</strong> <strong>Container</strong> carriers are designed to<br />

provide safe and dependable service. With<br />

proper use and maintenance, these<br />

container carriers will operate at peak<br />

performance for many years.<br />

To promote this longevity, carefully study the<br />

information contained in this manual before<br />

putting the equipment into service. Though<br />

it is not intended to be a training manual for<br />

beginners, this manual should provide solid<br />

guidelines for the safe and proper usage of<br />

the container carrier.<br />

Once you feel comfortable with the material<br />

contained in this manual, strive to exercise<br />

your knowledge as you safely operate and<br />

maintain the container carrier. This process<br />

is vital to the proper use of the unit.<br />

A few notes on this manual:<br />

A copy of this manual is provided with every<br />

container carrier and shall remain with the<br />

container carrier at all times. Information<br />

contained within this manual does not cover<br />

all maintenance, operating, or repair<br />

instructions pertinent to all possible situations.<br />

Please be aware that some sections of this<br />

manual contain information pertaining to<br />

<strong>Stellar</strong> manufactured container carriers in<br />

For Technical Questions, Information, Parts, or Warranty, Call Toll-Free at<br />

800-321-3741<br />

Hours: Monday - Friday, 8:00 a.m. - 5:00 p.m. CST<br />

Or email at the following addresses:<br />

general and may or may not apply to your<br />

specific model.<br />

This manual is not binding. <strong>Stellar</strong> <strong>Industries</strong>,<br />

<strong>Inc</strong>. reserves the right to change, at any<br />

time, any or all of the items, components,<br />

and parts deemed necessary for product<br />

improvement or commercial/production<br />

purposes. This right is kept with no<br />

requirement or obligation for immediate<br />

mandatory updating of this manual.<br />

In closing:<br />

If more information is required or technical<br />

assistance is needed, or if you feel that any<br />

part of this manual is unclear or incorrect,<br />

please contact the <strong>Stellar</strong> Customer Service<br />

Department by phone at 800-321-3741 or<br />

email at service@stellarindustries.com.<br />

ATTENTION<br />

Failure to adhere to the instructions<br />

could result in property damage or<br />

even serious bodily injury to the<br />

operator or others close to the<br />

container carrier.<br />

Technical Questions, and Information service@stellarindustries.com<br />

Order Parts parts@stellarindustries.com<br />

Warranty Information warranty@stellarindustries.com<br />

iii

iv <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

** 60” cab--to--axle minimum<br />

is possible with reduced<br />

capacity rating.<br />

<strong>Container</strong> <strong>Carrier</strong> Specifications<br />

**84” Minimum<br />

Cab--to--Axle<br />

(Recommended)<br />

32”<br />

Aft of Axle<br />

Chassis<br />

GVW Rating<br />

of 30,000 lbs.<br />

or more is<br />

recommended<br />

Clearance Height:<br />

10” Minimum Fork Tip<br />

186” Maximum Mast Top<br />

Capacity: 2 through 10 cubic yard containers.<br />

Fork Lift Height: 10” Minimum, 186” Maximum.<br />

Mounting Frame: 27.75” Inside, 33.75” Outside.<br />

Valve: 20 GPM<br />

Forks: 1-1/4” T-1 High Strength Alloy Plate<br />

Lift Cylinders: Two 4” Bore x 29” Stroke, Two 4” Bore x 32” Stroke<br />

Hydraulic Tank: 10 Gallon Capacity.<br />

Controls: Inside Cab Cable Controls Standard<br />

Pivot Points: Permanently Lubricated and Greasable Bushings<br />

Lift Capacity: 8,000 lbs.<br />

Grease Fittings: At All Wear Points.<br />

Pump: 11 GPM<br />

Filter: 200 Mesh, In-tank Suction Strainer 25 Micron, return filter.<br />

Operating Pressure: 1,200 P<strong>SI</strong>.<br />

<strong>Container</strong> Bumpers:<br />

Rear Load <strong>Container</strong> Attachment<br />

Molded Rubber.<br />

Rotator Capacity: 8,000 lbs.

Chapter 1 - Safety<br />

Please Read the Following Carefully!<br />

This portion of the manual contains<br />

information regarding all <strong>Stellar</strong><br />

manufactured container carriers. Some<br />

items contained within this chapter may not<br />

apply to your specific equipment.<br />

Safety should be the number one thought on<br />

every operator’s mind. Three factors should<br />

exist for safe operation: a qualified operator,<br />

well-maintained equipment, and the proper<br />

use of this equipment. The following<br />

information should be read and understood<br />

completely by everyone working with or near<br />

the container carrier before putting the unit<br />

into operation.<br />

Please take note that <strong>Stellar</strong> <strong>Industries</strong>, <strong>Inc</strong>. is<br />

not liable for accidents incurred by the<br />

container carrier because of non-fulfillment<br />

from the operator’s side of current rules, laws,<br />

and regulations.<br />

General Safety<br />

It is the responsibility of the owner to instruct<br />

the operator in the safe operation of your<br />

equipment and to provide the operator with<br />

properly maintained equipment.<br />

Trainees or untrained persons shall be under<br />

the direct supervision of qualified persons.<br />

Do not operate equipment under the<br />

adverse influence of alcohol, drugs, or<br />

medication.<br />

Read all Danger and Caution decals on the<br />

equipment and understand their meaning.<br />

Personal Safety<br />

Keep clear of all moving parts.<br />

Always wear the prescribed personal safety<br />

devices.<br />

Always wear approved accident-prevention<br />

clothing such as: protective helmets, anti-slip<br />

Safety 1<br />

shoes with steel toes, protective gloves, antinoise<br />

headphones, protective glasses,<br />

breathing apparatus, and reflective jackets.<br />

Consult your employer regarding current<br />

safety regulations and accident-prevention<br />

equipment.<br />

Do not wear rings, wristwatch, jewelry, loosefitting<br />

or hanging clothing such as ties, torn<br />

garments, scarves, unbuttoned jackets or<br />

unzipped overalls, which could get caught<br />

up in the moving parts of the container<br />

carrier.<br />

Keep a first-aid box and a fire extinguisher<br />

readily available on the truck. Regularly<br />

check to make sure the fire extinguisher is<br />

fully charged and the first-aid kit is stocked.<br />

Do not use controls and hoses as handholds.<br />

These parts move and cannot provide stable<br />

support.<br />

Do not allow unauthorized personnel or<br />

equipment to enter within 10 feet of<br />

container carrier operating area.<br />

Never allow anyone to ride the container<br />

carrier or load.<br />

Maintenance Safety<br />

Never modify or alter any of the equipment,<br />

whether mechanical, electrical, or hydraulic,<br />

without <strong>Stellar</strong> <strong>Industries</strong>’ approval.<br />

Do not perform any maintenance or repair<br />

work on the container carrier unless<br />

authorized and trained to do so.<br />

ATTENTION<br />

The <strong>Manual</strong> Hardcase, which holds<br />

the maunal and other useful<br />

documents, must be installed<br />

permanently to the truck chassis.

