You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

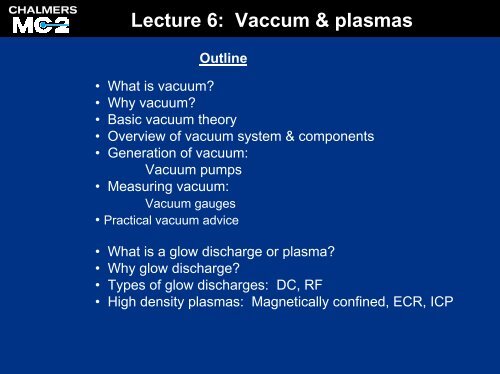

Lecture 6: Vaccum & plasmas<br />

Outline<br />

• <strong>What</strong> <strong>is</strong> <strong>vacuum</strong>?<br />

• Why <strong>vacuum</strong>?<br />

• Basic <strong>vacuum</strong> theory<br />

• Overview of <strong>vacuum</strong> system & components<br />

• Generation of <strong>vacuum</strong>:<br />

Vacuum pumps<br />

• Measuring <strong>vacuum</strong>:<br />

Vacuum gauges<br />

• Practical <strong>vacuum</strong> advice<br />

• <strong>What</strong> <strong>is</strong> a glow d<strong>is</strong>charge or plasma?<br />

• Why glow d<strong>is</strong>charge?<br />

• Types of glow d<strong>is</strong>charges: DC, RF<br />

• High density plasmas: Magnetically confined, ECR, ICP

<strong>What</strong> <strong>is</strong> <strong>vacuum</strong>?<br />

General definition<br />

• <strong>vacuum</strong> = empty space, from vacuus = [Latin] empty<br />

Scientific definitions<br />

• A pressure lower than atmospheric, in an enclosed area.<br />

• A space in which the pressure <strong>is</strong> significantly lower than<br />

atmospheric pressure.<br />

• A condition in which the quantity of atmospheric gas present <strong>is</strong><br />

reduced to the degree that, for the process involved its effect can be<br />

considered negligible.

Why <strong>vacuum</strong>?<br />

• Control a chemical reaction.<br />

Reaction rate, concentration, etc.<br />

• Create suitable condition for plasmas.<br />

~mbar<br />

• Long mean free path.<br />

Physical vapor deposition, cathode ray tube (CRT), etc.<br />

• Cavity free manufacturing.<br />

Vacuum mould, <strong>vacuum</strong> cast, <strong>vacuum</strong> package, etc.<br />

• Create forces and flows.<br />

Vacuum pick-up, <strong>vacuum</strong> cleaner, etc.

Ideal gas law<br />

• Experimentally found by Robert Boyle and publ<strong>is</strong>hed 1662.<br />

pV =<br />

nRT<br />

p = pressure<br />

V = volume<br />

n = number of gas molecules<br />

R = universal gas constant<br />

T = temperature<br />

• Works well for sub atmosphere pressure and normal temperature.<br />

• For better accuracy use a correction factor q(p,T). (gas specific)

Kinetic gas theory<br />

A theory that could explain Robert Boyle’s experimental results.<br />

The gas molecules…<br />

• …are treated as hard spheres.<br />

• …are many, small, and far apart compared to their size.<br />

• …collide elastically with walls and each other.<br />

• …moves randomly with constants speed between coll<strong>is</strong>ions.<br />

• …obey Newton’s laws of motion.

