Hinges Accessories PDF, 1.1 mb - FSB

Hinges Accessories PDF, 1.1 mb - FSB

Hinges Accessories PDF, 1.1 mb - FSB

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

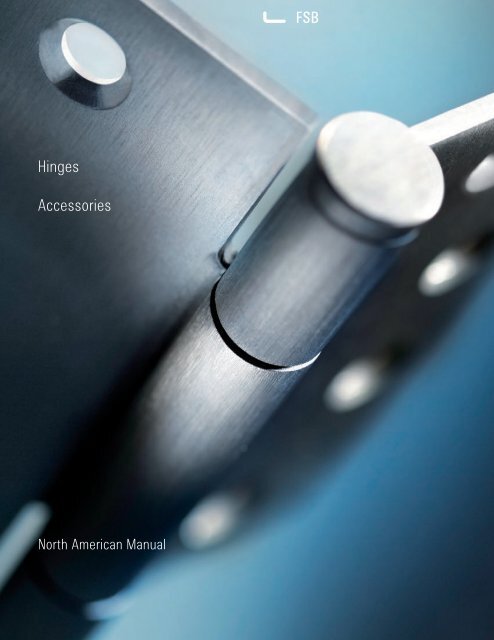

<strong>Hinges</strong><br />

<strong>Accessories</strong><br />

North American Manual

North American Manual<br />

About <strong>FSB</strong><br />

Designer Series<br />

Lockset Program<br />

Lever, Knob & Trim Designs<br />

Sliding Door Hardware<br />

Door Pulls & Glass Door Hardware<br />

<strong>Hinges</strong>, <strong>Accessories</strong><br />

Window Handles<br />

Brass & Bronze Products<br />

Door Closers<br />

METRIC Bath <strong>Accessories</strong><br />

Components<br />

Installation Instructions<br />

Specialty Applications

<strong>Hinges</strong>,<br />

<strong>Accessories</strong><br />

About <strong>FSB</strong><br />

New Products<br />

Materials and Finishes<br />

Overview<br />

<strong>Hinges</strong><br />

Two-Knuckle <strong>Hinges</strong><br />

Three-Knuckle <strong>Hinges</strong><br />

Technical Information<br />

<strong>Accessories</strong><br />

Door Stops<br />

Wall Mounted Doorstops<br />

Card Frames and Cable Box<br />

Coat Hook and Cabinet Knobs<br />

Kick and Push Plates<br />

Letterplates<br />

Bell Push Plates and Intercom<br />

Numerals<br />

4<br />

5<br />

6<br />

8<br />

10<br />

12<br />

14<br />

16<br />

20<br />

21<br />

22<br />

24<br />

25<br />

30<br />

32

About <strong>FSB</strong><br />

1881<br />

<strong>FSB</strong> was established in 1881.<br />

Together with a modest work -<br />

force, company founder Franz<br />

Schneider produced antiquestyle<br />

brass cabinet fittings.<br />

4<br />

1920s<br />

In the early 1920s, the first door<br />

and window fittings appeared in<br />

the <strong>FSB</strong> production program.<br />

The design of these years echoed<br />

the modernism of the Bauhaus<br />

era. Silver metal com po nents<br />

were co<strong>mb</strong>ined with black composite<br />

features.<br />

2000s<br />

<strong>FSB</strong> introduced a limited range<br />

of levers supplied in complete<br />

locksets to the Amercian design<br />

community. The first catalog<br />

was approximately 80 pages.<br />

Two later catalogs increased<br />

<strong>FSB</strong>’s North American offering<br />

to nearly 100 lever designs.<br />

In 2007, <strong>FSB</strong> expanded the<br />

North American distribution<br />

center, moving it to Madison,<br />

CT, where the majority of products<br />

are stocked in natural<br />

anodized aluminum and satin<br />

stainless steel. Stock items can<br />

be shipped in 48 hours. All<br />

non-stock items can be shipped<br />

within two to eight weeks regard -<br />

less of the product type, finish<br />

or project size.<br />

1950s<br />

Beginning with in-house designer<br />

Johannes Potente in the 1950s,<br />

<strong>FSB</strong> created the first handles<br />

which exemplify minimalism,<br />

modernism and ergonomics.<br />

<strong>FSB</strong> is still known for the use of<br />

these design principles today.<br />

Four of Potente’s lever designs<br />

have been included in the<br />

permanent collection of the Museum<br />

of Modern Art (MoMA).<br />

1990s<br />

Inspired by an international<br />

design workshop held in Brakel<br />

in 1986, <strong>FSB</strong> began engaging<br />

the market with contemporary<br />

designs in an initiative dubbed<br />

“Tour d’Europe.” Throughout<br />

this initative <strong>FSB</strong> created design<br />

suites with such renouned<br />

designers as Philippe Starck,<br />

Jasper Morrison, Richard Rogers<br />

and many others.<br />

For the past two decades, <strong>FSB</strong><br />

has continued to work with Architects<br />

and Designers to create<br />

handles – each with their own<br />

personality.<br />

2008<br />

<strong>FSB</strong> dramatically increased its<br />

product range for North Amer -<br />

ica, and issued expanded product<br />

specific catalogs of more<br />

than 500 pages.<br />

Each brochure focuses on<br />

one specific group of products<br />

based on applications. To request<br />

a manual, or view more<br />

detailed information, go to<br />

www.fsbna.com.

