ERPN API 610 Overhung End Suction Process Pump - Flowserve

ERPN API 610 Overhung End Suction Process Pump - Flowserve

ERPN API 610 Overhung End Suction Process Pump - Flowserve

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Pump</strong> Division<br />

<strong>ERPN</strong><br />

<strong>API</strong> <strong>610</strong><br />

<strong>Overhung</strong><br />

<strong>End</strong> <strong>Suction</strong><br />

<strong>Process</strong> <strong>Pump</strong><br />

Bulletin PS-10-20a (E)

<strong>Pump</strong> Supplier<br />

To The World<br />

<strong>Flowserve</strong> is the<br />

driving force in the<br />

global industrial<br />

pump marketplace.<br />

No other pump<br />

company in the<br />

world has the<br />

depth or breadth<br />

of expertise in<br />

the successful<br />

application of<br />

pre-engineered,<br />

engineered and<br />

special purpose<br />

pumps and<br />

systems.<br />

<strong>Pump</strong>ing Solutions<br />

<strong>Flowserve</strong> is providing pumping<br />

solutions which permit customers<br />

to continuously improve<br />

productivity, profitability and<br />

pumping system reliability.<br />

Market Focused<br />

Customer Support<br />

Product and industry specialists<br />

develop effective proposals and<br />

solutions directed toward market<br />

and customer preferences.<br />

They offer technical advice and<br />

assistance throughout each<br />

stage of the product life cycle,<br />

beginning with the inquiry.<br />

Dynamic Technologies<br />

<strong>Flowserve</strong> is without peer in the<br />

development and application of<br />

pump technology, including:<br />

• Hydraulic engineering<br />

• Mechanical design<br />

• Materials science<br />

• Intelligent pumping<br />

• Manufacturing technology<br />

Broad Product Lines<br />

<strong>Flowserve</strong> offers a wide range<br />

of complementary pump types,<br />

from pre-engineered process<br />

pumps, to highly engineered<br />

and special purpose pumps<br />

and systems. <strong>Pump</strong>s are built<br />

to recognized global standards<br />

and customer specifications.<br />

<strong>Pump</strong> Division<br />

<strong>Pump</strong> designs include:<br />

• Single stage process<br />

• Between bearing<br />

single stage<br />

• Between bearing<br />

multistage<br />

• Vertical<br />

• Submersible motor<br />

• Rotary<br />

• Reciprocating<br />

• Nuclear<br />

• Specialty

<strong>ERPN</strong><br />

<strong>API</strong> <strong>610</strong><br />

<strong>Overhung</strong><br />

<strong>End</strong> <strong>Suction</strong><br />

<strong>Process</strong> <strong>Pump</strong><br />

The <strong>ERPN</strong> is the pump of<br />

choice for severe chemical,<br />

petrochemical, refining and<br />

heavy duty industrial service<br />

where full compliance with <strong>API</strong><br />

<strong>610</strong> is not required. The <strong>ERPN</strong><br />

provides users with all of the<br />

important mechanical, hydraulic,<br />

emissions control and safety<br />

components furnished by<br />

<strong>Flowserve</strong> for all specific<br />

applications.<br />

The <strong>ERPN</strong> pump is of horizontal,<br />

end suction-top discharge,<br />

overhung centerline mounted<br />

configuration, <strong>API</strong> <strong>610</strong><br />

classification OH2.<br />

HED<br />

The <strong>ERPN</strong>, available in all <strong>API</strong><br />

<strong>610</strong> material combinations, can<br />

also be equipped with special<br />

features needed for demanding<br />

service requirements, including:<br />

• High suction pressure casing<br />

• Fan cooled bearing housing<br />

(optional water cooled)<br />

• Steam jacketing<br />

• Hot oil construction<br />

HWM<br />

<strong>Pump</strong> Division<br />

Broad Application<br />

• Petroleum refining,<br />

production, offsites<br />

and distribution<br />

• Petrochemical and<br />

heavy-duty chemical<br />

processing<br />

• Gas industry services<br />

• Boiler circulation and<br />

other high temperature<br />

services<br />

• Water and general<br />

industrial<br />

Complementary<br />

<strong>Pump</strong> Designs<br />

<strong>ERPN</strong> pumps may be<br />

used with other <strong>Flowserve</strong><br />