2 <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

Release system pressure before attempting<br />

to make adjustments or repairs.<br />

Do not attempt service or repair when PTO is<br />

engaged.<br />

Decals are considered safety equipment.<br />

They must be maintained, as would other<br />

safety devices. Do not remove any decals.<br />

Replace any decals that are missing,<br />

damaged, or not<br />

legible.<br />

The safety instruction plates, notices, load<br />

charts and any other sticker applied to the<br />

container carrier must be kept legible and in<br />

good condition. If necessary, replace them.<br />

Keep all surfaces of the container carrier free<br />

of oil and grease to avoid slippery surfaces<br />

and aid in inspections.<br />

Stability<br />

Know the container carrier components and<br />

their capabilities and limitations.<br />

Do not move the truck while the fork frame<br />

and container are raised. A raised load can<br />

create a top heavy unstable load.<br />

Overloading the container carrier may result<br />

in serious damage of self, others, equipment<br />

or the surroundings.<br />

Never exceed manufacturer’s load ratings.<br />

These ratings are based on the machine’s<br />

hydraulic, mechanical, and structural design<br />

rather than stability.<br />

Load Safety<br />

Move the control lever slow and smooth for<br />

steady oil flow.<br />

Be constantly aware of the container carrier<br />

position when operating the controls.<br />

Do not attempt to lift fixed loads.<br />

Deduct the weight of the body from the<br />

maximum load rating to determine how<br />

much weight can be lifted.<br />

Keep everyone clear when loading,<br />

unloading, and dumping.<br />

Do not push on fixed objects or bodies with<br />

the forks of the container carrier.<br />

Do not permit loose objects on the container<br />

carrier.<br />

Use a qualified person to assist in loading<br />

when the load is not visible to the operator.<br />

Do not leave container carrier unattended<br />

with suspended load.<br />

Be aware of the cushioning effect of springs<br />

and tires when loading/unloading.<br />

Never use the drivetrain of the chassis to<br />

assist the hydraulics in loading<br />

Environment<br />

Do not operate the container carrier during<br />

electrical storms.<br />

In extreme cold, allow adequate time to<br />

warm the truck before engaging the PTO. Do<br />

not rev the truck engine and over speed the<br />

hydraulic pumps as permanent damage to<br />

the pumps may occur. Follow the vehicle<br />

owner’s manual regarding operating the<br />

vehicle in such adverse conditions.<br />

In extreme cold, operate the controls slowly<br />

to allow for viscosity changes.<br />

ATTENTION<br />

<strong>Stellar</strong> <strong>Industries</strong>, <strong>Inc</strong>. is not liable for<br />

accidents incurred by the container<br />

carrier because of the operator’s<br />

non-fulfillment of current rules, laws<br />

and regulations.

Chapter 2 - Operation<br />

Job-Site Set-Up<br />

Thoroughly plan the lift before positioning the<br />

vehicle. Consider the following:<br />

1. The vehicle should be positioned in an area<br />

free from overhead obstructions to eliminate<br />

the need for repositioning.<br />

2. Position the vehicle so that it is impossible for<br />

any portion of the equipment to come within<br />

the minimum required safe distance of any<br />

power line. Maintain a clearance of at least<br />

10 feet between any part of the container<br />

carrier, or load, and any electrical line or<br />

apparatus carrying up to 50,000 volts. One<br />

foot additional clearance is required for every<br />

additional 30,000 volts or less. Remember to<br />

allow for winds that cause power lines to<br />

sway. It is recommended that a signal person<br />

be used when the vehicle is set-up near<br />

power lines.<br />

3. The vehicle should also be positioned on a<br />

firm and level surface that will provide adequate<br />

support.<br />

<strong>Container</strong> <strong>Carrier</strong> Controls<br />

1. Be familiar with the sequence and operation<br />

of the container carrier controls.<br />

2. Each individual container carrier function<br />

should have control function decals. Replace<br />

them immediately if they are missing or illegible.<br />

3. Keep hands, feet and control levers free from<br />

mud, grease and oil.<br />

4. Be familiar with the control levers and how<br />

they operate before attempting to operate<br />

the container carrier.<br />

5. Be prepared before beginning operation of<br />

the container carrier:<br />

• All protective guards must be in place.<br />

• Be aware of the surroundings: low branches,<br />

power lines, unstable ground.<br />

• Be sure all safety devices provided are in<br />

place and in good operating condition.<br />

• Be prepared for all situations. Keep fire extinguisher<br />

and first aid kit near.<br />

• Be sure all regular maintenance has been<br />

performed.<br />

• Visually inspect all aspects of the container<br />

carrier for physical damage.<br />

• Check for fluid leaks.<br />

Operation 3<br />

Operator Requirements<br />

Operation is limited to the following people:<br />

1. Qualified individual.<br />

2. Trainees under direct supervision of the qualified<br />

individual.<br />

3. Test or maintenance individual.<br />

4. <strong>Container</strong> carrier Inspector.<br />

Operators must:<br />

1. Demonstrate the ability to understand all<br />

decals, the owner’s manual, and any other<br />

information required for safe operation of the<br />

container carrier.<br />

2. Be able to demonstrate the ability to safely<br />

control the container carrier.<br />

3. Know all safety regulations.<br />

4. Be responsible for maintenance requirements.<br />

5. Understand and be fully capable of implementing<br />

all emergency procedures.<br />

6. Understand the operating procedures as outlined<br />

by this manual, AN<strong>SI</strong> Z245.6 and<br />

Federal/State Laws.<br />

Operator Conduct<br />

1. Operators will not engage in any operation<br />

that would cause them to divert attention<br />

away from the operation of the container carrier.<br />

2. Operators are responsible for all operations<br />

under their direct control.<br />

3. Operators will not leave a suspended load<br />

unattended.<br />

4. Operators will be familiar with the equipment<br />

and the maintenance required for proper<br />

care.<br />

<strong>Container</strong> <strong>Carrier</strong> Check List<br />

1. Check hydraulic oil level with all<br />

cylinders retracted.<br />

2. Grease all lubrication points.<br />

3. Fork stop pins are securely in place.<br />

4. Fork Frame safety latch and trunnion<br />

bar stop are free to move and work<br />

properly.<br />

5. Tires are properly inflated.<br />

6. Truck is fully operational: Brakes, Lights,<br />

etc.

4 <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

Lifting a Front Load <strong>Container</strong><br />

1 2<br />

Lower<br />

Forks<br />

1. If the forks are in the stored position, manually<br />

rotate them to the extended position and lock in<br />

place with the fork stop pin.<br />

CAUTION: Be sure that the area in which the container carrier is<br />

to be operated is clear of personnel and obstacles overhead,<br />

and on the ground.<br />

3 4<br />

Tilt<br />

Forks<br />

Tilt<br />

Forks<br />

3. Tilt the forks so that they are aligned with the container<br />

pockets.<br />

5 6<br />

Raise<br />

Mast<br />

5. Raise the mast and tilt the forks up until the container<br />

clears the ground.<br />

Raise<br />

Mast<br />

2. Engage the pump and raise the mast up a minimum<br />

of 2” to disengage the automatic safety<br />

latch.<br />

Note: Safety latch may be set so that it does not automatically<br />

engage by raising the latch and inserting the pin to hold it up;.<br />

When transporting a container, the pin should be removed so<br />

that the safety latch will engage.<br />

Lower<br />

Mast<br />

Back<br />

to <strong>Container</strong><br />

4. Back the truck up to the container to be lifted<br />

and align the forks with the container pockets.<br />

Continue backing until the forks extend through<br />

the pockets and container is against fork frame.<br />

Tilt<br />

Forks<br />

6. To transport the container, lower the mast completely<br />

down and tilt the forks all the way up, so<br />

that full contact is made will all rest pads.