New Products<br />

<strong>Hinges</strong><br />

<strong>FSB</strong> introduces a new line of<br />

hinges unique in their construction,<br />

finish and performance.<br />

<strong>FSB</strong> stainless steel two-knuckle<br />

and three-knuckle hinges utilize<br />

carbon steel and oil-impregnated<br />

sintered bronze bearings to minimize<br />

friction, thereby reducing<br />

wear and maintenance. <strong>FSB</strong><br />

stainless steel hinges may be<br />

supplied to simulate nearly all<br />

of our standard finishes, and are<br />

supplied with low-profile buttontip<br />

finials, giving the protruding<br />

hinge barrel an elegant, clean<br />

look.<br />

Sliding Door Hardware<br />

Building owners are demanding<br />

more efficient use of space.<br />

Consequently, architects and<br />

designers are utilizing many<br />

more sliding and pocket doors.<br />

In recognition of this trend<br />

<strong>FSB</strong> has developed an entire<br />

range of flush mounted trim for<br />

passage, privacy and entry<br />

applications. We demonstrate<br />

our penchant for divising<br />

aesthetically pleasing technical<br />

solutions by offering the market’s<br />

first flush pulls with spring<br />

loaded covers, as pictured<br />

above.<br />

A complete overview of these<br />

products is provided in the<br />

“Sliding Door Hardware”<br />

section.<br />

Bronze<br />

There is an increase in an “old<br />

meets new aesthetic” in which<br />

designers are co<strong>mb</strong>ining traditional<br />

finishes with more minimal<br />

and modern design. For<br />

years, <strong>FSB</strong> has offered ten of<br />

our best selling handles in solid<br />

brass, either polished or oxidiz ed<br />

to give them varying degrees of<br />

antiquing to suit the designers’<br />

needs.<br />

<strong>FSB</strong> now introduces Bronze<br />

as a new material for our lever<br />

handles and accessories. The<br />

special appeal of bronze is the<br />

patina that develops on its surface.<br />

In the course of daily use,<br />

polished bronze parts darken<br />

naturally, becoming more distinguished<br />

with time.<br />

We have created a complete<br />

section titled “Brass and Bronze<br />

Products” to cover all the<br />

pro ducts we offer in these two<br />

exceptional base materials. We<br />

offer eight bronze handles and<br />

ten brass handles for projects<br />

that may benefit from this “old<br />

meets new” aesthetic. All brass<br />

and bronze products can be<br />

oxidized to varying degrees of<br />

darkness, depending on “the<br />

mood” a designer would like to<br />

create.<br />

Glass Door Hardware<br />

Creating more open spaces<br />

has become a cornerstone of<br />

modern architecture. Utilizing<br />

large pieces of glass, whether<br />

for windows, doors, or walls,<br />

facilitates this objective.<br />

<strong>FSB</strong> has broadened its glass<br />

door program to include locks<br />

and hinges for swinging glass<br />

doors as well as exposed rolling<br />

gears for sliding glass doors.<br />

These products can be found in<br />

the section “Door Pulls and<br />

Glass Door Hardware”.<br />

5

Materials<br />

and Finishes<br />

Most of our hardware is available<br />

in aluminum and stainless steel<br />

as a base material.<br />

We offer up to 6 finishes on<br />

certain base materials with<br />

19 finishes overall. Aluminum<br />

is either anodized or powder<br />

coated.<br />

Base Material<br />

6<br />

Stainless Steel<br />

Aluminum Anodized<br />

Aluminum Powder Coated<br />

Bronze<br />

Brass<br />

On overview pages, and all pages<br />

throughout this catalog, only the<br />

base material is indicated. It<br />

can be assumed that all finishes<br />

shown to the right of the base<br />

material below are available<br />

whenever a base material is<br />

indicated for a product.<br />

<strong>FSB</strong> Finishes for <strong>Accessories</strong> (BHMA Code)<br />

6204 Satin (630)<br />

6205 Mirror Polished (629)<br />

6206 Matte<br />

0105 Natural Color (628)<br />

0205 German Silver (Champagne) Color<br />

0305 Brass Color (688)<br />

0405 Bronze Color (709)<br />

0704 Dark Bronze Color (710)<br />

1005 AluGrey<br />

8120 Black (693)<br />

8220 White (714E)<br />

8320 Red<br />

7305 Polished Oil Rubbed<br />

7615 Artificially Aged and Oil Rubbed (615)<br />

7625 Patinated and Oil Rubbed (613)<br />

4205 Polished Lacquered (605)<br />

4305 Polished Oil Rubbed (721)<br />

4694 Oxidized Lacquered<br />

4404 Oxidized Oil Rubbed (607)<br />

Our hinges are made from<br />

stainless steel and we can offer<br />

13 finishes on our two- and<br />

three-knuckle hinges.<br />

To confirm a particular finish is<br />

available, consult the bottom of<br />

the specific hinge page.<br />

The process for finishing hinges<br />

is different than those we use<br />

for our door hardware. Consequently<br />

the finishes listed below,<br />

by <strong>FSB</strong> finish code are only<br />

those finishes nearest equivalent.<br />

