warmboard: superior radiant technology - Fine Homebuilding

warmboard: superior radiant technology - Fine Homebuilding

warmboard: superior radiant technology - Fine Homebuilding

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

WARMBOARD: SUPERIOR<br />

RADIANT TECHNOLOGY<br />

The Science Of Comfort<br />

Thermodynamics is the field<br />

of science that studies the<br />

movement of heat. Moving<br />

heat from a furnace, boiler,<br />

solar panel, heat pump or<br />

other heat source, into your<br />

home is the job that any<br />

heating system must perform.<br />

How A Radiant Panel Works<br />

A <strong>radiant</strong> panel works by conducting heat from water in a<br />

tube to the surface of your floor, which releases that heat<br />

into your home. It’s that simple. This is why conductivity is<br />

the single most important thermodynamic property that a<br />

<strong>radiant</strong> panel must have. The laws of thermodynamics teach<br />

us how to maximize<br />

conductive efficiency<br />

in <strong>radiant</strong> systems:<br />

use a more conductive<br />

material, make that<br />

material thicker,<br />

and maximize the<br />

contact area of the<br />

conductive panel with<br />

the embedded tubing<br />

and the finished floor.<br />

You know this intuitively because there is a reason why frying<br />

pans are made of aluminum, not concrete. It also explains why<br />

frying pans with thick aluminum bottoms work better than<br />

thin ones.<br />

Performance Made Visible<br />

WHITE PAPER<br />

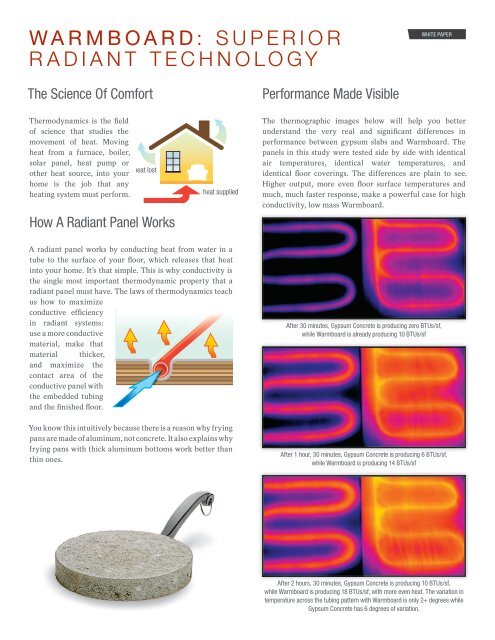

The thermographic images below will help you better<br />

understand the very real and significant differences in<br />

performance between gypsum slabs and Warmboard. The<br />

panels in this study were tested side by side with identical<br />

air temperatures, identical water temperatures, and<br />

identical floor coverings. The differences are plain to see.<br />

Higher output, more even floor surface temperatures and<br />

much, much faster response, make a powerful case for high<br />

conductivity, low mass Warmboard.<br />

After 30 minutes, Gypsum Concrete is producing zero BTUs/sf,<br />

while Warmboard is already producing 10 BTUs/sf<br />

After 1 hour, 30 minutes, Gypsum Concrete is producing 6 BTUs/sf,<br />

while Warmboard is producing 14 BTUs/sf<br />

After 2 hours, 30 minutes, Gypsum Concrete is producing 10 BTUs/sf,<br />

while Warmboard is producing 18 BTUs/sf, with more even heat. The variation in<br />

temperature across the tubing pattern with Warmboard is only 2+ degrees while<br />

Gypsum Concrete has 6 degrees of variation.

Engineered for Better Performance<br />

Warmboard was engineered to take maximum advantage of<br />

the laws of thermodynamics. The panel uses an alloy that is<br />

30% more conductive than conventional aluminum alloys.<br />

The thick aluminum plate is in direct contact with your<br />

finish floor material. The aluminum is also stamped in highly<br />

sophisticated dies so that it covers every square inch of your<br />

floor and makes excellent contact with the large diameter ½"<br />

tubing. The result:<br />

• Higher output at lower water temperatures for<br />

energy savings<br />

• More even floor temperatures for greater comfort<br />

• Moreevenfloortemperaturesforbetterperformancewith<br />

fine hardwood floors<br />

A Word About Thermal Mass<br />

In the past, <strong>radiant</strong> heat had a good reputation for comfort<br />

once the floor reached the correct temperature. But the<br />

high mass gypsum concrete slab based systems which were<br />

common when <strong>radiant</strong> was first popularized in the 1950’s,<br />

took many hours or even days to get to the right temperature.<br />

Given a blank sheet of paper, no engineer familiar with the<br />

laws of thermodynamics would choose such a material for a<br />

<strong>radiant</strong> panel. Gypsum concrete is a poor conductor and its<br />

high mass makes it difficult to accurately meet the changing<br />

heating needs of your home on any hourly or daily basis.<br />

Slab based <strong>radiant</strong> is less than ideal for other reasons:<br />

• They require additional construction costs to support<br />

their weight<br />

• They make it difficult to install hardwood and many other<br />

finish floor materials<br />

• Unyielding, rigidly hard slabs are uncomfortable to stand<br />

or walk on<br />

• They bring moisture into your home, increasing the risk<br />

of mold<br />

Warmboard Inc.<br />

8035 Soquel Drive, Suite 41-A<br />

Aptos, California 95003-3948<br />

877.338.5493<br />

<strong>warmboard</strong>.com<br />

020112<br />

The Right Amount of Heat, Right When<br />

You Want It<br />

All homes have their heat loads change throughout the day as the<br />

sun rises or sets, weather changes, lights or ovens are turned on,<br />

guests arrive or leave. Warmboard will quickly adjust your floor<br />

temperatures to meet those changes. High mass simply can’t<br />

keep up.<br />

70º<br />

50º<br />

30º<br />

Concrete chases temperature<br />

Warmboard maintains<br />

even temperature<br />

Outside<br />

temperatures<br />

6am 12pm 6pm 12am 6am 12pm<br />

When you return to a home that had its temperature lowered<br />

for vacation set back, low mass Warmboard will make you<br />

comfortable in a couple of hours instead of a day later.<br />

70º<br />

60º<br />

50º<br />

Warmboard gets to temperature<br />

far more quickly<br />

Concrete heats up slowly<br />

2 4 6 8 10<br />

Bottom line, Warmboard is the best choice for <strong>radiant</strong> because<br />

unlike the systems used in the infancy of the <strong>radiant</strong> industry,<br />

it was engineered to take maximum advantage of the laws of<br />

thermodynamics. Good science ensures your comfort.