Placing a Front Load <strong>Container</strong><br />

1 2<br />

Raise<br />

Mast<br />

1. Back the truck up close to where the container<br />

will be placed. From the transport position, the<br />

mast must be raised up a minimum of 2”, before<br />

tilting the forks, to disengage the automatic<br />

safety latch.<br />

3 4<br />

Back<br />

3. Back the truck up until the container is centered<br />

over the area where you want to set it.<br />

5 6<br />

Tilt<br />

Forks<br />

5. Tilt the forks down just enough to clear the container<br />

pockets and slowly pull the truck forward until<br />

the forks are out of the container pockets.<br />

Tilt<br />

Forks<br />

Raise<br />

Mast<br />

2. Tilt the forks and raise the mast until the bottom of<br />

the container is higher than and parallel with the<br />

surface on which you want to set the container.<br />

Lower<br />

Mast<br />

4. Slowly lower the mast and tilt the forks to keep<br />

the container level, until the container bottom is in<br />

full contact with the surface where it will sit.<br />

Tilt<br />

Forks<br />

Forward Lower<br />

Mast<br />

Operation 5<br />

6. After the last container has been placed, lower the<br />

mast completely down and tilt the forks all the way<br />

up so that full contact is made with the rest pads and<br />

disengage the pump.

6 <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

Lifting a Rear Load <strong>Container</strong><br />

1 2<br />

Back<br />

to <strong>Container</strong><br />

Raise<br />

Mast<br />

Rotate Forks<br />

to Stored<br />

Position<br />

1. If the forks are in the extended position, manually<br />

rotate them to the stored position and lock in<br />

place with the fork stop pin. Make sure both trunnion<br />

bar stops are in the ‘unlocked’ position.<br />

3 4<br />

3. Back the truck up to the container to be lifted<br />

and align the trunnion slots with the container<br />

trunnion bars. Continue backing until the slots<br />

are under the trunnion bars.<br />

5 6<br />

Tilt<br />

Forks<br />

5. Raise the mast up and tilt the forks to lift the container.<br />

Lower<br />

Mast<br />

Raise<br />

Mast<br />

2. Engage the pump and raise the mast up a minimum<br />

of 2” to disengage the automatic safety<br />

latch.<br />

Note: Failure to lift forks before tilting mast will result in overloading<br />

and possible damage to safety latch.<br />

Raise<br />

Mast<br />

Tilt<br />

Forks<br />

4. Raise the mast until the trunnion bars are securely<br />

located in the slots and tilt the forks up to make<br />

the rubber bumpers contact the container. Put<br />

both trunnion bar stops in the ‘locked’ position.<br />

Tilt<br />

Forks<br />

6. To transport the container, lower the mast completely<br />

down and tilt the forks up so that full contact<br />

is made with all rest pads. Disengage the<br />

pump before driving away.

Placing a Rear Load <strong>Container</strong><br />

1 2<br />

Raise<br />

Mast<br />

1. Back the truck up close to where the container<br />

will be placed. Set both trunnion bar stops to<br />

‘unlocked’ position. From the transport position,<br />

the mast must be raised up a minimum of 2”, before<br />

tilting the forks, to disengage the automatic<br />

safety latch.<br />

3 4<br />

3. Back the truck up until the container is centered<br />

over the area where you want to set it.<br />

5 6<br />

Lower<br />

Mast<br />

Back<br />

Back<br />

Forward<br />

5. Lower the mast to clear the container trunnion<br />

bars and slowly pull the truck forward until clear<br />

of the container.<br />

Raise<br />

Mast<br />

Tilt<br />

Forks<br />

Operation 7<br />

2. Tilt the forks and raise the mast until the bottom of<br />

the container is higher than and parallel with the<br />

surface on which you want to set the container.<br />

Lower<br />

Mast<br />

Tilt<br />

Forks<br />

4. Slowly lower the mast and tilt the forks to keep<br />

the container level until the container bottom is in<br />

full contact with the surface where it will set.<br />

Tilt<br />

Forks<br />

Lower<br />

Mast<br />

6. After the last container has been placed, lower<br />

the mast completely down and tilt the forks all the<br />

way up so that full contact is made with the rest<br />

pads and disengage the pump.

8 <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

Lifting a Large Rear Load <strong>Container</strong><br />

1 2<br />

1. If the forks are in the extended position, manually<br />

rotate them to the stored position and lock in place<br />

with the fork stop pin. Make sure both trunnion bar<br />

stops are the ‘unlocked’ position.<br />

3 4<br />

Back<br />

to <strong>Container</strong><br />

Rotate Forks<br />

to Stored<br />

Position<br />

3. Back up the truck to the container to be lifted<br />

and align the trunnion slots with the container<br />

trunnion bars. Continue backing until the slots are<br />

under the trunnion bars.<br />

5 6<br />

5. Attach a chain from the top of the fork frame to<br />

the container. Run the chain through a pipe to prevent<br />

the container from tipping forward if the truck<br />

has to make a sudden stop.<br />

2. Engage the pump and raise the mast up a minimum<br />

of 2”, before tilting the forks, to disengage the<br />

automatic safety latch.<br />

20˚<br />

to<br />

30˚<br />

Raise<br />

Mast<br />

Raise<br />

Mast<br />

4. Raise the mast until the trunnion bars are securely<br />

located into the slots are under the trunnion bars.<br />

Tilt<br />

Forks<br />

Lower<br />

Mast<br />

6. Put both trunnion bar stops in the locked position<br />

and tilt forks until the chain is tight. Tilt the forks all the<br />

way up and lower the mast completely down until full<br />

contact is made with all rest pads.

Trunnion<br />

Stop<br />

Unlocked<br />

Position<br />

Trunnion<br />

Bar<br />

Important Notes:<br />

Do not lift a container heavier than 8,000 lbs. max<br />

Do not rotate fork carriage with forks in stored position.<br />

Possible damage to fork carriage may result.<br />

Do not use rotator with rear load container.<br />

Directions<br />

1. Tilt forks up approximately<br />

15º<br />

before rotating the<br />

container.<br />

2. Slowly rotate fork<br />

carriage to empty<br />

container.<br />

Trunnion Bar Stops<br />

Operation of Rotator<br />

<strong>Container</strong><br />

Weight<br />

< 8,000 lbs.<br />

Trunnion<br />

Stop<br />

Locked<br />

Position<br />

Operation 9<br />

CAUTION<br />

Failure to tilt forks up before rotating container may result in container sliding<br />