<strong>FSB</strong> Finishes for <strong>Hinges</strong><br />

6204 Satin<br />

6205 Mirror Polished<br />

6206 Matte<br />

0105 Natural Color<br />

0205 German Silver<br />

(Champagne) Color<br />

0305 Brass Color<br />

0704 Dark Bronze Color<br />

1005 AluGrey<br />

4205 Polished Brass Color<br />

4404 Oxidized Oil Rubbed<br />

8120 Black<br />

8220 White<br />

8320 Red

Aluminum Stainless Steel<br />

0105<br />

Aluminum Natural Color Anodized<br />

0205<br />

Aluminum German Silver (Champagne)<br />

Color Anodized<br />

0305<br />

Aluminum Brass Color Anodized<br />

0405<br />

Aluminum Bronze Color Anodized<br />

0704<br />

Aluminum Dark Bronze Color<br />

Anodized<br />

1005<br />

AluGrey<br />

8120<br />

Aluminum Powder Coated Black<br />

approx. RAL 9004<br />

8220<br />

Aluminum Powder Coated White<br />

approx. RAL 9003<br />

8320<br />

Aluminum Powder Coated Red<br />

approx. RAL 3002<br />

Brass<br />

Bronze<br />

6204<br />

Satin Stainless Steel<br />

6205<br />

Mirror Polished Stainless Steel<br />

6206<br />

Matte Stainless Steel<br />

4205<br />

Brass Polished Lacquered<br />

4305<br />

Brass Polished Oil Rubbed<br />

4694<br />

Oxidized Brass Lacquered<br />

4404<br />

Oxidized Brass Oil Rubbed<br />

7305<br />

Bronze Polished Oil Rubbed<br />

7615<br />

Bronze Artificially Aged and Oil Rubbed<br />

7625<br />

Bronze Patinated and Oil Rubbed<br />

7

<strong>Hinges</strong>,<br />

<strong>Accessories</strong><br />

9101 0000/1<br />

Page 10<br />

9101 0050<br />

Page 12<br />

3816<br />

Page 16<br />

3881<br />

Page 18<br />

3895<br />

Page 20<br />

8<br />

3817<br />

Page 16<br />

3882<br />

Page 18<br />

3896<br />

Page 20<br />

9101 0002/3<br />

Page 10<br />

9101 0051<br />

Page 12<br />

3819<br />

Page 16<br />

3884<br />

Page 18<br />

3646 01<br />

Page 19<br />

9101 0004/5<br />

Page 11<br />

9101 0052<br />

Page 13<br />

3878<br />

Page 17<br />

3888/3889<br />

Page 19<br />

3650<br />

Page 22<br />

3879<br />

Page 17<br />

3896 00<br />

Page 19<br />

2328<br />

Page 22<br />

9101 0006/7<br />

Page 11<br />

9101 0053<br />

Page 13<br />

3880 01<br />

Page 17<br />

3880 xx<br />

Page 20<br />

3632<br />

Page 22

3641<br />

Page 22<br />

3656, 3657<br />

Page 23<br />

5222<br />

Page 24<br />

3829<br />

Page 28<br />

3863 00 3863 02<br />

Page 30 Page 30<br />

3643<br />

Page 23<br />

4001<br />

Page 21<br />

3801<br />

Page 25<br />

3835<br />

Page 29<br />

3812<br />

Page 31<br />

3654<br />

Page 23<br />

3689<br />

Page 23<br />

9865<br />

Page 21<br />

3808<br />

Page 26<br />

3845<br />

Page 30<br />

3810<br />

Page 31<br />

Stock Items<br />

(in Natural Color<br />

Aluminum and Satin<br />

Stainless Steel)<br />

3691<br />

Page 23<br />

3826<br />

Page 27<br />

5812<br />

Page 30<br />

4005<br />

Page 32<br />

Base Material<br />

Aluminum<br />

Stainless Steel<br />

Bronze<br />

Brass<br />

Rubber<br />

Alu + Color<br />

9

9101 Series<br />

Two-Knuckle <strong>Hinges</strong><br />

Stainless Steel (Stock Items )<br />

10<br />

0105 Natural Color<br />

0205 German Silver Color<br />

0305 Brass Color<br />

0704 Dark Bronze Color<br />

1005 AluGrey<br />

4205 Polished Brass Color<br />

4404 Oxidized Oil Rubbed<br />

0.355"<br />

(9.02)<br />

0.355"<br />

(9.02)<br />

0.059"<br />

(1.5)<br />

0.512"(13)<br />

1"<br />

(25.4)<br />

0.969"<br />

(24.6)<br />

1"<br />

(25.4)<br />

0.512"(13)<br />

0.059"<br />

(1.5)<br />

6204 Satin<br />

6205 Mirror Polished<br />

6206 Matte<br />

8120 Black<br />

8220 White<br />

8320 Red<br />

2.79"<br />

(70.86)<br />

3.5"(88.9)<br />

0.36"(9.14)<br />

0.687"(17.45)<br />

9101 0001 pictured above<br />

4"(101.6)<br />

0.375"(9.53)<br />

0.75"(19.05)<br />

9101 0003 pictured above<br />

3.5"<br />

(88.9)<br />

4"<br />

(101.6)<br />

0.118"(3)<br />

0.512"(13)<br />

0.128"(3.25)<br />

0.535"(13.6)<br />

9101 0000 (r.h.)<br />

9101 0001 (l.h.)<br />

Stainless Steel<br />

Two-Knuckle Hinge<br />

3 1 ⁄2 × 3 1 ⁄2" (88.9 × 88.9 mm)<br />

Minimum door thickness<br />

1 3 ⁄8" (35 mm)<br />

9101 0002 (r.h.)<br />

9101 0003 (l.h.)<br />

Stainless Steel<br />

Two-Knuckle Hinge<br />

4 × 4" (101.6 × 101.6 mm)<br />

Minimum door thickness<br />

1 3 ⁄4" (44 mm)<br />

LH – Left Hand Hinge RH – Right Hand Hinge

9101 Series<br />

Two-Knuckle <strong>Hinges</strong><br />

Stainless Steel (Stock Items )<br />

0105 Natural Color<br />

0205 German Silver Color<br />

0305 Brass Color<br />

0704 Dark Bronze Color<br />

1005 AluGrey<br />

4205 Polished Brass Color<br />

4404 Oxidized Oil Rubbed<br />

0.508"(12.9)<br />

<strong>1.1</strong>25"<br />

(28.58)<br />

1.234"<br />

(31.34)<br />

<strong>1.1</strong>25"<br />

(28.58)<br />

0.508"(12.9)<br />

0.059"<br />

(1.5)<br />

4.5"(114.3)<br />

0.375"(9.53)<br />

1"(25.4)<br />

9101 0005 pictured above<br />

0.508"(12.9)<br />

<strong>1.1</strong>25"<br />

(28.58)<br />

1.234"<br />

(31.34)<br />