Gas molecule speed d<strong>is</strong>tribution<br />

P<br />

Derived from kinetic gas theory<br />

() v<br />

⎡<br />

= 4π<br />

⎢<br />

⎣<br />

m<br />

2πkT<br />

⎤<br />

⎥<br />

⎦<br />

3<br />

2<br />

v<br />

2<br />

e<br />

−mv<br />

v = gas molecule speed<br />

m = gas molecule mass<br />

k = Boltzmann’s constant<br />

2<br />

2kT

v rms<br />

=<br />

Gas molecule speed & mean free path<br />

Derived from kinetic gas theory<br />

3kT<br />

m<br />

v rms = root mean square velocity<br />

λ =<br />

kT<br />

2π<br />

d<br />

2<br />

p<br />

λ = mean free path<br />

d = gas molecule diameter

Ultra-high <strong>vacuum</strong><br />

High <strong>vacuum</strong><br />

Fore <strong>vacuum</strong><br />

Low <strong>vacuum</strong><br />

General <strong>vacuum</strong> chart<br />

Mean<br />

free path<br />

Air<br />

pressure<br />

[mbar]<br />

1km<br />

100 m<br />

10 m<br />

1m<br />

1dm<br />

1cm<br />

1mm<br />

10 -13<br />

10 -12<br />

10 -11<br />

10 -10<br />

10 -9<br />

10 -8<br />

10 -7<br />

10 -6<br />

10 -5<br />

10 -4<br />

10 -3<br />

10 -2<br />

10 -1<br />

1<br />

10<br />

Altitude<br />

500 km<br />

200 km<br />

100 km<br />

50 km<br />

Application<br />

Advanced scientific research<br />

1000 km Space simulation<br />

High <strong>vacuum</strong> vapor deposition<br />

Industrial hard coating<br />

Space begins<br />

Incandescent lamp manufacturing<br />

Vacuum packaging<br />

100 11 km Commercial jet(250 mbar)<br />

8848 m Mt. Everest (320 mbar)<br />

1000 0m Sea level (1013 mbar)

m<br />

1<br />

10 -1<br />

10 -2<br />

D<br />

10 -5<br />

Molecular<br />

flow<br />

10 -4<br />

10 -3<br />

Intermediate<br />

Gas flow regimes<br />

10 -2<br />

• Mean free path < wall d<strong>is</strong>tance<br />

• Flow limited by molecule-molecule coll<strong>is</strong>ions<br />

• Gas <strong>is</strong> “pushed” around corners<br />

V<strong>is</strong>cous<br />

flow<br />

P<br />

10-1 1 mbar<br />

• Mean free path > wall d<strong>is</strong>tance<br />

• Flow limited by molecule-wall coll<strong>is</strong>ions<br />

• High conductance requires free line-of-sight over large solid angle

C = Q / (P – P p )<br />

S p = Q / P p<br />

3.6 m 3 /h = 1 l/s<br />

P<br />

P p<br />

Gas flow rates<br />

Q = 60sccm = 1 mbar l/s<br />

Q<br />

Q = Gas flow<br />

P = Pressure<br />

P p = Pump inlet pressure<br />

C = Conductance<br />

S p = Pumping speed<br />

Commonly:<br />

Process gas flow [sccm]<br />

Gas leaks [mbar l/s]<br />

Fore <strong>vacuum</strong> pumps [m 3 /h]<br />

High <strong>vacuum</strong> pumps [l/s]

Electrical feedthrough<br />

Ceramics<br />

Chamber walls<br />

Stainless steel<br />

Aluminum<br />

Vacuum system<br />

Motion feedthrough<br />

Metal bellows<br />

Magnetic coupled<br />

Elastomer O-ring<br />

Ferro-fluidic<br />

Windows<br />

Borosilicate glass<br />

Quartz<br />

Sapphire<br />

MgF<br />

Ceramics Flange seal<br />

Elastomer O-ring<br />

Metal seal<br />

Pump<br />

Gauge

Not shown<br />

Intermediate pump<br />

Roots<br />

Fore <strong>vacuum</strong> pump<br />

(Backing pump)<br />

Rotary vane<br />

Scroll<br />

Diaphragm<br />

Generation of <strong>vacuum</strong><br />

High <strong>vacuum</strong><br />

10 -5 -10 -11? mbar<br />

Process gas inlet<br />

Fore <strong>vacuum</strong><br />

10 0 -10 -3 mbar<br />

High <strong>vacuum</strong> pump<br />

Turbo<br />

Cryo<br />

Diffusion<br />

Ion<br />

Atmospheric pressure<br />

Exhausts

B<br />

A<br />

A<br />

Rotary vane pump<br />

• Very common fore <strong>vacuum</strong>- and general<br />

<strong>vacuum</strong> pump.<br />

• Typically 1 or 2 stage configuration.<br />

• Gas <strong>is</strong> moved by rotating vanes.<br />

• Oil <strong>is</strong> used as seal, lubricant, and coolant.<br />

B<br />

A<br />

B<br />

B<br />

A

Rotary vane pump<br />

+ High capacity from 10 3 to ~10 -2 mbar.<br />

- Potential back streaming of oil into <strong>vacuum</strong><br />

chamber.

Scroll pump<br />

• Moving scroll orbiting a fixed scroll.<br />

• Compressed gas volume pushed towards<br />

center outlet.

+ Oil free<br />

+ Reliable, low maintenance.<br />

Scroll pump<br />

- Low to medium capacity (10 3 to ~10 -2 mbar)

Diaphragm pump<br />

+ Oil free<br />

+ Reliable, low maintenance.<br />

- Low capacity (10 3 to ~1 mbar)

Roots pump<br />

• Counter rotating blades moves gas<br />

volume.<br />

• No contact between surfaces → oil free<br />

operation.<br />

• Runs very hot without fore <strong>vacuum</strong><br />

pump.