off of forks with possible damage to equipment and injury to personnel

10 <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong>

Chapter 3 - Maintenance<br />

Please read the following before performing any<br />

maintenance on the container carrier.<br />

1. Only authorized service personnel are to perform<br />

maintenance on the container carrier.<br />

2. Disengage the PTO before any service or repair is<br />

performed.<br />

3. Do not disconnect hydraulic hoses while there is<br />

still pressure in those components.<br />

4. Before disconnecting hydraulic components, shut<br />

off the engine, release any air pressure on the<br />

hydraulic reservoir, and move control levers<br />

repeatedly through their operating positions to<br />

relieve all pressures.<br />

5. Keep the container carrier clean and free from<br />

grease build-up, oil and dirt to prevent slippery<br />

conditions.<br />

6. Perform all safety and maintenance checks<br />

before each period of use.<br />

7. Replace parts with <strong>Stellar</strong> <strong>Industries</strong>, <strong>Inc</strong>.<br />

approved parts only.<br />

8. Immediately repair or have repaired any components<br />

found to be inadequate.<br />

Maintenance Procedures<br />

1. Position the container carrier where it will be out of<br />

the way of other operations or vehicles in the<br />

area.<br />

2. Place all controls in the off position and secure<br />

operating features from inadvertent motion.<br />

3. Relieve hydraulic oil pressure from all hydraulic circuits<br />

before loosening or removing hydraulic components.<br />

4. Label or tag parts when disassembling.<br />

Periodic Inspection<br />

Periodic Inspection should occur while the container<br />

carrier is in use. For the duration of the usage,<br />

inspect the container carrier for all of the following:<br />

1. Loose bolts and fasteners.<br />

2. All pins, bushings, shafts, and gears for wear,<br />

cracks, or distortion to include all pivot points, and<br />

bushings.<br />

3. Hydraulic systems for proper operating pressure.<br />

4. Main frame mount bolts.<br />

5. Cylinders for:<br />

A. Damaged rods.<br />

B. Dented barrels.<br />

C. Drift from oil leaking internally.<br />

D. Leaks at rod seals or holding valves.<br />

6. PTO and hydraulic pump(s) for leaks.<br />

7. Hydraulic hose and tubing for evidence of damage<br />

such as blistering, crushing, or abrasion.<br />

8. Presence of this owner’s manual.<br />

Maintenance 11<br />

Daily Inspection<br />

Daily Inspection should occur each day before the<br />

container carrier is put into use. Each day, inspect<br />

the container carrier for all of the following:<br />

1. Hydraulic oil level.<br />

2. Loose parts or damage to structures or weld.<br />

3. Cylinder movement due to leakage.<br />

4. Hoses for evidence of oil leaks.<br />

5. Controls for malfunction or adjustment.<br />

6. Parking brake operation.<br />

7. All securing hardware such as cotter pins, snap<br />

rings, hairpins, and pin keepers for proper installation.<br />

8. All safety covers for proper installation.<br />

9. Cylinder holding valves for proper operation.<br />

10. Equipment for missing, illegible, or defaced operating<br />

decals and safety signs.<br />

Monthly Inspection<br />

Monthly Inspection should occur at the beginning of<br />

every work month. Each month, inspect the container<br />

carrier for all of the following:<br />

1. Frame bolt tightness - turn barrel nuts and mounting<br />

bolts during the first month of operation on<br />

new machines and then quarterly thereafter.<br />

2. Cylinders and valves for leaks.<br />

3. Lubrication.<br />

4. Structural weldments for bends, cracks, or breaks.<br />

5. All pins and keepers for proper installation.<br />

6. All control, safety, and capacity placards for readability<br />

and secure attachment.<br />

7. Inspect all electrical wires and connections for<br />

worn, cut, or deteriorated insulation and bare<br />

wire. Replace or repair wires as required.<br />

8. Lubrication of all points requiring lubrication.<br />

General Service<br />

The following general suggestions should be helpful<br />

in analyzing and servicing your container carrier.<br />

Using the following systematic approach should be<br />

helpful in finding and fixing problems:<br />

1. Determine the problem.<br />

2. List and record possible causes.<br />

3. Devise checks.<br />

4. Conduct checks in a logical order to determine<br />

the cause.<br />

5. Consider the remaining service life of components<br />

against the cost of parts and labor necessary to<br />

replace them.<br />

6. Make the necessary repair.<br />

7. Recheck to ensure that nothing has been overlooked.<br />

8. Functionally test the new part in its system.

12 <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

Choice Lubricants for DX Bearings<br />

Greases Recommended<br />

Type of Grease Description<br />

Premium Quality<br />

Multi-Purpose<br />

Stabilized, Anti-Oxidant Lithium Base<br />

Lithium Base with 3% Molybdenum Disulfide<br />

High Drop Point<br />

Multi-Purpose Calcium Based, for General Automotive and Industrial Use<br />

Calcium Grease, Water Stabilized, High Drop Point<br />

Anti-Friction Bearing Calcium Based with EP Additives<br />

Lithium Based<br />

Sodium Based<br />

Extreme Pressure (EP) Lithium Based with EP Additives<br />

Calcium Based with EP Additives<br />

High Temperature Modified Sodium Based, High Drop Point<br />

Transmission Semi-Fluid, Calcium Based<br />

Molybdenum Filled Lithium Based with 2% Molybdenum Disulfide<br />

Graphite Filled Sodium Based with 2% Graphite<br />

Block Grease Sodium Based Solid Grease<br />

White Grease Aluminum Complex Based with Anti-Oxidant & Rust<br />

Inhibitors & Zinc Oxide Additives<br />

Silicone Lithium Based with Silicone Oil Lubricant<br />

Greases Not Recommended<br />

Type of Grease Description<br />

Cup Grease Light Service Calcium or Sodium Based Grease<br />

Graphite Filled Greases with More than 10% Graphite<br />

Molybdenum Filled Greases with More than 10% Molybdenum Disulfide<br />

Fluorocarbon Low Molecular Weight Chlorofluoroethylene Polymer<br />

with Inert Thickeners<br />

White Grease Calcium Based, Zinc Oxide Filled<br />

Cleanliness<br />

An important item in preserving the long life of the container carrier is keeping<br />

dirt, grime, and corrosive material out of the working parts. Thoroughly wash and<br />

grease the container carrier periodically.

Chapter 4 - Installation<br />

<strong>Container</strong> <strong>Carrier</strong> Mounting and Assembly<br />

Study names and locations of the parts and<br />

familiarize yourself with the container carrier<br />

before starting the assembly . Reading the<br />

step-by-step instructions that follow will be<br />

helpful.<br />

Safety<br />

Read all of the safety notations in the assembly<br />

instructions for your protection.<br />

Accidents can be prevented by recognizing<br />

the cause of an accident before it can happen.<br />

Assembly<br />

Select an area for assembly that will be<br />

large enough to accommodate the completed<br />

unit. The surface of the work area<br />

should be as level as possible. Use the proper<br />

hand tools to ensure proper bolt tightness.<br />

Refer to the chart below for the recommended<br />

torque values for different sizes of<br />

bolts.<br />

Recommended Torque Values in Ft-Lbs<br />

For SAE GRADE 2 and GRADE 5 coarse<br />

thread cap screws and bolts shown are suggested<br />

maximum for fasteners, carrying only<br />

the residue oil of the manufacturer.<br />

Size<br />

(DIA-TPI)<br />

5/16-18<br />

3/8-16<br />

7/16-14<br />

1/2-13<br />

9/16-12<br />

5/8-11<br />

3/4-10<br />

7/8-9<br />

1-8<br />

1 1/8-7<br />

1 1/4-7<br />

1 3/8-6<br />

1 1/2-6<br />

Bolt DIA<br />

(<strong>Inc</strong>hes)<br />

0.3125<br />

0.3750<br />

0.4375<br />

0.5000<br />

0.5625<br />

0.6250<br />

0.7500<br />

0.8750<br />

1.000<br />

1.1250<br />

1.2500<br />

1.3750<br />

1.500<br />

Grade 5 Grade 8 Grade 9<br />

Plain<br />

(Ft-Lb)<br />

17<br />

31<br />

49<br />

75<br />

110<br />

150<br />

265<br />

395<br />

590<br />

795<br />

1120<br />

1470<br />

1950<br />

Plated<br />

(Ft-Lb)<br />

13<br />

23<br />

37<br />

57<br />

82<br />

115<br />

200<br />

295<br />

445<br />

595<br />

840<br />

1100<br />

1460<br />

Plain<br />

(Ft-Lb)<br />

25<br />

44<br />

70<br />

105<br />

155<br />

220<br />

375<br />

605<br />

910<br />

1290<br />

1815<br />

2380<br />

3160<br />

Plated<br />

(Ft-Lb)<br />

18<br />

33<br />

52<br />

80<br />

115<br />

160<br />

280<br />

455<br />

680<br />

965<br />

1360<br />

1780<br />

2370<br />

Plated<br />

(Ft-Lb)<br />

22<br />

39<br />

63<br />

96<br />

139<br />

192<br />

340<br />

549<br />

823<br />

1167<br />

1646<br />

2158<br />

2865<br />

Installation 13<br />

Proper Bolt Use<br />

Do not use these values if a different torque<br />

value or tightening procedure is given for a<br />

specific application. Torque values listed are<br />

for general use only. Check tightness of fasteners<br />

periodically.<br />

Sheer bolts are designed to fail under predetermined<br />

loads. Always replace shear bolts<br />

with identical grade.<br />

Fasteners should be replaced with the same<br />

or higher grade. If higher grade fasteners<br />

are used, these should only be tightened to<br />

the strength of the original.<br />

Tighten plastic insert or crimped steel-type<br />

lock nuts to approximately 110 percent of<br />

the dry torque values shown in the chart<br />

below, applied to the nut, not to the bolt<br />

head. Tighten toothed or serrated-type lock<br />

nuts to the full torque value.<br />

Note: “Lubricated” means coated with a<br />

lubricant such as engine oil, or fasteners with<br />

phosphate and oil coatings. “Dry” means<br />

plain or zinc plated without lubrication.<br />

Tighten lubricated bolts to approximately<br />

80% of dry bolts.<br />

The stadard container carrier weighs approximately<br />

2,000 lbs. with rotator 2,500 lbs.<br />

Make sure that all chains and handling<br />

equipment are adequately rated for this<br />

weight.<br />

Model Number<br />

Know the model number of the <strong>Stellar</strong><br />

<strong>Container</strong> <strong>Carrier</strong> being mounted. Use this<br />