<strong>1.1</strong>25"<br />

(28.58)<br />

0.508"(12.9)<br />

0.059"<br />

(1.5)<br />

6204 Satin<br />

6205 Mirror Polished<br />

6206 Matte<br />

8120 Black<br />

8220 White<br />

8320 Red<br />

4"(101.6)<br />

0.375"(9.53)<br />

1"(25.4)<br />

9101 0007 pictured above<br />

4.5"<br />

(114.3)<br />

4.5"<br />

(114.3)<br />

0.128"(3.25)<br />

0.535"(13.6)<br />

0.128"(3.25)<br />

0.535"(13.6)<br />

9101 0004 (r.h.)<br />

9101 0005 (l.h.)<br />

Stainless Steel<br />

Two-Knuckle Hinge<br />

4 1 ⁄2 × 4 1 ⁄2" (114.3 × 114.3 mm)<br />

Minimum door thickness<br />

2 1 ⁄8" (54 mm)<br />

9101 0006 (r.h.)<br />

9101 0007 (l.h.)<br />

Stainless Steel<br />

Two-Knuckle Hinge<br />

4 × 4 1 ⁄2" (101.6 × 114.3 mm)<br />

Minimum door thickness<br />

1 3 ⁄4" (44 mm)<br />

LH – Left Hand Hinge RH – Right Hand Hinge<br />

11

9101 Series<br />

Three-Knuckle <strong>Hinges</strong><br />

Stainless Steel (Stock Items )<br />

12<br />

0105 Natural Color<br />

0205 German Silver Color<br />

0305 Brass Color<br />

0704 Dark Bronze Color<br />

1005 AluGrey<br />

4205 Polished Brass Color<br />

4404 Oxidized Oil Rubbed<br />

0.355"<br />

(9.02)<br />

0.355"<br />

(9.02)<br />

0.059"<br />

(1.5)<br />

0.512"(13)<br />

1"<br />

(25.4)<br />

0.969"<br />

(24.6)<br />

1"<br />

(25.4)<br />

0.512"(13)<br />

0.059"<br />

(1.5)<br />

6204 Satin<br />

6205 Mirror Polished<br />

6206 Matte<br />

8120 Black<br />

8220 White<br />

8320 Red<br />

2.79"<br />

(70.86)<br />

3.5"(88.9)<br />

0.36"(9.14)<br />

0.687"(17.45)<br />

4"(101.6)<br />

0.375"(9.53)<br />

0.75"(19.05)<br />

3.5"<br />

(88.9)<br />

4"<br />

(101.6)<br />

0.118"(3)<br />

0.512"(13)<br />

0.128"(3.25)<br />

0.535"(13.6)<br />

9101 0050<br />

Stainless Steel<br />

Three-Knuckle Hinge<br />

3 1 ⁄2 × 3 1 ⁄2" (88.9 × 88.9 mm)<br />

Minimum door thickness<br />

1 3 ⁄8" (35 mm)<br />

9101 0051<br />

Stainless Steel<br />

Three-Knuckle Hinge<br />

4 × 4" (101.6 × 101.6 mm)<br />

Minimum door thickness<br />

1 3 ⁄4" (44 mm)

9101 Series<br />

Three-Knuckle <strong>Hinges</strong><br />

Stainless Steel (Stock Items )<br />

0105 Natural Color<br />

0205 German Silver Color<br />

0305 Brass Color<br />

0704 Dark Bronze Color<br />

1005 AluGrey<br />

4205 Polished Brass Color<br />

4404 Oxidized Oil Rubbed<br />

0.508"(12.9)<br />

<strong>1.1</strong>25"<br />

(28.58)<br />

1.234"<br />

(31.34)<br />

<strong>1.1</strong>25"<br />

(28.58)<br />

0.508"(12.9)<br />

0.059"<br />

(1.5)<br />

0.508"(12.9)<br />

<strong>1.1</strong>25"<br />

(28.58)<br />

1.234"<br />

(31.34)<br />

<strong>1.1</strong>25"<br />

(28.58)<br />

0.508"(12.9)<br />

0.059"<br />

(1.5)<br />

6204 Satin<br />

6205 Mirror Polished<br />

6206 Matte<br />

8120 Black<br />

8220 White<br />

8320 Red<br />

4.5"(114.3)<br />

0.375"(9.53)<br />

1"(25.4)<br />

4"(101.6)<br />

0.375"(9.53)<br />

1"(25.4)<br />

4.5"<br />

(114.3)<br />

4.5"<br />

(114.3)<br />

0.128"(3.25)<br />

0.535"(13.6)<br />

0.128"(3.25)<br />

0.535"(13.6)<br />

9101 0052<br />

Stainless Steel<br />

Three-Knuckle Hinge<br />

4 1 ⁄2 × 4 1 ⁄2" (114.3 × 114.3 mm)<br />

Minimum door thickness<br />

2 1 ⁄8" (54 mm)<br />

9101 0053<br />

Stainless Steel<br />

Three-Knuckle Hinge<br />

4 × 4 1 ⁄2" (101.6 × 114.3 mm)<br />

Minimum door thickness<br />

1 3 ⁄4" (44 mm)<br />

<strong>FSB</strong> hinges are not yet UL listed<br />

and should only be specifi ed for<br />

applications not requiring fi rerated<br />

or UL listed hinges.<br />

Please contact <strong>FSB</strong> North<br />

America for the current status<br />

of our UL approval.<br />

13

9101 Series<br />

Information and Specifi cation<br />

Site/Situation<br />

Serious consideration should<br />

be given to the type of door and<br />

frame being installed as well as<br />

the nature of the building and<br />

the door’s specifi c location. For<br />

example, very frequently used<br />

doors, in a hospital or school,<br />

tend to be put under more arduous<br />

stresses than in residential<br />

applications. The table to the<br />

right shows some estimates<br />

of traffi c in certain building/<br />

locations.<br />

All <strong>FSB</strong> two- and three-knuckle<br />

hinges are swaged and full mortise,<br />

for use with all door and<br />

frame materials. They are designed<br />

for use in high frequency<br />

situations, with other specifi c<br />

requirements guiding the appropriate<br />

hinge choice.<br />

Hinge Size<br />

The size of hinge to be used<br />

is determined not only by the<br />

weight but also the door size,<br />

thickness and any clearances<br />

required.<br />

It should be noted that if extra<br />

“clearance” is required to allow<br />

the door to, for example,<br />

swing out and lay fl at around<br />

any decorative casing then this<br />

should be considered in guiding<br />

hinge choice.<br />

14<br />

Frequency of Door Operation<br />

Type of Building and Door Annual Cycles <strong>FSB</strong> <strong>Hinges</strong> to Use<br />