models depending upon<br />

application requirements.<br />

These include:<br />

• Single stage vertical<br />

in-line pumps<br />

• Single and two stage<br />

between bearing pumps<br />

• Multistage between<br />

bearing pumps<br />

• Vertical, double casing<br />

pumps<br />

VTP-Can<br />

WUC<br />

3

4<br />

<strong>ERPN</strong><br />

<strong>API</strong> <strong>610</strong><br />

<strong>Overhung</strong><br />

<strong>End</strong> <strong>Suction</strong><br />

<strong>Process</strong> <strong>Pump</strong><br />

The <strong>Flowserve</strong> <strong>ERPN</strong> pump line,<br />

founded on the engineering and<br />

safety parameters of <strong>API</strong> <strong>610</strong>,<br />

is designed around a modular<br />

system. This modular system<br />

provides maximum mechanical<br />

and hydraulic design flexibility<br />

and allows each pump to be<br />

customized for an individual<br />

application.<br />

The modular system, building off<br />

a platform of standard components,<br />

draws upon the following<br />

optional configurations:<br />

• Closed impeller with front<br />

and back wear rings for<br />

standard services<br />

• Inducer design for low NPSHA<br />

service requirements<br />

• Semi-open impeller design<br />

with back vanes for liquids<br />

containing abrasive particles<br />

• Free flow impeller design with<br />

back vanes for non-clogging<br />

applications containing fibers,<br />

solids, etc.<br />

• Magnetic drive for sealless<br />

needs<br />

Operating Parameters<br />

• Flows to 1100 m 3 /h<br />

(4800 gpm)<br />

• Heads to 230 m (755 ft)<br />

• Temperatures to 350˚C<br />

(660˚F)<br />

• Working pressures to<br />

60 bar (870 psi)<br />

• <strong>Suction</strong> pressures to<br />

50 bar (725 psi)<br />

<strong>Pump</strong> Division<br />

Flanges are in accordance<br />

with ASME B16.5 Class<br />

300 RF standard or 600<br />

RF optional<br />

<strong>Pump</strong> Casing and Cover<br />

feature metal to metal<br />

fit with fully confined,<br />

controlled compression<br />

gasket to ensure proper<br />

sealing and alignment.<br />

The casing will be of<br />

double volute design for<br />

all discharge flanges of<br />

80 mm (3 in) and above<br />

Guide Vane in suction<br />

nozzle for larger sizes<br />

preserves available NPSHA<br />

while reducing vortexing<br />

and assuring uniform flow<br />

to pump inlet<br />

Centerline Supported<br />

<strong>Pump</strong> Casing<br />

accommodates nozzle<br />

loads in accordance<br />

with <strong>API</strong> <strong>610</strong> design<br />

requirements:<br />

• Minimal shaft<br />

misalignment<br />

• Extended rotor,<br />

bearing and seal life

Renewable Wear Rings<br />

for both the casing and<br />

impeller reduce replacement<br />

parts cost.<br />

• Secured by threaded<br />

dowels<br />

• Clearance between wear<br />

surfaces in compliance<br />

with <strong>API</strong> <strong>610</strong> standards<br />

Carbon Steel Bearing Housing<br />

• Labyrinth type oil seals retain<br />

oil and exclude atmospheric<br />

contaminants and moisture<br />

• Optional bearing isolators<br />

available<br />

• Optional oil mist or oil<br />

purge for continuous bearing<br />

lubrication<br />

<strong>API</strong> <strong>610</strong> Standards for the<br />

most critical parameters are<br />

met in all versions of the <strong>ERPN</strong><br />

family of pumps.<br />

• Vibration limits<br />

• Deflection limits at seal faces<br />

• Nozzle loading capabilities<br />

• Balancing grades<br />

<strong>API</strong> 682 Seal Chamber<br />

accommodates a wide variety<br />

of seal configurations including<br />

dual pressurized and unpressurized<br />

cartridge types for the<br />

most severe services. A full<br />

complement of <strong>API</strong> <strong>610</strong> seal<br />

flush piping plans is available.<br />

Cartridge Seal Mounting<br />

assures:<br />

• Ease of maintenance<br />

• Precise seal face setting for<br />

maximum seal life<br />

Back Pull-out of rotating<br />

assembly simplifies<br />

maintenance as neither the<br />

motor nor piping connections<br />

are disturbed.<br />

<strong>Pump</strong> Division<br />