model number whenever referring to the<br />

assembly or parts listing pages. The number<br />

is stamped on the name plate which is<br />

located on the front frame member.<br />

Right and Left sides can be established by<br />

standing behind the truck frame and looking<br />

towards the front, or the direction of travel.

14 <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

1. Cut the truck frame. Refer to page 15.<br />

2. Install bumper. Refer to page 15. See<br />

Government Regulations for acceptable<br />

placement.<br />

3. Fabricate a clearance spacer (if applicable).<br />

Refer to page 15.<br />

4. Bolt the carrier to the truck frame. Refer<br />

to page 16.<br />

5. Weld side retainer plates to carrier frame.<br />

Refer to page 16.<br />

6. Install hoist up light. Refer to page 17.<br />

Truck Chassis<br />

The <strong>Stellar</strong> <strong>Container</strong> <strong>Carrier</strong> will mount on any dual rear wheel chassis, one ton or larger,<br />

that meets minimum dimensional requirements. (See Figure 1 below.)<br />

Figure 1<br />

Chassis<br />

GVW Rating<br />

of 30,000 lbs.<br />

or more is<br />

recommended.<br />

Basic Installation Overview<br />

84” Minimum<br />

Cab-to-Axle<br />

(Recommended)<br />

60” Cab-to-Axle minimum<br />

is possible with reduced<br />

capacity rating.<br />

7. Install P.T.O. and hydraulic pump. Refer<br />

to P.T.O. and Pump manufacturer instructions.<br />

8. Install suction and pressure hoses. Refer<br />

to pages 18 and 19. See pages 33 and<br />

34 for Reservior Assembly.<br />

9. Install in-cab controls. Refer to pages 20<br />

and 24.<br />

10. Install fenders. See Government<br />

Regulations for acceptable placement.<br />

11. Place decals. Refer to page 25.<br />

12. Hydraulic start-up. Refer to page 26.<br />

32”<br />

Aft of Axle<br />

Clearance Height:<br />

10” Minimum Fork Tip<br />

186” Maximum Mast Top<br />

Rotator Frame: 27.75” Inside, 33.75” Outside Capacity: 2 through 10 cubic yard containers

Truck Preparation<br />

Installation 15<br />

1. Cut the truck frame off a minimum of 1” behind the rear spring shackle. Note: Make<br />

sure not to cut rear of frame off shorter than 32” from center of axle to end of frame. See<br />

Figure on page 14.<br />

2. The container carrier must mount on a good supporting surface. If there are any rivets<br />

or other obstructions on the top of the truck frame, a 1/2” x 3” x 84” bar with clearance<br />

holes drilled at each rivet location should be welded to the truck frame or bottom of the<br />

container carrier. If the truck frame has a hump above the rear axle, spacers must be<br />

placed under container carrier at each U-Bolt location to level it.<br />

TYP 2<br />

PART # 51618<br />

PULL PLATE PINTLE 30K W/ BUMPER<br />

Bumper Installation<br />

TYP 2<br />

FRAME RAIL<br />

TYP 2

16 <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

1. Carefully remove the banding holding the fenders and box of parts.<br />

2. Set the container carrier on the truck frame with the rear of the container carrier even with<br />

the truck frame. See Figure 1. Center the container carrier on the truck frame at the front<br />

and rear.<br />

3. Locate the U-Bolts as shown on Figure 3. The rear U-Bolt may have to be moved to just in<br />

front of the rear stop for the overload spring. The front U-Bolt must be located as shown.<br />

4. Put the U-Bolt shims (PN 44915) under the U-Bolts as shown on Figure 3. Weld to the container<br />

carrier support frame.<br />

5. Tighten all U-Bolts.<br />

<strong>Container</strong> <strong>Carrier</strong> Mounting Instructions<br />

6. Weld retainer plates (PN 44916PC) to either inside or outside of container carrier frame so<br />

they contact truck frame to prevent side movement. Do not weld to truck frame.<br />

4<br />

5<br />

3<br />

7<br />

6<br />

2<br />

PN 45085<br />

MTG KIT CONTAINER CARRIER<br />

ITEM<br />

PART<br />

DESCRIPTION<br />

QTY.<br />

2 44916PC<br />

PLATE<br />

RETAINER<br />

KPCC<br />

4<br />

3 44914 FLAT U BOLT STRAP KPCC 6<br />

4 44915<br />

FLAT<br />

U BOLT<br />

SHIM<br />

KPCC<br />

6<br />

5 45086 U BOLT 0.75X3.50X18.00 ST 6<br />

6 C0538 NUT 0.75-10 HHGR8 NYLOC 12<br />

7 C6219 WASHER 0.75 SAE FLAT YELLOW GR8 12<br />

Figure 3

1. Locate the switch mounting plate (PN<br />

44766) on the curb side base tube on the<br />

carrier. See Figure 4 below.<br />

Figure 4<br />

ITEM PART DESCRIPTION QTY.<br />

1 45907 SWITCH REMOTE KP60 1<br />

2 0437 CAP SCR 0.25-20X1.25 HHGR5 3<br />

3 0333 NUT 0.25-20 HHGR5 NYLOC 3<br />

2. Mount the remote switch (PN 45907) to<br />

the mounting plate with 1/4 NC x 1-1/4”<br />

Cap Screws and Lock Nuts.<br />

3. Pick a suitable location on the truck dash<br />

which is plainly visible to the operator for<br />

the “hoist up” warning light.<br />

4. Drill a 3/4” diameter hole for the light.<br />

The “hoist up” decal is to be located<br />

under or near the warning light. Do not<br />

install light at this time.<br />

5. Two 16’ long pigtails with bullet terminals<br />

are provided. The female bullet terminals<br />

will be used at the light. The male<br />

bullet terminals on the pigtail may be<br />

cut-off if not used.<br />

6. Connect the pigtail wires to the power<br />

source and ground per the wiring diagram.<br />

Note: The optional Air Control<br />

Tower also has a hoist-up light. Power<br />

wires from both lights can be “T” connected<br />

and ground wires can be “T”<br />

connected. Do not wire in series as if one<br />

Hoist-Up Light Installation<br />

3<br />

2 1<br />

PN 52135 SWITCH BRACKET<br />

Installation 17<br />

light should fail, neither light would function.<br />

7. Caution: The LED warning light is polarity<br />

sensitive. Connect the bullet terminals<br />

from the white ground wire of the light<br />

to the pigtail wire running to the ground.<br />

Connect the bullet terminals from the<br />

colored wire of the light to the pigtail<br />

wire running to the power source. Verify<br />

the light works before proceeding.<br />

8. Slide the rubber grommet off of the light<br />

base then push and seat the grommet<br />

into the drilled hole. The outside edge<br />

of the grommet should be flush with the<br />

mounting surface. Insert the light into<br />

the grommet by gently pressing in the<br />

light.<br />

9. Raise the fork frame. Check that the<br />

“hoist up” warning light is on.<br />

10. Lower the fork frame and check that the<br />

warning light goes off. Check to be sure<br />

the spring on the remote switch is bent<br />

over evenly and not binding or rubbing.<br />

Figure 5

18 <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

44<br />

Oil Tank, Valve and Hose Installation<br />

Please read the following closely:<br />

44<br />

21<br />

Figure 7<br />

Clean all hydraulic components and keep all hoses, tubes, valves, and fittings capped until<br />

they are to be installed.<br />

Warning: Escaping fluid under pressure can penetrate the skin, causing serious injury. Avoid<br />

the hazard by relieving pressure before disconnecting hydraulic lines. Tighten all connections<br />

before applying pressure.<br />

Search for leaks with a piece of cardboard. Protect hands and body from high pressure fluids.<br />