High frequency Special Order<br />

Large dept. store entrance 1,500,000<br />

Large offi ce bldg. entrance 1,200,000<br />

High frequency <strong>FSB</strong> Standard<br />

School entrance 400,000 Two- and Three-<br />

School toilet door 225,000 Knuckle <strong>Hinges</strong><br />

Store or bank entrance 150,000<br />

Offi ce building toilet door 118,000<br />

Average frequency<br />

School corridor door 30,000<br />

Offi ce building corridor door 22,000<br />

Store toilet door 18,000<br />

Dwelling entrance 15,000<br />

Low frequency<br />

Dwelling toilet door 9,000<br />

Dwelling corridor door 3,600<br />

Dwelling closet door 2,200<br />

Guidance on the suitability of<br />

individual hinges can be found<br />

on the following and product<br />

specifi c pages.<br />

The drawing to the right shows<br />

the plan detail of a standard<br />

hinge installation.<br />

Door Thickness<br />

Backset Inset<br />

Clearance<br />

Door Open<br />

Door Thickness

9101 Series<br />

Information and Specifi cation<br />

Nu<strong>mb</strong>er of <strong>Hinges</strong><br />

Typically, three hinges are fi tted<br />

to each door. Hinge positions<br />

are determined by the weight of<br />

door, its situation and its construction/resistance<br />

to warping.<br />

The usual positioning is symmetrical,<br />

see examples.<br />

<strong>Hinges</strong> for use with Doors<br />

of excess width<br />

Wider doors increase the pressure<br />

and bending stresses<br />

exerted on the hinge. This<br />

must be allowed for by reduction<br />

in the mass of the door leaf<br />

supported by the hinges. The<br />

factors by which the door mass<br />

has to be adjusted for excessive<br />

widths of door are calculated by<br />

dividing the door height by its<br />

width.<br />

Approximate door construction<br />

average weights<br />

The table to the right shows<br />

the approximate door weights<br />

per area when using various<br />

materials.<br />

Example:<br />

A 7'6" x 3'3" “Solid Core” door<br />

leaf at 1¾" thick will have an<br />

approximate weight of 110lb<br />

Nu<strong>mb</strong>er of <strong>Hinges</strong> to be used<br />

on Standard Doors<br />

Door height No. hinges<br />

Up to 7' 3 hinges<br />

7' to 12' 4 hinges<br />

12' to 15' 5 hinges<br />

Doors over 15' please contact<br />

<strong>FSB</strong>.<br />

For a factor of two or greater,<br />

no allowance has to be made.<br />

When the factor is less than<br />

two, the door mass has to be<br />

increased by the value required<br />

to bring the factor to two expressed<br />

as a percentage.<br />

These percentages are shown in<br />

the Side Loading Calculations to<br />

the right.<br />

For extra heavy doors or doors<br />

with a low height to width ratio<br />

(see below) the positions should<br />

be modifi ed to help account<br />

for the increased side loading*<br />

placed on the hinges.<br />

*As the door has an eccentric<br />

centre of gravity a side loading<br />

force is placed on the hinges.<br />

This is the force trying to pull<br />

Side Loading<br />

Calculation<br />

the hinges off the door frame.<br />

Where, for example, the door<br />

leaf regularly engages on a door<br />

stop the use of two hinges low<br />

down should be considered.<br />

7 7⁄8"(200)<br />

7 7⁄8"(200)<br />

9 27⁄32"(250)<br />

9 27⁄32"(250)<br />

Door Size Factor Normal Increase of<br />

Mass of Door Leaf<br />

Door Height Door Width<br />

6' 8" 3' 6" 1.90 10 %<br />

6' 8" 4' 0" 1.67 33 %<br />

7' 0" 3' 6" 2.00 0 %<br />

7' 0" 4' 0" 1.75 25 %<br />

7' 6" 4' 0" 1.88 12 %<br />

8' 0" 4' 0" 2.00 0 %<br />

Door Thickness 13 ⁄8" (35 mm) 13 ⁄4" (44 mm) 2" (51 mm) 21 ⁄8" (54 mm)<br />

lbs/ft² kg/m² lbs/ft² kg/m² lbs/ft² kg/m² lbs/ft² kg/m²<br />

Hollow Metal 4 19.5 5 24.4 6 1 ⁄2 31.7 7 33.6<br />

Kalamein – – 5 24.4 – – – –<br />

Hollow Core 2 9.8 2 1 ⁄2 12.2 – – – –<br />

Solid Core 3 1 ⁄2 17.0 4 1 ⁄2 22.0 5 1 ⁄4 25.6 5 1 ⁄2 27.1<br />

Mineral Core 3 1 ⁄2 17.0 4 19.5 – – – –<br />

Pine (White) 3 14.6 3 1 ⁄2 17.0 4 19.5 4 1 ⁄4 20.6<br />

Oak 5 24.4 7 34.2 8 39.0 8 1 ⁄2 41.3<br />

Ash 4 19.5 5 24.4 6 29.3 6 1 ⁄2 31.0<br />

Birch 4 1 ⁄4 20.8 5 1 ⁄2 26.9 6 1 ⁄4 30.5 6 1 ⁄2 32.3<br />

Mahagony 3 1 ⁄2 17.0 4 1 ⁄2 22.0 5 1 ⁄4 25.6 5 1 ⁄2 27.1<br />

Center<br />

Line<br />

15

Doorstops<br />

16<br />

9<br />

40 20<br />

25<br />

60 16,5<br />

40<br />

47<br />

28<br />

28<br />

16,5<br />

31,5 15,5<br />

76,5<br />

As with all architectural hardware,<br />

door stops will only give<br />

satisfaction if correctly fitted<br />

and properly used. Before<br />

ordering or fabricating, it is<br />

necessary to check the weight<br />

of the door leaf, the angle of<br />

contact, the height of the bottom<br />

of the door from the floor<br />

and the quality of the flooring<br />

itself.<br />

Stock Items<br />

(in Natural Color Aluminum<br />

and Satin Stainless Steel)<br />

3816<br />

Aluminum<br />

Stainless Steel<br />

3817<br />

Aluminum<br />

3819<br />

Aluminum<br />

Depending on requirements, it<br />

is then possible to choose between<br />

simple stops, stops with<br />

anti-skew capability, stops with<br />

baseplates, directional and nondirectional<br />

stops and, finally,<br />

stops fitted straight into the floor<br />

or those where rawlplugs are<br />

used.

Doorstops<br />

24<br />

48<br />

24<br />

24<br />

32<br />

Ø 40<br />

Ø 48<br />

52<br />

Ø 40<br />

Stock Items<br />

(in Natural Color Aluminum<br />

and Satin Stainless Steel)<br />

3878<br />

Aluminum<br />

Stainless Steel<br />

Design: Christoph Ingenhoven<br />

3879<br />

Aluminum<br />

3880 01<br />

Rubber<br />

17

Doorstops<br />

18<br />

34<br />

Ø 45<br />

37<br />

Ø 40<br />

70<br />

75<br />

Ø 45<br />

Ø 40<br />

20<br />

10<br />

As with all architectural hardware,<br />

door stops will only give<br />

satisfaction if correctly fitted<br />

and properly used. Before<br />

ordering or fabricating, it is<br />

necessary to check the weight<br />

of the door leaf, the angle of<br />

contact, the height of the bottom<br />

of the door from the floor<br />

and the quality of the flooring<br />

itself.<br />

Stock Items<br />

(in Natural Color Aluminum<br />

and Satin Stainless Steel)<br />

3881<br />

Aluminum<br />

Stainless Steel<br />

Brass<br />

3882<br />

Aluminum<br />

3884<br />

Aluminum<br />

Stainless Steel<br />

Bronze<br />

Brass<br />

3884 10<br />

Black Baseplate<br />

Depending on requirements, it<br />

is then possible to choose between<br />

simple stops, stops with<br />

anti-skew capability, stops with<br />

baseplates, directional and nondirectional<br />

stops and, finally,<br />

stops fitted straight into the floor<br />

or those where rawlplugs are<br />

used.