Roots pump<br />

+ High capacity from 10 to ~10-4 mbar.<br />

(Medium capacity from 1000 to ~10 mbar)<br />

+ Oil free<br />

- Works best together with fore <strong>vacuum</strong> pump.

• Best pump capacity<br />

for heavy (slow) gas<br />

molecules.<br />

Turbo pump<br />

• Fast moving rotor (30k to 90k rpm) with<br />

several stages and many blades per stage.<br />

• High efficiency in the molecular regime<br />

where gas molecules collide with rotor blade<br />

and not each other.<br />

• Some modern pumps have magnetic,<br />

non-contact, bearings.<br />

Stator<br />

blade<br />

Rotor<br />

blade

Turbo pump<br />

+ High capacity from 10 -3 to ~10-8 mbar.<br />

+ Low maintainance.<br />

- Sudden large gas loads may cause severe,<br />

expensive damage.

Cryo pump<br />

Cool head with several plates (stages).<br />

The metal top side of the cool (12K)<br />

plates traps gas molecules by<br />

cryocondensation.<br />

The bottom side of the plates are<br />

coated with active charcoal and traps<br />

gas molecules by cryoadsorption.<br />

The cooling <strong>is</strong> done with a Helium<br />

filled refrigerator loop.<br />

He gas expender<br />

He gas compressor

Cryo pump<br />

+ Very High capacity down to ~10-9 mbar.<br />

+ No contamination.<br />

- Pump saturates if exposed to high pressure or<br />

continuous gas flow.<br />

- Need periodic regeneration of cool head.<br />

Gas Typical pumping speed<br />

[l/s]<br />

Water vapor 9000<br />

Air 3000<br />

Hydrogen 5000<br />

Argon 2500

Diffusion pump<br />

• Hot dense oil vapor <strong>is</strong> forced through<br />

central jets angled downward to give a<br />

conical curtain of vapor.<br />

• Gas molecules are knocked downwards<br />

and eventually reach the fore <strong>vacuum</strong><br />

pump.

Diffusion pump<br />

+ Simple pump without moving parts.<br />

+ High capacity from 10-3 to ~10-8 mbar.<br />

+ Low maintenance.<br />

- Needs cooled baffle to reduce oil contamination of<br />

<strong>vacuum</strong> chamber.

Ion pump<br />

Array of steel tubes<br />

Titanium plate<br />

Magnet<br />

• Free electrons move in helical trajectories towards<br />

the anode, ionizing gas molecules upon coll<strong>is</strong>ions.<br />

• Gas ions strike the Ti cathodes and some gets buried.<br />

• Sputtered Ti deposits inside the tubes and getters gas molecules<br />

through chemical reactions.<br />

B<br />

Ti<br />

U

Ion pump<br />

+ Simple pump without moving parts.<br />

+ Can work at very low pressure ~10 -11 mbar.<br />

+ Oil free.<br />

- Not suitable for gas loads.

Pumping speed diagram<br />

At what Argon gas load [sccm] can we maintain a pump inlet pressure of 1x10-4 mbar?<br />

= p ⋅ P S Q<br />

p<br />

= 3500⋅10<br />

−4<br />

mbar ⋅l<br />

=<br />

s<br />

0.<br />

35<br />

mbar ⋅l<br />

=<br />

s<br />

0.<br />

35⋅<br />

60 sccm<br />

=<br />

21sccm

Measuring <strong>vacuum</strong><br />

10 -12 10 -10 10 -8 10 -6 10 -4 10 -2 10 0<br />

[mbar]<br />

10 2<br />

Bourdon<br />

T/C<br />

Pirani<br />

Capacitive membrane<br />

McLeod<br />

Penning<br />

Schultz-Phelps Ion gauge<br />

Bayard-Apert Ion gauge<br />

Invert Magnetron<br />

RGA

Pirani <strong>vacuum</strong> gauge<br />

• A heated wire res<strong>is</strong>tor in a gauge tube.<br />

• A second wire res<strong>is</strong>tor in a closed reference tube.<br />

• The two wire res<strong>is</strong>tors are 2/4 of a Wheatstone bridge.<br />

• Higher pressure cools the wire and res<strong>is</strong>tance drops.<br />

• The pressure <strong>is</strong> measured from the<br />

unbalanced bridge .<br />

• Pirani gauge works well for pressure<br />

10 1 to ~10 -5 mbar.