If an accident occurs, see a doctor immediately. Any fluid injected into the skin must be surgically<br />

removed within a few hours or gangrene may result.<br />

Note: Use pipe sealant on pipe thread joints only.

Installation 19<br />

Oil Tank, Valve and Hose Installation Continued...<br />

Item PN Description Qty.<br />

1 52898 PUMP HYD MUNCIE PK1-11-02BSBB 2.46 CID 1<br />

2 C4747 NIPPLE O'RING 45 4603-20-16 1<br />

3 C1123 HOSE CLAMP 88 DB-20 2<br />

4 17767 HOSE SUCT 1.25 10FT 1<br />

5 45124 FTG BULKHEAD 8WJLO-WLNL-S 4<br />

6 46721 HOSE 0.5(471TC-JC-J9-8-8-8-84) 1<br />

7 C6229 FILTER LONG ZAE-10L 1<br />

8 C5552 FILTER STRAINER TFS-1220-0 1<br />

9 C2126 PLUG DRAIN MAGNETIC 3/4 1<br />

10 C6014 FTG ADAPT 8-12 FLO-S MNPT/MFS 1<br />

11 26455 RSRVR ASM 10GAL K MODEL 1<br />

12 15462 CAP FILL ASS'Y W/ 3 NECK 1<br />

13 12386 CAP SCR 0.50-13X7.50 HHGR5 4<br />

15 C6106 NUT 0.50 HHGR5 NYLOC 4<br />

16 0347 NUT 0.38-16 HHGR5 NYLOC 8<br />

17 0529 CAP SCR 0.38-16X2.50 HHGR5 8<br />

18 45020 PIN 1.25X7.00 W/HOLE 6<br />

19 50638 HOSE 0.38(471TC-JC-JC-8-8-6-63) 2<br />

21 1556 FTG ADAPT 90 8-C50LO-S 4<br />

22 19369 HOSE CLAMP 4.13-7.00 5416K38 4<br />

23 45077 CYLINDER 4.00X29.00 KPAC 2<br />

25 50636 HOSE 0.38(471TC-JC-JC-8-8-6-102) 2<br />

26 50637 HOSE 0.38(471TC-JC-JC-8-8-6-44) 2<br />

27 45072 CYLINDER 4.00X32.00 KPAC 2<br />

28 50639 HOSE 0.38(471TC-JC-JC-8-8-6-55) 2<br />

29 45023 PIN WLDMT 1.25X10.31 2<br />

30 50640 HOSE 0.38(471TC-JC-J9-8-8-6-52) (TILT CYLINDERS) 2<br />

50641 HOSE 0.38(471TC-JC-J5-8-8-6-53) (LIFT CYLINDER EXTEND) 1<br />

50642 HOSE 0.38(471TC-JC-J5-8-8-6-54) (LIFT CYLINDER RETRACT) 1<br />

31 47150 VB V20 2-SECTION W/ LOCKOUT KPCC 1<br />

45529 VB V20 3-SECTION W/ LOCKOUT KPCC 1<br />

32 C4227 FTG ADAPT 90 8-12 C5OLO-S 2<br />

34 31676 HOSE 0.50(471TC-JC-JC-8-8-8-120) 1<br />

35 D0549 FTG ADAPT 16-8 F5OG5-S 1<br />

36 C0930 CAP SCR 0.31-18X3.00 HHGR5 3<br />

37 0342 NUT 0.31-18 HHGR5 NYLOC 3<br />

38 46655 PLATE SERIAL VALVE PLATE KPCC #74-373 1<br />

43 C6226 FILTER HEAD 25GPM .75NPT 1<br />

44 1544 FTG ADAPT 8 F5OLO-S 5

20 <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

The standard cable controls supplied with<br />

<strong>Stellar</strong> equipment are a high-quality assembly<br />

which seal out moisture, are corrosion<br />

protected, and engineered to minimize<br />

backlash (lost motion). After the container<br />

carrier frame is mounted to the truck chassis,<br />

the remote cable controls may be<br />

installed.<br />

Cable Control Mounting<br />

1. On the hydraulic control valve, remove<br />

the screws holding the spool cover plate.<br />

Postion the handle assembly on the valve<br />

face and install the screws provided with<br />

the handle kit. Install the clevis pin and<br />

cotter pin.<br />

2. The valve is mounted to the valve bracket<br />

welded to the left side of the main<br />

assembly.<br />

3. Position the control cable bulkhead plate<br />

on the top of the valve bracket welded<br />

to the left side of the main assembly.<br />

Install the control cable bulkhead plate<br />

with 1/2” cap screws and nuts, or weld. If<br />

necessary, temporarily assemble the<br />

threaded cable end to the bulkhead<br />

plate for proper positioning with the valve<br />

handles.<br />

4. Mount the cable controllers to the control<br />

mount supplied. Other mounting<br />

options are shown in the following illustration:<br />

FLUSH<br />

MOUNTING<br />

<strong>SI</strong>DE<br />

MOUNTING<br />

Cable Control Installation<br />

Figure 9<br />

BANKED<br />

TOGETHER<br />

Important<br />

A. A good cable path is essential for a<br />

properly operating system. Keep bends<br />

in the cable path to a minimum and as<br />

generous as possible. Under no circumstances<br />

should any bend be tighter than<br />

an 8” radius.<br />

B. Protect the cable from heat above 225ºF<br />

and avoid hot areas such as the exhaust<br />

system, etc.<br />

C. Protect the cable from physical damage<br />

such as pinching or crushing and do not<br />

use cable supports which may crush or<br />

deform cable.<br />

D. Allow room for flexing where the cable is<br />

attached to moving parts of the equipment<br />

so that the cable is neither kinked<br />

nor stretched.<br />

5. Choose a mounting location which is<br />

convenient and comfortable for the<br />

operator and provides adequate clearance<br />

for the control lever movement.<br />

Check the underside of the cab for reinforcement<br />

members, air lines, wiring harnesses,<br />

and linkages before cutting into<br />

the floor. Be sure the location chosen<br />

allows the cables to be led easily away<br />

from the control. Reversing control direction<br />

usually is not necessary. In most<br />

cases, the direction of the lever movement<br />

for a given valve function can be<br />

changed by switching the hydraulic lines<br />

at the valve. If this is not an option, control<br />

operation can be changed simply by<br />

turning the cable controller 180º.<br />

6. Cut a hole for the control cables to pass<br />

through.<br />

7. If using the control provided, mark and<br />

drill four (4) .375” diameter holes for the<br />

3/8” cap screws provided.