Doorstops<br />

Doorstop with Coathook<br />

49<br />

49<br />

30<br />

Ø 46<br />

100<br />

20<br />

48<br />

42<br />

48 42<br />

Ø 46<br />

40<br />

35<br />

80<br />

Stock Items<br />

(in Natural Color Aluminum<br />

and Satin Stainless Steel)<br />

3888<br />

Aluminum<br />

3889<br />

Aluminum<br />

3896 00<br />

Rubber<br />

Supplied with grey rubber<br />

bumper.<br />

Design: Jasper Morrison<br />

3646 01<br />

Aluminum<br />

Stainless Steel<br />

Doorstop with Coathook<br />

19

Wall Mounted<br />

Doorstops<br />

20<br />

Ø55<br />

Ø 45<br />

Ø 45<br />

120<br />

60<br />

90<br />

120<br />

60<br />

90<br />

120<br />

Ø25<br />

Ø 40<br />

Ø 46<br />

Door stops mounted to the wall<br />

need to be fitted in such a way<br />

that the door leaf strikes them<br />

as head-on as possible. Any<br />

un due lateral force is likely to<br />

cause the stop to be worked<br />

loose.<br />

Stock Items<br />

(in Natural Color Aluminum<br />

and Satin Stainless Steel)<br />

3880 xx<br />

Aluminum<br />

Stainless Steel<br />

Bronze<br />

xx = 02 (length 120 mm)<br />

xx = 03 (length 90 mm)<br />

xx = 04 (length 60 mm)<br />

3895<br />

Aluminum<br />

Stainless Steel<br />

3896 xx<br />

Aluminum<br />

Stainless Steel<br />

xx = 02 (length 120 mm)<br />

xx = 03 (length 90 mm)<br />

xx = 04 (length 60 mm)<br />

Supplied with grey rubber<br />

bumper.<br />

Design: Jasper Morrison<br />

<strong>FSB</strong> advises against fitting stops<br />

at door-handle height. The resultant<br />

shock waves are transmitted<br />

via the lock follower to<br />

the lock mechanism, eventually<br />

causing it to suffer damage.

Card Frames<br />

Cable Box<br />

The <strong>FSB</strong> cable box ensures tidy<br />

cable management at work<br />

desks. Connections for telephones<br />

and fax machines, task<br />

lights, desktop computers and<br />

all that goes with them are ideally<br />

accommodated in this elegant<br />

cable box.<br />

89 66<br />

48<br />

82<br />

96<br />

120<br />

82<br />

100<br />

120<br />

64 46<br />

23–38<br />

1,2<br />

23–38<br />

55<br />

68<br />

86<br />

90<br />

85<br />

2,5<br />

Ø 85<br />

Bonding groove<br />

Clip<br />

Cap<br />

29<br />

Its heavy-duty design is such<br />

that the cap remains resolutely<br />

clipped in place no matter how<br />

obdurate the cabling beneath.<br />

The slit is sealed by a brush<br />

gasket that adapts itself to the<br />

cables inserted.<br />

400x<br />

Aluminum<br />

X = 1 suitable for paper<br />

dimension 74 × 105 mm<br />

4002 suitable for paper<br />

dimension 37 × 105 mm<br />

4003 suitable for paper<br />

dimension 52 × 74 mm<br />

4004 suitable for paper<br />

dimension 26 × 74 mm<br />

36<br />

55<br />

70<br />

86<br />

20<br />

9865 00xx<br />

Aluminum<br />

Stainless Steel<br />

Height less rim<br />

xx = 00 38.0 mm<br />

xx = 02 33.0 mm<br />

xx = 04 29.0 mm<br />

xx = 06 23.0 mm<br />

External diameter 90.0 mm<br />

Internal diameter 80.0 mm<br />

Inlet diameter 85.0 mm<br />

Rim thickness 1.2 mm<br />

Rim projection 2.5 mm<br />

Slit length 58.0 mm<br />

The <strong>FSB</strong> cable box is<br />

available in:<br />

Alu Natural Color Anodized<br />

Alu Brass Color Anodized<br />

Alu + Color Black<br />

Alu + Color White<br />

Alu + Color Grey<br />

Satin Stainless Steel<br />

21

Coathook<br />

Cabinet Knobs<br />

22<br />

90<br />

34 34<br />

28 37<br />

70 43<br />

Ø 33<br />

33<br />

27<br />

32<br />

40<br />

Ø 16<br />

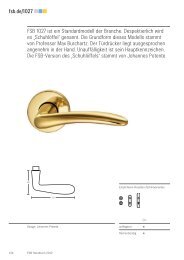

Quiz question: how can you tell<br />

whether cabinet knob design<br />

<strong>FSB</strong> 3632 is the <strong>FSB</strong> Philippe<br />

Starck original or a cheap copy?<br />

Stock Items<br />

(in Natural Color Aluminum<br />

and Satin Stainless Steel)<br />

3650<br />

Aluminum<br />

Design: Jasper Morrison<br />

2328<br />

Aluminum<br />

3632 xx<br />

xx = 04 (r.h.) or 05 (l.h.)<br />

Aluminum<br />

Stainless Steel<br />

Screw M4 × 30 mm<br />

Design: Philippe Starck<br />

3641<br />

Aluminum<br />

Stainless Steel<br />

Screw M4 × 30 mm<br />

Design: Jasper Morrison<br />

Answer: by its design and cost.<br />

Philippe Starck fashioned an<br />

elaborate right- and lefthand<br />

version.<br />

The plagiarisers reduced the<br />

effect to cheap symmetry.<br />

<strong>FSB</strong> continues to supply solely<br />

original designs.