Capacitive membrane gauge (CM)<br />

• The unknown pressure P x decide the position of the<br />

metal membrane electrode relative a fixed second<br />

electrode in a closed volume.<br />

• The electrode capacitance can be converted to<br />

pressure.<br />

• Gauge <strong>is</strong> usually calibrated at a pressure

Penning <strong>vacuum</strong> gauge<br />

• Penning gauge often cylindrical in shape.<br />

• DC d<strong>is</strong>charge generated by ~ 2kV.<br />

• Pressure converted from d<strong>is</strong>charge current.<br />

• Penning gauge works well for pressure 10 -2 to<br />

~10 -9 mbar.<br />

B<br />

Magnet<br />

U<br />

I<br />

~ 2kV

I<br />

I g<br />

Ion <strong>vacuum</strong> gauge<br />

• Electrons are emitted from a hot filament.<br />

• Electrons are attracted towards the positive<br />

grid but pass several times before captured.<br />

• Coll<strong>is</strong>ions with gas molecules creates ions<br />

that are collected on negative pin.<br />

• Pressure <strong>is</strong> converted from current I g .<br />

• Ion gauge works well for pressure 10 -4 to<br />

~10 -10 mbar.

Vacuum advice<br />

• The walls of a vented chamber can host a<br />

large amount of condensed matter. Mainly<br />

water.<br />

When the chamber <strong>is</strong> evacuated, the<br />

condensed matter evaporates from the walls.<br />

Th<strong>is</strong> process can prevent good <strong>vacuum</strong> for<br />

weeks.<br />

• Keeping the chamber warm when vented<br />

reduces the condensation on the walls.<br />

• Heating the walls of a evacuated chamber<br />

speed up evaporation rate x2 per 10ºC.<br />

• Do not try to compensate <strong>vacuum</strong> leaks with a<br />

larger pump. Find the leaks and fix them!

<strong>What</strong> <strong>is</strong> a glow d<strong>is</strong>charge?<br />

• Glow d<strong>is</strong>charge also called plasma<br />

• Plasma <strong>is</strong> partially ionized gas.<br />

• The glow <strong>is</strong> excess electromagnetic energy<br />

radiating from excited gas atoms and molecules.

Why glow d<strong>is</strong>charge?<br />

• Neutral particles are difficult to accelerate. Ions<br />

and electrons can be extracted from a glow<br />

d<strong>is</strong>charge and easily accelerated.<br />

• Accelerated inert ions are used for:<br />

Ion milling<br />

Sputter deposition<br />

• Accelerated reactive ions are used for:<br />

Reactive ion beam etching (RIBE)<br />

Reactive ion etching (RIE)<br />

• Accelerated ions can be filtered and counted:<br />

Residual gas analys<strong>is</strong> (RGA)

Why glow d<strong>is</strong>charge?<br />

• Radicals from a plasma <strong>is</strong> used for:<br />

Chemical vapor deposition (PECVD)<br />

Plasma etching<br />

• The electromagnetic radiation from a plasma <strong>is</strong> used for:<br />

General illumination (light tubes, …)<br />

Light sources for optical lithography<br />

LASERs

Glow d<strong>is</strong>charge processes<br />

• D<strong>is</strong>sociation<br />

e* + AB ⇔ A + B + e<br />

• Atomic ionization<br />

e* + A ⇔ A + + e + e<br />

• Molecular ionization<br />

e* + AB ⇔ AB + + e + e<br />

• Atomic excitation<br />

e* + A ⇔ A* + e<br />

• Molecular excitation<br />

e* + AB ⇔ AB* + e<br />

* <strong>is</strong> exited state

DC-plasma reactor<br />

Electrodes must have electrically conducting surfaces.<br />

Pressure<br />

1mTorr – 1Torr

Ionization<br />

DC-plasma reactor<br />

Anode<br />

Cathode<br />

Secondary<br />

electron em<strong>is</strong>sion

Glow, charge, & field d<strong>is</strong>tribution

RF-plasma reactor<br />

Electrically <strong>is</strong>olated electrode surfaces OK.<br />

13.56 MHz<br />

Pressure<br />

1mTorr – 1Torr

Area A 1<br />

DC-bias<br />

V 1 / V 2 ≈ (A 2 / A 1 ) 4<br />

Area A 2

Magnetically confined plasma<br />

Magnetron, commonly used for sputter deposition sources.

Water<br />

Water<br />

Inductively coupled plasma (ICP)<br />

Process gas inlet<br />

Antenna<br />

RF-gen<br />

Z-match Electrostatic shield<br />

Exhausts

B =<br />

e fm 2π<br />

0.<br />

09<br />

T<br />

Electron cyclotron resonance (ECR)<br />

9<br />

2π<br />

⋅2.<br />

54⋅10<br />

⋅9.<br />

3⋅10<br />

−19<br />

1.<br />

6⋅10<br />

=<br />

ω0<br />

=<br />

eB<br />

m<br />

=<br />

= 90 mT<br />

− 31<br />

T<br />

=<br />

2.45 GHz