Bearing Configurations<br />

Standard-roller type radial<br />

bearing and duplex, single<br />

row, 40˚ angular contact<br />

back-to-back mounted<br />

thrust bearings.<br />

Dynamically Balanced<br />

Impeller limits vibration<br />

and assures smooth<br />

operation over wide flow<br />

range.<br />

• Casting techniques<br />

and manufacturing<br />

processes for fine<br />

finish, high efficiency<br />

• Positively locked,<br />

anti-rotation impeller<br />

nut with threads<br />

unexposed to pumped<br />

fluid<br />

5

6<br />

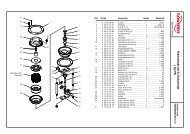

Options and<br />

Technical Data<br />

Non-Clogging Recessed<br />

Impeller Design<br />

<strong>ERPN</strong>-O Semi Open<br />

Design with Replaceable<br />

Front Wear Plate<br />

Inducer<br />

A high specific speed, axial flow<br />

pumping device, an inducer<br />

provides significant improvement<br />

in suction performance by<br />

reducing NPSHR.<br />

The <strong>ERPN</strong>-M range of sealless<br />

process pumps is the solution<br />

for applications where leakagefree<br />

pumping of hazardous,<br />

toxic, explosive or ultra-high<br />

valuable liquids is required, and<br />

any emissions or leakage due<br />

<strong>ERPN</strong> Range Chart<br />

TDH - 50 Hz<br />

m 3 /h<br />

gpm<br />

ft m<br />

300<br />

800<br />

600 200<br />

500<br />

400<br />

300 100<br />

80<br />

200<br />

60<br />

50<br />

40<br />

100<br />

30<br />

80<br />

60 20<br />

50<br />

40<br />

30 10<br />

8<br />

20<br />

6<br />

5<br />

15<br />

m3 /h<br />

gpm<br />

<strong>ERPN</strong> – MAG Drive<br />

6<br />

8<br />

10<br />

1<br />

2<br />

2<br />

5<br />

6<br />

8<br />

10<br />

3<br />

2 Pole<br />

4 Pole<br />

4<br />

20<br />

5<br />

6<br />

30<br />

8<br />

40<br />

10<br />

50<br />

60<br />

80<br />

20<br />

100<br />

30<br />

40<br />

200<br />

50<br />

60<br />

300<br />

80<br />

400<br />

100<br />

500<br />

600<br />

3<br />

4<br />

20<br />

5<br />

6<br />

30<br />

8<br />

40<br />

10<br />

50<br />

60<br />

80<br />

20<br />

100<br />

30<br />

40<br />

200<br />

50<br />

60<br />

300<br />

80<br />

400<br />

100<br />

500<br />

600<br />

to mechanical seal failure is<br />

unacceptable. Safety features<br />

such as temperature probe<br />

(thermocouple), pressure switch<br />

and secondary containment seal<br />

are part of the standard scope<br />

of supply.<br />

Flow Rate - 60 Hz<br />

Flow Rate - 50 Hz<br />

200<br />

800<br />

1000<br />

200<br />

800<br />

1000<br />

300<br />

400<br />

500<br />

600<br />

300<br />

2000<br />

400<br />

500<br />

600<br />

2000<br />

800<br />

1000<br />

1600<br />

3000<br />

4000<br />

5000<br />

6000<br />

3000<br />

800<br />

1000<br />

1300<br />

4000<br />

5000<br />

ft m<br />

400<br />

1000<br />

300<br />

800<br />

600 200<br />

500<br />

400<br />

300 100<br />

80<br />

200<br />

60<br />

50<br />

40<br />

100<br />

30<br />

80<br />

60 20<br />

50<br />

40<br />

30 10<br />

8<br />

20<br />

7<br />

<strong>Pump</strong> Division<br />

<strong>API</strong> Material<br />

Combinations<br />

• S-5 Carbon steel with<br />

carbon steel internals<br />

• S-6 Carbon steel with<br />

12% chrome internals<br />

• S-8 Carbon steel with<br />

316 SS internals<br />

• C-6 12% chrome with<br />

12% chrome internals<br />

• A-8 316 SS with 316 SS<br />

internals<br />

• D-1 Duplex with duplex<br />

internals<br />

In addition the <strong>ERPN</strong><br />

is also available in low<br />

temperature carbon<br />

steel and super duplex<br />

stainless steel.<br />

Baseplate Options<br />

• Drain pan design<br />

– Welded and fabricated<br />

carbon steel<br />

– Sloping drain pan<br />

with drain connection<br />

• Drain rim design<br />

– Drain rim provided<br />

along baseplate<br />

perimeter<br />

– Drain pan provided<br />

below complete unit<br />

TDH - 60 Hz

Global<br />

Engineered Services<br />

and Support<br />

Total Cost Reduction<br />

Asset Management<br />

Product Life Cycle<br />

Performance Re-rates<br />

Site Diagnostics<br />

Repair Services<br />

Energy Management<br />

Spare Parts<br />

Maintenance Contracts<br />