Cabinet Knobs<br />

32<br />

34<br />

30<br />

Ø 29<br />

Ø 26<br />

Ø 33<br />

70<br />

60<br />

90<br />

80<br />

Ø 14<br />

29<br />

27<br />

27<br />

24<br />

24<br />

Stock Items<br />

(in Natural Color Aluminum<br />

and Satin Stainless Steel)<br />

3643<br />

Aluminum<br />

Stainless Steel<br />

Screw M4 × 30 mm<br />

Design: Jasper Morrison<br />

3654<br />

Aluminum<br />

Stainless Steel<br />

Screw M4 × 30 mm<br />

Design: Jasper Morrison<br />

3689<br />

Aluminum<br />

Screw M4 × 30 mm<br />

3691<br />

Aluminum<br />

Stainless Steel<br />

Screw M4 × 30 mm<br />

3657<br />

Aluminum<br />

3656<br />

Aluminum<br />

23

Kick and<br />

Push Plates<br />

Kicking plates and finger plates<br />

Doors are not always opened<br />

gently or with clean fingers. To<br />

prevent doors being soiled or<br />

mutilated, <strong>FSB</strong> supplies finger<br />

plates for the area adjacent to<br />

the lever handle and kicking<br />

plates for where feet tend to<br />

make contact.<br />

Kicking and finger plates are<br />

available in a wide variety of<br />

materials (aluminum, stainless<br />

steel, brass) and thicknesses.<br />

With or without screwholes<br />

For asse<strong>mb</strong>ly purposes, <strong>FSB</strong><br />

kicking and finger plates are<br />

supplied as standard with holes<br />

for 3 mm countersunk screws.<br />

On express request, they may<br />

be supplied without screwholes,<br />

however.<br />

Plates 1 mm thick (<strong>FSB</strong> 5222<br />

for example) can be made and<br />

delivered with self-adhesive foil<br />

instead of screwholes. Fitting<br />

such items requires experience<br />

and care on the part of the user.<br />

Most importantly, the surface of<br />

the door needs to be absolutely<br />

even and clean.<br />

24<br />

Perforations<br />

Finger plates are generally machined<br />

to accept roses and<br />

backplates. <strong>FSB</strong> supplies finger<br />

plates as standard with piercings<br />

for the lever handle rose and for<br />

a standard europrofile cylinder.<br />

Return Edges<br />

Kicking plates and finger plates<br />

can feature a return edge. To<br />

ensure a good fit, detailed drawings<br />

need to be enclosed with<br />

orders that take account of all the<br />

structural tolerances involved.<br />

Should no such drawings or<br />

models be forthcoming, <strong>FSB</strong> will<br />

always treat dimensions cited<br />

for straightforward return edges<br />

as internal dimensions, notably<br />

in the case of rebated doors.<br />

5222 1 mm<br />

Aluminum<br />

Stainless Steel<br />

Bronze<br />

5223 1.5 mm<br />

Aluminum<br />

Stainless Steel<br />

5224 2 mm<br />

Aluminum<br />

Stainless Steel<br />

Custom perforations available.<br />

Please first send us a dimensioned<br />

drawing. We will then furnish<br />

you with a counter drawing for<br />

verification purposes together<br />

with a price quote.<br />

Risk of Injury<br />

Items such as kicking plates,<br />

ventilation plates, ventilation<br />

grills, ventilation covers and<br />

perforated plates are made of<br />

thin, sharp-edged material.<br />

When fitting them, it is important<br />

to make sure they lie flush<br />

against the surface to which<br />

they are to be attached. Such<br />

items should be handled with<br />

extreme care when being unpacked,<br />

fitted, checked for positioning<br />

and, indeed, throughout<br />

their service life.<br />

Carelessness in this respect<br />

can easily lead to fingers getting<br />

injured, especially in the course<br />

of cleaning routines.

Letterplates<br />

Fixing holes:<br />

10 mm Ø, 8 mm deep<br />

5.5 mm Ø through<br />

Install with M5 screws as<br />

provided.<br />

8<br />

Ø 10 Ø 5,5<br />

75<br />

28<br />

20<br />

75<br />

28<br />

20<br />

295<br />

275<br />

255<br />

255<br />

390<br />

370<br />

350<br />

350<br />

48<br />

48<br />

3801 20xx<br />

Aluminum<br />

xx = 01 (without nameplate)<br />

xx = 02 (with nameplate)<br />

Opening size<br />

325 × 32 mm<br />

Cutout size in the door<br />

350 × 48 mm<br />

3804 20xx<br />

Aluminum<br />

xx = 01 (without nameplate)<br />

xx = 02 (with nameplate)<br />

Opening size<br />

230 × 32 mm<br />

Cutout size in the door<br />

255 × 48 mm<br />

25

Letterplates<br />

Letter plate system 3808 is<br />

available as:<br />

- Letter plate set with black<br />

spacer and inner flap for door<br />

thickness 40 – 70 mm or door<br />

thickness 71 – 100 mm.<br />

- Letter plate, without spacer or<br />

inner flap, with concealed<br />

fixing or for wall mounting.<br />

290<br />

11,5<br />

90 78 50<br />

26<br />

7<br />

40–70<br />

71–100<br />

246<br />

R 8<br />

14 90 60<br />

265<br />

277<br />

236<br />

290<br />

36/Ø 9<br />

3808 xxxx<br />

Stainless Steel<br />

Bronze<br />

Opening size<br />

230 × 35 mm<br />

Cutout size in the door<br />

246 × 60 mm<br />

Concealed fixing from the in side<br />

or through the inner flap.<br />

xxxx = 0061 (40 – 70 mm)<br />

xxxx = 0071 (71 – 100 mm)<br />

Letter plate set<br />

without nameplate,<br />

with spacer and inner flap<br />

xxxx = 0001<br />

xxxx = 0101 (wallmounting)<br />

Letter plate without nameplate,<br />

without spacer or inner flap<br />

xxxx = 0062 (40 – 70 mm)<br />

xxxx = 0072 (71 – 100 mm)<br />

Letter plate set with nameplate,<br />

spacer and inner flap<br />

xxxx = 0002<br />

xxxx = 0102 (wallmounting)<br />

Letter plate with nameplate,<br />

without spacer or inner flape<br />

Fixing holes:<br />

9 mm Ø, 36 mm deep<br />

4.5 mm Ø through<br />

Install with M4 screws as<br />

provided.