Cable Control Installation Continued...<br />

Installation 21<br />

Cable Connections<br />

8. Remove the screw from the cable controller where the cable end will install. Do not<br />

remove the other screws passing through the cable control housing.<br />

9. Screw the hex threaded<br />

cable end into the cable<br />

controller end. Moving he<br />

cable controller handle<br />

will allow easier access to<br />

start the thread. If the<br />

hex threaded cable end<br />

is not visible, make certain<br />

the cable is free to slide<br />

back and forth and shake<br />

the cable end with the<br />

end in the downward<br />

position.<br />

10. Install the control head end of the cable into the cable controller. Reinstall the<br />

cable controller screw passing through the groove in the end of the cable housing.<br />

11. Check the control for free movement and correct valve control.<br />

12. To connect the cable to the valve handle, start by removing the mounting nut from<br />

the cable assembly (Large nut in photo above).<br />

13. Install the threaded portion of the cable assembly through the bulkhead weldment<br />

and replace the mounting nut.<br />

14. Install the clevis provided to the cable end. The cable end should be parallel to the<br />

bulkhead weldment.<br />

15. Locate the clevis on the<br />

control valve handle. If a<br />

hole is not provided in the<br />

control valve handle for the<br />

clevis, drill a .375” diameter<br />

hole through the valve handle<br />

as illustrated. Install pin<br />

and keeper included with<br />

clevis.<br />

16. Do a final check of the controls<br />

for free movement and<br />

correct valve control.<br />

VALVE<br />

CONTROL CABLE<br />

BULKHEAD PLATE<br />

1-1/2”<br />

Figure 10<br />

Figure 11<br />

DRILL .375” DIA<br />

HOLE THROUGH<br />

HANDLE IF<br />

HOLE NOT<br />

PRESENT

22 <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

Pre-Assembled Air Control Tower Installation<br />

1. Determine a suitable location which is in<br />

a comfortable location for the driver and<br />

dnot in the way of the transmission lever.<br />

2. Position the lower bolt holes so that the<br />

bolts will miss any cable, wires, or structural<br />

members in or under the cab floor.<br />

3. Mark and drill the four (4) .375” diameter<br />

holes for the 3/8” cap screws supplied for<br />

the tower.<br />

4. Determine a location in the area<br />

between the mounting holes to run the<br />

air lines.<br />

5. Drill a 2” to 3” diameter hole through the<br />

floor of the truck. Remove all burrs and<br />

sharp edges. Line the hole with the<br />

grommet material supplied.<br />

6. Using the washers on the underside of the<br />

floor, attach the tower to the floor with<br />

3/8” cap screws and lock nuts.<br />

After the control tower has been mounted,<br />

the air lines can be routed. The air line tubing<br />

is color coded as follows:<br />

Blue - Tilt Cylinder Extend<br />

Green - Tilt Cylinder Retract<br />

Orange-Lift Cylinder Extend<br />

Yellow-Lift Cylinder Retract<br />

Red-PTO<br />

Black-Exhaust<br />

Silver-Supply<br />

Black-Rotate Clockwise<br />

Black-Rotate Counter-Clockwise<br />

Air Control Installation<br />

To remove an air line from a fitting, push the<br />

line in, hold the internal sleeve of the fitting,<br />

then pull the air line out.<br />

1. Pass the air lines through the hole lined<br />

with grommet material in the floor.<br />

2. Route the exhaust air line outside of the<br />

truck cab.<br />

3. Determine a suitable route for the air lines<br />

to the control valve. Avoid sharp bends,<br />

sharp edges, and heat sources.<br />

4. Install supplied elbow fittings into air actuators.<br />

5. Connect the air lines to the elbow fittings<br />

in the air actuators.<br />

6. Bundle the air lines together and secure,<br />

out of the way.<br />

Start-up Procedure<br />

1. Charge the air system of the truck.<br />

Check all lines for leakage.<br />

2. Operate the controllers and check for<br />

correct hydraulic movement. Note: The<br />

controllers pressurize the port toward the<br />

handle is moved. If the function is to be<br />

reversed, exchange the air lines at the<br />

controller or actuator.<br />

3. After the correct connections have been<br />

made and the <strong>Stellar</strong> eqipment completely<br />

installed, engage the PTO to<br />

check operation.