Materials Upgrades<br />

Turnkey Services<br />

Field Repairs<br />

Installation<br />

Project Supervision<br />

Commissioning<br />

Equipment Upgrades<br />

Condition Monitoring<br />

Systems Analysis<br />

Field Machining<br />

Service Dedication<br />

<strong>Flowserve</strong> Engineered Services is<br />

focused on providing customers<br />

with uncompromising service and<br />

support, where and when needed.<br />

Engineered Services is dedicated<br />

to delivering the highest quality<br />

support by integrating its<br />

extensive pump and materials<br />

engineering knowledge with<br />

creative service solutions.<br />

Engineered Services prides itself<br />

in understanding the business<br />

challenges facing customers and<br />

is prepared to manage solutions<br />

to succeed as a team.<br />

A worldwide network of service<br />

and repair centers staffed by<br />

highly skilled engineers and<br />

technicians is available around<br />

the clock, seven days a week to<br />

respond to customer queries,<br />

to evaluate and troubleshoot<br />

problems and to provide<br />

reliable solutions.<br />

Strength of Experience,<br />

Commitment to Excellence<br />

<strong>Flowserve</strong> has long served<br />

industries requiring superior<br />

equipment performance and<br />

service life.<br />

• Oil and gas production<br />

• Hydrocarbon processing<br />

• Chemical processing<br />

• Water resources<br />

• Power generation<br />

• Nuclear<br />

• Mining and mineral processing<br />

• Pulp and paper<br />

• General industry<br />

Engineered Services is dedicated<br />

to maximizing equipment<br />

performance and providing<br />

reliability-centered maintenance<br />

programs for pumps and related<br />

equipment, regardless of manufacturer.<br />

Using the FlowStar<br />

asset management software,<br />

Engineered Services tracks<br />

performance and supports<br />

improvement programs using a<br />

service life cycle cost business<br />

approach. The results are<br />

improved reliability and<br />

increased profitability.<br />

<strong>Pump</strong> Division<br />

Your Business Partner<br />

<strong>Flowserve</strong> partners with<br />

customers to respond to<br />

the dynamic business<br />

conditions that affect<br />

them. <strong>Flowserve</strong> will work<br />

with customers to drive<br />

efficiency, maximize<br />

throughput and control<br />

process quality. Whether<br />

your needs involve onsite<br />

technical assistance<br />

or broader project<br />

planning with full turnkey<br />

responsibility, you can<br />

rely on the strength of<br />

<strong>Flowserve</strong> Engineered<br />

Services to deliver professional,<br />

reliable results.<br />

7

<strong>Flowserve</strong>... Supporting Our Customers<br />

With The World’s Leading<br />

<strong>Pump</strong> Brands<br />

USA and Canada<br />

<strong>Flowserve</strong> Corporation<br />

<strong>Pump</strong> Division<br />

Millennium Center<br />

222 Las Colinas Blvd., 15th Floor<br />

Irving, Texas 75039-5421 USA<br />

Telephone: 1 972 443 6500<br />

Telefax: 1 972 443 6800<br />

Europe, Middle East, Africa<br />

Worthington S.P.A.<br />

<strong>Flowserve</strong> Corporation<br />

Via Rossini 90/92<br />

20033 Desio (Milan), Italy<br />

Telephone: 39 0362 6121<br />

Telefax: 39 0362 303396<br />

Your local <strong>Flowserve</strong> representative:<br />

Jeumont-Schneider Jeumont-Schneider <strong>Pump</strong> Division<br />

To find your local <strong>Flowserve</strong> representative<br />

please use the Sales Support Locator System<br />

found at www.flowserve.com<br />

Or call toll free: 1 800 728 PUMP<br />

Latin America and Caribbean<br />

<strong>Flowserve</strong> Corporation<br />

<strong>Pump</strong> Division<br />

6840 Wynnwood Lane<br />

Houston, Texas 77008 USA<br />

Telephone: 1 713 803 4434<br />

Telefax: 1 713 803 4497<br />

Asia Pacific<br />

<strong>Flowserve</strong> Pte. Ltd.<br />

<strong>Pump</strong> Division<br />

200 Pandan Loop #06-03/04<br />

Pantech 21<br />

Singapore 128388<br />

Telephone: 65 6775 3003<br />

Telefax: 65 6779 4607<br />

Printed in U.S.A.<br />

December 2003<br />

© <strong>Flowserve</strong> Corporation