Letterplates<br />

Letter plate system 3826 20 is<br />

available as:<br />

- Letter plate set with black<br />

spacer and inner flap for door<br />

thickness 40 – 70 mm or door<br />

thickness 71 – 100 mm.<br />

- Single as letter plate.<br />

275 15 16,5<br />

240<br />

83 78<br />

40 16,5 83<br />

40–70<br />

71–100<br />

R 8<br />

265<br />

230<br />

275<br />

50<br />

3826 20xx<br />

Aluminum<br />

Stainless Steel<br />

Brass<br />

Opening size<br />

230 × 40 mm<br />

Cutout size in the door<br />

240 × 50 mm<br />

Fixing of letter plate and inner<br />

flap must be made separately.<br />

xx = 61 (40 – 70 mm)<br />

xx = 71 (71 –100 mm)<br />

Letter plate set<br />

without nameplate,<br />

with spacer and inner flap<br />

xx = 62 (40 – 70 mm)<br />

xx = 72 (71 –100 mm)<br />

Letter plate set<br />

with nameplate, spacer and<br />

inner flap<br />

27

Letterplates<br />

28<br />

275<br />

83 42<br />

249,5<br />

370<br />

83 42<br />

344,5<br />

3826 20xx<br />

Aluminum<br />

Stainless Steel<br />

xx = 01 (without nameplate)<br />

xx = 02 (with nameplate)<br />

without spacer or inner flap<br />

Opening size/cutout size in the<br />

door 230 × 40 mm<br />

3829 00xx<br />

Aluminum<br />

Stainless Steel<br />

xx = 01 (without nameplate)<br />

xx = 02 (with nameplate)<br />

without spacer or inner flap<br />

Opening size/cutout size in the<br />

door 325 × 40 mm

Letterplates<br />

Letter plate system 3835 00 is<br />

available as:<br />

- Letter plate set with black<br />

spacer and inner flap for door<br />

thickness 40 – 70 mm or door<br />

thickness 71 – 100 mm.<br />

- Single as letter plate.<br />

270 18,5<br />

240<br />

78 R 8<br />

85 15 40 10 50<br />

85<br />

40–70<br />

71–100<br />

265<br />

230<br />

270<br />

3835 00xx<br />

Aluminum<br />

Stainless Steel<br />

Opening size<br />

230 × 40 mm<br />

Cutout in the door<br />

240 × 50 mm<br />

Fixing of letter plate and inner<br />

plate must be made separately.<br />

xx = 61 (40 – 70 mm)<br />

xx = 71 (71 –100 mm)<br />

Letter plate set<br />

without nameplate,<br />

with spacer and inner flap<br />

xx = 01<br />

Letter plate without nameplate,<br />

without spacer or inner flap<br />

xx = 62 (40 – 70 mm)<br />

xx = 72 (71 –100 mm)<br />

Letter plate set<br />

with nameplate,<br />

spacer and inner flap<br />

xx = 02<br />

Letter plate with nameplate,<br />

without spacer and inner flap<br />

29

Letterplates<br />

Bell-Push Plates<br />

30<br />

78<br />

82<br />

55<br />

55<br />

275<br />

320<br />

44<br />

Stock Items<br />

(in Natural Color Aluminum<br />

and Satin Stainless Steel)<br />

3845<br />

Aluminum<br />

for aperture size<br />

255 × 40 mm<br />

5812<br />

Aluminum<br />

for aperture size<br />

280 × 65 mm<br />

3863 00<br />

Aluminum<br />

3863 02<br />

Stainless Steel<br />

Bronze

Intercom<br />

Instruction:<br />

Bell pushes may only be<br />

connected to a protective low<br />

voltage (max 42 V). Given the<br />

high no-load voltage involved,<br />

we recommend connecting the<br />

light socket (lamp operation<br />

max. 24 V/40 mA) to the safety<br />

transformer (8 V).<br />

90<br />

90<br />

90<br />

90<br />

155<br />

130<br />

155<br />

130<br />

290<br />

265<br />

7<br />

7<br />

36/Ø 9<br />

7<br />

7<br />

3812 xxxx<br />

Stainless Steel<br />

Bronze<br />

xxxx = 0011 (single)<br />

xxxx = 0012 (double)<br />

xxxx = 0111 (single, wall -<br />

mounting)<br />

xxxx = 0112 (double, wall -<br />

mounting)<br />

Mill out size<br />

W 245 × H 70 × D 30 mm<br />

3810 xxxx<br />

Stainless Steel<br />

Bronze<br />

xxxx = 0011 (single)<br />

xxxx = 0012 (double)<br />

xxxx = 0111 (single, wall -<br />

mounting)<br />

xxxx = 0112 (double, wall -<br />

mounting)<br />

Mill out size<br />

W 245 × H 70 × D 30 mm<br />

Fixing holes:<br />

9 mm Ø, 36 mm deep<br />

4.5 mm Ø through<br />

Install with M4 screws as<br />

provided.<br />

Intercom and bell-push plates<br />

and letter plate 3808 are available<br />

on request with visible<br />

fixing for 5 mm Ø countersunk<br />

head screws.<br />

31

Numerals<br />

Item nos:<br />

xx = available nu<strong>mb</strong>ers or<br />

letters (shown to the right)<br />

Example:<br />

4005 02 = Nu<strong>mb</strong>er 2<br />

Only lower case letters<br />

“a” to “e” are available.<br />

32<br />

01<br />

127 108<br />

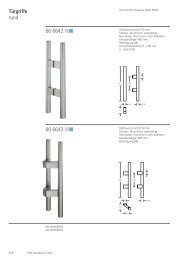

<strong>FSB</strong>’s program of numerals and<br />

letters draws on a design that<br />

Otl Aicher recommended to our<br />

company as a headline type face.<br />

For Otl Aicher, good legibili ty<br />

from a distance was all important.<br />

Our numerals and letters are<br />

made of 4 mm-thick stainless<br />

steel, material code 1.4301.<br />

All characters feature two standardised<br />

fixing points comprising<br />

4 mm threaded sockets.<br />

These are fitted with bolts which<br />

in turn are secured in 8 mm<br />

rawlplugs.<br />

4<br />

4005 xx<br />

Stainless Steel<br />

Bronze<br />

Each character is supplied with<br />

a fixing template that also determines<br />

the distance between<br />

characters. Custom spacing can<br />

be achieved by reducing the<br />

width of templates.<br />

02 03 04 05 06 07 08 09 00<br />

11 12<br />

13<br />

14<br />

16<br />

15