Air Controls - PN 47144<br />

PN 47144<br />

ITEM PART DESCRIPTION QTY.<br />

1 52901 CONTROL TOWER ASM 2SECT AIR 1<br />

2 0345 CAP SCR 0.38-16X1.50 HHGR5 4<br />

3 0346 WASHER 0.38 USS FLAT ZINC 8<br />

4 0347 NUT 0.38-16 HHGR5 NYLOC 4<br />

5 45687 ELBOW ADAPTER MALE SWIVEL (NOT SHOWN) 4<br />

1<br />

2<br />

3<br />

3<br />

4<br />

Installation 23<br />

CAB FLOOR

24 <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

3-Section Air Controls - PN 46152<br />

PN 46152<br />

ITEM PART DESCRIPTION QTY.<br />

1 52902 CONTROL TOWER ASM 3SECT AIR 1<br />

2 0345 CAP SCR 0.38-16X1.50 HHGR5 4<br />

3 0346 WASHER 0.38 USS FLAT ZINC 8<br />

4 0347 NUT 0.38-16 HHGR5 NYLOC 4<br />

5 45687 ELBOW ADAPTER MALE SWIVEL (NOT SHOWN) 6<br />

1<br />

2<br />

3<br />

3<br />

4<br />

CAB FLOOR

8<br />

10<br />

3<br />

6<br />

9<br />

14 15<br />

LOOKING AT TOP OF VALVE BANK<br />

MOUNTING BRACKET<br />

11<br />

BOTH <strong>SI</strong>DES *<br />

PN 46288<br />

16<br />

1<br />

BOTH <strong>SI</strong>DES<br />

ITEM<br />

PART<br />

DESCRIPTION<br />

QTY.<br />

1 25627<br />

DECAL<br />

CRUSH<br />

POINT<br />

4<br />

2 45697 DECAL CAUTION PTO SPEED (NOT SHOWN, PLACE IN CAB) 1<br />

3 45726 DECAL WARNING HYDRAULIC SAFET74-276 1<br />

4 45906 DECAL K-PAC HOIST UP (NOT SHOWN, PLACE IN CAB) 1<br />

5 45971 DECAL DNGRSTAND CLEAR, KPCC 74-346 2<br />

6 45972 DECAL CAUTION-LATCH KPAC (PLACE QTY1 IN CAB) 2<br />

7 45973 DECAL CARRIER CNTRLS KPCC (NOT SHOWN, PLACE IN CAB) 1<br />

8 45974 DECAL CAUTION-OPERATIN INSTR 74-345 1<br />

9 45975 DECAL CAUTION-FORK CARRIAGE (PLACE QTY 1 IN CAB) 2<br />

10 45976 DECAL DNGR WATCH ELEC LINES K74-347 1<br />

11* 16094 DECAL STELLAR LOGO5.00X13.00REFLECT 2<br />

12* 13002 DECAL HYD OIL SPECIFICATION (NOT SHOWN, PLACE ON RSRVR) 1<br />

13 42971 DECAL OIL FILTER CHANGE (NOT SHOWN, PLACE ON RSRVR) 1<br />

14<br />

4214<br />

DECAL<br />

CONTACT<br />

STELLAR<br />

1<br />

15<br />

35234<br />

DECAL<br />

STELLAR<br />

MADE<br />

IN<br />

THE<br />

USA<br />

1<br />

16 46655 PLATE SERIAL VALVE PLATE KPCC (NOT INCLUDED IN PN46288 DECAL KIT) 1<br />

* Not <strong>Inc</strong>luded in PN 46288<br />

Decal Kit - PN 46288<br />

5<br />

Installation 25<br />

BOTH <strong>SI</strong>DES

26 <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

Hydraulic System Start-Up Procedure<br />

Caution: Do not operate the pump until the<br />

system is filled with oil. Damage to the<br />

pump bearing and shafts can occur.<br />

1. Grease the lift cylinder and fork cylinder<br />

pivot points and the container carrier<br />

hinge pins.<br />

2. Fill the reservoir with 10 gallons of high<br />

quality of SAE 10 hydraulic oil i.e.: Arco<br />

Duro 150, Harmony 32 AE by Gulf, or<br />

Mobil DTE 25.<br />

Warning: Escaping fluid under pressure can<br />

penetrate the skin can cause serious injury.<br />

Avoid the hazard by relieving pressure<br />

before disconnecting hydraulic lines.<br />

Tighten all connections before applying<br />

pressure. Search for leaks with a piece of<br />

cardboard. Protect hands and body from<br />

high pressure fluids. If an accident occurs,<br />

see a doctor immediately. Any fluid injected<br />

into the skin must be surgically removed<br />

within a few hours or gangrene may result.<br />

Hose Kit PN - 49534 PN 49534<br />

3. Check the carrier for loose parts, tools,<br />

clamps, or chains.<br />

4. Check the overhead area for obstructions.<br />

5. Clear all equipment from under the rear<br />

of the container carrier.<br />

6. Slowly extend the cylinders. Check for<br />

binding.<br />

7. Raise and lower the fork frame and tilt<br />

the forks up and down.<br />

8. Extend the cylinders completely a third<br />

time, and bleed off any entrapped air.<br />

9. Check all connections and components<br />

for leaks.<br />

10. Retract the cylinders, pressurize the lines,<br />

and check for leaks.

CONTROL<br />

VALVE<br />

Hydraulic Schematic<br />

4<br />

2<br />

ITEM PART DESCRIPTION QTY.<br />

1 50636 HOSE .38X102.00 2<br />

2 50640<br />

HOSE<br />

. 38X52.<br />

00<br />

2<br />

3 50637<br />

HOSE<br />

. 38X44.<br />

00<br />

2<br />

4 50641<br />

HOSE<br />

. 38X53.<br />

00<br />

1<br />

5 50638<br />

HOSE<br />

. 38X63.<br />

00<br />

2<br />

6 50642<br />

HOSE<br />

. 38X54.<br />

00<br />

1<br />

7 50639<br />

HOSE<br />

. 38X55.<br />

00<br />

2<br />

8 50643 HOSE .38X217.00 2<br />

6<br />

7<br />

1<br />

5<br />

8<br />

3<br />

Installation 27<br />

TILT CYLINDERS<br />

LIFT CYLINDERS<br />

ROTATOR MOTOR

28 <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

HOIST UP<br />

LIGHT<br />

TRUCK CAB<br />

Note: The Hoist Up Light will only<br />

be activated when the iginition is hot.<br />

It is recommended to tap into the<br />

PTO light power source when wiring.<br />

TAG LIGHT<br />

(BROWN)<br />

TAG LIGHT<br />

(BROWN)<br />

WHITE<br />

FUSE<br />

BLOCK<br />

COLORED<br />

RED CLEARANCE<br />

(WHITE/BROWN)<br />

LH TURN/<br />

STOP<br />

RED LIGHT<br />

(WHITE/<br />

BROWN/<br />

YELLOW)<br />

PTO<br />

LIGHT<br />

PTO<br />

GROUND<br />

LH TURN/<br />

STOP<br />

RED LIGHT<br />

(WHITE/<br />

BROWN/<br />

YELLOW)<br />

GROUND<br />

TO FRAME<br />

BACKUP<br />

WHITE LIGHT<br />

(WHITE/<br />

BLACK)<br />

Electrical Schematic<br />

REMOTE<br />

SWITCH<br />

CAPPED<br />

(NOT USED)<br />

GROUND<br />

(WHITE)<br />

PN 40310<br />

PN 38056<br />

PN 12516<br />

JUMPER TO MID-BODY<br />

CLEARANCE LIGHTS<br />

GROUND<br />

(WHITE)<br />

REAR CLEARANCE<br />

(BROWN/WHITE)<br />

EXISTING TRUCK<br />

WIRING HARNESS<br />

BACK-UP LIGHT<br />

(BLACK)<br />

LH, TURN, BRAKE, LIGHT<br />

(YELLOW)<br />

TAIL, CLEARANCE, LIGHT<br />

(BROWN)<br />

RH, TURN, BRAKE, LIGHT<br />

(GREEN)<br />

BACK-UP ALARM<br />

(WHITE/BLACK)<br />

BACK-UP ALARM<br />

(WHITE/BLACK)<br />

Note:<br />

Installed inside<br />

of the frame rail.<br />

NOTE: GROUND THE<br />

WHITE WIRES TO THE<br />

BUMPER.<br />

BACKUP<br />

WHITE LIGHT<br />

(WHITE/<br />

BLACK)<br />

RH TURN/<br />

STOP<br />

RED LIGHT<br />

(WHITE/<br />

BROWN/<br />

YELLOW)<br />

RH TURN/<br />

STOP<br />

RED LIGHT<br />

(WHITE/<br />

BROWN/<br />

YELLOW)<br />

RED CLEARANCE<br />

(WHITE/BROWN)

Assembly Drawings 29<br />

Chapter 5 - Assembly Drawings<br />

14<br />

11<br />

2<br />

3<br />

2<br />

3<br />

2<br />

4<br />

1<br />

Base Assembly - PN 45029<br />

7<br />

2<br />

9<br />

1<br />

6<br />

10<br />

12<br />

PN 45029<br />

10<br />

ITEM PART DESCRIPTION QTY.<br />

1 0340 WASHER 0.25 USS FLAT ZINC 3<br />

2 0347 NUT 0.38-16 HHGR5 NYLOC 9<br />

3 0530 CAP SCR 0.38-16X2.75 HHGR5 6<br />

4 1554 FTG ADAPT 8-F5OLO-S 4<br />

5 1556 FTG ADAPT 8 C5OLO-S 4<br />

6 3381 HOSE CLAMP BOLT ON 1210 CRANE 1<br />

7 8621 CLAMP HOSE/TUBE AG-3 2<br />

8 19369 HOSE CLAMP 4.13-7.00 5416K38 4<br />

9 45012 BASE KPCC 1<br />

10 45020 PIN 1.25X7.00 W/ HOLE 4<br />

11 45031 PIN 1.25X9.44 W/ HOLE 2<br />

12 45072 CYLINDER 4.00X32.00 2<br />

13 45077 CYLINDER 4.00X29.00 2<br />

14 45764 PLUG PLASTIC 6.00X6.00 SQ-6 2<br />

5<br />

8<br />

13

30 <strong>Container</strong> <strong>Carrier</strong> Owner’s <strong>Manual</strong><br />

3<br />

6<br />

Lift Frame Assembly - PN 45033<br />

2<br />

6<br />

7<br />

8<br />

10<br />

ITEM<br />

PART<br />

DESCRIPTION<br />

QTY.<br />

1 44959 LIFT FRAME WLDMT KPCC 1<br />

2 45023<br />

PIN<br />

WLDMT<br />

1.<br />

25X10.<br />

31<br />

2<br />

3 c1592<br />

ZERK<br />

1/<br />

8 NPT<br />

STRAIGHT<br />

4<br />

4 42660 COLLAR 0.53X0.75X1.00 UHMW 1<br />

5 45106PC CATCH ARM WLDMT KPCC 1<br />

6 0249 BUSHING BPC20DXR20 1.25X1.25 8<br />

7 0530 CAP SCR 0.38-16X2.75 HHGR5 2<br />

8 0347 NUT 0.38-16 HHGR5 NYLOC 2<br />